What is the difference between heating pipes made of different materials? What are the features of connections and what else should you pay attention to when choosing?

The heating boiler has been selected and purchased, you can begin to supply heat to the house. But how to choose the right pipes for your heating system? The situation is approximately the same as with boilers: manufacturers praise their products, and in stores they try to sell what is more expensive. On the Internet, opinions vary even more.

There are no downright bad pipes. Each technology has its pros and cons, and the quality of the entire pipeline depends on the correct combination of pipe material and the method of their connection.

What is a harness and what is it made of?

The heating system has two main parts - the boiler and radiators or heated floors. What connects them and ensures safety is the harness. Depending on the type of installed boiler, different elements are used, therefore they usually consider separately the piping of solid fuel units without automation and automated (usually gas) boilers. They have different operating algorithms, the main ones being the ability to heat the boiler heater in the active combustion phase to high temperatures and the presence/absence of automation. This imposes a number of restrictions and additional requirements that must be met when piping a boiler running on solid fuel.

An example of a boiler piping - first there is copper, then there are polymer pipes

What should be in the harness

To ensure safe heating operation, the boiler piping must contain a number of devices. Must be:

- Pressure gauge. To control the pressure in the system.

- Automatic air vent. To bleed air trapped in the system so that plugs do not form and the movement of the coolant is not blocked.

- Emergency valve. To relieve excessive pressure (connected to the sewerage system as a certain amount of coolant is released).

- Expansion tank. Necessary to compensate for thermal expansion. In open-type systems, the tank is placed at the top point of the system and is a regular container. In closed heating systems (necessarily with a circulation pump), a membrane tank is installed. Installation location: in the return pipeline, in front of the boiler entrance. It can be inside a wall-mounted gas boiler or installed separately. When using the boiler to prepare water for domestic hot water, an expansion tank in this circuit is also required.

- Circulation pump. Mandatory for installation in systems with forced circulation. To increase heating efficiency, it can also be used in systems with natural circulation (gravity). Placed on the flow or return in front of the boiler before the first branch.

Approximate wiring diagram for a floor-standing boiler

Some of these devices are already installed under the casing of a gas wall-mounted boiler. The wiring of such a unit is very simple. In order not to complicate the system with a large number of outlets, the pressure gauge, air vent and emergency valve are assembled into one group. There is a special housing with three outlets. The corresponding devices are screwed onto it.

This is what a security group looks like

Install a safety group on the supply pipeline immediately at the boiler outlet. They are placed so that it is easy to control the pressure and you can manually release the pressure if necessary.

What pipes to use

Today, metal pipes are rarely used in heating systems. They are increasingly being replaced with polypropylene or metal-plastic. Piping a gas boiler or any other automated boiler (pellet, liquid fuel, electric) is possible immediately with these types of pipes.

A wall-mounted gas boiler can be connected with polypropylene pipes immediately from the boiler inlet

When connecting a solid fuel boiler, at least a meter of supply pipe cannot be made with a metal pipe and, best of all, a copper pipe. Then you can switch to metal-plastic or polypropylene. But this is not a guarantee that polypropylene will not collapse. It is best to provide additional protection against overheating (boiling) of the TT boiler.

Which polymer pipes are better? Polypropylene or metal-plastic? There is no clear answer. Polypropylene piping is good because of the reliability of the connections - properly welded pipes are a monolith. (Read how to connect polypropylene pipes here). But the maximum permissible temperature of the coolant in the system is not higher than 80-90°C (depending on the type of pipe). And then, prolonged exposure to high temperatures leads to rapid destruction of polypropylene - it becomes brittle. Therefore, piping the boiler with polypropylene is done only in low-temperature systems based on automated boilers.

If there is protection against overheating, the boiler piping can be made with polypropylene pipes

Metal-plastic has a higher operating temperature - up to 95°C, which is sufficient for most systems. They can also be used to piping a solid fuel boiler, but only if there is one of the systems for protecting against overheating of the coolant (discussed below). But metal-plastic pipes have two significant drawbacks: narrowing at the connection point (fitting design) and the need to regularly check the connections, as they leak over time. So, lining the boiler with metal-plastic is done under the condition that water is used as a coolant. Antifreeze liquids are more fluid, so it is better not to use compression fittings in such systems - they will still leak. Even if you replace the gaskets with chemically resistant ones.

