This synthetic thermal insulation material was created by American specialists in 1941.

As soon as it is not called: extruded or extruded polystyrene foam, EPS, EPS, XPS. But this does not change the essence, as do the widest possibilities of artificial insulation: from decorating door frames and ceilings to thermal insulation of railways, highways, sports grounds and ice arenas.

Which is not surprising, since extruded polystyrene foam has excellent characteristics (see below).

Thermal insulation of walls. Insulation with extruded polystyrene foam.

Despite the widespread use of EPS, most people purchase it to insulate walls, which are the main source of heat loss (up to 45%). Here are some useful recommendations for those who plan to insulate the walls of their home with extruded polystyrene foam.

- It is better to carry out work in dry weather. Air temperature - not lower than +5°C.

- The slabs must be glued from below, in strictly horizontal rows.

- Each top row is glued end-to-end to the bottom row. Try to install the stove correctly the first time, because after a couple of minutes it will be difficult to dismantle it.

- If the wall is old, with peeling and falling off plaster, then the slabs must be fixed with dowels.

- During the first three days after installation, it is necessary to protect the wall from direct sunlight. Then you can install a reinforcing mesh on it.

- After installing the mesh, we recommend waiting another 3 days, then start plastering. Work should be carried out in a temperature range from +5 to +25°C in clear and calm weather. Apply the plaster using the wet-on-wet method. This means that until the bottom layer is dry, lay the top one.

Adhesive for extruded polystyrene foam

The author of the article, when solving this issue, chose Ceresit CT 84 (not an advertisement) - this glue was recommended three times: at a construction forum, in a store, the manager whom I trust and the head of the installation department spoke very highly of Ceresit. The glue sets very quickly and reliably - even at high humidity and is quite economical. I applied it with this thing with a 20 mm indentation from the end, and then in the center along the slab. We overwintered the first winter and the flight was normal.

Description

Density

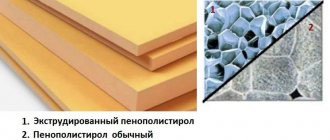

High-quality EPS has a homogeneous structure and closed pores of a much smaller size than conventional polystyrene foam (no more than 0.2 mm). Due to its increased compressive density, EPS can be used where foam plastic is too soft. Extruded polystyrene foam can withstand a load of 35 tons per 1 m2!

Installation work

Another advantage that this material structure provides is the ability to process it comfortably. Many people know how difficult it was to cut foam plastic. The balls crumbled, scattered and became magnetized to hands, tools and surfaces. And even with careful handling, the slab could crack and break in the wrong place.

House insulation with Penoplex

Extruded polystyrene foam is free of all these disadvantages. It is easy to cut with a regular hacksaw. The cut is precise and even. And the slabs are laid directly on the base - no additional layers of steam and waterproofing are required. The joints are sealed with polyurethane foam. EPS does not emit toxic substances or unpleasant odors. Working with it does not require special equipment for installers.

Moisture absorption

The dense structure increased the moisture resistance of the material (against the background of vulnerable mineral wool, water absorption of 0.2 looks like an error). In the first 10 days, the side cells on the cut collect a minimal amount of moisture. Then water absorption stops, water does not pass inside.

Usually houses are insulated from the outside, but in some cases internal thermal insulation is necessary. How to insulate walls from the inside of a house: see the review of thermal insulation materials.

You can find a guide to covering your house with siding yourself here.

And in this article https://microklimat.pro/uteplenie/doma/potolka/v-chastnom-dome.html you can find tips on choosing material for ceiling insulation in a private home. Mineral wool, polystyrene foam, bulk materials - which is better to choose?

Thermal conductivity

In the battle to retain heat, even a slight difference in thermal conductivity matters. For different brands of expanded polystyrene, this figure ranges from 0.037 to 0.052 W/(m* °C). Extruded polystyrene foam has an indicator of 0.028 - 0.03 W/(m* °C)!

Chemical resistance

XPS has proven to be resistant to:

- various acids (organic and not);

- salt solutions;

- ammonia;

- cement and concrete;

- lime;

- alkalis;

- alcohol dyes, alcohol;

- carbon dioxide, oxygen, acetylene;

- freons (fluorinated hydrocarbons);

- paraffin;

- water and water-based paints;

- bacteria and fungi.

Other properties

The thickness of the produced slabs can be from 2 to 12 cm.

For ease of installation, three types of edges are available:

- Straight.

- With the selected quarter (marked with the letter S).

- Tenon - groove (letter N on the marking).

The outer surface can be smooth or corrugated (indicated by the letter G on the marking).

