The Slobozhanka stove with a long burning time is suitable for heating garages, utility rooms and buildings in summer cottages. It is also installed in greenhouses, workshops and storage rooms. This is a simple device that can be easily assembled yourself if you have some experience in carrying out such work and the appropriate tools and materials.

General view of the Slobozhanka stove

Laying firewood and ignition

In order to put firewood into the combustion chamber, it is necessary to lift the press from the outside by the pipe protruding from the stove. Make a bookmark and light the fuel on top. You can open the firebox door halfway. In this case, the open end of the 80 mm pipe must be closed, for example, with a small piece of steel sheet. The damper on the chimney opens completely.

In this position, the stove should operate on solid fuel for about twenty minutes so that it warms up well. When all the wood has burned out, it is necessary to remove the remaining fuel and ash from the firebox and make a new stack. This firewood is set on fire from above; for this you can use paper, cardboard, dry branches and other materials. As soon as the main fuel ignites, the press is lowered onto it, the firebox door is closed, the 80 mm pipe is opened, and the chimney pipe damper is closed halfway.

The firewood smolders, releasing pyrolysis gas, which, together with a small amount of smoke, passes into the gap between the edges of the press and the walls of the stove. In the second chamber, the gas is mixed with heated air, which enters through holes made in the 80 mm pipe. Through it, the bulk of the air enters the upper firebox, the minimum - into the smoldering zone of the firewood. The air is heated by passing through a pipe, which is located in the very heart of the flame obtained from the combustion of pyrolysis gases.

This is one of the simplest designs that you can quickly make with your own hands. For a heating system in a small house, this is the most acceptable option. Practice has shown that one bookmark is enough for 12 hours.

No. 1. Water heating system

The water heating system is organized in the garage by analogy with residential premises. The coolant is heated in the boiler, and then it passes through pipes and radiators, uniformly heating the entire garage room. After the heat supply stops, the pipes remain heated for another couple of hours. This is the main advantage of this system.

The main disadvantage is the complexity of the organization. In addition, the water in the heating circuit may freeze, so if the system will not be used in the coming days, it is better to drain the water. On the other hand, frequent water changes lead to rapid corrosion of pipes and radiators. To avoid this problem, it is better to use metal-plastic equipment. It is better not to use ordinary water in the heating system - it is replaced with antifreeze, a non-freezing coolant.

The complexity of the arrangement results in another drawback - the high price. The most economical way to heat a garage is to connect its circuit to a home boiler. The cost of general heating will increase, but it will still be cheaper than organizing an independent heating system.

If it is not possible to connect to your home system, you will have to install a separate boiler. It can run on different fuels. The following types of boilers are used in the garage heating system:

- An electric boiler is the easiest to install, extremely safe, but expensive to operate. Even if you are not worried about electricity bills, you should not use such boilers in areas with frequent power outages, power surges, or in regions with severe windy winters, because the wires may break, which will ultimately lead to freezing of the water in the system. If you do not manage to drain the water in time, the pipes may burst;

- gas boilers are used extremely rarely in garages, since not everywhere there is access to a gas pipeline. If the gas pipeline runs nearby, then you are very lucky - gas heating is inexpensive, and such systems are quite simple in terms of operation. The main thing is to follow safety precautions;

- boilers for liquid and solid fuel. You can choose a stove that runs on wood, coal, diesel or waste oil - it all depends on which resource is more accessible in your case. Solid fuel boilers require constant monitoring and frequent loading of fuel. Pyrolysis and pellet units are more convenient in this regard, but they are not cheap; the most economical option is a potbelly stove, which can also be used in a water heating system.

For all boilers, except electric ones, you will have to organize a chimney. In addition to the boiler, radiators, heating pipes and chimney pipes, you will need a circulation pump and an expansion tank. All this costs money, so using a hydronic heating system only makes sense in large garages. Often such heating is done at service stations and commercial auto repair shops. If the garage is small, then there is no point in organizing such a complex water heating system - this is an option for more or less spacious rooms where constant heating is required.

The operating principle of a water heating system is quite simple. The coolant heats up, passes through the pipes, gives off heat and returns to the boiler. The system can be one- or two-pipe. A single-pipe system is much easier to organize and cheaper; it is best suited for a small private garage. In this case, the heated coolant sequentially enters the radiators, i.e. in the first radiator the temperature will be higher than in the last, where the antifreeze reaches it already cooled down. The two-pipe system allows for more uniform heating, but much more materials will be needed.

Even if the garage is not attached to the house, but is located nearby, you can try to connect it to the home heating system, but there are limitations. The distance from the garage to the house should not be more than 20 m, and the pipes must be properly insulated.

