Penoplex Comfort

Penoplex Comfort is used in construction work in country cottages, houses and dachas, due to which it is successfully used for thermal insulation of balconies, foundations, basements and loggias, as well as for roofs, ceilings, floors and garden paths.

If you need to insulate a sauna, bathhouse or even a swimming pool, then Penoplex Comfort is perfect for these purposes. An important advantage that Penoplex Comfort has is its low thermal conductivity. The material does not allow cold to pass through and retains heat for a long time, which allows it to be used for insulating attics, loggias and balconies. The use of Penoplex Comfort is justified by its unique properties, which make it possible to easily install a heat-insulating layer. Penoplex Comfort sheets are light in weight, while their density varies between 20-30 kilograms per cubic meter. The material can be used in the temperature range from -50 to +75 degrees. When purchasing Penoplex Comfort, you can count on a service life of at least 50 years without loss of original properties.

You can view the Penoplex Comfort polystyrene foam options available for sale or compare their characteristics here.

Penoplex Foundation

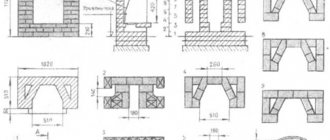

When building a foundation, first of all, it is necessary to take care of comprehensive protection from freezing and moisture. To achieve optimal results, it is recommended to use Penoplex Foundation. This type is ideal for both internal insulation of the foundation and external insulation of the base of the building (including the base) with Penoplex.

For example, a 100 mm thick Penoplex sheet can be used to insulate the foundation in very harsh climatic conditions and in places where the soil is not at all stable and the groundwater level is high. The thickness of the Penoplex Foundation is 50 mm - this is a size sufficient to insulate the foundation under normal conditions.

You can view the Penoplex Foundation foam polystyrene options available for sale or compare their characteristics here.

Penoplex Facade

Penoplex Facade slabs allow you to create a lightweight and moisture-resistant heat-insulating layer on the external surfaces of any structure. The material Penoplex Facade has excellent thermal insulation properties, avoids cold bridges, does not absorb moisture and has high strength, and therefore is able to withstand any loads during operation and installation.

Pnoplex Façade panels have a rough surface; the strips are applied to the surface of the slabs using a router, which helps improve adhesion to the wall. In addition, Penoplex Facade slabs have a special tongue-and-groove located on all sides, which allows them to be perfectly evenly joined and provide a continuous layer on the surface outside the building to create plastered facades.

Penoplex Wall

Penoplex Wall is also actively used for insulating facades and internal partitions. As a rule, this type of product is used to soundproof vertical walls from inside the house. Penoplex Wall is resistant to temperature changes and moisture. In addition, this material is characterized by durability and ease of installation.

What is this. History of the creation of the material

The material first appeared back in 1941, when the DOW CHEMICAL company (USA) patented a fundamentally new product with high thermal insulation properties and moisture resistance. The production of the material was put on stream, but initially it was manufactured only for the needs of the Navy.

Due to its resistance to wet environments, Penoplex has been used for the production of life rafts. After some time, the material began to be used in refrigeration units. Penoplex occupied its rightful niche only in 1950, when it began to be used in construction. It is curious that in the US construction market the material is known under the brand name STROYFOAM.

Penoplex is a Russian brand that appeared only in 1988.

What is Penoplex? Essentially, it is foamed polystyrene, which is produced on extrusion machines. In its structure, the material resembles polystyrene foam, which is familiar to many, but has a denser structure and, accordingly, better characteristics.

Application errors

A typical mistake in using Penoplex is more likely to do with belief in some “miraculous” properties of the material, or with the usual reluctance to delve into questions.

Nomadic teams of insulation workers impose their opinions on thermal insulation, seeking their own benefit. Penoplex is often imposed as a more expensive material for insulating walls, floors, and roofs, instead of foam plastic or mineral wool that is economically or technically feasible.

And so that the owners do not find it too expensive, they simply use sheets 20 mm or 30 mm thick to insulate the walls.