The color range of extruded polystyrene foam is varied. There are no uniform standards yet, so each manufacturer produces slabs of different sizes, thicknesses and different colors to indicate different quality EPS.

The properties of EPS do not change even after 1000 freezing-thawing cycles, or after prolonged immersion in water. Extruded polystyrene foam remains unchanged even in conditions of -60 +85 °C!

Orange slabs

Cons and weaknesses:

- Penoplex is vulnerable to solvents, some gases (methane), petroleum jelly, tar, gasoline, oil and fuel oil.

- Susceptible to destruction upon contact with polyvinyl chloride (siding).

- Flammability. It corresponds to the level of flammability of wood, but all foam plastics emit toxic substances when melted that suffocate a person faster than carbon monoxide.

- The material must be protected from direct exposure to ultraviolet radiation (not used open).

- There are temperature restrictions when insulating baths, saunas and fire pits. The surface should not be heated above +75 °C.

- Just like polystyrene foam, extruded polystyrene foam can be damaged by rodents. They don't eat it, but grind it up and build nests in it.

There are no ideal materials, therefore, knowing about its shortcomings, you need to be able to adjust technologies to suit them. For example, in order to protect residents in case of fire, it is not recommended to use EPS for internal insulation of ceilings, and plastering should be done on top of the insulation layer.

To protect the wall from rodents, Penoplex slabs can be covered with fine mesh.

Specifications

Low thermal conductivity. A very important value that affects the temperature in the room. The thermal conductivity of XPS does not exceed 0.03 W/Mk.

Hygroscopicity. This indicator for extruded polystyrene foam is also in the lower limits, due to which the material is stable in the external environment and retains its unique characteristics for a long time.

Chemical inertness. EPPS practically does not react with other chemical compounds.

Fire safety. Extruded polystyrene foam is non-toxic and does not emit harmful substances when burned. Its total combustion is possible only at high temperatures. EPS will not ignite from a match or cigarette butt.

| Name | Dimension | Specifications | ||||

| 31С | 31 | 35 | 45C | 45 | ||

| Density | kg/m³ | 28,0-30,5 | 25,0-30,5 | 28,0-37,0 | 35,0-40,0 | 38,1-45,0 |

| Compressive strength at 10% linear deformation, not less | MPa (kgf/cm²; t/m²) | 0,20 (2; 20) | 0,20 (2; 20) | 0,25 (2,5; 25) | 0,41 (4,1; 41) | 0,50 (5; 50) |

| Ultimate strength during static bending, not less | MPa | 0,25 | 0,25 | 0,4 | 0,4 | 0,4-0,7 |

| Elastic modulus | MPa | 15 | 15 | 15 | 18 | 18 |

| Water absorption in 24 hours, no more | % by volume | 0,4 | 0,4 | 0,4 | 0,4 | 0,2 |

| Water absorption in 30 days | % by volume | 0,5 | 0,5 | 0,5 | 0,5 | 0,4 |

| Fire resistance category | group | G4 | G1 | G1 | G4 | G4 |

| Thermal conductivity coefficient at (25±5)°С | W/(m°K) | 0,030 | 0,030 | 0,030 | 0,030 | 0,030 |

| Calculated thermal conductivity coefficient under operating conditions “A“ | W/(m°K) | 0,031 | 0,031 | 0,031 | 0,031 | 0,031 |

| Calculated thermal conductivity coefficient under operating conditions “B” | 0,032 | 0,032 | 0,032 | 0,032 | 0,032 | |

| Heat absorption under conditions “A” (with a period of 24 hours) | 0,32 | 0,32 | 0,33 | 0,35 | 0,35 | |

| Heat absorption under conditions “B” (with a period of 24 hours) | 0,33 | 0,33 | 0,34 | 0,36 | 0,36 | |

| Vapor permeability coefficient | mg/(m h Pa) | 0,008 | 0,008 | 0,007 | 0,007 | 0,007 |

| Specific heat capacity, s | kJ/(kg °K) | 1,45 | 1,45 | 1,45 | 1,40 | 1,40 |

| Sound insulation of partition (GKL-PENOPLEX 50 mm-GKL), Rw | dB | 41 | 41 | 41 | — | — |

| Improvement index for structural noise insulation in floor construction | dB | 23 | 23 | 23 | — | — |

| Operating temperature range | °C | -50…+75 | ||||

Classification

Marking 31C

Marking 31C has established itself as a high-quality element of insulation of unloaded sections of structures. An excellent example in this direction is work with foundation walls. This marking can be found in the underfloor heating product.

31C has also found wide application in work on insulation of sewer systems. Operation is intended exclusively in structures that are protected from fire, since its fire resistance level corresponds to category G4.

