home⇒ construction mat⇒ finishing⇒ insulation

Basalt mineral wool is a high-quality sound and heat insulating material made from mountain gabbro-basalt rocks. The basis of basalt wool is fiberglass.

Typical slab size in width/length format: 600x1200 (mm).

Grid size of thermal insulation boards for facade insulation:

- 200x1000 (mm), thickness from 20 to 200 (mm). 500x1000 (mm), thickness from 20 to 180 (mm). 600x1200 (mm), thickness from 20 to 180 (mm).

Grid size of thermal insulation boards for insulation of partitions and walls:

- 600x1200 (mm), thickness from 50 to 100 (mm). 1000x2500 (mm), thickness from 20 to 100 (mm). 1000x4000 (mm), thickness from 50 to 100 (mm). 1000x4750 (mm), thickness from 100 to 200 (mm).

Grid size of thermal insulation boards for floor insulation:

- 600x1000 (mm), thickness from 20 to 120 (mm). 1000x2500 (mm), thickness from 20 to 100 (mm). 1000x4000 (mm), thickness from 50 to 100 (mm).

Grid size of thermal insulation boards for insulating flat and pitched roofs:

600x1000 (mm), thickness from 50 to 120 (mm). 600x1200 (mm), thickness from 20 to 180 (mm). 1000x4750 (mm), thickness from 100 to 200 (mm).

1000x3000 (mm), thickness from 100 to 200 (mm). 1000x6000 (mm), thickness from 100 to 200 (mm). 1200x2000 (mm), thickness from 40 to 200 (mm).

Basalt slabs retain their properties for 30-40 years after thermal insulation.

Important: the coefficient of thermal conductivity of products ranges from 0.035 to 0.039 (W/Mk), density - from 30 to 220 (kg/m3)), load distribution - up to 70 (kPa).

Stone wool is a popular material for insulating various building structures. Basalt insulation has unique performance characteristics. A wide range of varieties of stone wool allows it to be used where other materials are ineffective.

The basis of the wool is gabbro-basalt rocks, crushed and melted at a temperature of +1500C. The result of special processing of a semi-finished product made from natural wood is strong, elastic fibers reminiscent of fiberglass. The difference from mineral wool is that it is environmentally friendly and lacks harmful impurities.

Advantages:

excellent thermal insulation properties.

10 cm of basalt wool replaces 140 cm of silicate brick walls in terms of thermal insulation quality; good sound insulation. Noise level is reduced by 20%; high fire resistance. Refers to non-combustible materials.

Class - NG; practically does not absorb moisture. Ideal for rooms with high humidity; bacteria and mold fungi do not multiply on the surface of the insulation. Basalt wool does not rot; the material is non-toxic, does not harm the environment and humans; good strength.

The material does not change dimensions, does not shrink; low chemical and biological activity. When in contact with stone wool, the base does not rust, crack, etc.; rodents did not like the taste of stone wool.

The material withstands the invasion of mice and rats; long service life. The insulation will withstand up to 40 years of operation without changing its properties; ease of installation. Basalt mats, rolls and slabs are easy to transport, cut and lay on any surface; a wide range of coatings (mats, rolls, slabs, etc.).

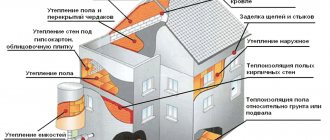

Application

The properties of basalt insulation explain its wide range of applications:

- for insulation of wet and suspended ventilated facades; for insulation of roofs of various shapes; for thermal insulation of floors, walls, partitions; for insulation of walls finished with sandwich panels when using layered masonry; in bath complexes and saunas; in ventilation pipes, chimneys, wherever structures exposed to high temperatures; to protect pipelines. Temperatures of -170C and +1000C on the surface are not a hindrance for stone wool; in shipbuilding. For insulation and soundproofing of cabins, decks and other parts of the ship.

