Given the abundance of offers of various types of thermal insulation, choosing the appropriate material for insulation is quite difficult. Ravaterm, polyspen, stirex, penofol, penoplex and technoplex are just some of the foam materials used for insulation of external and internal premises. There is not much truthful information about what modern insulation based on styrene polymers is, so many experts prefer to collect practical reviews on which is better, technoplex or penoplex. This is a complex and time-consuming path, so first it is better to compare the characteristics and draw a conclusion about how penoplex and technoplex differ, and what is the difference between them.

What to choose - Technoplex or Penoplex? Review of brands

TechnoNIKOL and Penoplex are the main producers of extruded polystyrene foam in the Russian Federation; their products are rightfully in demand in private and industrial construction. Their cost, performance and performance characteristics are largely similar; the question of which brand is better to choose is quite relevant. Some users believe that there is no difference at all between Technoplex and Penoplex and that the only difference is the color and size of the slabs, while others provide strong arguments in their reviews in favor of their chosen manufacturer. Only a comparison of the range and properties will help you find the truth.

Description of the material, features and characteristics

Technoplex is a specialized brand of expanded polystyrene from TechnoNIKOL, manufactured using the extrusion method with the addition of nano-sized graphite particles. This insulation is produced in the form of dense, non-shrinkable, silver-colored slabs of standard size (it is noteworthy that, upon agreement with the manufacturer, you can buy Technoplex slabs with other dimensions). The recommended scope of application mainly affects interior work: thermal insulation of floors, balconies, partitions and ceilings.

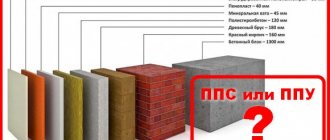

Penoplex is manufactured using the same method, but with the addition of some brands of fire retardants. This allows you to significantly expand the operating range, making it almost universal. This building material is recommended to be chosen when protecting foundation structures from freezing (including buried ones), insulating roofs, floors, and facade walls. The size of Penoplex slabs is always the same: 1200×600 mm, thickness varies from 20 to 150 mm. The color of the insulation is orange.

Both varieties tolerate temperature changes well, retain a stable shape and properties during operation and are resistant to biological influences. Both Technoplex and Penoplex have slabs with an L-shaped edge; they are recommended to be purchased if it is necessary to eliminate cold bridges. Like any other XPS polystyrene foam, they are afraid of organic solvents and compositions with toluenes and acetone, but are inert to other chemical reagents.

Comparison of characteristics and prices

Penoplex is represented by 10 brands for private and industrial use, TechnoNIKOL - 9 (of which only one is Technoplex). A review of the product range shows that Penoplex focuses on professional construction, while its competitor focuses on individual construction. Despite the loud statements of the manufacturers, there are no radical differences between the brands. The average cost of 1 m2 of Penoplex insulation with a thickness of 50 mm is 230 rubles, for Technoplex with similar properties - 176, but with wholesale purchases or third-hand purchases this difference is partially erased.

The results of a comparison of the main characteristics, taking into account the declared data of the manufacturers, are summarized in the table:

| Technoplex | Penoplex | |

| Limits of initial density, kg/m3 | From 26 to 35 | From 25 to 47 |

| Minimum thermal conductivity, W/m K | 0,032 | 0,03 |

| Water absorption by volume,% | 0,2 | 0,4 |

| Vapor permeability mg/m h Pa | 0,01 | 0,012 |

| Flammability group | G4 | G3 and G4 |

| Dimensions: L×W | 1180×580 1200×60 | 1200×60 |

| Slab thickness, mm | 20, 30, 40, 50, 60, 100 | 20, 30, 40, 50, 60, 80, 100, 120, 150 |

| Modulus of elasticity, MPa | 17 | 15-18 |

| Compressive strength at 10% deformation, MPa, not less | 0,2-0,25 | Depends on the brand: from 0.12 to 0.3 |

| Operating temperature, °C | -75 to +75 | -100 to +75 |

Analysis of indicators shows that Technoplex better withstands exposure to moisture and steam and is not inferior in strength characteristics. Thanks to the inclusion of fire retardants in the composition, Penoplex wins in terms of fire safety, although the upper limit of their operating temperature is the same. The materials protect rooms and buildings equally well from heat loss (with a slight advantage of Penoplex).