The heat saving effect from such a thin layer is minimal, or even practically unnoticeable. And the significant costs for gluing and plastering using the Wet Facade technology are wasted money.

What is Penoplex made of? Compound

We have before us a completely artificial material, which is made from chemical components mixed in certain proportions. The technology involves using a temperature of 140 degrees, which causes the ingredients to melt and foam, forming porophores. If we talk about specifics, the following materials are used in production:

- Polystyrene.

- Ground perlite.

- Lemon acid.

- Tetrabromoparaxylene.

- Barium or zinc stearate.

- Bicarbonate of soda.

The use of such components in certain proportions forms a strong cellular-porous structure filled with gas.

If you want to stick it on the wall...

If, for some reason, a decision is made to insulate the walls with penoplex (possibly due to the manufacturer’s statements about the great durability of the material...), then the wet facade technology must be done at least correctly.

- The torn insulation layer from below and above must be protected by appropriate strips.

- A flat, durable wall surface is provided on which the sticker will be applied.

- The sheets are glued with the appropriate glue, with the maximum-largest area of close contact with the wall on the glue... And also much more....

Advantages and disadvantages of heat-insulating material

Like any building material, this insulation has its strengths and weaknesses. The fine balance of price and quality makes it competitive and distinguishes it from numerous analogues. Let us immediately note that it is not worth singing odes of praise to Penoplex: despite many undeniable advantages, there are also disadvantages. If you conduct an impartial analysis of the characteristics, you will get the following picture.

Pros:

- High thermal insulation performance.

- Absolutely neutral to humid environments.

- Convenient installation.

- Easy to process.

- Multifunctionality.

- Durability (subject to certain conditions).

- Soundproof.

Minuses:

- Low fire safety of unmodified material.

- Low vapor permeability.

- Sensitive to aggressive substances: gasoline, acetone, oil paint.

- Unstable to ultraviolet light. Destroys in direct sunlight.

Types and technical characteristics of thermal insulation board

It is worth noting that the material has different densities, which determines the scope of its application. Usually the manufacturer indicates this data on the packaging, significantly simplifying life for inexperienced builders. So, according to their characteristics and scope of application, the following types of extruded polystyrene can be found on the market:

- For roofing . This material is suitable for increasing the thermal insulation of roofs and is used in commercial and residential buildings. The density of this category varies between 28-33 kg/m3 .

- For walls . Suitable for insulating facades and interior spaces. Here the density indicators are 25-32 kg/m3 .

- For the foundation . The density of the material varies between 29-33 kg/m3 , area of application: initial stages of construction, arrangement of basements.

- "Comfort" . Here the density indicators look like this: 25-35 kg/m3 , due to its characteristics, the material is the optimal solution for multi-storey buildings (apartments, balconies, loggias).

- Type "45" . This category is the densest on the market: 35-47 kg/m3 . The area of application of the material is to improve the properties of a runway or road surface in conditions of extremely low temperatures.

Considering that the cost of a material directly depends on its density and thermal insulation, knowledge of these features will help you purchase the right material and save money.

If we talk about technical characteristics, Penoplex has the following parameters:

| Physical and mechanical properties | Those. norms | Unit change | Penoplex – Roofing | Penoplex-Wall | Penoplex-Foundation | Penoplex-Comfort | Penoplex-Type 45 |

| Average density | GOST 17177-94 | kg/m3 | from 28.0 to 33.0 | from 25.0 to 32.0 | from 29.0 to 33.0 | from 25.0 to 35.0 | from 40.1 to 47.0 |

| Compressive strength at 10% linear deformation, not less | GOST 17177-94 | MPa | 0,25 | 0,20 | 0,27 | 0,20 | 0,50 |

| Water absorption in 24 hours, no more | GOST 17177-94 | % by volume | 0,4 | 0,4 | 0,4 | 0,4 | 0,2 |

| Flammability group | Federal Law 123 (TR on TVET) | group | G3 | G3 | G4 | G4 | G4 |

| Thermal conductivity coefficient at (25+5)С | GOST 7076-99 | W/m∙єS | 0,032 | 0,032 | 0,032 | 0,032 | 0,032 |

It is worth noting that the material achieved such high performance thanks to fully insulated cells, whose diameter is 0.1/0.3 mm.

