Due to prevailing stereotypes, the name “boiler” is often associated with an electric water heating tank. Although there are other versions of household appliances that provide autonomous hot water supply to private houses and apartments. Under certain conditions, the use of gas appliances and indirect heating containers is much more profitable and comfortable. To choose a storage water heater, it is worth comparing the operating principle of different types of boilers, connection nuances and operating features.

Types of storage water heaters

At the moment, there are several types of units for autonomous hot water supply. They are all created with one goal, but achieve it in different ways, that is, using different energy carriers. The homeowner has the opportunity to choose the one that best suits him in all respects.

So, the following types of heating boilers are offered on the modern market:

- electric storage heaters;

- indirect heating boilers;

- gas boilers;

- flow heaters.

Note. Directly translated from English, the word “boiler” means “boiler”. This means that they include not only storage, but also all kinds of instantaneous water heaters. Not taking them into account would be unfair to users.

Electric boilers

This is the most common type of hot water supply, most often used in apartments and small private houses. The reason for this popularity is the relatively low cost and ease of installation, which does not require any permits. The devices are quite reliable in operation and satisfy most user requirements. To understand the principle of operation of a water heater, consider its structure shown in the figure:

The unit is a tank, usually round or oval, enclosed in a layer of heat-insulating material (usually polyurethane foam), covered with a decorative casing. The container itself can be made of the following materials:

- steel with enamel coating;

- stainless steel;

- plastic.

An electric heating element located at the bottom of the tank heats the water to a temperature limited by a thermostat. Its maximum value, accepted in all electric boilers, is 75 ºС. While there is no water supply, the design of the electric boiler provides for maintaining the set temperature in the mode of automatically turning the heating element on and off. The latter has additional protection against overheating and in an emergency situation will automatically turn off when the water temperature reaches 85 ºС.

Note : The optimal operating mode for the boiler is heating to 55 ºС. In this mode, the device provides the required amount of water for domestic hot water and at the same time saves energy. Unfortunately, the storage water heater often operates at maximum power due to the fact that in winter the water supplied from the water supply is too cold and the heating element in economical mode does not have time to warm it up.

Water is drawn through a tube leading to the upper zone of the tank, where the water is hottest. At the same time, cold water is supplied to the lower part of the boiler, where the heating element is installed. To protect steel tanks from electrochemical corrosion, the water heater device includes a magnesium anode. Over time, it deteriorates and therefore requires replacement approximately once every 2-3 years.

Using the services of a specialist is necessary

Only a specialist guarantees the safety of the connection.

Gas equipment is prohibited from installing, connecting, or starting up by persons who do not have the appropriate qualification certificate. Therefore, hiring a company or specialist is necessary. The list of required documents includes a project, permits from the gas service, and certificates of chimney inspection.

The easiest job is to replace, for example, an old water heater or boiler. For operations in a new house or the organization of additional structures (gas supply, coolant routes, equipment piping) - obtaining all permits will take a lot of time. The preparation of documents and procedures for their approval by regulatory authorities should also be entrusted to specialists.

Indirect heating boilers

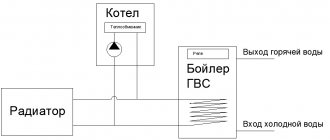

These devices do not produce thermal energy on their own, although some models have a built-in heating element to maintain the water temperature in different situations. In normal mode, the boiler prepares water for hot water supply, heating it with a coil with coolant flowing through it. The diagram below shows the design of an indirect heating boiler:

A large-capacity insulated tank (sometimes up to 1000 l) has a built-in coil with coolant supplied to it from the boiler. As in an electric boiler, cold water is supplied to the lower part of the tank, and hot water is taken from the upper part. The unit is capable of providing a significant flow of hot water, and therefore is used in private homes with a large number of consumers.

The usual exchange of heat between environments with different temperatures is the operating principle of an indirect heating boiler. But in order to get water from the tap with a temperature of 55 ºС, the boiler must heat the coolant to at least 80 ºС, this is one of the disadvantages of this water heater. The second drawback is the long time it takes to load a large-capacity tank, so in the case of intensive water withdrawal, people living in the house need to adapt to using hot water according to a certain schedule.

Like electric boilers, indirect water heaters are equipped with a magnesium anode to protect the steel tank from corrosion. More complex and expensive models are equipped with two coils; coolant from the boiler flows through one, and the second can be connected to an alternative source of thermal energy. They can be another boiler or a solar collector. To maintain the temperature in different situations, a heating element with a thermostat is built into the upper zone of the container.

Indirect heating units are produced in wall-mounted and floor-mounted versions and can work with any source of thermal energy. Manufacturers of boiler equipment often offer them in conjunction with double-circuit boilers. In this case, the heat generator maintains the heating temperature and loads the boiler, alternately switching between these two systems.