User reviews confirm the characteristics declared by the manufacturers. Penoplex inspires more confidence when insulating external building structures, while Technoplex inspires more confidence when insulating internal ones. There are no differences in installation technology; many positively evaluate the ease of working with the slabs and the possibility of doing it yourself. When cutting Technoplex or Penoplex expanded polystyrene slabs, a uniform finely dispersed structure with closed cells is visible.

Summary: whose products and in what cases is it better to choose?

It is easy to see that there is not much difference between insulation materials; personal preferences decide a lot. Penoplex appeared on the construction market earlier and, accordingly, inspires more confidence. But many consider it unreasonably expensive, and in the absence of strict requirements in terms of fire safety, they decide to purchase the more affordable Technoplex. The main criterion was and remains the intended use - the insulation is selected taking into account operating conditions and expected loads.

According to the stated information, Technoplex is positioned as an internal insulation, Penoplex as a universal one. In practice, each brand has its own functional purpose; to determine which one is better to choose, you need to compare slabs with the same thickness and density. Many people make the mistake of comparing Technoplex from TechnoNIKOL or Penoplex, forgetting about the Carbon line from the first manufacturer. Counterfeits are found in both cases; it is recommended to buy products only from official dealers or check for the appropriate certificate.

Specifications

Special attention should be paid to the strength of the materials in question. When conducting special studies, it was revealed that the compressive strength of both products is equal to the same value - 250 kiloPascals. If we take the bending strength of the slabs, then the values of insulation will be different:

- Penoplex can withstand loads within 0.4...0.7 MPa;

- For technoplex this indicator is within 0.3 MPa.

Penoplex insulation

From the information provided, we can conclude that the first material is better suited for thermal insulation of areas with bending loads on products. The difference can also be seen in the operating temperature range:

- Penoplex slabs are operated in a temperature range of -50...+75 degrees;

- Construction products can withstand temperatures within 75…+75 degrees.

Now let’s begin to describe such important characteristics of insulation as thermal conductivity and water absorption. If penoplex slabs can absorb moisture up to 0.1% of the total volume per day, then for an analogue this figure increases two or even three times. According to experts, fractions of a percent of water absorption do not affect the performance of materials.

Packaging of Technoplex insulation from the TechnoNIKOL company

If we take mineral wool, then the ingress of water into the fibers of such products leads to a loss of heat insulating properties.

Other studies by scientists have shown that both types of insulation slightly change their original characteristics after 1000 cycles of alternating freezing and thawing.

| Insulation characteristics | Penoplex | Technoplex |

| Scope of use | Road works, thermal insulation of roofs, internal and load-bearing walls of civil buildings | Insulation of residential and non-residential premises |

| Additional components included in the raw material | Graphite particles | Special additives that prevent the material from burning |

| Product density indicators | 30-45 kg/m3 depending on the purpose and manufacturer | 25-35kg/m3 |

| Flammability of materials | 4th category | 4th category |

| Water absorption of insulation | 0.2-0.4% of the total volume | No more than 0.2% |

| Vapor permeability of products | 0.012 mg/(mh*pa) | 0.010 mg/(mh*pa) |

| Material cost limits depending on thickness and other characteristics | From 90 to 250 rubles per square meter | From 100 to 290 rubles per square meter |

The difference between Technoplex and Penoplex: which is better?

After the construction of a building, the owners always wonder what kind of insulation is best to use for, strictly speaking, thermal insulation of the home.

And this question is quite reasonable, since the construction market has a colossal number of different insulation materials, which, as it seems to many, only specialists can compare in terms of efficiency.

Insulation of the room with Penoplex

Fortunately, this is a misconception, and everyone can figure out which insulation is better. It is only necessary to have information and technical parameters of the analyzed thermal insulation materials.