What types of pipes can be used?

When carrying out installation work on a heating boiler, elements made of metals and polymers can be used. When choosing, you should pay attention to such characteristics as thermal insulation properties, ease of installation and operation, durability, and cost of products.

Based on the sum of these criteria, the following types of pipes are used to perform piping.

High-quality but expensive copper products

Copper piping is relatively rare, since such pipes are quite expensive and also require special skill during installation.

At the same time, structures made from this metal have a number of significant advantages, namely:

- good heat dissipation;

- resistance to corrosion and aggressive substances;

- resistance to freezing;

- high heat resistance.

Copper heats up quickly and well with a minimum amount of thermal energy, so parts made of this material will constantly generate heat during the transportation of the coolant.

Copper pipes can withstand significantly higher temperatures than plastic ones (up to +300°C), while they practically do not change in size. Hot coolant can also circulate in steel structures, but in this case the risk of corrosion increases

Pipes made of this metal can withstand environmental influences. Over time, they can only become covered with a thin layer of oxide, which does not affect the performance characteristics at all.

Unlike pipes made of steel or polymers, ductile copper structures do not burst when the coolant in them freezes.

The disadvantages of copper pipes for heating include the impossibility of using them to create closed structures in grooves, as well as the already mentioned high cost.

Budget steel products

Another common option is products made of steel.

Their advantages include:

- High strength , allowing you to easily tolerate mechanical loads.

- Low temperature coefficient of linear expansion , due to which the length of the parts remains unchanged even at high temperatures.

- High thermal conductivity , allowing efficient heat transfer.

The disadvantages, first of all, include the tendency to corrosion, which destroys the metal, which is why such elements need to be painted or coated with an anti-corrosion compound.

The disadvantage of steel elements is that they are difficult to install, requiring special equipment and professional skills. The manufacture of structures from such elements must be trusted to specialists

When choosing, it is better to give preference to stainless steel pipes: they are more expensive, but they demonstrate greater resistance to environmental influences and better performance characteristics.

Durable and lightweight polypropylene pipelines

Such products, made from modern types of plastics, have become widespread due to many positive aspects.

Main advantages:

- Affordable cost : prices for such products are much lower than for metal counterparts.

- A light weight. Such elements weigh very little, thanks to which you can save effort and money on their storage, transportation and installation.

- Easy to install . Plastic pipes are easily assembled into finished structures. With the help of a special soldering iron, even a non-specialist can quickly arrange the wiring.

- Coolant circulation rate . Polypropylene pipes, even if they have a complex shape, practically do not form blockages. This facilitates the flow of water, the speed of which remains unchanged throughout the entire service life (20-50 years).

- Good resistance to high pressure . This allows the use of plastic elements even under difficult operating conditions.

The main disadvantage of PPR pipes is their high coefficient of thermal expansion, due to which these products slightly increase in length when heated. To counteract this phenomenon, measures must be taken by installing compensators.

Polypropylene pipes allow you to create heating circuits of any degree of complexity. However, designs with a large number of elements make installation difficult and negatively affect the efficiency of the heating system

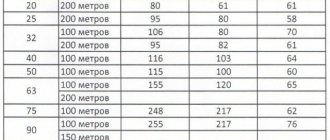

In addition, there are special pipe options, which include aluminum foil-reinforced products marked PN 25 - they can be used in systems with pressures up to 2.5 mPa and temperatures of +95°C, as well as reinforced PN 20 elements that allow operation in conditions temperature +80°C and pressure 2 MPa.

Gas boiler piping

Modern gas boilers have good automation that controls all parameters of the equipment’s operation: gas pressure, the presence of a flame on the burner, the pressure level and temperature of the coolant in the heating system. There is even automation that can adjust work to weather data. In addition, wall-mounted gas boilers in most cases contain such necessary devices as:

- safety group (pressure gauge, air bleed valve, emergency valve);

- expansion tank;

- circulation pump.

In wall-mounted gas boilers, an expansion membrane tank and a safety group are already installed

The parameters of all these devices are indicated in the technical data of gas boilers. When choosing a model, you need to pay attention to them and choose a model not only by power, but also by the volume of the expansion tank and the maximum volume of coolant.

