The name “Buleryan” (also known as buller, bullerjan, buller, breneran) has already become a household name. If “Buleryan stoves” means “warm, long-lasting and economical.” There is a lot of information on the Internet about these miracle stoves - they write about their high efficiency, their surprisingly long burning time (more than 12 hours) and, as a result, their efficiency. In this article we will figure out whether these stoves are as good as they are said to be. Let's see what the real pros and cons of these stoves are and in which cases it will be a good purchase, and in which it is better to wait.

Structure of the Buleryan stove and principles of operation

A heater with a high efficiency of about 80%, operating on all types of solid fuel, with the exception of coal. We will look at several models to make a homemade buleryan.

Design and principle of operation of the Buleryan boiler

Let's understand the very structure of this miracle oven and determine the operating principle. In simple human language, a Buleryan stove is a heat-resistant metal structure with a number of pipes that perform natural circulation.

This air heater is designed for heating residential and non-residential premises. Depending on the size and efficiency of the stove, it can heat a small country house, a warehouse or production facility, or a greenhouse.

Buleryan stove

The basic operating principle of the furnace is the design of two chambers. Fuel is placed in one of the chambers. The fuel loading chamber is specially designed so that it contains a small amount of oxygen and the fuel does not ignite completely. If there is a lack of oxygen, firewood or briquettes slowly smolder, forming pyrolysis gas, which burns out in the second of the chambers. Maximum fuel economy - on one tab and high efficiency in comparison with similar devices. This explains why the Buleryan stove is so popular among users. After studying this article, you will be able to make buleryan with your own hands.

Kindling technology

To use the stove, no specialized knowledge or skills are required. The boiler is easy to heat and maintain.

You can melt Buleryan as follows:

- Fuel is loaded into the firebox. First, firewood of small thickness is used. The fuel should be dry, this will minimize the amount of condensation that forms and allow the fire to start quickly.

- The wood is set on fire. The dampers that regulate the draft and the amount of air supplied are fully open.

- After hot coals have formed in the firebox, thicker firewood is loaded through the door. The dampers are installed in the desired position to ensure long-lasting combustion.

After all the above steps, Buleryan will work as normal. The frequency of laying firewood depends on the intensity of fuel combustion.

Buleryan power calculation video

Buleryan stoves of four types of power, purposes and areas of application:

- Household with hob

- Buleryan household classic

- Industrial boiler Buleryan with power from 60 kW

- Buleryan stove with water circuit

Table for calculating the power of a Buleryan boiler

When choosing a boiler, it is necessary to take into account not just the area of the room, but the cubic capacity - the height of the room is taken into account.

About heating a private house

Okay, the reader may say, but you need to warm up! Yes, but stove heating is used mainly in private households, and there water heating is pure prejudice, a stereotype of “centralized” thinking. For the efficiency of a central thermal power plant, indeed, the heat capacity of the coolant is of paramount importance, otherwise it will cool down before it reaches subscribers.

What about in a private house? What, should we run a line from the kitchen or furnace around the entire area to the living room/bedroom? Isn’t it easier to disperse the warm air through the rooms, which the bubbler gives, as they say, from the top? Judge for yourself:

- Air ducts can be made with a simple tool from cheap materials: tin, plasterboard, plywood, just cardboard, but pipes are expensive, they need to be bent, boiled, soldered.

- No registers, expansion tank, fittings, or automation are needed.

- You can forget about fistulas and leaks once and for all.

- Ductwork with fans and louvers does not require a design or permit. It is enough to calculate for yourself which section should go into which room.

- Heat transfer into the walls (and this is up to 15% of heat loss through water) is zero; here the poor thermal conductivity of the air works to our advantage.

- Install adjustable blinds at the exits - here you have easy, quick temperature control in rooms. It’s better not to compare it with setting up water heating.

- If you place the exit blinds on the walls farthest from the window above the floor, then the air will give up its heat to the room by the time it gets to where it can heat the street. And everyone knows how batteries in window sills increase the entropy of the Universe.

- The same technique will also provide a warm floor without any additional costs or work.

- The walls are straight, there are no deformities in sight - design the interior as you please.

