The roof is built in order to protect the house from precipitation, but it will not be able to perform this function if the smallest cracks and gaps between the roofing material and the adjacent elements are not eliminated. The outlet of the chimney pipe needs more careful sealing. Since the size of the hole in the slope is 2-5 centimeters larger than the diameter of the smoke exhaust channel, a gap is formed between them, through which water penetrates into the rafter frame. To prevent leaks, bitumen mastic, cement mortar and sealants are used, however, the effectiveness of these materials decreases over time. To solve the issue of insulating the joint between the pipe and the roof once and for all, experienced roofers advise installing Master Flash elastic penetration.

Device

The Master Flash penetration is a stepped pyramid on a rectangular base made of silicone or rubber. Each of the steps has a corresponding diameter, so it is used for waterproofing pipes of any diameter. The Master Flash penetration is put on through the head, moved to the base of the chimney outlet to the roof and secured to the surface of the slope using self-tapping screws. Manufacturers offer models made from two different materials:

- Made of rubber. Master Flash is made from ethylene-propylene rubber, which belongs to the class of synthetic elastomers, has high elasticity, flexibility, and a high degree of moisture protection. They are used for chimneys in which the gas temperature is not higher than 100-120 degrees, since this material melts and burns. EDPM rubber has a porous structure and has low resistance to chemical compounds that contain fat and mineral oils.

- Made from silicone. Master Flash made of silicone is used for chimney pipes whose operating temperature exceeds 120-130 degrees. They tolerate heating well up to 220-240 degrees. Therefore, they are used to isolate the smoke exhaust duct of devices operating on solid fuel. Silicone products do not tolerate direct sunlight well, so they last less. This type of passage isolation device is non-flammable.

Master Flash compactor device

Important! Manufacturers produce straight Master Flash penetrations, which are used for installation on flat roofs, and angular penetrations (30 and 45 degrees), intended for pitched roofs. When choosing a model for installation with your own hands, be guided by the slope of the slopes; if only straight lines are available, take a larger penetration.

Nuances when choosing a device

Depending on the installation location and type of structure, the type of penetration must be appropriate. Master Flash has provided products for every occasion.

For a chimney or other place where high temperatures are present, it is rational to purchase an accordion or sandwich type penetration. It is also necessary to take into account that the material is designed for temperatures that should not exceed 100 degrees. The equipment is available in grey, green, black and burgundy. The penetration will not lose color for a long time thanks to the production technology.

Corner and straight penetration designs are presented in a similar color scheme. They are flexible, absorb any vibrations and respond to pipe displacement (expansion or contraction). The device is also sensitive to movements of snow cover, which makes it possible to ensure tightness.

The cuffs of the penetrations are designed so that they can be mounted on any surface and at any angle of inclination.

Equipment

Using the Master Flash penetration is the simplest way to insulate the joint between the chimney and the roof. Its installation takes no more than 30 minutes, and it lasts at least 15 years. To do the installation yourself, you will need:

- Master Flash penetration of the appropriate size made of silicone or rubber. Choose a model based on the diameter of the chimney pipe and the temperature of the gases inside it. Pay attention to the base of the product: products with a metal-reinforced flange last longer, however, it provides a poor fit to textured roofing materials.

Corner penetration

Direct penetration - Plate. This term refers to a galvanized steel product that is placed over the penetration to protect from sunlight. Outwardly, it resembles a plate without a bottom; ready-made models are sold in hardware stores, but making such a device with your own hands from sheet steel is also quite simple.

Drawing of a decorative plate for decorating a passageway - Fasteners, sealant and screwdriver. If you do the installation yourself, you will need self-tapping screws with a press cap, a heat-resistant silicone-based sealant and a screwdriver.

Note! At each penetration stage, the corresponding pipe diameter is indicated. To prepare the Master Flash for installation with your own hands, you need to accurately determine the size of the chimney and cut the device according to the mark with ordinary scissors. Experienced roofers say that the hole in the flexible penetration should be 20% smaller than the pipe.

What is Master Flush

Master Flash ensures the sealing of the pipe.

The Master Flash penetration is a two-component product made of sheet metal and an elastic truncated cone. The base is an aluminum plate with a side of up to 80 cm. The top is made in the form of a straight pyramid with protrusions in height. The connection of the parts is made by soldering and is absolutely sealed.

The principle of operation of the Master Flash penetration is to simultaneously press the flexible part against the pipe, and the rigid part against the roof surface. The remaining cracks are sealed with a sealant, and the metal itself is tightly screwed to the flooring.

Advantages

Elastic products for sealing the passage of pipes through the roof have earned the trust of craftsmen and have become more popular than traditional methods of sealing gaps. Master Flash is optimal for DIY installation due to the following qualities:

- Tightness. It reliably protects the gap between the pipe and roofing materials from moisture penetration, preventing the possibility of leaks.

- Elasticity. Due to their flexibility, rubber penetrations tightly cover the pipe and fit tightly even to profiled roofing materials. These devices are suitable for roofs of any shape and slope.

- Versatility. It is suitable for roofs covered with corrugated sheets, metal tiles, roofing felt, slate and bitumen shingles.

- Easy to install. Do-it-yourself installation can be done in 10-15 minutes alone; even an inexperienced craftsman can do this work.

- Durability. Due to their resistance to temperature changes, chemical influences, and moisture, rubber penetrations have a long service life and do not require frequent replacement.

- Strength. Products made from high-quality rubber have a durable structure that is resistant to mechanical damage.

- High temperature resistance. The maximum permissible temperature at which silicone can be used to insulate a chimney meta-inlet is 220-240 degrees. This heat resistance allows Master Flash to be used for heating devices using any type of fuel.