Wiring diagram for a wall-mounted gas boiler

In the simplest case, the boiler piping contains only shut-off valves at the entrance to the boiler - so that repair work can be carried out if necessary. A dirt filter is also installed on the return pipeline coming from the heating system to remove possible contaminants. That's all the harness.

Heating system made of polypropylene pipes

The technical characteristics of the object and the amount of allocated funds affect the heating installation scheme. In apartments in multi-storey buildings it is connected to the Central Heating Network, and in private houses - with an individual boiler. Regardless of the type of object, the system can have one of three designs.

Single-pipe

The system is characterized by simple installation and quantity of materials. It uses one pipe for supply and return, which reduces the number of fittings and fasteners.

It represents one closed circuit with alternating vertical or horizontal placement of radiators. The second type is used specifically in private homes.

As the coolant passes through each radiator, its temperature decreases. Therefore, a single-pipe circuit is not able to heat the entire object evenly. There is also the difficulty of temperature control, since the heat loss factor is not taken into account.

If the radiators are not connected through valves, then when one battery is repaired, the heat supply is stopped throughout the entire facility. When installing such a network in a private house, an expansion tank is connected. It allows you to compensate for changes in pressure in the system.

A single-pipe circuit allows the installation of radiators with temperature controllers and thermostatic valves that allow for the correction of heat loss. Ball valves, valves and bypasses are also installed for repairing individual sections of the thermal circuit.

Two-pipe

The system consists of two circuits. One of them is for serving, and the second is for returning. Therefore, a larger number of pipes, shut-off valves, fittings, and consumables are installed. This increases installation time and budget.

The advantages of a 2-pipe network include:

- Uniform heat distribution throughout the entire facility.

- Minimal pressure loss.

- Possibility of installing a low power pump. Therefore, coolant circulation can occur by gravity.

- Repairing an individual radiator is possible without shutting down the entire system.

A 2-pipe system uses a passing or dead-end coolant flow pattern. In the first case, it is allowed to install batteries with the same heat output or radiators with different power, but with thermostatic valves.

The associated circuit is used if the thermal circuit is long. The dead-end option is used for short highways. When installing a 2-pipe network, it is necessary to install radiators with Mayevsky taps. Elements allow air to be released.

Solid fuel boiler piping

Any owner of a TT boiler knows that during the active combustion phase a lot of heat is released. Over time, experience comes - when and how exactly to close the damper, for what period of time, etc. But if you get a little distracted, the water in the system will overheat and may even boil. To prevent this phenomenon, the boiler piping without automation must contain several devices that prevent the system from boiling. Only in this case can wiring around the house be done with polymer pipes. Otherwise, sooner or later, the overheated coolant will soften the material, the pipes will burst with all the ensuing consequences. Therefore, piping a solid fuel boiler, in addition to the traditional elements - a safety group, an expansion tank and a circulation pump - contains a significant number of additional devices and usually requires quite a lot of money.

One of the simple schemes for piping a solid fuel boiler

The cyclical nature of the operation of solid fuel boilers leads not only to boiling of the system, but also to the fact that the house is either very hot (when the fuel is actively burning), or cold - when everything has burned out. To eliminate these phenomena, there is a solution: install an indirect heating boiler or a heat accumulator. Both are containers with water, they just perform different functions and, accordingly, are connected in different ways.

Connection with an indirect heating boiler

An indirect heating boiler heats water for domestic hot water and is connected on one side to the heating system, and on the other to the hot water distribution comb. In this way, temperature changes are mitigated and water is heated for technical needs. Not a bad decision.

Wiring diagram for a solid fuel boiler with an indirect heating boiler

How does this scheme work? If the water temperature in the water heater is lower than the set one, the boiler is connected to heating the water in the tank. During this time, the heating system is turned off and cools down a little. After heating the water to the required temperature, the boiler switches back to working with the heating circuit. When warm water is consumed, the temperature in the tank drops again, and heating is connected again.

It’s not difficult, but with such a scheme, overheating is still possible - the consumption of hot water does not always coincide with the phase of active fuel combustion. In this case, overheating is possible.