The coolant is replaced every 5 years.

Performance characteristics

The Slobozhanka stove has the following characteristics:

- Long-term combustion, and therefore the heat supply, is ensured for six to twelve hours, everything directly depends on the type of solid fuel used. For example, well-compacted sawdust smolders for up to twelve hours, and needles or cones for about six hours;

- The efficiency is about 90%, which ensures the production of thermal energy up to 16.00 kW/hour;

- The furnace operates on various solid types of energy carriers of plant origin, and some models operate on waste oil;

- Heating time at full load is about 12 hours;

- Various combustion chamber volumes. If you use a metal barrel for the body, then 200 liters. That is, you can choose the volume of the combustion chamber that best suits the conditions for heating rooms with different functional purposes and area;

- High degree of fire safety due to the absence of open flame and soft combustion, smoldering of fuel. This allows the use of heating devices of this type in greenhouses (plants can grow half a meter from the stove).

Initial conditions

- The garage is generally visited twice a day or even less often. Therefore, the heating method we choose should be sufficiently autonomous and not require constant attention. Steel potbelly stoves can be eliminated immediately: after kindling, the room will cool down in a couple of hours.

- The room has a small volume. We have already mentioned the case of the garage-workshop; however, in most cases a moderate heat output is required.

The price of materials or a ready-made solution should not be prohibitive. Most car enthusiasts, you know, are not interested in investing in installing a geothermal heat pump in the garage.

Operation of long-burning furnaces

Heating using conventional stoves is being reborn. All this is due to the fact that long-burning stoves have appeared on the market. Their popularity is growing, and the fact is that with the help of these units you can obtain more thermal energy with lower fuel costs. The efficiency of these devices is 100%, plus there are fewer harmful exhausts that pollute the environment.

To understand how long-burning units differ from conventional heating stoves, you need to remember one school experiment. A match burns faster if its head is pointed downwards. At the same time, it releases a small amount of heat. If you hold a match vertically with the head up, it burns longer, the flame turns blue, and more thermal energy is released.

Why is this happening? The thing is that in this position the match burns out from the fire, which goes down, and does not tend to go up, which is much simpler. In addition, wood burns slowly, due to which it emits flammable gases called pyrolysis. They, in turn, rising towards the fire, burn, releasing a large amount of heat. So much for the double effect.

Hence the name of the furnaces that use this solid fuel combustion technology. The process itself is called pyrolysis.

General information

We all know how quickly wood burns in a stove, often not providing as much heat as desired. But in brick this process continues not only longer, but also with greater efficiency.

In most cases, this depends on the draft and the chimney, for which in the first it is increased, and in the second it is adjusted with a special damper. Then the heat “does not fly out into the chimney”, but accumulates on the chimney or the stove itself.

If there is not enough of it, it will become smoky and dull, and blue lights will run through it. In this case, the firewood will, of course, burn longer, but it will not be possible to achieve the required temperature in the firebox.

The name “long-burning stove” appeared due to the fact that heating devices changed their technical characteristics.

- have a powerful heating element that allows water or air heating of the greenhouse;

- do not depend on the gas supply system; firewood or wood products can be used as fuel for a long time;

- Efficiency is about 85%;

- ease of maintenance;

- efficiency.

The design of long-burning cast iron stoves differs from conventional ones, where the main “accumulator” of heat is red brick. Metal heats up faster, but also gives off heat. Therefore, in order to increase the heat transfer time, a conceptual decision was made - to reduce the combustion rate, for which the oxygen supply was reduced.

The photo shows the “Vologda” stove

Although the fuel in this case cannot give the same combustion temperature as in the traditional mode, it is enough to heat the metal walls to 60 - 70˚C, which corresponds to heating the surface of a conventional red brick stove after the end of the active firebox.

However, heat begins to radiate from the device after 30 minutes, and not after 1-1.5 hours. This parameter is the main trump card for manufacturers, which is based on the fact that you do not need to constantly monitor the stove; it is enough to throw firewood into it two or three times.

Homemade long-burning bubafon

Using a grinder, cut off the weld seam from the top end of the barrel and smooth out the sharp edges. The result is a cylinder and a lid with a finished flange. Using a hammer or sledgehammer, bend the edges of the cylinder inward. And bend the flange of the lid outward. Turn the cap over and place it on the cylinder. The lid will sit securely in place without slipping.

Using a chisel, cut a hole for the blower pipe in the center of the lid (so that it fits freely into the hole, it is enough to use a diameter of 102 mm).

Assembly diagram for “bubafoni”.

The hole for the plug on the lid can be sealed tightly, but it is better to leave it: by looking inside you can regulate the combustion process.

