Author: Yuriy Fedorovich Kolesnikov, thermal power engineer

A stove made from car wheel disks can heat a room up to 15-16 square meters. m, heating a bathhouse or becoming an inexpensive, effective cooking device, which is what this article is actually about. Its main advantage is the availability of high-quality material - thick, resistant and durable steel. Boiler steel in sheets and profiles is expensive, and ordinary structural steel in a furnace structure quickly burns out.

The additional advantage of a disk oven can be seen through experience. Take two pieces of metal of approximately the same size and weight: one from simple steel, and the other cut from a wheel rim, and heat it up stronger, at least in the kitchen on gas. The first one will immediately give off the smell of hot iron, and the second one can be heated to orange (about 900 degrees), without feeling anything unpleasant in the air. A furnace made from wheel rims practically does not dry out the air and does not emit harmful fumes into the atmosphere, because the rims for the wheels are made of special steels that are resistant to corrosion. They are, of course, not standardized for heat resistance, but the reserve of resistance that is built into them is quite enough for a wood-coal stove.

What is good about a stove made from rims?

In addition to the availability of the main components, a homemade stove has a number of advantages:

- Ease of construction.

- Compact sizes that you can choose yourself based on the diameter of the discs.

- Fast heating and good heat dissipation.

- Durability, thanks to the thickness and good quality of the steel.

- Resistance to deformation even under prolonged exposure to humidity and high temperatures.

- Possibility to use different types of fuel - wood, coal, fuel pellets.

Sauna with a disk stove

Among the disadvantages, we note the following points. Firstly, metal is a good conductor, and the stove becomes very hot when heated, which can cause burns and injuries. And secondly, a disk stove cools down as quickly as it heats up - approximately 1.5-2 hours after the last batch of fuel burns out. Therefore, it should not be considered as a permanent heating device, but it will be just right for heating a bathhouse or utility rooms!

Note! Even a large sauna stove made from truck disks can heat a room with an area of no more than 15 m2. Therefore, for large rooms you will need a more powerful device.

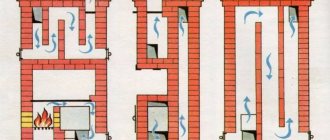

Features of the location of the rims

The wood burning in the firebox will give off its heat through the walls of the first rim, in which the bottom is cut out. It is welded to the second disk, where the bottom is in place, making it possible to fill it with stones. There is a pipe running inside through which combustion products will escape. The pipe should go inside the third rim, where instead of the bottom there is a gas divider. It is made of sheet metal. The last stage of gas cooling takes place inside the last rim, which looks like a tank with a tap and a lid. As a result, the stove works no worse than factory models, and in terms of durability it turns out to be even better than any of them.

Materials and equipment for work

To make a stove from wheel rims with your own hands, you will need the following set of tools:

- A grinder with metal circles or a gas cutter.

- Welding machine and electrodes.

- Protective equipment: glasses, leggings.

- 2 cuts of 50 cm each of metal pipe with a thickness of 5 mm and a diameter of 160 mm.

- Iron sheet 8 mm.

- Door hangers (can be replaced with large bolts and nuts)

- Fire brick.

- Cement-sand mortar for masonry and clay.

- 4-6 steel channels.

To build the body, you will need 4 disks from a truck, for example a KrAZ. These wheels will make a stove with a diameter of 0.5 m and a wall thickness of 1 cm - this is quite enough to heat a bathhouse or other utility room.

Used truck wheels

Please note! Wheels from passenger cars will not work - their radius is too small.

Preparing tools

If you decide to make a hearth for a cauldron or a regular stove using car wheels, then you need to take care of the availability of tools, among them the following should be highlighted:

- welding machine;

- electric drill;

- chisel;

- sledgehammer;

- disks;

- paint brush;

- ruler;

- grinder;

- hacksaw for metal;

- hammer;

- file;

- pliers;

- roulette

It is noteworthy that almost any of the disk-based models made will be portable, which is very convenient, because this design can be used in a bathhouse or on the street. It is best to use stamped steel disks, the diameter of which varies from 40 to 50 cm. Their height can be 25 cm. The hearth for a cauldron, like a sauna stove, cannot be made of aluminum disks, or those made on the basis aluminum alloys.