Marking 35

Marking 35 has significant differences from 31C. They consist in the difference in specific gravity indicators and the general level of fire resistance. In the creation of expanded polystyrene with the marking 35, a fire retardant is used, with the help of which it is possible to increase fire resistance.

Due to its fire resistance qualities (low flammability), the product has also proven popular for roofing. The most popular work in which grade 35 polystyrene foam is used is the insulation of all kinds of structures that perform enclosing functions.

Marking 45

Expanded polystyrene with the marking 45 is superior to the first two options due to the fact that its compressive strength has a huge margin. It can be successfully used not only in insulation; it opens up all its possibilities in such large-scale work as road construction. Expanded polystyrene grade 45 is also actively used in work on runways.

Characteristics:

- The specific gravity of polystyrene foam has little effect on heat retention performance.

- The specific gravity indicator has an impact on the strength characteristics.

- The effectiveness of insulation (thermal insulation) is affected by the thickness of the sheet.

Markings of polystyrene foam 31 and 31C have basically similar qualities. The most striking difference between these two brands lies in the categories that are responsible for fire resistance. 31 has category G1, and 31C G4.

An opposite example is marked polystyrene foam 45 and 45C. Unlike expanded polystyrene 31 and 31C, these are different on literally every point. One of the few indicators that these brands of expanded polystyrene have in common is fire resistance at the G4 level.

Special opinion

Some experts believe that extruded polystyrene foam should not be used as wall insulation. They indicate the low vapor permeability of XPS, they say, the walls should breathe and not be wrapped as if in a plastic bag, which leads to fungi and mold. To get rid of such unpleasant effects, you will then have to install supply and exhaust ventilation or upgrade the insulation system. And these are additional moral and material costs.

Of course, every specialist has the right to his own opinion, so we will not use the format of this article to find out who is more right. But in fairness, we note that there are several popular myths about extruded polystyrene foam that somewhat scare away beginners. Let's try to dispel them.

Making at home

Extruded polystyrene foam is obtained from polystyrene foam granules.

It is impossible to produce XPS at home; this requires expensive equipment - an extruder and a production line. You can make ordinary foam plastic from polystyrene granules. At the same time, you should not focus on independent production of slabs - it will be unprofitable. This idea is suitable for obtaining fancy shapes for the purpose of doing Hand Made. The technological process is as follows:

- The granules are poured into a fifth of the bucket and the steam generator hose is directed into them.

- The raw material is doused with steam and at the same time mixed until it increases in size.

- The balls are placed in a pre-prepared mold and continue to be heated in it with a hot stream until sintering.

At the end of the process the mass is allowed to cool. The mold is opened or broken to reveal the finished product. The more elegant the thing, the smaller in diameter the original balls should be.

Myths and realities

1. Firstly, the statement that EPS boards are short-lived does not stand up to criticism. As a result of official laboratory studies, it was found that they can withstand temperature changes with an amplitude of 40 degrees. Extruded polystyrene foam only does not like direct ultraviolet rays, so you need to cover the entire structure with materials that protect its surface well.

2. The second myth is that styrene, which is used in the production of XPS, is a very harmful component. But in fact, this colorless liquid has a second class of harmfulness and is on par with the detergents and washing powders that we use every day.

There is no release of toxic components during the combustion of EPS, since it consists of 95% air. Even after fifty years of operation, traces of styrene decomposition cannot be detected in the slabs.

3. And finally, the third myth is about the high flammability of EPS. We have already written that extruded polystyrene foam does not ignite from a cigarette butt or match. In every apartment there are many other items that are ready to burst into flames even from a small fire source: plastic, carpets, furniture, household appliances, etc. Of course, if the fire has already spread to the walls, then the EPS will also begin to burn. But only as a last resort. After all, its ignition temperature is almost 500°C. For comparison, the combustion temperature of regular cotton is 253°C.

In addition, EPS in most designs is covered on top with other materials. It is practically impossible for a spark to hit its surface.

What is the material

Strength and low thermal conductivity are due to the fine-cell structure of the material.

Among all polystyrene foams, extruded polystyrene is the strongest. This polymer is produced in the form of sheets of a certain size. The structure itself is obtained by foaming polystyrene, while it goes through the stage of heating in an extruder until it melts. Next, it is squeezed into a certain shape and, after cooling, cut.

The high strength of such a heat insulator is due to its fine-cell structure obtained at the time of sintering. The pores inside the polymer have a closed round shape, due to which extruded plastic (EPS) does not allow steam and moisture to pass through.

Eps or foam?

Which material is better suited for wall insulation: extruded polystyrene foam or polystyrene foam. Even experts cannot answer this question unequivocally.

