Heating a private house with gas cylinders is a necessary measure in the absence of a main gas pipeline. This heating method is often chosen for country houses and dachas with an area of up to 70-100 sq.m. In order to save gas, the building is insulated as much as possible, and a gas boiler is used in conjunction with electrical appliances, if electricity is connected.

The fuel used is liquefied propane gas or mixtures (propane + butane), depending on the season. After processing natural gas under high pressure, it changes from a gaseous state to a liquid state and is pumped into cylinders. Liquefied hydrocarbon gases in the abbreviated version are called LPG.

For heating with LPG, cylinders with a capacity of 50 liters are used (gas weight in liquid state is up to 22 kg). The cylinders are filled to 80% of the volume, because... gas is capable of expanding with increasing temperature and can rupture the cylinder. Also, when the contents of the cylinder are exhausted, complete emptying is not allowed, but only 90%.

What you need to connect

To install a heating system on gas cylinders you will need:

- Gas boiler equipped with a burner for liquefied gas;

- Gas cylinders with a capacity of 50 l;

- Gearboxes;

- Ramp, if several cylinders are connected;

- Shut-off valves;

- Gas pipeline in the form of pipes and hoses for connecting equipment to the system.

Equipment for heating a private house with gas cylinders

When choosing a gas boiler, you should pay attention to models with the lowest operating pressure and high efficiency. Many boiler models are already equipped to work with natural and liquefied gas. If a connection to the main gas pipeline is not expected, then it is better to choose just such a boiler to operate on LPG.

Otherwise, additional equipment is purchased: nozzles for the burner or an entire burner for liquefied gas, and in some models, a gas valve. The natural gas boiler burner is designed for lower pressure in the system and has a valve with a large hole, which can lead to an emergency.

General information

Liquefied gas is hydrocarbons mixed in certain proportions - propane and butane. Using a special technology, the mixture is cooled, goes into the liquid phase, after which it is filled with 50-liter cylinders, which have been so familiar to us for a long time. Previously, they were often used to operate gas stoves, and are still used in remote regions for the purpose of cooking.

In equally remote areas, where there is no gasification and solid fuel is too expensive, hydrocarbon gas can be used to heat residential premises. Of course, the price of the issue is significantly higher than when heating with natural gas, but in its absence this is almost the only alternative. In addition to liquefied gas, there is also diesel fuel, but then the cost of equipment and its operation will be even more expensive.

Advice. If heating with gas cylinders is planned as a temporary option, and subsequently it is planned to burn other types of fuel, then it makes sense to think about purchasing a combination boiler, in which it is possible to install burners for gas, diesel fuel or pellets.

Fuel in cylinders is convenient to use for private houses or cottages whose area is within 100 m2. An enlarged calculation of liquefied gas consumption shows that heating such a building requires a heat generator with a capacity of 10-12 kW. Considering its efficiency of 92%, we obtain a consumption of about 18 liters of liquefied fuel per day. Since when refueling the container is not completely filled in accordance with the rules and holds about 42 liters of propane, about 14 cylinders will be needed per month. In real life, especially if the country house is well insulated and the climate in winter is not harsh, less fuel will be required.

In large buildings with an area of more than 100 m2, heating with bottled gas is impractical. Empty vessels will have to be replaced with full ones almost every day and the costs of transporting and refilling them will have to be incurred. In such cases, stationary containers for large-capacity fuel are installed near the house - gas tanks, filled with gas from special tank cars.

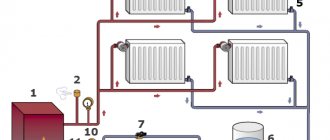

Connection diagram to the boiler

The cylinders are connected to the system through a special reducer, which converts the gas from liquid to gaseous for further supply to the boiler.

Gas cylinders with separate reducers Please note! The gas flow rate through the reducer should be 1.8-2.0 cubic meters per hour; a conventional gas reducer with a flow rate of 0.8 cubic meters per hour is not suitable for this system.

When connecting cylinders to the boiler, two options are used: one common reducer for all cylinders or a separate reducer for each. The latter option is safer, but also more expensive.

Several cylinders can be connected to a gas boiler at once, which allows you to increase the time between their refills. For this, a ramp is used - a two-arm manifold that distributes the cylinder capacities into two groups, the main and reserve.

First, gas is selected from the cylinders of the main group, and when it runs out, the ramp automatically switches the boiler to the reserve group. The moment of switching is accompanied by a signal. After connecting already filled cylinders to the ramp, the boiler automatically switches to operation from the main group.

Connection diagram of cylinders to the ramp

Note! Gas cylinders are installed at a distance of at least 2 m from the boiler, but the optimal option for their placement is in a separate non-residential premises or an insulated gas cabinet on the north side of the house.

Do not expose gas cylinders to direct sunlight.