Fire safety rules when installing homemade stoves

An oven made from car wheels heats primarily with infrared radiation. To convert this flow into warm air, the stove needs to be shielded: surrounded by a casing of steel sheets installed at a distance of 7-10 cm from the heater and with the same gap from the floor.

Safety rules for operating metal furnaces:

- A reinforced concrete slab or steel sheet must be laid on the floor so that the fire-resistant structure extends beyond the contours of the furnace by at least 60 cm in each direction - this will protect against fire if coals accidentally fall out of the firebox.

- The metal stove and chimney must not come into contact with flammable materials. Use insulating pads if necessary.

- Before lighting, always check for draft in the channels. If it is not there, you need to warm up the chimney with a small amount of burnt wood or clean the passages and ash pan.

- Do not use liquid lighters - they may cause fire to escape from the firebox opening.

Shielding a metal stove

Tip! If possible, install the stove in the bathhouse so that the firebox faces the dressing room. This arrangement has many advantages: it is more convenient to heat, in windy weather the smoke will not get into the steam room and the dressing room will get some of the heat.

Design Features

We have looked at one of the features of constructing a furnace of this type, let’s move on to others. In the vast majority of cases, a disk furnace is configured as a combined furnace. The key reason for this decision is that the steam obtained from the stove, made up entirely of disks, is quite hard and uncomfortable

For a sauna, with its low humidity, this is not so important, but in a Russian steam bath this circumstance is certainly worth paying attention to

To obtain high-quality soft steam, you must have a stove with a brick firebox. The discs are used as a container for laying closed stone backfill and as a mounted hot water tank for heating water. The use of an open heater is very limited due to the impossibility of burning the fuel in the stove to its fullest extent, so soot fragments will settle on the stones, which will cause them to enter the steam room atmosphere the first time you try to add steam with a ladle of water.

If it is not possible to build a stone firebox, then it is worth making a full-size stove from cargo disks, which are much larger than passenger cars and have a main seat diameter of about 20 - 22 inches. To reduce the overall height and laying of the disk segments, the design should be made with an embedded-type grate, made of a steel circle with a thickness of 6-10 mm along the diameter of the internal fit and reinforcing rods with a thickness of 12-16 mm.

A hole with a diameter of 150-170 mm is cut in the center of the circle onto which reinforcement sections are welded at intervals. The air passage of such a grate is enough to accelerate to a power of 25-27 kW. When installing the grate, it is necessary to provide a thermal gap within 8-10 mm; a metal ash pan with a diameter of about 200 mm is placed under the grate hole.

Again, taking into account the fact of the formation of hard steam in conditions of high humidity in a Russian steam bath, it is better to use a stove of this type for arranging a Finnish dry steam sauna. In general, step-by-step instructions for making a stove of this type can be viewed in the attached video

In general, step-by-step instructions for making a stove of this type can be viewed in the attached video.

Any type of sauna stove, made with your own hands from available materials, is characterized by its simple design and ease of installation. Thanks to its compact size, the wheeled sauna stove heats up quickly and therefore has high heat transfer.

A homemade disk oven has a number of advantages:

- availability and low cost of building materials;

- ease of manufacture;

- high strength and durability;

- ergonomic design that does not take up much space;

- accelerated heating and high thermal output;

- resistance to mechanical damage and deformation;

- inertness when exposed to high moisture and high temperatures;

- possibility of using different types of fuel - wood, coal, pellets.

We suggest you read: How to install a stove in a wooden house?

Among the disadvantages of the device are the following:

rapid heating of metal discs can lead to injury and burns if the stove is handled carelessly; rapid cooling of the structure will require a doubling of the volume of fuel used.

For these reasons, a stove made from car wheels should not be considered as the main heating equipment for a country house or cottage, but it is quite suitable for temporary heating of bathhouses and technical rooms.

How to make a stove from disks for a sauna with your own hands

First of all, the discs need to be prepared: cleaned of debris, rust or paint residues using sandpaper. After this, you can begin manufacturing the structure, following the stages of work in the specified order.

Water container

To equip the upper chamber of the future stove, two rims are needed. The water will be heated in this tank, so it must be sealed. To do this, cut out the central plates for fasteners from 2 disks with a grinder, leaving only the rims. They are stacked on top of each other and welded together.