And given the fact that Penoplex and Technoplex are now the most popular insulation materials, this article will focus on which of these insulation materials is better, and what is the difference between them.

The main signs of a quality XPS

XPS is produced from polystyrene granules by extrusion. High-quality material is very durable, has a low thermal conductivity coefficient, and does not absorb moisture. Regardless of the area in which the XPS board will protect the object from heat loss, when choosing a material you should pay attention to several key indicators. They are important for any design.

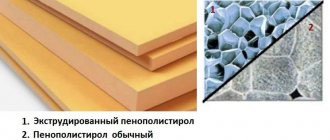

Uniform structure. The edge of the slab should be inspected. The cell size of high-quality material is 0.05–0.08 mm. It is virtually impossible to distinguish such a cell with the naked eye. But if the material is of poor quality, then the cell is easy to notice, and a microscope is not needed for this.

Strength. It is this indicator that determines the resistance of the material to loads. Many people mistakenly believe that the density of the material is important. But this is not true at all. Let's take ice and an XPS board as an example. The density of ice is very high - it is 900 kg/m³. The density of XPS is about 25 kg/m³. But at the same time, the strength, that is, the ability to resist loads, is much lower in ice. If ice is destroyed under a press pressure of 10 tons, then XPS completely retains its shape.

A low-quality slab with low strength values can easily deform under load. At the same time, it is very inconvenient to work with - it will crumble and break when cutting. There are materials on the market with different strength ratings. So, for wall insulation, an indicator of 100 kPa with 10% linear deformation will be sufficient, but when building a USHP-type foundation, grades that can withstand at least 400 kPa are used.

Thermal conductivity. Everything is simple here: the lower the thermal conductivity coefficient, the better the material retains heat in the room. It is best to focus on the range from 0.030 to 0.037 W/mK.

Shape and size. XPS boards from major manufacturers are most often equipped with a special L-edge. When laying, the slabs are joined into a lock, forming a single thermal insulation circuit. If there is no such edge, then the seams between the insulation will have to be filled with special foam. And this means time and additional costs.

It is important that the slab itself is level, otherwise during installation you will have to press it to the surface. For large structures, for example, USHP, it is more profitable to take slabs of increased size - with a length of 2.4 meters. Laying such XPS is faster, and the thermal insulation layer is more uniform due to fewer seams.

Technoplex or penoplex: what to choose?

The house should not only be beautiful and comfortable, but also warm. Therefore, it is very important to choose the right insulation.

There are many different insulation materials on the construction market. This article will tell you about such modern insulation materials as Technoplex and Penoplex, how they differ and which one is better to choose.

Let's start with what they consist of. Both insulation is made of extruded polystyrene foam (EPS). EPS is heated polystyrene (the familiar white foam balls) and a foaming agent.

The difference between foamed polystyrenes

As mentioned above, the use of liquid and powder gas-forming agents is better, so products obtained using this technology have stable thermal insulation characteristics. Although, this cannot be called the only reason why Technoplex and Penoplex do not contain freon. There are two more:

- Sealed cells of new material that have not yet been used have remnants of freon. Formally, it is called safe, but in reality it is better not to deal with it. It can cause lung problems in children.

- Over time, the gas will be forced out of the cells by air and humidity. And if dirty raw materials containing styrene were used in the manufacture of the material, then the contents will penetrate into the external environment.

And if technical grades of EPS, such as Penofol, are used to treat foundations, highways, and plinths, then the presence of freon in the composition does not affect the material in any way. But to insulate your home, it is better to use safe products. Therefore, the answer to the question: Penoplex or Penofol, which is better, can be answered - the first option.

How do you know which is better Penoplex or expanded polystyrene? After all, many recommend insulating with foam plastic, because it has a low price and excellent characteristics. To answer this question, you need to know how penoplex differs from expanded polystyrene. Let's start with production technology.

