Electric boilers can fail. Repair of boilers depends on their type and configuration.

Heating element and electrode devices have a similar structure, and therefore their repair is carried out almost the same way. Repair of induction boilers is different. The only exception is the repair of the induction coil.

The main reasons why the boiler does not turn off

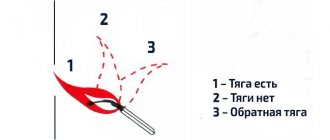

First you need to understand how automation works in modern boilers. Most models provide the following operating scheme:

- The user sets the desired temperature value on the thermostat.

- The system begins to heat up.

- The temperature sensor takes temperature readings all this time.

- When the set value is reached, the sensor sends a signal to the control board, which is responsible for turning off the boiler.

- When the temperature in the circuit decreases, this is also recorded by sensors and switches on again.

One of the most common reasons why an electric boiler does not turn off is a malfunction of the temperature sensor. Because of this, the system simply “does not understand” that the required temperature has been reached and the unit needs to be turned off. The boiler works constantly, and in this mode it not only consumes a lot of fuel, but also wears out.

Fixing the problem usually consists of four steps:

- sensor diagnostics;

- checking all connections, tightening the wiring if necessary;

- cleaning oxidized contacts;

- replacement of faulty components.

If the problem is not with the temperature sensors, we can talk about low temperature in the heating return pipe. There can be many reasons for this: poor-quality thermal insulation of the house, slow movement of the coolant along the circuit, etc. The result is the same - the coolant cools quickly, and the boiler constantly works to maintain the desired temperature.

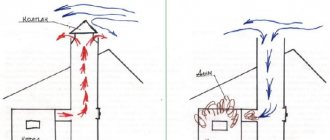

Very often the greatest heat loss occurs on the roof. You can tell that the roof has poor thermal insulation by the large number of icicles. The more there are, the worse the insulation.

The reason for cooling of the coolant is often its slow movement. Most often this is caused by the following factors:

- Filters are clogged.

Small debris, dirt, etc. gradually accumulate on the filter. It is enough to clean it thoroughly. Filters are usually cut off by shut-off valves, so you can turn off the water and clean them yourself without hassle. - Pump fault.

The pump may not operate correctly due to breakdown, improper installation and other reasons. But often owners themselves set the minimum operating speed. Sometimes the problem is solved by simply increasing the speed.

The third common reason why a gas boiler does not turn off for a long time is clogging of one of the heat exchangers. Due to such blockages, the turbine continues to operate continuously, constantly pumping liquid. At the same time, the pressure becomes weaker and the water heats up more slowly. Such phenomena are caused, for the most part, by the large volume of magnesium and potassium contained in ordinary tap water. Gradually they accumulate on the heat exchanger elements during heating.

In some models, you can clean the tubular radiator yourself. But there are some particularly complex ones (for example, bithermic ones), for the cleaning of which it is necessary to involve a specialist.

Other reasons why the boiler does not turn off

Sometimes the reasons are completely elementary, and solving the problem takes literally a couple of seconds. In addition to the above reasons for the incorrect operation of the boiler, we can add:

- Minimum value on the thermostat.

If this value is not enough to fully heat all the required power, the system will simply work continuously, consuming a lot of fuel, but not giving the desired result. To solve the problem, it is often enough just to increase the value on the thermostat. - The burner is not set correctly.

The problem often occurs with burners with flame modulation. You need to make sure that its power is sufficient for the required heating. If not, just increase this value. - The programmer on the outdoor thermostat does not work.

If problems are found, you may need to install a new programmer. But the decision to replace should be entrusted to an experienced expert. - The installation was initially carried out incorrectly.

Such situations are also not uncommon. Especially when installing it yourself or installing it by inexperienced specialists. It is necessary to at least check whether the strapping sequence according to the diagram is followed. If there are any defects or irregularities, this may well cause incorrect operation: the boiler will go out, not turn off, not reach the desired temperature, etc. - The electronic board is faulty.

The problem is not widespread, but if it occurs, you need to contact a specialist. He will carry out diagnostics, repairs, and, if necessary, replace the board with a new one. We do not recommend performing these manipulations on your own.

Why is the correct operation of the heating boiler so important?

In addition to the financial side, there is an even more important one - the health of the residents. It is believed that the recommended temperature for residential premises is 21 degrees Celsius. For the bedroom - 18 degrees.