The production technology of these materials is different, which affects their physical characteristics. Thus, the strength of extruded polystyrene foam is higher than foamed polystyrene, but it is several times more expensive.

The strength and rigidity of a material of the same density differs from one manufacturer to another. Here you need to compare and make a decision based on a specific task.

For reference: the gradual transition from foam to XPS can be considered a global trend. For example, in the homeland of XPS in the USA, the use of foam plastic in some areas of construction is already prohibited.

Application area

The extruder is used in various areas of the national economy. Two types of products are used in construction: non-pressed and extruded. Unpressed polystyrene foam is obtained when foamed styrene granules undergo polymerization in an aqueous suspension under high pressure. And extrusion is obtained when the molten mass is forced through an extruder. They are mainly used for insulation of floors and ceilings in the construction of residential buildings. Due to the fact that it is solid in structure, it can be used for insulation of those surfaces where significant loads on the surface are possible.

In addition, it can be used for thermal insulation of walls where its resistance to loads is not so important. But on the other hand, its increased thermal insulation characteristics are important. After all, when using materials with a low thermal insulation coefficient for insulation, the result is that the buildings have to be insulated with something else, since the walls do not provide normal thermal insulation. As a result of using cheap materials for insulation, it is necessary to dismantle and still use high-quality materials.

How to choose

To facilitate the selection of a suitable brand of expanded polystyrene, it is recommended to pay attention to the following criteria.

Manufacturers

To create reliable thermal protection, it is recommended to give preference to well-known brands that produce insulation that meets the requirements and declared characteristics. It is possible to produce high-quality material only if you have modern equipment and adherence to the technological process. Among the companies that deserve trust are:

- Technoplex;

- KNAUF;

- URSA;

- PENOPLEX;

- TechnoNIKOL;

- Elite-Plast.

The main argument in favor of the products of a particular manufacturer is the availability of a certificate of quality and environmental friendliness of the raw materials used for the production of expanded polystyrene.

Length, width, thickness

Manufacturers produce standard and non-standard slab sizes. The sheets have different lengths, thicknesses and widths. The predetermining parameter when choosing insulation is thickness. It varies from 20 to 100 mm. A clear understanding of the purpose for which insulation is being purchased - external or internal work, for the floor or roof - will help you decide on a purchase.

Standard sheets have a length and width of 1000, 2000 mm. Upon special order, the manufacturer cuts the slabs according to individual parameters. Sheets available for sale:

- 1200x600 mm;

- 500x500 mm;

- 900x500 mm;

- 1000x1000 mm;

- 1000x500 mm.

If the length of the product exceeds 2000 mm and the width is 1000 mm, GOST standards allow cutting slabs 10 mm smaller. With a sheet thickness of up to 50 mm, there may be a difference of 2 mm (in either direction).

Interior or exterior work

Expanded polystyrene is not produced separately for interior and exterior use. The insulation is selected taking into account the brand, thickness and density of the sheet.

| Place of application | Plate thickness, mm |

| First floor (for floor) | from 50 |

| Second floor (for floor) | 20-30 |

| Additional sound insulation on the floor | 40 |

| For interior wall cladding | 20-30 |

| For external wall cladding | 50-150 |

Sheet sizes

Extruded polystyrene foam is produced in slabs with the following parameters:

- width range – 500-600 mm;

- length range – 1200-2400 mm;

- thickness range – 20-150 mm.

At the request of the client, sheets can be cut into different sizes.

Manufacturers of popular products

Expanded polystyrene has many advantages, which is why many foreign and domestic manufacturers have included this construction insulation in their product line.

Thermit is a Krasnoyarsk plant producing effective thermal insulation. Manufactures XPS for various insulation applications. The products are made in accordance with GOST 32310-2012 and have earned many medals at exhibitions.

Comfort is XPS, which is one of the brands of Penoplex. It comes in different thicknesses with sheet sizes of 585x1185 mm. The delivery comes packaged with a special film that protects against UV radiation.

Working with floors

Here the slabs are laid without additional fixation.

Floor insulation Source yandex.net

Preparing the rough foundation is similar for walls and ceilings. The difference is that the floor must be covered with waterproofing. As a rule, this is a technical polyethylene film with a thickness of 150 microns. A damper tape must be laid around the perimeter.

Laying of extruded polystyrene is carried out in 1 or two 2 layers with offset joints of each subsequent row. The joints are filled with polyurethane foam. If the floor is leveled with cement mortar, then a reinforcing mesh is laid. With heating systems, a heat-reflecting film is attached before this. There is no need for additional layers for sheets of gypsum fiber board, chipboard or plywood.