Description

The basis of the wool is gabbro-basalt rocks, crushed and melted at a temperature of +1500C. The result of special processing of a semi-finished product made from natural wood is strong, elastic fibers reminiscent of fiberglass. The difference from mineral wool is that it is environmentally friendly and lacks harmful impurities.

Advantages:

- excellent thermal insulation properties. 10 cm of basalt wool replaces 140 cm of silicate brick walls in terms of thermal insulation quality;

- good sound insulation. Noise level is reduced by 20%;

- high fire resistance. Refers to non-combustible materials. Class – NG;

- practically does not absorb moisture. Ideal for rooms with high humidity;

- Bacteria and mold fungi do not multiply on the surface of the insulation. Basalt wool does not rot;

- the material is non-toxic, does not harm the environment and humans;

- good strength. The material does not change dimensions and does not shrink;

- low chemical and biological activity. When in contact with stone wool, the base does not rust, crack, etc.;

- Rodents did not like the taste of stone wool. The material tolerates invasion of mice and rats well;

- long service life. The insulation will withstand up to 40 years of operation without changing its properties;

- ease of installation. Basalt mats, rolls and slabs are easy to transport, cut and lay on any surface;

- a wide range of coatings (mats, rolls, slabs, etc.).

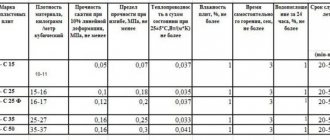

Dimensions, weight, thermal conductivity, density

The technical characteristics of stone wool are superior to other insulation materials in many respects.

Basics:

1.Dimensions. There is no standard size for all types of stone wool.

The dimensions depend on where this type of insulation will be used. The length of the slabs ranges from 1000 to 1200 mm, width - 500-600 mm, thickness - 20-240 mm. 2. Density depends on the type of material. Indicators range from 30-40 kg/m3 to 190kg/m3.3. Water absorption - no more than 2% of the volume.

Hydrophobic material.4.Vapour permeability – 0.3 mg/(m.h.Pa).5.High fire resistance. Melting point: +1114C.6.Compressive strength at 10% deformation – 5-80KPa.

7. Thermal conductivity is low - 0.032¬ 0.048 W/(mK).

average cost

Prices in Moscow for universal basalt heat insulator in slabs range from 1,500 to 3,500 rubles per 1 m3. A package with a volume of 0.3 m3 costs from 410 to 645 rubles.

In the regions, a basalt slab costs from 450 rubles per package of 0.288 m3 (sometimes you can buy it with a 20% discount), the product in rolls: 150 rubles per 1 kg. The price of material for rigid roofing work is approximately 1,680 rubles per 1 m3. The cost of environmentally friendly mats without phenol ranges from 1,300 rubles per 0.3 m3 package, with foil covering from 295 rubles per 1 m2.

TechnoNIKOL basalt insulation

TechnoNIKOL Corporation is a large Russian holding. On the market since 1992. Production sites and branches are located in 38 countries. TechnoNIKOL's rich assortment of basalt wool will allow you to choose the right type of insulation.

Review of titles:

1.Technolight.Used for heat and sound insulation of surfaces with low external loads. Insulate pitched roofs, floors, attic walls, and ceilings in attics. Thickness – 40-200mm, density – from 30 to 40kg/m3.

2.Technovent.The main purpose is insulation in residential and industrial premises. Component of a ventilated facade. Thickness – 40-200mm, density – from 80 to 100kg/m3.

3.Rocklight.I insulate horizontal, vertical, inclined structures. Among them: floors, ceilings, multi-layer frame walls, attic space. Thickness – from 50 to 100mm, density – 30kg/m3.

4. Technofas. Plates are used in industrial and civil construction.

Suitable for thermal insulation of facades. Decorative plaster can be applied on top of them. Thickness – from 40 to 240mm, density – 145kg/m3.