When the temperature is above 24 degrees, a person becomes tired, weak, the skin becomes dry due to a lack of moisture in the room, and natural sweating is disrupted. Temperatures below 20 degrees increase the risk of exacerbation of chronic diseases, reduce resistance to ARVI, and increase blood pressure.

If you need any type of boiler installed or repaired, contact us. We will install, configure, check, and repair equipment efficiently and inexpensively. Contact the number or leave a request on the website.

If the boiler does not turn on

The cause of this problem may be the burnout of any electronic part: control panel, power control board, or failure of the heating element. Failure can be determined by assessing the operation of the indicator lights. For this:

- Turn on the boiler and set the desired coolant temperature. The water in the tank should be cold. Current should flow to the heating element, and the electric boiler operation indicator should light up. It is often connected to the same cable that leads to the heating element. This cable comes from the power control unit.

- Check to see if the indicator lights up. If it burns, then there is a problem with the heating element. If not, then there is a breakdown in the electronic part.

Most common faults

The most common malfunctions of electric boilers can be divided into two categories:

• Failure of heating elements.

• Failure of control and monitoring equipment.

When electric heating elements fail, it is necessary to replace the heating elements in the electric boiler in electric boilers of the heating element type, or to replace the electrodes in an electrode-type boiler. Below we will look at how to do this yourself.

If there is a problem with the control and monitoring system, you must first identify the faulty unit and either repair it or, if repair is impossible, replace it. If you do not have a special radio engineering education and the necessary circuit diagram, then it is better to contact a specialized workshop and entrust the repair to a specialist. Since without the necessary knowledge and skills it is impossible to make proper repairs and the consequences can be very disastrous.

Heat loss does not correspond to boiler power

Constant operation of the boiler may be due to insufficient power of the device. The coolant, having passed through the pipes, returns, and by this time, the water has not had time to heat up due to insufficient power. Therefore, the gas boiler does not turn off. The boiler power is selected based on a number of key parameters:

- area of heated premises and number of storeys of the building;

- climate features of the region;

- the materials from which the house is built, the quality of thermal insulation materials, the quality of seam sealing, window insulation, the number of chambers of window profiles, etc.

- the number and volume of all heating devices and pipe circuits installed in the system, additional buffer tanks, separators;

- temperature level that needs to be maintained.

It is best to entrust the calculation of boiler power to a professional or use special formulas or online calculators that allow you to determine the main characteristics of the boiler as accurately as possible, taking into account all parameters.

Often, a simple formula is used to calculate power, which is defined as 1 kilowatt of power per 10 square meters. m of heated room . In this case, several correction factors are used that take into account climatic conditions, the degree of thermal insulation of the house and other parameters. In addition to choosing the boiler itself, it is important to correctly select the remaining components of the system, pipes with the appropriate cross-section to ensure the required throughput.

Low gas pressure

Even if, according to factory specifications, the boiler has sufficient power, the device may not reach the required level to heat the coolant due to low gas pressure. The optimal pressure in a low-rise cottage is considered to be 1.5-2 atmospheres. For a high-rise building, 2-4 atmospheres is considered acceptable.

Blood pressure can drop for various reasons. One of the reasons is a decrease in pressure at the boiler inlet. If the system uses a pressure reducer, you need to adjust the device and increase the pressure using this device.

It is also necessary to check the settings on the gas valve. The pressure at the gas valve should not be lower than permissible according to the regulations. If the valve is set incorrectly, the boiler will not operate at full capacity. The valve adjustment is usually done by the boiler installer.

A clogged gas filter can also cause a drop in pressure. To check this factor, you need to unscrew the filter and, if necessary, clean it. Having completed all these procedures, the gas boiler should begin to turn off.

What is an electric boiler

An electric boiler is a special high-tech equipment designed for heating various types of premises. A distinctive feature of such a unit is the use of a special type of fuel - electrical energy. In many respects, the boiler is superior to equipment operating on other types of fuel: liquid, solid, gas.

Electrical equipment is considered the safest to use. But in order for it to function well, it is necessary to strictly follow the rules of its operation and perform timely technological maintenance.

Watch the video about the operating principle and design of the Protherm Skat electric boiler.

Device

Despite the wide variety of boilers with different operating principles, the design of all models is approximately the same. The main place in the structure is given to the heating element. Depending on the type of heater used and the principle of its operation, there are several types of boiler units.

All heating elements are located in heat exchangers, which are considered the main structural elements of the boiler unit. If they malfunction, heating of the coolant is impossible.