Then, at the top of the barrel, a place is marked for attaching a piece of the chimney pipe.

The intended hole is cut out and a piece of chimney pipe 20-25 cm long and 150 mm in diameter is welded. You can install a shut-off valve directly inside the pipe. The stove body is ready.

Next in line is the air supply device. For greater rigidity, the edges of the pancake are bent (so that the pancake does not curl from the heat). A hole is cut in the center of the pancake for the blower pipe, and it is welded. If a lid from another barrel is used for the pancake, then the hole for the cork is sealed tightly: during combustion, gases will pass only around the circumference of the pancake. Channels or corners are welded to the pancake from the bottom side. The air supply device is also ready.

It will be inserted inside the cylinder. An adjustment valve of the same diameter as the pipe is placed at the top of the blower pipe. A threaded pin is welded vertically to the inner wall of the pipe; a hole is drilled at the edge of the damper for this pin, ensuring that the damper mounted on the pin closes the pipe exactly.

After installing the damper, tighten it with the wing nut. By loosening the nut, moving the damper towards the edge of the pipe and tightening the nut back, it will be possible to regulate the flow of air into the firebox.

Place the lid on top and the entire stove is ready.

All that remains is to install the chimney pipe. Its diameter must be less than 150 mm, otherwise combustion products will not be completely removed. For good traction, it is better to have a pipe 5 m long. Install it near the stove, preferably on legs. Weld the bottom of the pipe hermetically.

Connect the stove end-to-end to the elbow, which is welded to the chimney pipe, tighten it with a clamp, placing fiberglass under it for tightness. To drain the condensate that collects in the pipe, a ball valve is welded under the pipe elbow (a rod can be used to clear the blockage).

This tap is absolutely necessary, since freezing of the condensate can cause the weld to rupture. Condensation, in addition, can flow into the stove, and through leaks in the connecting clamp - out.

Now you can now heat the “bubafonya” stove. After removing the cover, pull out the air supply device. Place the firewood - the height should not exceed the height of the lower edge of the chimney elbow. If you place firewood vertically, more will go in. You can choose large logs, up to 20 cm in diameter - they will burn without any problems.

A top layer of finely chopped wood chips is formed. Place a rag or paper on top and pour a little kerosene on it. Now the firewood is covered with a pancake of the air supply device, and the stove lid is strung on top. When opening the air damper, throw a piece of lit paper or rag inside the air supply pipe (matches quickly go out due to strong draft).

When the firewood flares up with a characteristic crackling sound, the blower damper is completely closed. Bubafonya can work in this mode without any supervision for days.

This long-burning wood stove produces little ash due to the fact that the wood burns almost completely. The ashes may not be removed for a long time.

As you can see, it is quite possible to construct “Bubafonya” stoves with your own hands. Many craftsmen make them not only from barrels, but also from old gas cylinders and large fire extinguishers. The main requirement for a future furnace is strong steel walls.

This is how you can make a long-burning stove.

Homemade long-burning stove

We will offer you one of the simplest models that you can make with your own hands. For heating a dacha or country house, this design is considered simply optimal. The production basis is the solid fuel model “Stropuva”.

This is a vertical cylindrical unit that can be constructed from a pipe with a diameter of 200 to 500 mm.

Let's start with preparing the materials:

- pipe 200-500 mm;

- pipe 100 mm;

- pipe 80 mm;

- steel sheet 4 mm thick;

- channel.

Tools

Please note that in order to make a long-burning stove, you must be a good welder. The amateur level is not suitable here. So, the necessary tools:

- electric welding machine;

- gas-burner;

- Bulgarian;

- hammer;

- tape measure and chalk.

Preparing parts

First of all, a large pipe is prepared. You need to make two holes in it with a cutter: one rectangular for storing firewood, the second on the other side at the top of the stove for a chimney with a diameter of 100 mm. At this stage, you can weld a 20-25 cm long pipe from a 100 mm pipe under the chimney to the round hole.

Three pancakes (circles) are cut out of a steel sheet: two with a diameter equal to the outer diameter of a large pipe, one 1 cm less than the inner diameter. A hole of 82-85 mm is made in the middle of one of the large pancakes. An 80 mm hole is made in a small pancake.

Making a press

The Stropuva design has one element called a press. It performs two functions: the first is a separating unit that divides the firebox into two parts, the second is that with its help oxygen is supplied to the combustion chamber where the wood is smoldering.

It is made from a small pancake to which an 80 mm pipe is welded. Its length should be enough to protrude beyond the stove body cover. In this pipe, closer to the pancake, holes with a diameter of 8-10 mm are made around the perimeter at a height of 20-25 cm.