5.Technoflor. Three types. SOIL - for insulating heated floors and floating floors. PROF is needed where there is a large load on the floor - in warehouses, gyms.

STANDARD – for floating floors that require a thermal insulation layer. Thickness – from 20 to 150mm depending on the type. Density – from 90 to 110 kg/m3.

6. TechnoNIKOL stitching mat. Fire protection, thermal insulation of residential and industrial buildings. A galvanized mesh is attached to the mat to facilitate installation and add rigidity to the finished structure.

They insulate ventilation ducts, cylindrical, flat, cone-shaped surfaces, heating up to +750C. Thickness – from 40 to 200mm. Density – from 80 to 100 kg/m3.

Foil-coated basalt wool is also included in the list of TechnoNIKOL products.

Available in rolls. The cost of TechnoNIKOL basalt insulation varies. The popular type Rocklight costs 1,300 rubles/m3. The most expensive material is with a density of 180 kg/m3 - Tekhnoruf B60 - 6000 rubles/m3.

Selection of basalt slabs

Choosing a type of slab should begin with determining the place of its application:

- roof or attic insulation;

- insulation of frame walls;

- external insulation of aerated concrete walls;

- many other options.

Specialized foil fireproof insulation for stoves Source Technowool.com.tr

Of course, the selection and purchase of insulation should be entrusted to professionals. But, manufacturers have provided a wide range of products, positioned according to the type of intended use.

| Purpose | Brand |

| Base and insulation of flat roofs | TechnoNIKOL Technoruf N30, Izovol K-120 |

| For roof or attic | TechnoNIKOL Technolight Extra, TechnoNIKOL Technoruf, Izovol Izobel L-25, Paroc Extra, Greenguard Universal, Isover Master of Warm Roofs |

| For walls and partitions | Rockwool Light Butts, TechnoNIKOL Technoblock/Technolight, Rockwool Acoustic Butts |

| For facade | TechnoNIKOL Technofas, TechnoNIKOL TechnoFas Cottage, Rockwool Facade Butts, Izovol F-120, TIZOL Euro-Facade Optima |

| For ceilings and floors | Rockwool Light Butts, Rockwool Acoustic Butts, Rockwool Floor Butts, Paroc eXtra Light, TechnoNIKOL Rocklight, Izovol St-50, Isover Frame House |

Rockwool basalt insulation

The ROOCKWOOL group of companies unites enterprises from different countries. Representative offices and production facilities have been opened in Russia, Belarus, and Ukraine. On the market for more than half a century. Rockwool's products are used in premises for various purposes.

Review:

1. Fire insulation. Rockwool basalt wool is used in shipbuilding for thermal insulation of devices that have a fire and explosion hazard.

2.Technical insulation. Indispensable for air conditioning systems, ventilation ducts, chimneys, heating systems, pipelines, boilers and tanks. Insulates parts and devices with high and low temperatures.

3. Passive fire protection systems. Rockwool stone wool is needed for fire resistance of ceilings and steel structures, for the protection of chimneys and ventilation shafts.

4. Rockwool facade panels. Panels containing high-density stone wool - up to 200 kg/m3, withstand moisture and open fire well. Used in the construction of new facilities and during the reconstruction of existing buildings.

5. Ceiling systems. Based on stone wool, the Rockwool company produces ROCKFON suspended ceilings. The products improve the acoustic properties of the room and the microclimate in it. Used in hospitals, schools, offices, industrial and commercial facilities.

6. Agricultural soils GRODAN. Purpose – thermal insulation of the soil layer when growing plants in greenhouses.

7. ALFAROCK mineral mats. Single-sided foil insulation.

Available in 5m rolls. Density 60kg/m3. Suitable for thermal insulation of various surfaces with medium load.

8. LAPINUS fibers. Basalt wool fibers are used to insulate individual components and parts in the automotive industry. The product range from the Rockwool company includes more than 30 products in rolls, sheets and mats. For each building or room you can choose the appropriate type of Rockwool stone wool.