Depending on the design and manufacturer, the equipment may have different configurations.

- Electronic control unit. Regulates the temperature by turning the equipment on and off at the right time.

- Circulation pump (heat pump). It is a mandatory component of the system and maintains a stable speed of coolant movement in the circuit. It produces forced circulation of liquid and creates the necessary pressure in the system, while ensuring the most effective heat exchange and heating of the room.

- Expansion tank. Not all types of electric boilers with a pump are equipped with an expansion tank. Therefore, if you purchase equipment without a tank, you will need to purchase this part separately and install it by cutting it into the pipe heating circuit.

- Filters. They purify and remove various impurities from water.

- Safety valves. Protect the system from unwanted deviations in operation.

- Safety valve. Connected to the return pipe. Performs emergency water release when the pressure rises above the established norm.

- Pressure gauge. This device determines the pressure of liquids and gases inside the boiler and pipes of heating systems; it is necessary for monitoring.

- Thermal switch . Shuts down equipment when it overheats. Connected to a temperature sensor located at the top of the electric boiler.

- Automatic air valve. It is located above the heating tank and produces an emergency release of air from the tank in case of excess pressure.

Types of electric boilers

Depending on the operating principle of the heater, all electric boilers are divided into three types.

Electric heating elements

The principle of operation is based on simple electrical heating of elements that give off their heat to the liquid. Heating element – heating element. Water or other approved liquids are used as a coolant, in accordance with the operating instructions.

Induction

Their action is based on the principle of electromagnetic induction. The heating element is a coil, inside of which there is a pipeline filled with water. When an electric current passes through the coil under the influence of an electromagnetic field, the coolant heats up.

Ionic

The working element in such structures are electrodes placed in a special aqueous medium, where the process of heating the coolant occurs when alternating current passes through it.

A feature of the use of this type of boiler is the mandatory monitoring of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomenon of electrolysis and breakdown should not be allowed. Failure to comply with these requirements may result in equipment failure.

The liquid used cannot be used for domestic purposes. The heat carrier, which circulates through the pipes and enters the working tank of the boiler, comes into direct contact with the electric current. It is not recommended to carry out repair and commissioning work without the involvement of an experienced technician.

Types of electric boilers and their fundamental differences

Electric boilers differ in the type of working heating elements and are:

Electrode-type boilers for heating water use the property of water to conduct electric current, releasing heat. It is very simple to describe their basic structure: two electrodes are immersed in water and alternating current is passed through them.

Heating element boilers use a completely different principle. These electric boilers use special tubular electric heating elements (TEH) as a heating device.

Since these boilers have fundamental differences in the types of heating elements, the repair of electric boilers has significant differences.

Preventative measures and prevention of overheating

Measures to prevent and prevent emergency situations include the following:

- Install an additional circuit to cool a boiler that runs on solid fuel. In a double-circuit boiler, when the coolant increases, the liquid can be cooled due to the water supply system.

- Installing a buffer tank, it will prevent the boiler from boiling, take on excess temperature, and can also store heat for the heating circuit.

- You need to install an uninterruptible power supply. If there is a power outage, the uninterruptible power supply will automatically turn on, energy will come from the battery, and the system will continue to operate.

- Periodically clean the ventilation system.

Prevention and recommendations for use

- In order for an energy-saving electric heating boiler to serve for a long time, deposits must be periodically removed with a cleaning solution. Even if it is barely noticeable, it won’t get any worse.

- Turn the taps periodically, even when the boiler is not in use - this will prevent them from souring.

- Inspect all threaded connections for cracks. It is recommended to change ALL gaskets once a year.

Useful video on the topic:

Doesn't turn off

If the electric boiler does not turn off when it overheats, the problem is in the thermostat. It does not open the contact, although it reaches critical temperatures.

You can check this like this:

- Unsolder it from the board.

- Heat with a soldering iron or over a gas stove.

- Now test with a multimeter.

If the contact is still there, it is broken and needs to be replaced. Often the problem occurs with boilers for heating private houses .

They are much more powerful than apartment ones and the thermostat breaks down faster.

Makes noises

There will always be a slight background sound - this indicates normal operation of the pump. It’s bad when the noise becomes unnatural, loud and occurs after several years of using the boiler.

This indicates limescale deposits inside the heat exchanger. Treatment: washing with special solutions. If you can already hear a crackling sound, then it is unlikely that you can save the heat exchanger - only replace it.