On the reverse side, four channels are welded crosswise to the pancake

It is important here that they do not cover the hole. With their help, the weight of the press increases, plus their size creates a gap between the steel circle and the smoldering firewood

Oxygen will flow into this gap through a pipe (essentially telescopic) from above into the combustion zone.

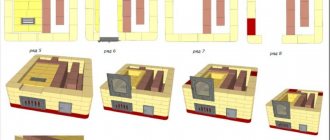

Furnace assembly

First, the lower blank pancake is welded to the stove body. Then a press is installed inside the unit with the pipe facing up. A large pancake with a hole is installed on top. It is simply put on the protruding 80 mm pipe and scalded along the edges of the stove body.

A door is hung on hinges, which can be made from a cut-out part. Only 20 mm corners are welded around the perimeter, and an asbestos cord or strip must be attached under them. This is done to seal the combustion chamber.

Now you need to install the heating unit in the place in the house where you plan to operate it. Connect the chimney and take it outside.

Please note that long-burning wood stoves of this type do not require a vertical chimney. It is better to install the first section horizontally with a slight angle of 3º

Modernization of a potbelly stove

Installing a potbelly stove in a garage will provide warmth and comfort. But the efficiency of this furnace can be increased by 10-15%. Here is a list of technical solutions:

- Installing a brick jacket on the back and sides - we have already talked about this. The thickness is half a brick;

- Installing a chimney with a long horizontal section - it will retain some of the heat escaping into the chimney. We put the stove in one corner, extend the chimney to the other, and then take it upstairs;

- We cover the walls with steel sheets - they will reflect infrared radiation back into the room;

- Installing a steel jacket around the stove - we surround the potbelly stove with steel sheets located at a distance of 40-50 mm from its walls. This solution forms a convector that forces air to circulate throughout the garage.

This is quite enough to “squeeze” the maximum thermal energy out of the stove. When installing a furnace to heat your garage, do not forget to take care of purchasing a fire extinguisher.

Hello! For heating, I purchased a Butakova stove, model student, power 9 kW

Because I’ve never encountered such stoves before and there’s not much space in the garage. The question arose: where is the best place to put it?

There are several options

1)

The first option immediately disappears because curtain, and the minimum distance to flammable materials should be 50 cm. But at the same time, the machine can be placed closer to the racks and ensure the maximum distance to the stove.

2)

The second option, according to the rule, with an indentation of 50 cm. But the stove will be located near the gas tank and I don’t like this, the distance between the stove and the car is 90 cm. Also, the wall with the gate is frozen with frost, when the firebox is fired it will all run away

3)

I'm leaning towards the third option. There is a closet in the corner, a very convenient place for it. Step back 50 cm from the cabinet and install the stove. The stove will be located relative to the car opposite the rear wheel or rear door, depending on how you stand. The chimney will be straight into the roof, and not like many do into the wall, so the location of the stove is free. Also, the stove will be located closer to the center of the garage, which will give more uniform heating. And the work area is near the racks; there is no point in heating the gates.

And another question: a stove can be heated for up to 8 hours on one stack. What should you do in the following situation, for example, you lit the stove, did everything, and the stove is still heating? You can’t leave it unattended; you don’t want to sit and wait for several hours until the firewood burns out.

Comments 57

Why can't it be left unattended? make a proper hood for it so that nothing falls off, and you can leave it, I have a Buleryan, I leave it in the minimum burning mode, although it is on the left hand, in the same place as your stove, only on the side of the “face” of the car

Great thing, this stove. Recently I had the opportunity to work in an ordinary metal garage, although I don’t know how and with what it was insulated, but the fact that it was insulated is exactly where such a stove was installed. The garage warmed up to a comfortable temperature very quickly)

what kind of stove? is there any information on it?

professor-butakov.ru/pb/Butakov’s stove an improved version of buleryan

In order not to wait 8 hours, you can bookmark less. In general, there is a gun for short-term work. Although manufacturers focus on the fire safety of their product...

The stove should be as close to the gate as possible, but because of the curtain, then option No. 2 will do, but I would advise putting some kind of screen between the machine and the stove. From my own experience, I have a homemade potbelly stove using option No. 1, and one day in severe frosts when I was heating the garage, I decided to lean on the rear left fender of the car and almost burned my hand. The car got very hot from the stove, and the body itself, the tire and rim, and the bumper... I think your stove has a much higher efficiency than mine, so I advise you to put at least a sheet of metal between it. The further the stove is from the gate, the worse it warms up garage. I originally had it at the back wall and it turns out that it’s hot at the back wall, but it’s cold coming from the gate.