Fire safety

Basalt slabs are characterized by increased fire resistance. Melting of the material occurs when exposed to temperatures not lower than 1100 °C for at least 2 hours. When ignited, basalt wool does not emit smoke or other toxic volatile compounds. High-quality slabs manufactured in accordance with GOST meet all modern fire safety requirements and can be used in wooden housing construction without any additional fire safety measures.

A clear example of the heat resistance of a basalt wool slab Source Lubnyastroy.rf

Types of basalt insulation

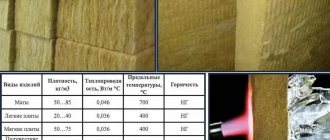

There are several types of stone wool. The features of each type of insulation determine the scope of application.

Available in the form of: slabs; rolls;

mineral mats.

Consists of: a base; a layer of metallized film or aluminum foil.

The reflectivity reaches 97%.

Application area:

to protect against heat loss in regions with strong winds. Insulate roofs and building facades in conditions of high humidity. Excellent results are achieved by using foil-coated basalt insulation in baths and saunas; for thermal insulation of electric and gas stoves;

to protect equipment during nitrogen production, to insulate oxygen columns.

Basalt fibers are produced in special furnaces from volcanic rocks.

Fibers are divided into two types: continuous; staple. Fibers have different diameters: from 0.6 microns to 50–500 microns. The scope of application depends on the thickness of basalt fibers: microthin - used in filters for purifying liquids and gases; ultrathin - for the manufacture of filters, sound and heat-absorbing devices; superthin and thin - for stitched mats and cardboard, various filters, long strips of thermal insulation, soft thermal insulation boards having a waterproof layer; thick ones - filter wastewater in drainage systems; thick and coarse - resistant to rust. They often replace metal for reinforcing various materials.

The use of stone wool slabs as insulation has been known for over 100 years. Basalt slabs are used for insulation of external and internal surfaces of walls. The slabs have different densities and thicknesses.

The higher the expected load on the insulated surface, the greater the density and thickness of the material should be. Manufacturing companies offer a wide range of basalt slabs with a thickness from 20 to 240 mm and a density from 30 to 190 kg/m3. The size of the slabs ranges from 1000x500mm to 1200x600mm. These parameters make it possible to install basalt insulation slabs as simply and quickly as possible. To increase the heat and sound insulation properties, stone wool is used in the form of slabs and mats.

Walls can be insulated both externally and internally. For ventilated facades and thermal insulation of external walls, stone wool with a density of 80 to 140 kg/m3 is used. Thickness – at least 60mm. The use of basalt wool for wall insulation as part of sandwich panels has become widespread. High resistance to precipitation and temperature changes explains the popularity of insulation made from recycled basalt rocks. Basalt wool is an ideal material for insulating chimneys.

Resistance to high temperatures and aggressive environments has been proven over years of operation of the material. Select basalt wool taking into account the following requirements: maximum density; minimal shrinkage during heating of surfaces. Multi-layer stone wool pads reinforced with a metal layer are suitable for chimney insulation. Reinforcement provides the necessary rigidity and avoids deformation when heating chimneys. Passive fire protection systems and technical insulation from the Rockwool company have proven themselves well. The use of basalt wool avoids heat loss through the chimney. The material effectively protects floors and walls from overheating.

How does mineral wool differ?

Mineral wool is a generalized name for fibrous materials obtained from inorganic raw materials. First of all, it is used for thermal insulation of buildings, various technological or household equipment, occupying more than 70% of the turnover of this market segment. Several varieties are produced, the technical requirements for which are set out in GOST 31913-2011.

Difference between mineral wool and material of manufacture

Mineral fibers can be obtained from various inorganic raw materials. During the production of finished products, they are intertwined and firmly bonded to each other, giving the mass overall elasticity and airiness. Depending on the composition of the initial mixtures, there are three main types of such insulation.