Disc core cutting

The upper part of the tank is closed with a metal lid or a movable flap. For safety reasons, you can combine these two options and tightly weld the larger segment of the lid, making only the small hole through which water will be poured into the tank sliding or hinged. A metal plate cut from a sheet is welded to the bottom of the chamber.

The structure of the upper part of the stove

After welding, holes are cut in the upper part and at the bottom of the container along the diameter of the chimney pipe. It will pass through the entire tank, should be tightly overlapped by the walls and come out through the bottom. A thin tube is installed in the side of the tank near the bottom at an angle to the floor and is closed with a tap to drain hot water.

Note! The tank must be checked for leaks. Fill it with water and carefully inspect the cracks for leaks, paying special attention to the joints between the walls of the container and the slots for the pipes. If defects are found, they must be eliminated by welding, but only after removing the water and drying the tank.

Arrangement of the heater and the upper part of the firebox

From the two remaining rims you need to make a heater and a firebox cover. The core is cut out of one, the second remains intact. The blanks are placed one on top of the other and stitched together by welding so that the hub of the whole disk is in the middle (it will serve as a grid). The container remains open at the top - stones are poured here. The lower part of the cylinder will serve as the upper part of the firebox.

Natural round-shaped stones, which are used in saunas and baths - diabase, basalt, peridotite, are best suited for arranging a heater. But they are quite expensive. Therefore, you can look for heater material near the nearest body of water - these stones have been well hardened by humidity and sun. The best option is dark-colored rocks with a non-layered structure.

The best stones for a heater

Please note! The stones in the stove, although slowly, are destroyed under the influence of high temperatures. And this makes it difficult for smoke to pass through. Therefore, periodically the contents of the heater should be sorted out and replaced.

Foundation and brickwork

It is recommended to install a sauna stove made of rims on a strong and fire-resistant foundation. It can be built from reinforced concrete screed, and the top surface can be lined with fire-resistant bricks.

When the base is dry, you can begin to work on the bottom of the oven. For a stove with masonry 62*62 cm, you will need 60 pieces of red heat-resistant bricks. They are held together with clay diluted with water and laid in a square. Don't forget to provide a cavity for the blower and a hole for the door. Attach the grate to the top of the masonry.

Stove assembly

All parts of the structure are assembled sequentially. The metal part is connected to the brick part, the firebox and ash pan are closed with doors cut from a metal sheet.

Scheme of a stove-stove for a sauna made from wheel rims

On a note! For comfortable use, it is advisable to equip the door with a handle made of one large bolt. And to prevent firewood or coals from accidentally falling out, use a latch made of a narrow metal plate and a small loop.

Next, a second section of pipe is welded to the central hole of the hub, located between the firebox and the heater, and sewn to the upper part of the chimney running through the water tank. Stones are placed in the heater: large and medium ones at the bottom, small ones at the top.

To strengthen the structure, metal channels are welded to the rim of the heater and the water tank, which are installed at a slight angle to the top of the body. The pipe is led into a chimney lined with fire-resistant bricks and equipped with a damper.

Such a stove will heat the steam room and water in the tank in just an hour.

Some recommendations for using a disk oven

During operation, some difficulties may arise that can be completely avoided if you follow some simple rules:

The main thing is to reliably weld all the joints of the future stove. During operation, smoke may enter the steam room through unsealed cracks.

This is not very pleasant, so pay special attention to welding work. Of course, with prolonged use due to high temperatures, cracks may occur, but they can be easily eliminated with clay and well-dried sand.

Sand can help find new cracks. Before you start using the stove, it needs to be treated with paint. The paint must be resistant to high temperatures. You need to pay special attention to the upper part of the structure. The evaporation of the liquid occurs precisely in it. Sometimes metal can corrode and, as a result, lose its properties. A stainless steel sheet must be installed on the chimney pipe. High temperature water has a negative effect on structures. A pre-prepared clamp may be suitable for fastening. You can buy it in a store or make it yourself. Observe fire safety. If the floor in the bathhouse is wooden, then there must be a fire-resistant structure. In front of the room where the firebox is located, you need to install a piece of iron 20 by 30 centimeters. This will be a fireproof shield. Insulate the entire area below. Fill the distance between the insulation and the stove with sand and stones. It is recommended to fill the gaps between the stove and the insulation with dry sand and fill the top with stones. These natural materials will absorb the high temperature that the stove gives us. In addition, they perfectly retain the resulting heat and, thanks to this, can allow the stove to maintain the temperature longer even after the fire has died out. And thirdly, this is an excellent decor for your bathhouse.