Video: Buleryan and garage heating

Design and device features

Buleryan type stoves have a unique design. Two chambers of the boiler, surrounded by tubes on the outside, in which natural convection is formed. Cold air is drawn in from below through the openings of the pipes, and heated air rises from above in the range of 110-120*. For more efficient operation of the stove, it has air and flue gas regulators - damper regulators; with their help, you can achieve the longest smoldering time, up to 5-8 hours continuously. User reviews and videos under the section. The article provides a drawing and assembly diagrams.

Buleryan stove with water circuit

The Buleryan stove with a water circuit is an improved version of a conventional stove, repeating its design, but allowing you to heat several rooms instead of air; this boiler heats water, which circulates through the system. This type of stove has an advantage over the traditional Buleryan boiler.

Buleryan device with a water circuit

The main advantage of this is that the water cools down more slowly, and you can also connect the required number of radiators to the boiler.

Buleryan stove with water circuit

You can assemble a Buleryan stove with a water circuit with your own hands, or buy a factory-made stove.

Scheme of Buleryan with a water circuit

A Buleryan stove with a power of 7-9 kW and a water circuit can heat a small two-story building. You can assemble the stove yourself by adding a water circuit to the buleryan, plugging the heat exchangers and connecting it to the heating system.

Buleryan furnace in production

Burner for working off in a buleryan furnace

As one of the types of fuel, waste automobile and other oils (any automobile oil, frying oil, fuel oil) can be used, this significantly reduces the cost of the heating process. To do this, a pyrolysis burner is mounted to an ordinary classic ready-made Buleryan boiler or to a home-made heater.

pyrolysis burner for Buleryan stove

The consumption in this case is approximately 1.5-2.5 l/hour. The video attached under the article below describes in detail, in diagrams and drawings, the installation of the stove, how you can make such a Buleryan-type stove with your own hands.

Buleryan with hob

Buleryan boiler with a cooking surface

Buleryan boiler with a cooking surface is an undeniable solution. Installed in dachas, small country houses, in the garage. The outer surface of the heater heats up to high temperatures in a short time. You can also make this model of a Buleryan stove with your own hands by welding a sheet of metal with cut out circles on top of the pipe structure.

Buleryan with hob

What to look for when choosing

Before purchasing a stove, it is necessary to determine the volume of the room for heating which it will be used. It is better to purchase a product whose power exceeds the minimum required.

When choosing, there are a number of factors to consider:

- type of hatch for loading fuel. The oven door can be made in 3 options - all-metal, cast iron, with built-in glass. From an aesthetic point of view, it is better to choose a product whose hatch is equipped with an observation window. Manufacturers use heat-resistant glass. Thanks to this, the window does not collapse even with strong heat;

- type of draft control damper lever. Some manufacturers equip the damper control handle with an extension. In such models, adjustments do not require going to the back wall of the oven;

- presence of a hob. The stove can be manufactured in 2 versions - classic or with a built-in cooking surface. The Buleryan cooker does not differ in its characteristics from the classic model. If the stove will be used not only for heating the room, but also for cooking, you can choose a model with a built-in surface;

- a method of adjusting the amount of air supplied to the firebox. The blower hatch can be made of a damper or a latch located on the door body in the form of a butterfly. The choice is made based on the person’s personal preferences;

- protective screen. Some models have a casing on the side surfaces. It is used to protect against burns when touching Buleryan. If the stove will be used in a residential area, it is better to choose a model with a protective screen.

Manufacturing options

Is it possible to make buleryan with your own hands? There are two models to choose from, which option to choose is up to the master, it all depends on the materials available, the experience of craftsmanship and the skills of the master himself. One option is to make a stove from profile pipes, the second is from a gas cylinder.

Buleryan from a profile pipe

Do-it-yourself Buleryan from a profile pipe.

A simple design of a Buleryan stove - a model made from pipes. Buleryan can be made from round pipes or from profile pipes 60*40 mm. The photographs show step by step how to make a Buleryan cauldron with your own hands at home.

Schemes and drawing

Make a Buleryan stove with your own hands: the pipes can be bent or welded at the choice of the master.

The main task is to comply with the general principle of the boiler structure, its operation has not been disrupted, the diagram below shows a boiler made of round pipes, according to the same principle we use profile pipes.

Drawing for making a Buleryan stove

If you adhere to the diagram, then it is assumed that the pipes will be curved. Since not every craftsman can do this process, you can simplify this task and weld the pipes into the desired configuration.