Glass wool

Glass wool is made from quartz sand, soda and lime - the same components from which ordinary glass is smelted. Such enterprises often engage in its recycling, involving waste and substandard products in the original mixture.

Ready-made mats have excellent thermal insulation, but are gradually being forced out of the market due to the relatively high fragility of the fibers. Any mechanical impact on them leads to the release of tiny particles with sharp edges. When working with them, it is necessary to use thick protective clothing, eye and respiratory protection. According to safety requirements, glass wool is installed under an outer shell made of durable materials. In this state, it does not pose a threat to human health.

Stone wool (basalt wool)

Stone wool can be obtained from various rocks: diabase, basalite, porphyrite, dolomite, limestone, but basalt, which gives it its second name, is more often used.

Insulating mats containing only basalt fibers resemble glass wool in their properties. They are used exclusively for thermal insulation of process equipment. Material intended for insulation of building structures usually contains synthetic and mineral additives. They play the role of binders, changing the content of which you can achieve the required density and specified mechanical properties.

Slag

Slag is obtained from blast furnace waste. It is slightly cheaper than mineral wool produced by other methods, but is inferior to them in thermal resistance and thermal conductivity. Its tendency to absorb moisture makes it unsuitable for insulating foundations, external walls and roofs. Due to its low environmental safety and fragility, it is not used in residential construction, so we will not consider the dimensions of this insulation.

Differences in mineral wool by release form

With a low specific gravity, good elasticity and the ability to maintain its dimensions, mineral wool is suitable for insulating large areas. In construction and industry, products of two forms are most widespread.

Mats

For insulating flat surfaces of walls and roofs, rigid and semi-rigid rectangular slabs are best suited. They are easily fixed on a solid base and can themselves carry an additional load in the form of a thin outer layer of protective plaster. Usually their thickness is constant throughout the product, but mats with a trapezoidal overall profile are also available.

Stone wool slabs.

Rolls

It is convenient to use soft types of insulation in the form of long strips about 1.0-1.2 meters wide. They are supplied rolled into compact rolls, which is convenient for storage and transportation.

Roll of glass wool.

Harmfulness of basalt insulation

The negative properties of stone wool are too exaggerated. Supporters of the version: “basalt insulation is harmful” explain their position by the presence of formaldehyde resin that binds the fibers. There is nothing to worry about.

Phenol in this case is not dangerous. During the production process, harmful resins are completely neutralized. Even at the manufacturing stage, the permissible limit is not violated.

No harmful substances are released from basalt insulation. The material does not cause allergic reactions and does not irritate the skin.

Advice: when insulating various surfaces, protect your lungs with a respirator. Basalt fibers crumble and turn into fine dust. A simple device will prevent basalt dust from entering the respiratory system. Basalt insulation or stone wool has long been successfully used for various purposes.

Learn the main types of stone wool. Select the appropriate type of basalt insulation. This way you will achieve maximum effect from its use.

- Date: 04/09/2015 Comments: Rating: 22

Basalt insulation is a thermal insulation material. Stone-based wool is popular among consumers because it has properties such as non-flammability and resistance to deformation.

It has low thermal conductivity and hydrophobicity, and is readily used for insulation of residential and industrial premises. For ease of installation, basalt insulation is produced in slabs with standard sizes. Manufacturers can change the thickness, length and width of the product to satisfy all customer requests.

The advantages of basalt wool are: low thermal conductivity, long service life, resistance to the formation of fungus and mold, high sound insulation, fire safety and chemical resistance.

To work with walls, smaller sizes are usually used, which are convenient to install alone, and when insulating the roof, it is recommended to use longer and wider basalt slabs.

They can be coated on one side with various coating materials. Aluminum foil, fiberglass, or other materials are used as an additional covering.

The edges of the sheets may have the ability to spring, which greatly facilitates the installation of insulation into a frame made of wood or metal. The flexible edge device is made on the long side and is marked with a special marking for user convenience. If the sides are difficult to distinguish, then marks must be left on the outside for ease of use.