How much brickwork does extruded polystyrene replace?

The answer to this question lies in the thickness of the insulation boards. It looks like this:

- Penoplex 20 mm thick = 370 mm brickwork.

- Penoplex 30 mm = brickwork 750 mm.

- Penoplex 47 mm = brickwork 925 mm.

Accordingly, an insulation board can replace a brick wall that is twice as thick as the insulation itself.

Useful tips

Most homeowners turn to external rather than internal wall insulation with penoplex. This is explained by the fact that the second option hides the usable area of the room.

When decorating floors after insulation, they often turn to grouting. For this it is better to use sandpaper. You can proceed to this stage after the reinforcing layer has completely dried. Despite the strength of penoplex, you should be careful when working with it, since this material can still be damaged or broken.

Select high-quality and most effective glue for penoplex. A special adhesive foam is ideal for laying this insulation: it firmly and tightly attaches the material to the base and holds it quite reliably. Make sure that the thickness of the penoplex for wall insulation is at least 5 cm. Ensure that the insulation is securely and tightly attached to the base. Use both nails and glue.

When installing insulation, you cannot do without a profile, especially when it comes to installing a frame structure. It is advisable to purchase a bubble or laser tool, which is both easier and more convenient to use.

To make the external insulation of a house more effective and complete, it is recommended to insulate the foundation in advance (the basement can also be insulated along with it). In this case, all the work is done quite simply: first you need to dig out the foundation, clean it of any dirt, and then glue the foam sheets. After this, the base can be buried.

When installing penoplex on the facade of a building, you must ensure that the panels overlap each other by about 10 cm. This way you can avoid the formation of cracks.

Extruded polystyrene foam is a strong and durable material, but it does not tolerate contact with the following substances:

- gasoline, diesel fuel, kerosene;

- acetone and other ketone solvents;

- formaldehyde and formaldehyde;

- benzene, xylene, toluene;

- various esters;

- polyesters;

- coal tar;

- oil paints.

It is most convenient to apply glue to materials using a notched trowel. In this case, it is advisable to make the adhesive layer no more than 10 mm.

Facade penoplex glued to the ceilings needs to be bandaged vertical seams. This technology is very similar to laying bricks.

If you are going to plaster a wall insulated with penoplex, then you should first apply a base composition with a reinforcing mesh. The density of the latter must be at least 145 g/m2. Make sure that the size of the overlap is about 10 cm. Next, you need to lay a leveling plaster layer (its thickness should be at least 5 mm). Only then should the thermal insulation material be covered with decorative finishing.

If you are sheathing a house with penoplex in 2 layers, then first glue the starting layer, and on top of it place the next layer with a slight offset. Before this, it is worth treating the slabs with a roller.

Before installing insulation, old coverings should be removed only if they have noticeable damage or crumbling areas. If the previous finish does not have any defects or complaints, then penoplex can be placed on it.

Penoplex can be installed on a variety of substrates. It can be safely used for a private/country house or city apartment. In addition, you can easily install this insulation not only on walls, but also on the roof/ceilings.

Experts advise not to rush to insulate the house until it shrinks completely. Otherwise, the layer of plaster will become cracked and may begin to crumble. To carry out thermal insulation work, it is necessary to select only high-quality materials and tools.

Leveling the bases for laying penoplex can be done with plasterboard. However, the presence of this material will reduce the additional space in the room. Owners of city apartments with uneven floors often turn to such solutions.

If you decide to lay penoplex on a wall made of foam concrete, then it will come in handy to install a vapor barrier material. These components are not needed only if we are talking about bases whose structure is not porous.