In conclusion, I would like to say that building a sauna stove yourself from old disks is not so difficult. You just need to follow the recommendations and carry out each stage of work conscientiously.

Stove made of disks for heating utility rooms

A disc stove for a bath differs from other heating structures in that it has a special water container and a brick base. If you only need to heat a room (for example, a small country house or a garage), the design will be much simpler. For the base of such a stove, you can install several refractory bricks or a section from old radiators, on which a sheet of metal 5-8 mm thick is installed.

The simplest design of a homemade stove made from wheel disks is done like this:

- Using a grinder, the central part of three of the four disks is cut out.

- Two disks are welded together. In the lower one, the bottom is covered with a round plate cut from a steel sheet, or immediately welded to a metal base.

Blank for the lower chamber

- A small square hole is cut on the side surface with a grinder, and a door is made from the resulting piece of metal. It can be attached to the body with welded bolts and nuts, equipped with an iron handle and latch. This part of the body will simultaneously serve as an ash pan and a blower - to increase traction, just slightly open the door of the lower chamber.

Fire door

- The two remaining disks are also welded together so that the whole disk with the uncut core is at the bottom - this is where the firewood will be stacked. A hole is also cut out on the side of the firebox and a door is mounted.

- The top of the stove is covered with a plate in which a round hole is made for the chimney pipe.

- All parts of the body are connected by welding, a pipe with a valve at the top is lowered into the upper hole and welded.

- The finished stove can be painted using heat-resistant enamel.

Ready oven for heating

Important! Seams are the weak point of any oven made from wheel rims. They must be welded with the utmost care, otherwise the smoke will penetrate into the room through the cracks, instead of completely escaping into the chimney. If the seams become thinner and burn out during operation of the stove, the cracks can be covered with clay and sprinkled with dry sand.

Additional recommendations

To make the stand for a cauldron made from car rims more convenient and practical to use, you need to take care of the special features:

Additional stability can be added to the assembly using legs. They are made from profiled steel, which is cut to size. The blanks are welded to the sides of the furnace or the bottom and flanges. A tripod is the best option in terms of stability and economy. A good solution would be to make a separate stand for the stove from car rims for the cauldron. Its advantage is that it is not rigidly connected to the main structure and can serve as a support for anything. If there is a stand, the profiled bottom of the lower section will work as a grate. This will significantly increase draft and increase the temperature of the arch. You can simplify the project, reduce labor intensity, and save on materials if you make the oven from two segments. In this case, the roof of the structure will become lower, which will negatively affect heat transfer. This is due to the fact that during combustion pyrolysis gases are released, their contribution to the total heat release is decisive. If the arch is not high enough, they do not have time to burn completely. Contact with the cold walls of the casing causes soot deposition. Over time, the inner surface of the vault becomes coked. The heat output of the furnace is noticeably reduced. Soot fire cannot be ruled out. The versatility of the design allows you to convert the cauldron oven into a grill and barbecue with minimal changes. Without unnecessary cuts, you can get by with ready-made holes on the surface of the product - they will create several temperature zones. If you install a grate on top, it will combine the functions of a flame divider and a rasper - this will allow you to simultaneously cook roast beef of varying degrees of doneness

It is important to understand that a large company will need a more solid stove; Gazelle disks are suitable for its manufacture. They do not need to be welded together, which is a definite plus.

Heat-resistant metal adhesive can successfully handle the functions of a weld seam. Good potbelly stoves are obtained with horizontal wheel rims. It is better to cut off their convex parts with a grinder. The sections welded together form a capacious thick-walled cavity with a complex surface. Such a potbelly stove will heat up the room faster and take longer to cool down. To make such a stove, it is better to use wheel rims from trucks; they will provide a sufficient firebox volume and increase heat transfer. The efficiency of such devices is higher.

The area under the supports must exceed the parameters of the cauldron: the higher this ratio is, the more stable the entire structure will be.