Very often, a potbelly stove is used to heat a garage. Moreover, you can do it yourself, but you don’t need to spend money for it. It is enough to look in the bins for unnecessary metal parts.

Butakov stove

Convection ovens developed by Professor Butakov are widely represented on the market and can be used for heating greenhouses, although this option is also used quite rarely.

This heating equipment is produced by various manufacturers, including companies:

- Zubkevich is the developer of furnaces of this type;

- Termofor is one of the largest manufacturers, for which Zubkevich developed the model;

- Teplodar is a clone, although a very successful one;

- Convection.

Furnaces from different manufacturers have both their advantages and disadvantages. When purchasing, rely on expert recommendations and reviews.

The operating principle and functional purpose of this type of heating equipment fully corresponds to Buleryan stoves.

The stove body is a parallelepiped in which convective air pipes and a two-chamber firebox are located.

Also provided:

- ash pan;

- flap;

- chimney.

Slobozhanka

The stove was named after the historical area where it was “born.” It is a full-fledged heating device with a hob.

According to the principle of operation, the Slobozhanka is similar to the Bubafone, but the air flow here is from the side. Next, it is pulled into the perforated casing located inside the housing and rises up. In this case, the fuel takes in as much air as is required for smoldering, and the excess moves on.

The air in the slobozhanka enters all the fuel layers, so the pyrolysis process occurs more actively, and the furnace operates more efficiently.

General Tips

Construction of a furnace is a labor-intensive process with many nuances. Here are the main ones:

- if the foundation is poured in excessively hot weather, then it must be moistened from time to time so that the screed does not crack;

- the first row is laid out dry, so it needs to be formed from even bricks that can be tightly fitted to one another;

- to achieve the desired plane surface of the brick, it can be trimmed with a grinder;

- hewn or chipped bricks cannot be placed with the damaged surface inside the furnace, since on this side the material is less refractory;

- Any cast iron elements cannot be installed flush with the masonry, so that it does not collapse; make a layer of mortar or clay.

Baking in a summer kitchen is not only convenient, but also delicious. With a barbecue you can easily cook meat over coals, and a cauldron will help you prepare wonderful soups or porridges over a live fire. And it always adds piquancy to any dish.

Bubafonya

If the above-mentioned stoves that support long-term combustion must, in most cases, be purchased at specialized retail outlets, then the heating devices discussed below can be made independently, if you have the necessary materials, tools and skills, which reduces the cost of the equipment. In some cases, craftsmen can assemble both Buleryan and Butakova at home, on their knees, but this applies to extreme sports.

Therefore, greenhouses are heated in most cases with homemade stoves that support long-term combustion.

One type of such heating equipment is Bubafonya. At its core, it is a convection oven with a body made of a barrel or gas cylinder, into which various types of solid fuel are placed through the door. An ash pan is provided at the bottom. And smoldering is ensured by the fact that a metal pancake with its own weight exerts constant pressure on the burning wood or other type of fuel from above. Thanks to this, greenhouses on one tab can be heated for quite a long time.

Slobozhanka

Greenhouses can also be heated with such a type of convection ovens as Slobozhanka, which are also called “super potbelly stoves”.

This stove consists of:

- combustion chambers;

- air supply and distribution channel;

- convection shirt;

- additional elements (everything directly depends on the design features of a particular model).

The Slobozhanka stove can be purchased in specialized stores or assembled with your own hands; there is nothing complicated about it.

The main difference between this type of long-burning convection ovens is the upper system of ignition and combustion of fuel, and the supply of oxygen from below the firebox.

In this case, combustion can be:

- upper side;

- top center.

Let us highlight three main types of Slobozhanka stoves:

- with an L-shaped pipe for lateral oxygen supply into the combustion chamber;

- with air supply through the central part using a guide pitoid;

- with air supply from the lower side part.

Thus, regardless of the method of supplying air to the combustion chamber, the most efficient heat exchange is ensured.

We also note that installing Slobozhanka stoves in greenhouses is also beneficial for the reason that various materials can be used as fuel, from classic firewood to pine cones and needles.

As you can see, there are many long-burning stoves that differ in design features, functional purpose, cost and a number of other parameters. And we have listed only the main, but not all types of convection, gas-generating heating devices that can be used in greenhouses. The choice is yours, we only note that the long burning of fuel, which is provided by stoves of this type, allows you to maintain a certain temperature regime in greenhouses over a long period of time.

A little theory

The Slobozhanka stove, which provides long-term combustion, is a generalized concept; models differ in:

- the system and principle of air supply to the firebox;

- firebox size;

- the presence of a main and/or additional ignition unit.

A common feature for all models is the use of a top-type solid vegetable fuel combustion and ignition system.