Dimensions of insulation boards

Penoplex is produced in the form of slabs, with the following external parameters: length - 1,200/2,400 mm, width - 600 mm. Thanks to its porous structure, the material has a relatively low weight even with impressive dimensions, and is easy to process.

| Dimensions, mm | Type (density) | |||

| Penoplex C (25-32 kg/m3) | Penoplex K (28-33 kg/m3) | Penoplex F (29-33 kg/m3) | Penoplex 45 (35-47 kg/m3) | |

| width | 600 | 600 | 600 | 600 |

| length | 1200 | 1200 | 1200 | 2400 |

| thickness | 20; 30; 40; 50; 60; 80; 100 | 20, 30, 40, 50, 60, 80, 100 | 20; 30; 40; 50; 60; 80; 100 | 40, 50, 60, 80, 100 |

When performing interior work, you need to take into account that the space will be reduced by the thickness of the insulation + finishing coating.

| Slab thickness (mm) | Number of slabs per package (pcs.) |

| 20 | 18 |

| 30 | 12 |

| 40 | 9 |

| 50 | 7 |

| 100 | 4 |

The key indicator of thermal insulation is the thickness of the slab. Depending on the installation conditions, the recommended material thickness looks like this:

Let's conduct a comparative analysis with other popular insulation materials that are found on the domestic construction market.

Dimensions of penoplex sheet depending on thickness, density and purpose

Penoplex Comfort is a popular heat insulator for apartments and country houses, with a material density from 25 kg/m3 to 35 kg/m3. Its slabs have the following dimensions:

- Slab length – 0.6 m. Slab width – 1.2 m. Slab thickness – 15cm, 12cm, 10cm, 8cm, 6cm, 5cm, 4cm, 3cm, 2cm.

Penoplex Foundation is a dense and durable insulation material that can be used to insulate foundations and basements of buildings. The density of this insulation is from 29 kg/m3 to 33 kg/m3. It comes in sizes:

- Slab length – 0.6 m. Slab width – 1.2 m. Slab thickness – 15cm, 12cm, 10cm, 8cm, 6cm, 5cm, 4cm, 3cm, 2cm.

Penoplex for pitched roofing is a rigid and lightweight insulation material that allows you to create a pitched roof.

Its plates have a special groove for a tighter fit to each other. The density of this insulation is from 26 kg/m3 to 34 kg/m3. Its slabs have dimensions:

- Slab length – 0.6 m. Slab width – 1.2 m, 2.4 m. Thickness – 10 cm, 15 cm.

Penoplex Facade is a universal insulation material, the surface of which has increased roughness, which improves adhesion to plaster and painting compounds. The density of this insulation is from 25 kg/m3 to 32 kg/m3. Its slabs have the following dimensions:

- Slab length – 0.6 m. Slab width – 1.2 m. Slab thickness – 15cm, 12cm, 10cm, 8cm, 6cm, 5cm, 4cm, 3cm, 2cm.

Penoplex Wall is an analogue of Penoplex Facade.

Its slabs have increased resistance to moisture and mechanical stress. The density of this insulation is 25 kg/m3 to 35 kg/m3. Penoplex board sizes:

The slab is 0.6 m long.

- The width of the slab is 1.2 m. The thickness of the slab is 15cm, 12cm, 10cm, 8cm, 6cm, 5cm, 4cm, 3cm, 2cm.

Penoplex GEO is an insulation material of increased strength and density, which is suitable for loaded buried structures. The density of such penoplex is from 29 kg/m3 to 33 kg/m3. This material is available in sizes:

- Slab length – 0.6 m. Slab width – 1.2 m. Slab thickness – 15cm, 12cm, 10cm, 8cm, 6cm, 5cm, 4cm, 3cm, 2cm.

Penoplex Roofing is a durable and moisture-resistant insulation material for creating a roof.

Its plates have a special groove for tight joining. The density of such penoplex is from 28 kg/m3 to 33 kg/m3. Dimensions of one plate:

- Slab length – 0.6 m. Slab width – 1.2 m. Slab thickness – 15cm, 12cm, 10cm, 8cm, 6cm, 5cm, 4cm, 3cm, 2cm.

Available analogues. What is the difference? Which is better and warmer?