Another thing is a violation of the connection diagram of the electric boiler to the heating system . It is possible that water is not flowing from the expansion tank and the pump is running idle.

By the way, this is also one of the answers to the question: “ why does the boiler turn off for no reason?”

The heat exchanger is clogged

During operation of the heating system, deposits of combustion products are formed in the heat exchanger, as well as solid salt deposits in the form of scale inside the combustion chamber. As a result, heat transfer is significantly reduced. In particularly advanced cases, a thick layer of scale is a poor conductor of heat; as a result, the flame does not heat the water to the required temperature.

There are several ways to completely clean the heat exchanger:

- electric discharge method “Streamer” is a complex procedure that allows you to clean the heat exchanger from an old layer of soot and soot without harming the walls of the chamber itself;

- hydrodynamic method using a high-pressure pump - an express method for slight contamination of the heat exchanger, which allows you to clean the chamber without removing it;

- chemical flushing with a booster is an option that allows you to remove old layers of soot and tar, but this method must be used carefully so as not to damage the walls of the heat exchanger;

- cationization method to remove scale inside the heat exchanger;

- "reverse osmosis" as a method of descaling;

- use table vinegar (3-10% acetic acid solution) in equal parts with water, the duration of exposure to combat scale is approximately 12 hours, after using the solution the heat exchanger must be rinsed with water.

Only some of these methods are available for cleaning the heat exchanger yourself. The first three methods of getting rid of soot and soot require special equipment and are carried out by specialists. After this procedure, the boiler will switch to normal operation and begin to turn off. Heating costs will also be reduced.

Thermostat is not installed where it should be

For proper operation of the boiler room, it is very important to adhere to the diagram for connecting the thermostat to the gas boiler. Using a thermostat provides a short delay after reaching the set temperature, which can significantly reduce the number of boiler starts and stops, save resources and reduce equipment wear.

To connect the thermostat to a boiler with a Dry Contact circuit, two conductors are connected, and the cable length should be no more than 50 meters. In this case, the thermostat should not be installed next to the boiler. It is also unacceptable to install a thermostat in an unheated room.

If the boiler does not heat the water

It does not heat the coolant due to failure of the heating element, provided that all other components and indicators are working. Repair of electric boilers is carried out as follows:

- Disconnect the device from the power supply, close the shut-off valves and drain the water from the boiler.

- Remove the housing of the electric heating boiler.

- If it is impossible to get to the heating element, other parts are dismantled.

- Unscrew the bolts that hold the heating element.

- They take out the heating element and put another one with the same characteristics in its place. At the same time, change the gasket.

- Fix the heating element with bolts.

- Install other components if they were removed.

Next, install the protective casing and check the functionality of the device.

Problems with the heating circuit

The pump must be selected according to the requirements of the heating circuit.

Malfunctions in the operating mode of the heating circuit are not always associated with a malfunction of the main heating element. If the boiler works, but does not heat the batteries, the reason must be sought in the wiring itself.

List of main heating circuit malfunctions:

- the filter on the return line or the needle tap (Maevsky tap) is clogged;

- insufficient power of the circulation pump;

- the rules for installing a heating circuit with natural circulation have not been followed.

Any of the above problems must be resolved before the start of the heating season. Otherwise, the room may be left without heat for several days, since the repair involves completely draining the coolant.

Noise in the middle of the tank

If the boiler is making noise, then you need to listen to the sounds.

- The noise is uniform and monotonous.

- The noise is uneven. Cods are heard.

If the boiler makes noise evenly and monotonously, then there are no problems with its operation. The source of noise is the heating of water. This noise can be weak, or it can be loud. It all depends on whether the heating system is open or closed. If it is open, the boiler makes louder noise. The reason is the presence of air in the coolant .

You can get rid of noise by converting an open system to a closed one.

When the boiler makes uneven noise and crackles are heard, this is a breakdown. The cause may be scale on the heating element. The high temperature of the heating element causes the scale to heat up, which is accompanied by increased noise. Uneven sound and crackling occurs due to the fact that the thickness of the scale in individual areas of the heating element is different. The noise is generated like this:

- First, thin deposits of limestone are heated. They don't make too much noise.

- Thicker deposits are then heated. They take longer to heat up. That's why they hum louder than fine deposits.

- The cracking sounds are very thick. This sound can also be created by plaque, which has begun to lag behind the heating element.

You can get rid of noise by regularly cleaning the heating element from scale.