Important! In some cases, the elasticity of Master Flush is the main advantage over other types of insulation. Only rubber and silicone penetrations have the ability to compensate for changes in the dimensions of the roofing material under the influence of thermal expansion.

Recommendations

- For flat roofs, any “master flush” with a wide, compacted base will do. But for corrugated sheeting, it is always better to choose something more flexible, with reinforcing elements around the perimeter of the fold due to the high edges of the sheet. A dense base will be more difficult to bend and therefore more difficult to ensure a seal.

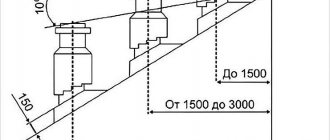

- For roofs with a slope of 45 degrees, a roof with a round or square flange is suitable. For roofs with a slope of 60 degrees, it is recommended to choose penetrations with an elastic base that are much larger in area for better installation.

- If there is no corner “master flush” on sale that corresponds to the angle of inclination of the roof slope, then you can purchase a straight one, but with a larger base area. Due to the flexibility of the material and the corrugation of the cone, the tilt will be invisible.

Terms of Use

Elastic rubber penetration Master Flash is the best option for waterproofing the gap where the chimney passes through the roof. However, it is not suitable for all cases. Professional roofers and manufacturers recommend using this device for DIY installation on the following types of smoke exhaust ducts:

- Sandwich chimneys. Between the two galvanized steel contours of these pipes there is a thermal insulating layer of basalt fiber. The insulation retains heat in the inner pipe, so the outer surface of the chimney remains cool. Rubber models are used to waterproof sandwich pipes.

- Stainless steel chimneys. Stainless steel chimneys that remove combustion products from solid fuel stoves are heated to high temperatures. Therefore, heat-resistant silicone penetrations are used to seal the target between the roof and the pipe. The use of conventional rubber models is possible if the chimney is connected to a condensing-type gas boiler.

Note! If you want to insulate the outlet of a bare pipe with Master Flash, you can use a special sleeve. A section of 50-100 cm is cut out of a pipe whose diameter is larger than that of the chimney. The section of the chimney passing through the roof is tightly wrapped with fireproof material, and then the sleeve is put on and secured with a steel clamp.

Blitz tips

- When choosing between cone materials - rubber or silicone, you need to roughly estimate the expected heating of the pipe. If this is a gas exhaust pipe, its heating in most cases is small, which means that a high-quality rubber seal will be quite sufficient. If this is a stove chimney in a bathhouse, then it is better to immediately install a silicone product.

- If you make a mistake while cutting the upper edge of the cone, which leads to it hanging on the pipe, you can wrap a bitumen seal around it, and if this is not enough, you can additionally install a metal sleeve.

Installation

Each passage of Master Flash is supplied with detailed instructions to facilitate DIY installation. Since the work is performed at height, you should follow safety precautions, use a safety rope and a helmet. Installation is performed as follows:

Instructions for installing the seal

- If a protective cap is placed on the pipe, it is removed. The top of the penetration is cut with a knife to the required diameter.

- Pull the device onto the pipe through the head. If the penetration is too slow, the pipe is treated with a soap solution, which makes the task easier.

- A heat-resistant silicone-based sealant is applied to the base of the penetration in an even, thick layer and pressed against the surface of the roofing material.

- Additionally, secure the base using self-tapping screws with a press cap. Do not overdo it with the number of screws, because when the sealant is washed off, water will begin to flow into the holes.

- If the installation takes place on a roof made of bitumen shingles, the upper part of the base is tucked under the covering elements.

- A decorative plate in the color of the roof is installed on the penetration.

Important! If, while cutting the penetration, you made a mistake and made a hole of a larger diameter or damaged the device, you can try to secure it to the pipes using sealant and a steel clamp.

General installation principles

To install the penetration, you will need a very small set of tools that every owner has:

- screwdriver;

- mallet;

- glue gun;

- self-tapping screws;

- sealant;

- marker;

- knife or scissors.

Since you will have to work at heights, while also being on an inclined surface, you need to think carefully about safety issues. Reliable insurance, a helmet, goggles and gloves are required. Fencing and warning signs should be placed below.

Installation of master flash on corrugated sheets:

- Try the plate on the roof. Draw its outline with a marker, taking 5-10 cm more in each direction.

- Prepare the surgical field. Remove debris, snow from the corrugated sheet covering, clean the surface from moss, mold, rust, and other foreign substances.

- Carry out a similar procedure with the exhaust duct. There should be no protruding parts on it. If there are sharp edges, they must be bent, cut off or ground off.

- Carry out control measurements. Mark the cut location on the pyramid. Once again, make sure that the calculation is correct and remove excess silicone.

- Remove the shipping film from the penetration. Clean the product from dust and crumbs.

- Lubricate the pipe with soapy water. Carefully place the cap on its head and slowly lower it with scrolling to the level of the coating. Press down the pyramid so that the plate presses on the flooring.

- Raise the base and install it in this position at a height of 40-50 cm from the surface.

- Apply a continuous layer of sealant inside the marked contour. Check that it is evenly distributed over the entire area.

- Place the plate in the lower position. If possible, insert its upper edge under the cladding. Starting from the center, press it into the hollows of the coating. If the metal gives in poorly, use a mallet.

- At intervals of 10 cm, attach the plate to the roofing material. Tighten tightly, but not so tightly that the sealant squeezes out from under it.

- Paint the penetration to match the color of the roof.

If the work is done correctly, the penetration will serve properly for at least 15 years, and its subsequent replacement will not cause much trouble.