- Penoplex or Mineral wool

If you compare these materials, you must take into account their scope of application. For example, mineral wool is definitely not suitable for a foundation or basement: it absorbs moisture well, which leads to weight gain. Accordingly, the insulation slides down, exposing the walls. To avoid these problems, you will have to install additional moisture insulation, and this proportionally increases costs.

However, in terms of heat and sound insulation, Penoplex loses to mineral wool, although the latter material looks more difficult in terms of installation.

- Penoplex or Foam plastic

Both materials do not absorb moisture, so they are equally suitable for insulating basements. Thermal conductivity indicators are better for Penoplex, but only slightly. It is worth noting that polystyrene foam can be classified as an eternal material, and the service life of Penoplex declared by the manufacturer is 50 years .

Therefore, for internal and external insulation, both materials can be used with equal efficiency, but if service life plays a decisive role, it is better to give preference to polystyrene foam.

- Technoplex or Penoplex

These are two materials that are almost identical in their properties. Here you can observe the same indicators of mechanical strength and bending resistance: 250 kPa and 0.4 MPa , respectively.

If we talk about resistance to sub-zero temperatures, then Technoplex looks warmer - the operating temperature of the material: -70 degrees Celsius , however, such temperatures are difficult to meet in most regions of Russia. The thermal conductivity of the insulation is the same: 0.031 W/mK , but Technoplex is more resistant to humid environments.

- Styrex or Penoplex

There are no fundamental differences between these materials, so they have an identical scope of application. Here we can highlight the following difference: Stirex is more resistant to bending deformation, but is more expensive to purchase. In addition, Stirex is more suitable for insulating rooms where there is a significant difference between external and internal temperatures.

- Izolon or Penoplex

Thanks to its structure, Izolon is ideal for insulating floors and roofs, increasing the thermal and sound insulation of rooms. However, for walls it is better to use Penoplex as a material that is more convenient to install.

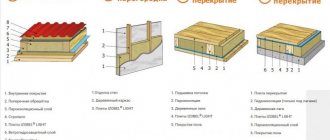

Roof thermal insulation

The work begins with laying insulation on the rafter system.

Measures to insulate this structural element are carried out either during construction or during the reconstruction of an old facility. Insulation is often carried out to turn a cold attic into a living space. Before starting work, you need to prepare the following materials:

- metal tiles or other roofing solution;

- sheathing;

- vapor-permeable moisture-resistant membrane;

- insulation;

- internal lining;

- rafter structure.

Work begins with laying insulation on the rafter system. The material is placed in a checkerboard pattern. After this, you need to lay a vapor-permeable membrane on it. Next, using longitudinal slats with a thickness of at least 40 cm, the heat insulator is fixed. In order to ensure ventilation between it and the roof, it is necessary to maintain a step of 300 mm.

After this, you can proceed to securing the transverse slats. Then, after placement, the roofing material is fixed on them. It is permissible to use metal tiles or any other.

Roll solutions for continuous flooring can be a good alternative

Penoplex differs from another popular insulation product - penoflex - by its high cost. However, this disadvantage is compensated by its excellent characteristics. It is ideal for use under plastering systems.

Penoplex is one of the best materials for creating effective thermal insulation. If you constantly feel cold in your home, then using it can solve this problem. There are significant costs involved in carrying out the work. But they are offset by savings on heating rooms. Proper implementation of the procedure minimizes heat loss and ensures comfortable living.

Three questions that concern buyers most

Fire safety. Is the insulation burning or not?

The answer to this question is clear: yes, it burns. Perhaps it is this feature that prevents the widespread spread of Penoplex. However, on the building materials market, there are products marked “G1” and “NG”, which means low-flammable and non-flammable material.

In this case, antiperen is used - a substance that prevents the spread of fire. It is worth noting that it is spread, not fire. Of course, for Penoplex to ignite, a fairly high temperature will be required, however, the essence is the same: the material is flammable!

Do mice chew insulation boards?

The material does not contain natural substances and therefore cannot attract rodents. However, this feature does not prevent mice and rats from chewing the insulation, making nests there and breeding offspring. To avoid these problems, a fine mesh is installed over the insulation.