Materials

- Metal sheet, thickness from 4 mm.

- Pipe profile (approximately 3-4 mm) size 6*4 cm - 7 pieces.

- A finished door or a piece of metal sheet.

- For the chimney outlet: pipe d-100-120 mm and a pipe for the damper.

- Door handle.

- Fittings for throttle and damper.

- The seal is heat-resistant in case of self-welding of the door.

- Hinges for doors.

Tools

- Welding + electrodes for it.

- Bulgarian and circles to it.

- Pipe bender (if the structure is curved)

- Electric drill and drills for it.

- Chalk or marker for marking.

- Roulette or ruler.

Step-by-step instruction

Without experience, it will not be easy to work; due to the non-standard shape, it is difficult to make a stove with your own hands, but it is possible. Be prepared to face difficulties, one of which is the number of welds, there will be a lot of them and they must be of high quality.

Profile pipes for assembling Buleryan

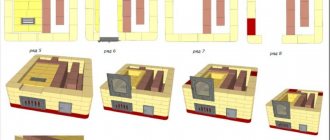

Bend 7 pieces of prepared pipes of the required length into the desired configuration according to the diagram and secure them with a welding seam.

Pipe blanks for frame

When you connect all 7 blanks together, you should get a structure of this type.

Buleryan step by step frame assembly

It is necessary to attach grate bars to the pipes from below (either ready-made, or make them yourself from metal blanks).

Frame made of seven blanks

After assembling the frame, we mark strips of metal and attach them pointwise between the pipes, or on top of the pipes, forming a casing.

Casing over pipes

Install the upper partition.

Partition in the Buleryan oven

The length of the partition should not reach the door by about 1/4. Approximately 7-10% of the total surface area will need to be carved out of the plate and welded. The main condition is the tightness of the welding seams! Next, we begin making the back wall. The easiest way is to make a pattern on cardboard or a sheet of thick paper, and then mark it on a sheet of metal.

Back wall of buleryan - blank

We mark the hole for the chimney pipe according to the size of the prepared pipe. Important: the chimney must start in the upper section, which is fenced off. Once ready, weld the wall at the back. Checking the tightness!

Now we come to one of the complex units - the front wall with the door. We cut out the wall itself in the same way as the back one, then we need to cut a hole in it for the door. This hole should be located closer to the grate, just above the grate.

Blank for the front wall

The diameter of the hole must match the size of the door. It is advisable to make it rather large; this will determine what kind of firewood will fit in the firebox. If you make the door yourself, then along the edge of the hole you need to weld a side from fittings curved to the shape of the hole, or a cut from a pipe of a suitable diameter (if the door is round). This side is needed for tightness. The door size will be slightly larger than the prepared hole.

Drawing for making a buleryan door

Along the edges of the door blank, you need to weld one strip of metal and, stepping back, weld a second one; the height of the side should be about 15 mm, so that the side on the front wall, when closing, is between these two plates on the door. To seal, an asbestos cord must be laid between these strips.

Prepared mechanism for the gate

We make a throttle. The damper is approximately 2-2.5 cm in diameter and about 10 cm long. A piece of pipe is best suited for this purpose. From the edge of the pipe, retreating 4-5 cm, we drill two holes, placing them radially. We pass a piece of reinforcement or a rod through the holes; one side will need to be bent - now this will be our throttle handle.

Throttle

Now you need to cut a round piece of metal slightly smaller than the pipe of the body itself - this will be our damper. Having inserted it into the body, we carefully weld it to the fittings. As a result, we get a damper that can be adjusted. The throttle itself now needs to be attached to the door. At the top we make a hole on a quarter of the surface and weld it.

Installation of hinges, shutter and damper for the chimney. The principle of its manufacture is similar to that of the regulator damper. We place the holes radially, pass metal reinforcement through them, then weld the damper and bend it at one edge to get a handle.

Handle to damper

Buleryan long-burning stove from a gas cylinder

Buleryan from a gas cylinder

A simple configuration of a Buleryan stove for self-production, the basis will be a used old gas cylinder. This will be a combustion chamber and will help avoid the additional work of welding the base. This configuration of the Buleryan stove is the most accessible for making at home, without special equipment.

Scheme drawings dimensions

Buleryan’s DIY diagram below provides complete information on the size and complexity of this design.