Comfortable stoves with installed legs

Can be installed on a grill and used as a barbecue

Potbelly stoves heat better with horizontal disks

Step-by-step algorithm

The first thing you need for construction is a pair of classic stamped car wheels made of durable metal. The sizes of the disks should be selected to suit your cauldron; option 13 may be suitable, or maybe 15, although a very large design is not needed.

Two stamped white discs

On one of the disks we mark a cutting line, exactly above the round holes, and cut off this circle using a welding machine.

Mark the cutting line

The cut circle will work perfectly as a lid on which you can put pots or a kettle, so don’t rush to throw it away.

The part is cut out

On the second disk, you need to weld the main central hole, which will require a small piece of thick metal.

Preparing the welding machine

We carry out welding work

Then the two disks are placed on top of each other and, using the same welding machine, they are connected into a single structure.

Circular welding process

Welding from all sides

This creates an impressive seam that firmly connects the two discs. To make it more presentable, you can modify it with a grinder, cutting off strongly protruding elements and grinding the edges.

Weld seam

In order for the structure to stand stably at the required level, you will need legs. The legs can be tightly welded to the grill if you are preparing a summer cottage, or you can make the structure detachable. In the second case, the device will be mobile; it can be easily carried in the trunk of a car and, if necessary, assembled. Small pieces of a profile larger in cross-section than the legs themselves can act as fastenings for the legs. These three parts should be welded to the grill on three sides (in this case, a tripod is made).

Leg parts

There is no need for precise calculations here; it is enough to roughly estimate equal distances and weld the necessary parts to the bottom of the grill made of disks at the same angle.

Leg clamps are welded

We also cut out the legs from metal, in particular we use a rectangular profile.

The legs themselves, cut from the profile

It is worth trying on the legs by inserting them into the prepared grooves. If they enter with difficulty, you should process the edges of the parts with a grinder, and then hammer them into the grooves with a hammer.

Legs installed

Next, mark the door that will open directly into the firebox and cut it along the line.

Marking the location of the door

At the next stage, you will have to use your imagination and engineering skills to create a decent hinge for the door. For example, you can make it from one bolt. It is necessary to cut off the cap from it, then select two nuts that are screwed onto it. One nut should be welded to the door, and the second to the wall of the grill. By screwing the bolt onto the threads of both nuts, you get a convenient loop. You can weld any piece of metal of suitable size as a handle.

The door is cut out

You can make two loops using the same bolts, here all the work is done at the discretion of the master.

Loop manufacturing option

To make it easier to transport the grill, you should weld lugs to it on both sides, or at least on one side. Such improvised handles will allow you to comfortably carry the barbecue without fear of getting dirty with soot, soot or dirt.

We weld the handles

For a more uniform smoke output, you can make four even cuts along the diameter of the disk. At this point, work with the hearth to form its shape is completed.

Making cuts from the top

To remove paint from car rims, you should burn the resulting grill on all sides. For final processing, you can use a brush or sandpaper.

Removing paint using improvised means

Then, using heat-resistant paint, you need to paint the structure in a suitable color. Black looks very harmonious.

Paint it black

As you can see, making a grill for a cauldron is quite simple; there are no special tricks here. A simple and convenient design will allow you to install a cauldron and cook pilaf, and if desired, you can make a shish kebab on it using skewers of suitable length.

Ready product

In this simple and uncomplicated way, we create excellent conditions for outdoor recreation, which is accompanied by cooking delicious and healthy food.

Trial fire

A self-made oven must sit for 24 hours so that residual stresses are completely resolved. Then it needs to be tested with a full load of fuel for three hours. The doors - at the firebox and the ash room - must be open.

Carrying out a trial fire

During the first test fire, the internal surfaces of the device are annealed. If minor defects are found on the welding seams - no more than two on one - they should be corrected a day after the stove has cooled. Then the test fire is repeated.

Small oven with grate for food

Useful tips

It is important to lay a high-quality seam at the welding site - no defects should be noticeable on it. When working with a welding machine, you cannot try to weld everything at once - the work is done in stages

After welding the parts together, you need to wait until the seam cools down to touch temperature. When assembling the structure, do not forget that for proper operation of the stove it is important to provide the size of the combustion chamber for the type of fuel you plan to use. After completing the work, be sure to test the design and eliminate any identified deficiencies.

Attention! All welding work must be carried out in compliance with safety regulations, wearing protective clothing and a mask. Do not touch parts until they have cooled down