Oxygen is supplied to the firebox from below, but as noted above, in different ways. There are three ways to supply air:

- using an L-shaped channel (pipe) to the bottom of the combustion chamber, a kind of upper lateral supply of oxygen from the side to the bottom of the firebox;

- from below directly in the center (a special pipe is used) up, that is, distribution also occurs from bottom to top;

- from the lower side part, while the walls of the stove warm up well.

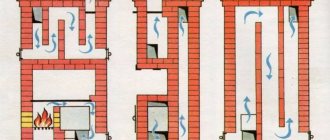

The Slobozhanka stove, in order to ensure long-term combustion, can have two basic principles of operation:

- lateral (the energy carrier burns from top to bottom of the firebox with a certain slope at a certain degree to the chimney);

- central (the energy carrier burns from top to bottom of the firebox with flame distribution to the sides of the firebox).

How it looks - look at the photo.

Greenhouse stove

Remember only one thing, no matter what design you choose to assemble the stove with your own hands using the presented drawings, the heat transfer, and therefore the efficiency, will be quite high and this is confirmed by reviews.

Long burning stove fireplace

Potbelly stove fireplace Expo

The fireplace attracts the appearance of an open fire, and many owners of country houses dream of having it in their living room. But some people think about the benefits of such a stove. The design of a classic English fireplace is based on the principle of long burning and allows the fire in the firebox to glow for a long time. But efficiency not exceeding 50% and low heat transfer are its significant disadvantages.

Important! Inside the firebox of an English fireplace there is a smoke tooth, which affects the internal circulation of air masses and flue gases. It does not allow the incoming air to escape upward, directing it to the log laying area

It does not allow the incoming air to escape upward, directing it to the log laying area.

Another option for a long-burning stove fireplace is the so-called Dutch oven. Before kindling, the ash pan is closed, and the firebox is loaded with firewood only a quarter of the way, without closing the door when burning. Most of the heated air will still fly out through the chimney into the street, but the effect of prolonged contemplation of the fire during the evening will remain indelible.

As a stove, the bubafonya is not ideal, but using the principles of its design, craftsmen have learned to create more advanced units that allow the fuel to burn out more slowly.

At the heart of the bubafoni there is a steel cylinder with incoming and outgoing pipes, as well as a “pancake” located inside in the form of an oppression with blades and an incoming air duct welded to it. As the fuel burns, the load gradually falls down under its own weight. The blades have a curved shape, thanks to which the gases scroll several times over the pancake until they burn out as much as possible.

The chimney for bubafoni is made to have an irregular cross-section so that the air that has not reacted with the fuel is not drawn out.

The fuel combustion process begins from the top layer, where air enters through the inlet pipe. The combustion zone then moves lower.

The disadvantage of bubafoni is its inability to work on coal and pellets, as well as its low efficiency. It will not be possible to add further portions of logs to it until the previous ones have completely decayed. And the top cover of the stove is not suitable for cooking, like that of a potbelly stove.

The second method or boiler No. 2

A pyrolysis boiler with a water heater, which does not require electricity or automation, works on the principle of counteracting the two laws of the square-cube. This refers to the laying of fuel and lining of fireclay bricks. Algorithm for the operation of a brick kiln:

At the beginning, the intensity of the pyrolysis process is ensured by the sublimation of the lightest volatiles. The “first heat” travels through the smoke circulation, being absorbed by the lining. At the stationary stage, the lining serves as a thermal buffer: when there is excess pyrolysis heat, it absorbs it and releases it when it cools. Upon completion of carbonization of the fuel, heat is gradually released by the lining, preventing the temperature from falling below the critical point.

Loading firewood or coal into a boiler with a heat buffer is done gradually. Sharp temperature fluctuations are contraindicated for her. If too sluggish fuel is used, it may stall. If it is too flammable, there is a risk of an emergency. If the first heat is not suppressed, the efficiency will not exceed 76-78%, since instantaneous heat transfer from the lining to the outside is excluded.

Bubafonya stove from a gas cylinder

Making a long-burning stove with your own hands from a fifty-liter gas cylinder is presented in the video.

The design of the stove is as simple as possible; it consists of only a few parts: a body, a lid, an air distributor and a chimney. For stability, the stove can be placed on legs from the corner. To remove ash from below, you can make an ash pan with a door.

Another video.

Sequencing

- The remaining gas is released from the gas cylinder and washed several times with water.

- Cut off the top of the cylinder. You can use it to make a furnace lid by making a hole with a diameter of 65 mm in the center. The edges of the lid and the furnace body are ground so that the lid fits tightly onto the body.