Scheme of ceiling insulation with mineral wool.

Manufacturers offer slabs made of basalt insulation of different types and parameters. They can be lightweight, intended for use as sound insulation and thermal insulation:

- internal walls; floors; insulation of attics; insulation of roof structures.

The slabs used most often have dimensions of 1000 x 600 x 50 mm. The package contains at least 10 pieces, and the covered area with this quantity will be 6 m². Products are packaged in polyethylene film.

These types of sheets with mineral wool can be installed during facade work without installing windproof films. They are readily used with frames with a hinged structure.

The industry produces rigid boards made with a synthetic binder material.

Their dimensions are 1000 x 600, and their thickness can vary from 30 to 200 mm. Different sizes allow consumers to select the desired type and carry out installation work in one layer. This brings great savings in time, effort and materials for installation.

The peculiarity of basalt slabs is that they have a combined two- or three-layer structure.

Their outer layer is denser, and the lower inner layer is particularly light. The hard layer is specially marked so that it is placed on the outside. Thanks to this, products with large parameters are easy to use and do not require the involvement of many workers.

Scheme of thermal insulation of a wall with basalt insulation.

When installing facade insulation, the products are suitable for plastering walls over a steel reinforcing mesh or over the surface of the outer layer.

For further plastering with a thin layer that will fall on the insulation, use façade types that have a special top coating. It is specially created to ensure that the plaster adheres to the surface.

Parameters of this type are 1000-1200 long, 500-600 wide and 50-180 mm thick. The use of basalt as thermal insulation on the outside of buildings allows for surface finishing by applying a thin layer of plaster.

For facade work, special lamella strips of standard sizes are offered to insulate walls with a curved surface.

Return to contents

For roofing without cement screed, products with a thickness of 50-180 mm and standard sizes are used.

For the same purpose, the manufacturer offers coatings with parameters exceeding a length of 1000 mm. For thermal insulation of roofs, it is more convenient to use a length of 1200, 2000, and a width of 1000, 1200 mm. The thickness of these slabs is 40-200 mm.

Rigid thermal insulation boards with dimensions 1200 x 1000 x 50-180, 2000 x 1200 x 50-180 mm are used in roofs on which a protective coating made of concrete or reinforced cement or asphalt concrete is laid on top of the insulation.

It is known that a 100 mm basalt slab has the ability to retain the heat of a building, as does a layer of sand-lime brick 1400 mm thick.

The manufacturer offers several options for basalt slabs, which are used for insulation. For walls and floors they have a standard length of 1000 mm, and for insulation of ceilings the length can be doubled.

Their width is standard and is 600 mm. Thickness starts from 20 and can reach up to 200 mm. Which type the consumer needs depends on his needs.

Of all the choices of home insulation, basalt is the most popular and environmentally friendly material, based on mineral wool. It is resistant to fire, made of basalt stone, without any admixtures of limestone, phenol, or dolomite.

Thermal conductivity information

The type and thickness influence the fact that the thermal conductivity of basalt insulation is in the range of 0.30-0.48 W/ (m * K). Such characteristics are preserved due to the fibrous structure of the material. Small air layers that form between the layers act as a heat insulator.

But we must take into account that the indicator may differ. The higher the numbers, the thicker the base is needed; the rule also works in the opposite direction. 10 cm of thickness for basalt seals is comparable to 1.5 meters of brickwork or 2 m of cellular concrete. 30 centimeters of a wooden frame have the same characteristics as the specified size of basalt insulation.

Distinctive characteristics

- has a high degree of thermal insulation; moisture-proof; resistant to chemicals; maximum exposure temperature – 1000 degrees. C; not susceptible to destruction by rodents; does not react to the influence of microorganisms; long service life; used as sound insulation for house walls and roofs; has an average fiber thickness of up to 6 microns, length - 50 mm; high resistance to mechanical loads.