By the way, Penoplex does not attract insects and is neutral to the appearance of mold and mildew.

Is polystyrene foam harmful to health?

In principle, Penoplex is an environmentally friendly material, provided that the material is created without violating production technology. However, given that we are talking about an artificial material, chemical components can evaporate under the influence of certain factors, for example, prolonged exposure to direct sunlight. Therefore, Penoplex is not found on the walls in its pure form and is always covered with finishing materials.

In addition, when the material burns, it releases acid vapors, carbon dioxide and other dangerous substances, including hydrogen chloride. Accordingly, in the event of a fire, there is a direct threat to human life.

Hexobromocyclododecane, which is a bioaccumulative toxin and is currently permitted in our country, but has been prohibited for use in the European Union since 2015, can be used as a flame retardant.

Installation technology

When laying on horizontal surfaces - floors, flat roofs - the slabs are simply laid on a flat surface. The surface should be without sharp changes, the maximum deviation is 2-3%. This requirement must be met so that voids do not form. When laying, we monitor the joints; it is advisable to glue them (you can use tape) or fill them with the same foam/glue on which the slabs are attached.

When using Foam plastic for insulation of balconies

If two layers of thermal insulation are laid, it is positioned so that the EPS slabs of the second row overlap the seams of the lower one. They also say that the slabs are laid with alternating seams or “staggered”.

When mounting on vertical surfaces, double fastening is used:

- Glue or adhesive foam is applied to the plane.

- Additionally fixed with umbrella dowels.

According to the technology for installing slab insulation on facades, umbrella dowels are installed at the junction of two sheets (any two sheets) and two additional fasteners in the plane of the sheet. That is, there are at least 8 fasteners per sheet (indicated in red in the figure). More is possible. Less - no. Unless, of course, you want the insulation and finishing to come off. If the winds in the region are strong, it is better to put more. To insulate the inside, you can install less (see diagrams below).

Schemes for installing umbrella dowels when installing Penoplex on vertical surfaces

During installation, on the outer slabs and around openings, we install fasteners more often: three to four elements per slab. To keep the insulation rigid in the corners of the openings, a mesh is attached to it before plastering. It is attached at an angle of about 45°, securing the joint. Under such conditions, there will be no problems with finishing inside or outside.

If plaster, facade tiles, finishing stone and other heavy materials are subsequently applied to Penoplex, before installation, care must be taken to improve the adhesion of the material to the wall and to the finish. Even if you are installing a Penoplex Wall with stripes, it is better to add roughness to the slab using a metal brush. And from both sides. If the wall is smooth, it also doesn’t hurt to add roughness - for better adhesion.

If the wall is smooth, it also needs to be processed by putting a metal attachment on the drill

To work with Penoplex, a special adhesive mixture is recommended: Ceresit ST 84, illbruck PU 010, Titan 753, Ceresit CT-85, Kreisel 210 and 220, Baumit ProContact, STO Baukleber, Soudal Soudabond, Penosil Fix and Go, Den Braven, Krass.

Where is Penoplex made? Reliable manufacturers you can trust

Penoplex is produced in Russia, so the material is sold in an affordable price segment. If we talk about brand representative offices, you can pay attention to the following cities:

- Kirishi . The production line has been operating since 1998, specializing in the production of standard size insulation. Currently, there are four lines involved. Total capacity up to 600,000 m3 annually.

- Perm branch . The plant was launched in 2005. Now, this is the most productive enterprise, supplying the market with about 650,000 m3 annually.

- Novosibirsk . The enterprise was launched for residents of the Siberian region of the country, specializing in the production of Penoplex with increased thermal insulation and water resistance.

- Taganrog . The plant produces about 500,000 m3 of insulation annually and, accordingly, fully supplies the residents of the Southern and Central regions with products.

It is worth noting that the products of these branches are subject to mandatory certification and undergo multi-stage quality control at all stages of production.

Share the post “Standard sizes of Penoplex. Types and characteristics. Comparison with analogues." by copying the link: https://kaksdelatsvoimirukami.ru/standartnye-razmery-penopleksa/