- In the upper part of the cylinder, a hole with a diameter of 100 mm is made for the chimney and a piece of pipe 30-40 cm long is welded horizontally.

- At the bottom of the cylinder, a cleaning door is made for the ash pan. To do this, cut out a rectangular section of the cylinder body, grind the sections, weld the hinges and install the door on the resulting hole. The door is equipped with a latch.

- The balloon is placed on legs for stability. They can be made from a corner, scraps of pipe or wheel rim. For ease of carrying, handles from a rod are welded on the sides.

- The most important part of the furnace is the air distributor. It must be heavy enough to effectively press down sawdust and wood chips, withstand the high temperature of the oven, and also have diverging blades. They can be made from corner scraps. The distributor itself is made of thick-walled steel - at least 6 mm. Cut out a circle with a diameter 20-40 mm smaller than the inner diameter of the oven with a hole in the center. A pipe with a diameter of 60 mm and a height greater than the height of the stove is installed in the hole. Air will flow through it to the combustion chamber. The blades are welded at the bottom of the disk.

- You can paint the stove body yourself with paint based on organosilicon compounds, having previously removed scale, rust and dirt from its surface. Any other paint will quickly burn, since the stove heats up to high temperatures during operation.

The temperature of the walls of a gas cylinder stove can heat up to 350 degrees during combustion! To avoid serious burns, use caution!

The homemade sawdust stove “Bubafonya” can be equipped with a water circuit. In this case, it is installed in a permanent place. Typically, this stove is used as a mobile stove: it can be placed in a greenhouse during freezing periods, used to heat a workshop or barn in the winter, or used to heat a garage. Subject to fire safety requirements, Bubafonya is safe and effective.

Operating principle

The Slobozhanka stove has the following operating principle. The fuel burns gradually, starting from the top layer and ending with the very bottom, that is, from top to bottom, and not from bottom to top, as in classic stoves.

The air heats up and transfers thermal energy to the walls of the housing, rises upward, warming up the chimney.

The degree of oxygen supply intensity, and therefore the temperature, the intensity of combustion (smoldering) is regulated by dampers, there can be several of them, it all depends on the design features of a particular model.

The combustion chamber has a “jacket” through which cold air is sucked in from below, heats up as it passes through, and when leaving the stove heats the room, ensuring continuous circulation of air masses. In most cases, the volume of heated air is regulated using a reflector cover, which also allows you to regulate the temperature in the room.

From theory to practice

So, let's move from theory to practice. Let's take a model with a central air supply to the combustion chamber.

We need to make an air supply and distribution channel. It is made from thick-walled pipe. Just take a piece of pipe along a length not exceeding the height of the combustion chamber. A bolt needs to be welded at the bottom. Then cut a piece of sheet steel with a diameter equal to the diameter of the pipe, drill a hole and secure it to the bolt using a nut. It turns out that the pipe in the lower part is closed by a coin that moves along the axis, and the intensity of oxygen supply to the firebox depends on how closed the section is, and therefore the nature of fuel combustion and the temperature in the room. Using an angle grinder, cut grooves in the pipe to supply air to the firebox with a width of at least 10.00 mm. It is also necessary to weld the circle. To do this, cut a “pancake” out of steel - a circle with a diameter smaller than the diameter of the combustion chamber; cut a hole in the center corresponding to the diameter of the pipe. All that remains is to put a circle on the pipe, 20-30 centimeters long, and weld it. Now let's move on to the body. You can use a gas cylinder, a barrel, or weld a sheet steel cylinder. In a cylinder or barrel it is necessary to cut off the top part, and in the cylinder the bottom must be welded; A hole for the chimney with a diameter of at least 100 mm is cut in the upper side part of the body to remove combustion products and a pipe of the appropriate diameter is welded; A hole is cut in the center of the bottom for installing a pipe made by us for supplying oxygen. The diameter of the hole is equal to the outer diameter of the pipe, which is installed as an air duct; Let's move on to making a heat-dissipating disk. Use sheet steel 10 mm thick. Cut a circle with a diameter slightly smaller than the diameter of the body; you can weld a handle from steel wire or fittings for convenience; Next we need to make a convection jacket (stove casing). To do this, take sheet steel and weld a cylinder with a diameter several centimeters larger than the diameter of the main body of the stove. It’s hard to imagine the Slobozhanka oven without a convection jacket; We connect the main body and the convection jacket. To do this, you can use solid or tubular type cylinders with heads. Make the holes using a drill. Then secure the heads to the rivets using a riveter; Making a cover for the main body

You can take the cut off top of a cylinder or the lid of a barrel and weld handles from rebar or large-diameter steel wire; Important condition. The stove must be located at least 25 centimeters above the floor level

This is necessary to ensure air circulation in the convection jacket. Therefore, do not forget to weld the legs, for example, from a corner of the appropriate length to the body.