Material

- The metal is no thinner than 3 mm for the ash pan.

- Cast iron door purchased or prepared in advance.

- Reinforcement or pieces for legs and grate.

- Used gas cylinder.

- For a chimney (pipe blank).

Tools

- Welding + electrodes.

- Grinder or grinder.

- Metal brush.

- For markings, chalk, marker.

- Roulette or ruler.

- Electric drill with drills of the required diameter.

- Pliers, hammer, chisel, metal file.

Step-by-step instruction

Step-by-step diagram for assembling a Buleryan stove

When starting work, first prepare the cylinder. To avoid the cylinder exploding, you need to make sure that there is no gas (residues) in it. A simple method is to fill the container with water to the brim, then drain the water and drain the container.

Drawing for buleryan from a gas cylinder

We mark the holes we need on the cylinder: square for the door, round for the chimney. To make a round hole you need either a cutter, or holes are drilled in a circle and then knocked out with a chisel and hammer. Clean it thoroughly with a file.

The simplest method for making a grate, if you don’t have one ready-made in size. We drill holes of the required diameter in the bottom of the oven, i.e. the cylinder.

Holes for ash pan

We weld a box for ash from the bottom of a sheet of metal, weld a door to this box and this box will act as a blower.

Blower for Buleryans

The doors are purchased, or we make them ourselves.

Doors for the Buleryan oven

We attach a pipe from a piece of pipe of the required diameter to the top of the cylinder. And finally, the last step is to secure the boiler to the legs or stand. The DIY Buleryan stove is ready for use.

About pipe batteries

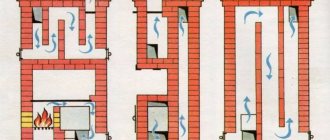

With a thermal power of up to 20-25 kW, the pipes in the batteries are made in the form of technologically simple semicircles, as on the left in Fig. In this case, the diameter of the pipes is 60-100 mm, and their number is 3-4 per battery.

Buleryan stoves of low and high power

With a higher thermal power, it is impossible to increase the diameter of the pipes proportionally; due to the low thermal conductivity of the air, the efficiency will decrease. It is necessary to increase the “tube” of the batteries. But with batteries of 6 or more pipes, the efficiency also drops; this is where the square-cube law applies to fuel loading.

Up to a power of 100-120 kW, designers get out of the situation by making pipes curved in the form of sinusoidal arcs and slightly inclined with the top of the arc downward. In this case, the firebox acquires a drop-shaped or ovoid cross-section, as on the right in Fig. With even greater power, computer modeling of the Buleryan with optimization is required, and a positive result of long, complex and expensive work is not guaranteed.

How to install Buleryan

The main stages of installing a Buleryan heater

- When choosing a place to install the stove, the main thing is to ensure free air convection for better heating of the room.

- The boiler gets very hot during operation, you need to provide a fireproof place for it.

- Under the boiler and in front of the firebox, it is necessary to place a metal sheet on the floor to prevent fire.

- It is recommended to install the stove no closer than 30 cm to the wall and with a distance of at least 60 cm from furniture and other objects.

- if the boiler is located in the corner of the room, then it is advisable to protect the walls with fireproof materials (metal, stone, brick).

- We put the Buleryan stove 20 cm from the floor for natural air convection, for this we mount a stand.

Boiler stand Buleryan

Chimney device

Types of chimney installation: one of them is classic (or traditional). This installation method is used at the initial stage of building a room. The chimney pipe is located vertically and passes through all ceilings.

Types of chimney devices

This method excludes the horizontal arrangement of any nodes. The second method is used at any time, at any stage of the construction of the premises, even after the construction is completely completed. This method is called coaxial; it works more efficiently than the traditional one, as it ensures high-quality removal of combustion products and is less fire hazardous.

Distributing heat throughout the rooms of the house

For the most effective use of the Buleryan stove, in order to heat not one room, but several or the entire house, corrugated pipes can be connected to the heat exchange pipes coming from the stove.

Corrugated pipes are distributed in rooms

The pipes are routed accordingly through the walls of the premises, if necessary through the ceiling. Decorative grilles are installed in the rooms to receive warm air.