The wall thickness of metal gas pipeline pipes must be at least 2 mm. Where it passes through the walls, the pipe is placed in a special case and foamed. The boiler is connected to the gas pipeline using a flexible connection, and a rubber-fabric hose (durite hose) is used for the reducer.

Advantages and disadvantages of this form of heating

Heating with gas from a cylinder presupposes system autonomy, low consumption of raw materials, stable in-pipe pressure, as well as simple operation.

If hot water is required, the water circuit can be connected to a general heating system and the boiler will heat not only the heating fluid, but also water for domestic purposes.

The cylinder is effective in use due to the ease of transition of gas from a liquid to an aggregate state, which ensures normal heating of housing and water.

This format is convenient to transport: relatively small containers can be transported on trucks while complying with safety requirements.

Installation of equipment powered by a tank does not require extensive work or specific skills: installation is carried out inside a new building or an old house with equal success. There is no need to lay pipes to a common main, which often requires partial dismantling of the floor and walls.

When other heating options are inconvenient or unavailable, liquefied gas will properly perform the tasks.

There are several disadvantages of the technique. You cannot leave tanks outside in winter, as during severe frosts condensation is released, which quickly freezes, preventing normal gas flow. The heating system does not receive the required amount of fuel even for the minimum load and performs an automatic emergency shutdown.

It is prohibited to place the gas source in unventilated rooms in case of a leak.

The gas is heavier than ordinary air, so if there is a leak, it will flow down and spread along the floor, which can lead to the accumulation of large amounts. This is dangerous to your health.

It is important to comply with all connection and storage conditions to ensure safety.

Storage of connected cylinders

Cylinders should also be stored in well-ventilated rooms without a basement underneath them, preferably inside separate outbuildings. If we are talking about a dedicated extension, then additional insulation will be required to prevent sudden winter shutdowns.

Thermal insulation is made of polystyrene foam, 5 cm thick, and the top is equipped with ventilation holes.

General information about gas cylinder heating, connection principles and operation can be viewed in the following video:

Liquefied gas consumption

To understand how efficient and expedient it is to heat a house using LPG, let’s calculate the consumption of bottled gas for a house with an area of 100 sq.m. In such a house, according to thermal calculations, it is recommended to install a 10 kW boiler. To produce 1 kW of heat, the boiler consumes an average of 0.12 kg/hour of gas. Gas consumption for heating the entire area will be 1.2 kg/hour, and per day - 28.8 kg. If we consider that a standard 50 liter cylinder contains about 22 kg of gas, then the weekly consumption will be about 9 cylinders, and this is absolutely impractical.

Gas cylinders with a volume of 50 liters

But in this mode, the boiler only works to heat up the heating system. The rest of the time, a properly adjusted boiler consumes 3-4 times less gas, i.e. about 8-9 kg of gas per day or approximately half a cylinder. per week to heat a well-insulated house of 100 square meters. m will need about 3 gas cylinders. In this case, the temperature inside the room will be maintained at +22 degrees (at -18-20 degrees outside).

Heating efficiency can be increased through the use of automation.

Note! A decrease in temperature at night by 6-7 degrees leads to a reduction in gas consumption by 25-30%.

This means that per week, to provide such a system with liquefied gas, you will need about 2 cylinders.

In the case of heating a country house, during the absence of the owners, you can set the temperature to +5+7 degrees (only to maintain the heating system in working condition). Then the gas consumption per week will decrease to 1 cylinder.

When increasing the heating area, the required number of cylinders is calculated in proportion.

How to make a pyrolysis boiler with your own hands

The technological process of manufacturing a boiler based on the pyrolysis operating principle includes plumbing and welding work.

Required materials and tools

To manufacture a high-quality unit, experience in working with the following tools is required:

- electric welding machine;

- electric drill;

- Angle Grinder;

- set of plumbing tools - square, level.

Materials and components required:

- metal: sheet, thickness 4 mm, 7.5 m²;

- pipe - 8 m (diameter 57 mm, wall thickness 3.5 mm);

It automatically performs manipulations with the damper: opening (to increase the combustion temperature) and closing (when the temperature reaches the maximum value).

A temperature sensor is a mechanical device for monitoring the amount of air passing into the combustion chamber.

The draft regulator can be installed both in a vertical and horizontal position, therefore it has 2 temperature graduation scales. When starting for the first time, the length of the chain connecting the air damper to the lever is adjusted.

The productivity of the boiler depends on the functioning of the chimney. To ensure good draft, the chimney must meet the quality requirements:

- height not less than 5 meters;

- good insulation;

- no sharp bends;

- condensate drainage;

- easy access for cleaning.

Device drawings and diagrams

A pyrolysis boiler without forced ventilation has the simplest design. The non-volatility of the design reduces the cost of operating the unit.