Widely used in the construction of residential and industrial buildings, catering establishments, for ventilation shafts, as thermal insulation, in the production of gas stoves, and refrigeration equipment. It does not compact over time, thereby maintaining its main functions - insulation of walls, for ceilings, insulation of parts.

We recommend the article Basalt insulation: characteristics

Life time

The material can withstand temperatures up to +1114 degrees without reaching the melting point. For this reason, basalt insulation can be used in difficult conditions, to insulate devices that operate at elevated temperatures. This factor does not affect the duration of use of the material.

The service life of basalt thermal insulation is 40-50 years. At the same time, there is a requirement for the operation of buildings, according to which each house must undergo an energy audit every 25 years. If the material loses its heat-saving qualities, the insulation is re-installed.

offers basalt insulation with the necessary parameters. We also sell other materials for thermal insulation from various materials - extruded polystyrene foam, stone wool, quartz-based mineral insulation, PIR boards. For additional advice, call our manager by phone.

Main categories

Insulation for walls is divided into 2 groups: for internal insulation and external insulation. These categories differ from each other only in their ability to pass steam or retain it. Mineral wool, packaged in slabs, mats, rolls, is easy to use, easy to cut and fills the most inaccessible corners, leaving virtually no waste after cutting.

TechnoNIKOL:

Technofas.

Available in the form of a slab measuring 600*1200*50/100 with a density of 145 kg per 1 m3. Technoven Standard. Plate. Dimensions 600*1200*50/100, density 80.

Knauf:

- Insulation FKD. Plate (600*1200* 20-160, density 140 -150.Insulation FKL, plate. 200*1000*20-200, density 85.Insulation FKD-S, plate 600*1200*60-180, density 140-160; Insulation HTB, plate 1000*500*20-180, density 35-150.

Rockwool:

- Fasrock, roll 1000*600*100, density 135; Wentirock max, roll 1000*600*50, density 50-90; Panelrock, plate 1000*600*50-100, density 65.

Attention!

The fine-fiber structure of mineral wool contains formaldehyde, and therefore is classified as a carcinogenic building material.

For safe installation, it is necessary to have special protection for the worker performing insulation or insulation. To prevent fibers from scattering throughout the room, the pressed slabs should be protected with membranes. And only after that begin finishing work.

Some installation tips

In the case of residential premises, one cannot do without thermal engineering calculations. Insulation of residential buildings is preferably carried out outside, unless additional instructions are provided. When installing, do not forget about hydro- and vapor barriers. The material may become wet, causing the original properties to be lost.

When insulating from the outside, there is no need for a vapor barrier layer. The side of the insulation facing the street must be covered with waterproofing. It is better to take a special membrane.

For fastening to vertical surfaces, use a separate type of glue. This is a type of cement-polymer mixture. Plasticizers and other types of additives are added to it.

What to use for the roof?

As you know, the greatest heat loss occurs through the roof of the building, so special attention must be given to the insulation of this zone (see.

How to properly insulate the roof of a house). A frivolous approach to selecting a heat insulator will force a stingy owner to pay twice. Basalt insulation for the roof must be at least 200 mm thick and securely fastened.

The insulating material “Basalt-Most”, which is used in the construction of children's and medical institutions, does not contain formaldehyde.

For pitched roofs use:

- insulation PAROS UNS 37, 610*1220*50, density 30 kg per 1m3; PAROS Extra 250*50, density 27-34; KNAUF 5500*1200*150; Rocklight 1000-1200*500-600*50-100; TECHNO Plates 100*60*5-10, density 126-154;Isover 1170*610*50 (see Isover: characteristics);Isover 1000*600*50-100, density 30.

For flat roof:

- PAROS Rob 50 1200 - 1800* 600, 900, 1200, density 20-30; Monrock Max 2000*1200*50-200, density 145 kg/m3; Tekhnoruf N 1200*600*100, density 100-135.