Heat distribution between rooms in a large house

However, it should be taken into account that the air leaving the furnace has a fairly high temperature; when passing pipes through partitions and ceilings, the conditions that are provided for the installation of chimneys must be observed. The photo below shows several wiring options.

Heat distribution from a common box

Galvanized or corrugated pipes are used for wiring.

Efficient heat distribution between rooms

Improving the stove design

Buleryan stone finishing

Very often, Buleryan is a design element, especially when it comes to a country house or a chalet-style house.

Brick screen for Buleryan stove

But if we are talking about a homemade device, its aesthetic parameters are of course inferior to products made in production.

Buleryan in the interior of a country house

The most successful way of decoration is to use brick or decorative stone.

Buleryan in the interior

To do this, it is not at all necessary to completely cover the stove with bricks; it will be enough to decorate the walls around the boiler or make a background wall-screen behind which the stove itself will be.

Decoration of the Buleryan stove

The photographs show interesting design options for our heater.

Buleryan boiler in a country house

Ready-to-purchase

Installing a buller in a heated room also has some features. Look at fig. On the left - the option is not entirely successful. And not only because it is necessary to chisel concrete floors, which requires a project with permission, load-bearing structures.

Options for installing a buller indoors

Firstly, to install a chimney passing through the attic and roof, you will need to collect a lot of paperwork in order to obtain permission from the fire department. And then also to comply with all fire safety requirements, which will not be easy or cheap.

Secondly, the condensate that settles from the flue gases of the buller (sludge condensate) has amazing physical and chemical properties. A special section will be devoted to them, but for now we note the following: although there are no separate sanitary rules for this substance, it is better for yourself to stay away from it. And in this case, the sludge condensate remains in the room.

The option on the right is good because you need to drill not into a concrete wall, but into a brick wall. It is, of course, also load-bearing, but it is loaded with less than the ceiling. Control authorities turn a blind eye to an opening in it up to 150 mm in diameter. And the standard diameter of the buller chimney is 100 mm. And getting a fire permit for an external chimney is much easier. And the sludge condensate will be outside.

In both cases, a foundation for the buleryan is not needed; a fireproof stand is sufficient. Other general conditions are as follows:

- The distance from a regular wall is at least 1000 mm.

- If the wall is covered with fire-resistant plaster (for example, vermiculite) with a layer of at least 25 mm, the buller can be moved 800 mm towards it.

- Within a radius of 1200 mm from the center of the firebox door there is a fire-resistant flooring, as for other stoves: steel from 1.5 mm on an asbestos cushion.

- The extension of the stand beyond the contour of the stove is at least 300 mm in all directions.

- If the buller is certified by the fire department for operation without a stand, is equipped with standard non-removable fireproof legs and a pocket-catcher in front of the ash pit door, you can place it without a stand directly on the floor, except for plank wood or plywood. You can use laminate or marmoleum.

Operating rules

A homemade long-burning boiler, Buleryan, has a simple structure, but to achieve better results in terms of efficiency and long service life, you must adhere to some simple rules:

- Only dry fuel is used for combustion: briquettes, pellets, firewood, wood chips, etc.

- After operating the stove, the ash should not be completely removed each time; its layer protects the bottom from burning.

- Do not use wet firewood; plaque forms on the walls of the boiler and chimney, which reduces the efficiency indicator.

- To achieve maximum efficiency indicators, you need to close the damper throttle and the blower door to enhance the convection process.

Who is the manufacturer

The patent for the manufacture of a long-burning wood stove belongs to the German organization “Bullerjan”. The company was the first to mass produce the product.

In the Russian Federation, the Laotherm organization manufactures stoves. Thanks to its design, the product quickly gained worldwide popularity.

Warming up of the air mass of the room is carried out in the shortest possible time. The furnace does not require the use of additional equipment, is easy to operate and repairable.

Bullers without pipes

Professor Innokenty Nikolaevich Butakov (not to be confused with Alexander Vladimirovich Butakov, also a professor, but a lawyer) actually invented the Buleryan back in the 20s of the last century, attaching an afterburner to the top of a potbelly stove with a heat shield. Nowadays, stoves such as “Butakov”, “Professor Butakov”, “Student” in modern design (see figure) successfully compete with Buleryans on the domestic market. Their technical characteristics and principle of operation are similar, like identical twins, but making “Butakov” yourself is much easier, as can be seen from the figure.

Convection oven Butakov