Technoplex, Penoplex and even Penofol are created during the extrusion process. This allows you to obtain a very dense linear structure, which affects the material’s resistance to water and humidity, as well as strength. Therefore, foam plastic is somewhat worse than materials created by extrusion methods.

Eps insulation

This is a unique material that has the following properties:

- low water absorption, almost equal to zero;

- high strength;

- not subject to rotting;

- low thermal conductivity;

- high frost resistance;

- non-toxic to humans;

- easy to install;

- durability;

- light weight;

- environmental friendliness.

The disadvantages of polystyrene foam insulation include:

- strong flammability and intolerance to direct sunlight. This is important to know, because storing polystyrene foam in the sun can completely ruin the material, and this will be unpleasant ;

- Although manufacturers claim that polystyrene foam is not chewed by mice, consumer reviews show the opposite;

- And of course the price, which is quite high.

But what is the difference between Technoplex and Penoplex? What's better?

Extruded polystyrene foam

Technoplex is a tile insulation made of extruded polystyrene foam with graphite particles. Thanks to graphite, the plates acquire a gray color and increased strength. 50 mm of technoplex is equivalent to a 600 mm wide foam block wall.

Technoplex is recommended for use for interior work. Produced by Technoplex.

Insulation is produced in the form of slabs of various widths, lengths and thicknesses:

- Length – 1180/1200 mm.

- Width – 580/600 mm.

- Thickness – 20, 30, 40, 50, 100 mm.

Technoplex is operated at temperatures from -70 0 C to +75 0 C. Its water absorption is only 0.2% - this is a very good indicator. Thermal conductivity is 0.032 W/(m*K).

Features of the material

TechnoNIKOL Carbon appeared precisely due to the desire of manufacturers to improve the formula of expanded polystyrene and achieve even better results.

TechnoNIKOL Carbon is produced using improved technology. The beginning of the manufacturing process is no different from normal work. Expanded polystyrene raw materials are poured into an extruder and melting begins under high pressure.

Already during remelting, microscopic carbon particles are added to the usual composition. These actions make it possible to improve the already excellent characteristics of polystyrene foam.

Its thermal conductivity indicators are at the level of 0.29-0.33 W/m3. No other insulation can boast such low thermal conductivity. The water absorption coefficient should also be noted separately.

It is only 0.2%, which is a kind of record. Carbon insulation also has a very low vapor permeability and high strength. All this follows from its high density, which amounts to as much as 30-35 kg/m3.

TechnoNIKOL Carbon insulation is sold in the form of plates. A medium-sized slab has dimensions of 600×1200. The thickness of the slab may vary depending on the type of insulation. And there are a lot of them.

Extruded polystyrene foam

Penoplex is a tile insulation made from extruded polystyrene foam. Unique thermal insulation characteristics are achieved thanks to the smallest cells filled with air.

Penoplex has a bright and recognizable orange color. Penoplex has excellent chemical resistance, but it is important to know that it is absolutely not resistant to gasoline (just like Technoplex). Due to its good strength properties, Penoplex can be used for external insulation.

There are different types in the Penoplex line (their names speak for themselves):

- roofing (insulation of attics and roofs of various configurations);

- wall (basement, walls, partitions, facade are insulated);

- foundation (used as insulation for the basement and floor of the first floor);

- comfort (can be used for any work, but is especially well suited for insulating apartments and balconies);

- 45 (has the best characteristics of all types, used in road construction and bridge construction).

. Penoplex is available in standard width and length - 600 mm by 1200 mm, respectively. But the thickness varies - from 20 mm to 150 mm.

Penoplex is used at temperatures from -50 0 C to +75 0 C. Water absorption - 0.4% - slightly worse than Technoplex, but still a very high figure. Thermal conductivity is 0.03 W/(m*K).