The good ability to transform and the elasticity of the material guarantee a tight fit to any surface, leaving no air gaps between mats and slabs laid next to each other. When compressed, the volume decreases up to 6 times, which significantly increases loading capacity.

Production of basalt fiber

The availability and prevalence of the material is explained by the widespread availability and ease of extraction of the source material. Basalt slabs are made from a product of natural volcanic activity. During an eruption, magma carries countless amounts of basalt from the lower layer of the earth's crust. No shortage or shortage of source material is expected.

The pieces extracted from the surface are sent to production and crushed. The fine-grained mixture is fed into a furnace, where it is heated to the melting temperature of basalt, which is 1500-1600oC. The melt is sent to centrifuges to obtain fiber and cool. Finished fibers with a length of 2 to 10 mm of different thickness (up to 8 mm) are coated with a binder composition and, under the influence of vibration and pressing, an almost finished product is obtained. Before packaging, it is cut and treated with a water-repellent compound. The scraps are recycled. To reduce the volume during transportation, air is pumped out of the sealed packaging.

Dimensions

The consumer is interested in what form basalt insulation is produced in: its dimensions, dimensions and which one is better to choose. At the exit from the manufacturing plant, basalt wool is packaged in rolls. In warehouses it is cut to the required size and comes in 1 to 10 pieces per package.

On the packaging, the manufacturer indicates the sizes of mineral wool slabs in a certain sequence.

The first is the length of the slab. This is followed by the width of the sheet and its thickness. The number of sheets is added to this information, which is important for the necessary calculation of the material.

Thickness and width

The thickness and width of basalt wool depend on the form of release. The material is produced in the following versions:

| Plates | Standard sizes are width 600 mm, length 1000 or 1200 mm. The thickness parameter is different - 20.50 100 mm |

| Rolls | Common sizes - 50x1000x4000, 200x1000x6000, 200x1000x3000, 200x1000x4750, 200x1200x2000 mm |

| Cylinders and mats | Dimensions depend entirely on the company producing the product |

Manufacturers also produce basalt chips. This is the waste that appears after cutting rolls or slabs. It is used to insulate only horizontal surfaces.

Cord basalt

For thermal insulation of linear objects, thermal insulating cord is produced from basalt fiber. Glass roving or steel wire is used as braiding. In the first case, the basalt heat-insulating cord is installed on pipelines with wall temperatures up to 400°C, in the second – up to 700.

Thermal insulation cord has a density of 150 – 200 kg/m3. The minimum diameter of the insulated pipeline is 15 mm.

Main uses of the cord:

- thermal insulation of power equipment;

- thermal protection of equipment used in everyday life;

- insulation of joints of reinforced concrete structures.

Insulating materials produced from basalt will provide thermal insulation of any building structures with an equally high saving effect, both during the insulation process and during operation. Warm up with pleasure.

Photo

A small gallery of photos of basalt slabs will give you an idea of how different slabs from different manufacturers, with different densities and thicknesses can look.

Basalt slabs ISOROC Super Warm. Teplostroy Photos

Basalt slabs Rockwool Standard 50 mm. Photo by Leroy Merlin

Basalt slabs Acoustic ultra-thin Rockwool 27 mm. Photo by Leroy Merlin

Why is it so important to maintain the vapor permeability of insulated structures?

Regardless of density, basalt insulation has good vapor permeability. The transition of the dew point to the volume of thermal insulation provides walls and ceilings with more comfortable operating conditions. For complete and timely removal of moisture, ventilated structures such as curtain walls or vapor-permeable plaster coatings are used.

Blocking natural vapor and gas exchange in the walls can have negative consequences, including worsening the microclimate in the house and reducing the living comfort of its inhabitants.

We will help you choose and buy building materials correctly, and a team of true professionals will provide construction services in the shortest possible time and at an affordable cost!