The diagram of a pyrolysis boiler with a natural smoke exhaust looks like this:

To increase high efficiency, some designs have double base walls

The boiler consists of three main chambers:

- loading room, used for adding fuel;

- an afterburner chamber where secondary air is supplied;

- heat exchanger exiting into the pipe.

The combustion of raw materials directs the gas flow from top to bottom. When air is supplied under the grate into the fireclay brick array, flammable gases are burned. The decomposition products go through the heat exchanger into the chimney. The draft is adjusted by a temperature sensor at the boiler outlet using a chain connected to the secondary air supply damper.

Detailed details with dimensions and tolerances can be found in the standard drawing:

A - boiler circuit controller; B - loading door; C—ash pan cover; D - smoke exhaust; E - coupling for temperature fuse sensor; F - safety valve pipe; G—circuit supply line; H - cold water supply to the heat exchanger; L - return line of the boiler circuit; M - expansion tank

Step-by-step instructions for manufacturing the unit

Making a pyrolysis boiler with your own hands is divided into stages:

- According to the drawing, parts for the body are marked and cut. After “sticking” the elements, a control measurement is made, then welding seams are made. Once in place, the back panel and side walls are welded on both sides, cleaned, and treated with welding sealant.

- The heat exchanger pipes are being installed.

- After welding the outer wall and door shells, a mechanical coolant control regulator is installed.

- The chimney is assembled by extending the pipe. The next part must be inserted inside the previous one so that condensation does not fall on the outside. The finished structure is painted with fireproof paint.

Gas cylinders in winter

If gas cylinders are located outside the house, then in winter at subzero temperatures the pressure of liquefied gas decreases and the boiler may simply turn off. To prevent this from happening, the cylinders are installed in a special cabinet with good ventilation, insulated with non-flammable materials. Also suitable for this purpose are detached non-residential buildings with minimal heating. When using cylinders, safety precautions should be observed:

Special cabinet for installing cylinders

- It is prohibited to heat containers with gas using open fire;

- There should not be a basement or cellar near the cylinders, since liquefied gas sinks down when leaking, has no odor and can accumulate to an explosive concentration;

- It is advisable to install a gas leak sensor;

- Storage of full containers is allowed at a distance of 10 m from the living space;

- Storing empty cylinders in the house is prohibited;

- Once every 4 years, it is necessary to check the cylinders for integrity and tightness.

Safe Operation

It is prohibited to use heaters, electric heaters, heating cables, etc. as a means of heating heating cylinders.

Tanks with fuel reserves can only be stored inside separate cabinets, the top of which is drilled to form ventilation. It is recommended to insulate the structure from the inside on the sides and below with polystyrene foam, without covering the ventilation holes. It is not allowed to insulate the cylinders themselves by heating them from the outside, even if they are partially covered with frost.

Frozen cylinders

It is important to follow the rules for filling tanks so that equipment does not explode at home.

Immediately after assembling the heating unit, it is necessary to check for leaks.

Gas pipes must have walls 2 mm or more thick, and in places where they pass through the wall, before pulling the pipeline, a special case with soft filling or a piece of pipe of a slightly larger diameter is placed. In the latter case, the voids are filled with construction foam.

Disadvantages of heating with liquefied gas

The main disadvantages of a heating system using gas cylinders:

- The inconvenience of periodically refilling cylinders, especially in the case of self-refueling (there is no delivery of cylinders to your home);

- The imperfection of the method of determining the fullness of the cylinder - by weighing;

- High gas consumption with an incorrectly adjusted system and, accordingly, a decrease in its efficiency;

- It is not always possible to create the necessary conditions for installing cylinders - stopping the boiler at low temperatures;

Gas cylinder refilling device

A little history

The development of the Bubafonya stove is attributed to folk craftsman Afanasy Bubyakin from Kolyma. Subsequently, a new invention was named in his honor. During his experiments, Afanasy relied on the design of the Lithuanian-made Stropuva pyrolysis boiler.

The domestic inventor tried to simplify the design as much as possible so that it could be built with your own hands. This specificity of Bubafoni explains its high popularity. Considering that the material for the manufacture of this device is mainly improvised means, it cannot boast of external aesthetics. The strengths of the stove are its simplicity, efficiency and reliability.

In what case can such a system be used?

This heating method is often chosen if electricity is not supplied to the house, but in the future it is planned to connect to the main gas pipeline. Then there is no need to buy two boilers, and buying a gas boiler will justify itself - it will only be enough to switch it from operating on liquefied gas to normal mode. Sometimes liquefied gas boilers are used simultaneously with electrical equipment or a heated floor system in order to save money.

When choosing a heating system using LPG, the area of the house and the degree of its thermal insulation must be taken into account. The optimal heating area with such a system is up to 100-150 square meters. m, and houses with high-quality thermal insulation and no cracks. Heating of areas over 150-200 sq. m is already becoming inefficient and requires regular refilling of too many gas cylinders.