Areas of use

Penoplex expanded polystyrene boards for external wall insulation should fit as tightly as possible to the base and to each other

Penoplex and Technoplex insulating boards can be used in a wide range of construction works and are generally interchangeable:

- civil and industrial construction;

- Walling;

- floor insulation in a private house, ceiling insulation;

- internal thermal insulation and external insulation of facades;

- insulation of basement floors and foundations;

- roofing;

- insulation of loggias and balconies;

- arrangement of terraces, verandas;

- arrangement of refrigeration chambers;

- insulation of septic tanks and swimming pools;

- thermal insulation of soil in road construction, including railway;

- installation of gas and oil pipelines;

- any construction work in permafrost regions;

- thermal insulation equipment for airports and runways.

Expanded polystyrene insulating boards are indispensable when installing a heated floor system. It should be noted that the smooth and rough surface of the slabs provides excellent adhesion to finishing materials.

Application of penoplex and technoplex boards

Comparison

The main technical characteristics of insulation are its thermal conductivity, water absorption and operating temperature.

The flammability group for both insulation materials is G4 (highly flammable). Their prices differ by 10% (Technoplex is more expensive).

After comparing them, it is clear that there are no significant differences between these insulation materials.

Yes, Technoplex has slightly better characteristics, but the cost is also higher. Despite the fact that Penoplex is cheaper, with individual construction the savings are insignificant.

What to choose

If we compare these two insulation materials, then Technoplex is more technologically advanced and has better qualities, but the difference between it and Penoplex is so insignificant that it is impossible to say for sure which one should be chosen.

By choosing polystyrene foam insulation, regardless of whether it is Technoplex or Penoplex, you can get not only thermal insulation, but also sound and vapor barrier.

However, it is worth remembering that polystyrene foam is still a chemical insulation, not a natural one. Therefore, when burned, it releases very caustic substances.

Modern technologies do not stand still, and today liquid foam has become widespread. Details here: https://teplo.guru/uteplenie/utepliteli/zhidkiy-penoplast.html

Analogs

In conclusion, I would like to note that other insulation materials made from extruded polystyrene foam can be found on sale, but less well known:

- Styrex;

- URSA (URSA);

- Technoflex;

- TechnoNIKOL "Carbon";

- THERMIT (TERMIT).

How Technoplex is used to insulate a room, see the following video:

Given the abundance of offers of various types of thermal insulation, choosing the appropriate material for insulation is quite difficult. Ravaterm, polyspen, stirex, penofol, penoplex and technoplex are just some of the foam materials used for insulation of external and internal premises. There is not much truthful information about what modern insulation based on styrene polymers is, so many experts prefer to collect practical reviews on which is better, technoplex or penoplex. This is a complex and time-consuming path, so first it is better to compare the characteristics and draw a conclusion about how penoplex and technoplex differ, and what is the difference between them.

The difference between Technoplex and Penoplex: which is better?

After the construction of a building, the owners always wonder what kind of insulation is best to use for, strictly speaking, thermal insulation of the home.

And this question is quite reasonable, since the construction market has a colossal number of different insulation materials, which, as it seems to many, only specialists can compare in terms of efficiency.

Insulation of the room with Penoplex

Fortunately, this is a misconception, and everyone can figure out which insulation is better. It is only necessary to have information and technical parameters of the analyzed thermal insulation materials.

And given the fact that Penoplex and Technoplex are now the most popular insulation materials, this article will focus on which of these insulation materials is better, and what is the difference between them.

Flammability

Both products belong to the fourth fire resistance group. Many novice builders believe that materials made from polystyrene foam have properties similar to polystyrene foam, but in reality everything looks somewhat different.

High-quality material does not support combustion

If polystyrene foam easily ignites under the influence of an open fire, then penoplex and technoplex begin to melt under the influence of high temperatures, but they do not support combustion. During this process, carbon dioxide and carbon monoxide are released.

If we compare which of the insulation materials is better in terms of cost, then the difference in price between these two materials does not exceed 10%, and a smaller amount of money will have to be paid for penoplex.

Thermal insulation of the house outside

Of course, the price of any of the materials described will depend on the cost of raw materials and the country of origin of the material, and the markups of intermediaries. As we see, the difference in price is insignificant, but penoplex wins in this matter.