Excellent choice for centralized feeding systems

Gas water heater built into the kitchen cabinet

If a mains line from a centralized supply system is connected to the house, a direct heating gas boiler, a well-known water heater, can be an excellent choice. Such a device is capable of:

- directly during selection, raise the water temperature by a significant amount;

- ensure safe operation;

- guarantee (when choosing the appropriate power model) operation at existing gas pressure parameters;

- meet the hot water needs of a large family.

The gas water heater operates according to a simple scheme. When water is withdrawn, the gas is automatically ignited. The burner transfers energy to a heat exchanger, which raises the temperature of the liquid passing along the route from the tubes. The following common engineering solutions exist:

- gas boilers with an open combustion chamber. This column segment is considered obsolete. Their installation must be carried out in a thoroughly ventilated room with sufficient access to oxygen; a chimney with good draft is necessary;

- geysers with a closed combustion chamber. A technological device that does not require the presence of a chimney, it operates on the principle of taking air from outside the house and releasing exhaust gases through a coaxial or combined outlet. This type of direct heating gas boiler is equipped with turbines to ensure efficient operation.

Modern models of dispensers with a closed combustion chamber can be installed in ordinary premises after assessing the quality of the chimney by regulatory authorities. Outdated boilers, especially those of high power, must be installed in specially designated places, boiler rooms or utility rooms, where a sufficient flow of oxygen is ensured.

Gas storage water heaters

These devices are structurally and externally reminiscent of electric boilers. The same tank hung on the wall, covered with a layer of insulation, only a gas burner is installed at the bottom, and at the top there is a chimney pipe. A gas boiler works on the same principle, only the heat source is a burner that heats a container of water. The water heater structure is shown in the diagram:

As can be seen in the figure, heating is carried out not only from the burner, but also by removing heat from combustion products. This is achieved through a steel flue with dividers, passing vertically through the container and exchanging heat with the water. The operation of the burner is controlled by an electronic unit, whose task is to extinguish or ignite it when the set temperature is reached or decreased. As usual, to protect the body, the boiler design includes a magnesium anode.

This type of water heater is not very popular due to the difficulties in designing and connecting gas-using installations. In addition, to operate a gas boiler you will need a full-fledged chimney; fulfilling this requirement is not always possible or too expensive.

The advantage of storage water heaters is that they can immediately produce a large flow of water for domestic hot water, but for a limited period of time. After this, they need a break to prepare the next portion of water.

Main characteristics of the speakers

Now let's talk about the practical aspects of using the speaker. One of the main characteristics is performance . It directly correlates with power, which is indicated in kW and shows the volume of water heated per minute by 25 °C.

The characteristics are usually indicated in the device passport. A regular water heater heats 10-20 liters of water per minute at 25 °C, although this value can vary significantly.

Another characteristic of modern speakers is power modulation . It shows how the power of the column can change depending on the flow of water and is measured as a percentage of the initial power.

For modulation, the columns are equipped with special fittings with a membrane, which changes the gas supply to the burner depending on the flow. Modulation in the range of 40-100% of the device power is considered normal.

The diagram shows the modulating valve and the principle of its operation, which is similar to the operation of a water unit and its membrane

About instantaneous water heaters

Unlike storage boilers, the principle of operation of a flow-through water heater is to quickly heat running water as needed, rather than in advance.

The heat sources are the same electric heating elements and gas burners, only they turn on after the hot water tap in the house opens. Such heaters include:

- geysers;

- flow electric heaters.

Note. Sometimes, to provide hot water supply to a private home, a plate boiler is used, which is a water-to-water heat exchanger. Like an indirect heating boiler, it transfers the energy of the coolant to water, only it does this in flow mode.

The design of the geyser is quite complex, and therefore deserves a separate topic. An electric water heater is simple: a powerful heating element heats running water in it. Having such an advantage as its small size, the device has too high power consumption and therefore its scope of application is limited. The design of a flow-through electric boiler is shown in the figure:

The advantage of instantaneous water heating devices is that they can supply heated water without preparation and for an unlimited time. But its consumption has limits, which is important when there are a large number of consumers.

What influences the choice of a specific device

Gas, for all its convenience and the amount of energy released during combustion, has a key feature. This is a dangerous fuel. Each gas-powered device, for example, a storage water heater or a water heater, must be installed and operated in compliance with certain rules, and have clearly marked safety systems. The choice of a particular unit may be influenced by:

- gas pressure indicators in the supply line;

- the type of gas supplied to the device;

- the ability to use coolant prepared by an external installation;

- the presence of interruptions in supply or insufficient pressure parameters to start the installation.

You should choose a storage water heater, geyser or combined device by carefully analyzing the capabilities and potential emergency situations.