As you can see, assembling the Slobozhanka stove yourself is not easy, but very simple. The only thing is, as noted above, heating devices of this type can differ significantly in design features, so adhere to the selected drawing and the general recommendations specified in our article.

Materials for making a long-burning stove

Long-burning stoves can be made by hand from sheet metal or various metal structures. Examples and drawings of such stoves are given below.

Barrel stove

A home-made heating device intended for heating utility rooms, made from a two-hundred-liter metal barrel. The stove runs on sawdust, shavings and other woodworking waste. Inside the large barrel, a small barrel for loading fuel is installed on a stand. Underneath is an ash pan - a drawer made of sheet metal.

The stove itself is placed on a stand, the role of which is played by a car disk. A smoke pipe is made from pipe scraps with a diameter of 100-150 mm. The barrel is equipped with a sheet metal lid with a handle and an opening for air supply.

A log sharpened to a cone is installed inside a small barrel; it is indicated in the drawing. Sawdust is poured around it. After compaction, the log is removed and the sawdust is set on fire. During the smoldering process, gas is released into the space of a large barrel, where it is burned.

Furnace with water circuit made of metal pipe

A homemade long-burning stove made of a metal pipe, which can burn wood or sawdust, is equipped with a water circuit.

Loading is done from below; to intensify combustion, an air distributor is installed inside the stove, pressing the smoldering wood. A telescopic hollow pipe is installed in the center of the disk, through which air flows directly into the combustion chamber, where, thanks to the ribs welded onto the disk, it is evenly distributed over the entire surface of the firewood. It lowers on its own as the fuel burns out. You can lift it before loading using a cable.

The loading door is located in the center of the oven. At the bottom there is a cleaning door and an ash pan. At the top there is a chimney. The stove is equipped with a water circuit with pipes for water inlet and outlet. Such a stove with a water circuit can heat small houses and other premises quite efficiently, and you can make it with your own hands from scrap materials.

Furnace from a waste gas cylinder

A stove can be made from a gas cylinder without extra costs or searching for suitable material. The dimensions of the 50-liter cylinder are perfect for making such a stove, and the wall thickness and tightness make it safe to use.

The design of the furnace as a whole does not differ from the previous model, this can be seen in the drawing. A propane tank with a cut off top is used as a body. You can make a lid of a suitable size from sheet metal with your own hands, with a hole for the air distributor pipe. Fuel is loaded through the top, filling the volume of the cylinder almost to the chimney. This stove operates on sawdust and other waste, as well as small firewood. The fuel is carefully compacted, ignited using wood chips or an ignition agent, an air distributor is installed, and then covered with a lid.

The efficiency of such a stove is quite high, and thanks to its sealed housing, it can be used to heat rooms where people stay for a long time. If desired, it can be equipped with a water circuit by passing the chimney through the boiler.

Types of fireplace stoves

The design discussed above is the simplest implementation of the idea of a fireplace-stove. In fact, there are much more efficient and functional structures that combine a separate fireplace and stove, install a hob, oven or heat exchange niches, etc.

Fireplace stove with bench

Fireplace stove with bench

A massive structure with a heated lounger or stove is not suitable for every home. For example, for a summer house it will be too big, since it will occupy a significant area of the room. If you install such a unit in a country house, you can achieve amazing comfort: such a design just begs to be installed in a living room combined with a kitchen.

Wall fireplace stove

A wall-mounted fireplace stove will save space in a small room

This design can be built in a small house to heat two adjacent rooms. As in the design discussed above, heating units can be heated separately. In this case, the fireplace can be used to quickly and comfortably heat a large room, while the heating of the back wall during operation of the stove will work to heat the bedroom. The disadvantage of this design can be considered the absence of a hob, which, however, is compensated by the compactness of the structure.

5220993d8a99101d96adbf2cb261e672.jpe

87e4199ded4b8661b2dd1e0235b55992.jpe 1e4d6cd87019e985f14ece023e868111.jpe 488eeeca13d0ce1bcbeb499f595cb697.jpe

Square fireplace stove with stove and oven

Multifunctional fireplace stove with stove and oven

A multifunctional heating device installed in a large room can divide it into several zones. On the side of the fireplace, you can create a cozy homely atmosphere for relaxing and gathering with friends, while the area adjacent to the stove can be used for cooking and other household needs. Fortunately, for this purpose the fireplace stove has a large hob and a spacious oven. The shelf above the fireplace can also be used to the maximum - it is convenient to dry fruits, mushrooms or medicinal plants on it.