Circuit with heat accumulator

The second way is to install a heat accumulator. This is also a container with water, but it is connected only to the heating system. Serves to mitigate temperature changes in the system.

This method is more reliable, but requires the installation of several separate circuits. The boiler heats water in a heat accumulator - it is connected to the TA inputs. This is one closed loop. The second circuit is used for heating - from the outlet of the heat accumulator (in the upper part of the tank), hot water enters the heating system, and cooled water from the return pipeline enters the lower part of the same tank. If necessary, you can also connect a water heated floor system.

Piping diagram of a TT boiler with a heat accumulator

With this design, there is no sudden increase in temperature during active combustion, which is usual for a solid fuel boiler. This is because the volume of the tank is added, so there is practically no overheating of the water. Then, when the fuel has burned out and the house begins to cool down in a conventional system, the heat stored in the heating phase continues to be consumed in the system with TA. In this way, the temperature background is equalized and the time between fires increases.

This type of piping for a solid fuel boiler is more reliable and the wiring from the heater can be done with polypropylene pipes, but the circuit from the boiler to the tank must be made with metal pipes. In this case, you can use steel ones, but copper ones are still better.

TT boiler piping with overheating valve

The third way to protect a solid fuel boiler from overheating is to install an automatic overheating protection device. This is a special valve with a temperature sensor. The principle of operation is simple: when a certain temperature is exceeded (usually 95-97°C), the valve opens the inlet of cold water from the water supply, and releases excess superheated water into the sewer. This is how, for example, REGULUS DBV 1-02, Regulus BVTS 14480 works.

Single-circuit and double-circuit heating boiler.

A single-circuit boiler has a fairly simple operating principle. During installation, it is connected to the chimney. For the normal functioning of the system, the presence of normal natural draft is sufficient.

Often, single-circuit boilers are installed, which in their design have an open combustion chamber, which requires the creation of certain conditions in the room.

During its operation, the boiler uses air from the room. That is why it should be installed in a separate room. It is worth noting that when a single-circuit boiler operates, substances and gases harmful to the human body accumulate, this is the main reason for the need to equip a room with a boiler with a chimney or hood. If all the above conditions are created, the risk of explosion will be eliminated and will also ensure the safe use of the equipment.

A double-circuit heating boiler differs from a single-circuit analogue in its universal purpose: it maintains the degree of coolant in the heating circuit and heats water for domestic needs. Single-circuit generators can also indirectly heat water. The heat transfer process is carried out during the passage of the coolant through the secondary heat exchanger.

The main difference between a double-circuit boiler and a single-circuit boiler is the direct transfer of thermal energy to water. The main feature is that when hot water is consumed, the coolant is not subject to heating, and parallel operation of two circuits is excluded. Practice shows that the operating mode of the boiler is not important for houses with high-quality thermal insulation, it follows that with thermal inertia, the heating circuit will be the same for any type of heating. An impressive volume of hot water can be obtained by combining a single-circuit design and heating columns.

A double-circuit boiler should not be designed in combination with a natural circulation system, since after heating of the coolant stops, the movement of the liquid quickly stops. The secondary heating process takes quite a long time, and the heat in the radiator is distributed unevenly.

The main advantage of the scheme is the ability to operate in natural circulation mode. The booster of the collector in this case is a pipe through which the coolant moves to the upper filling.

What else is needed in the system

The boiler piping will be incomplete if it does not have a tap to drain and fill the system. And it is better if they are separate. The specific installation location depends on the structure of the system, but there are certain rules:

- The drain tap is installed at the lowest point. This is very important if the heating system needs to be preserved for the winter - it is necessary that as little coolant remains in it as possible. If the system will operate constantly in winter, a tap (with or without a pipe) is usually attached to one of the radiators. This will be the place where the system drains.

Such a valve for draining the system can be installed in any convenient place (on the return pipeline)

One of the options for installing a tap for filling the heating system

In some systems, the drain and fill of the system are made from one tap. This is possible if there is a pump that pumps the coolant and there is a pressure gauge by which you can control the pressure created. If there is a separate tap for filling the system at a high point, it can be filled by gravity.

Among the various materials used for the installation of water heating systems, pipes made of copper are of particular interest. In terms of technical characteristics, only stainless steel pipes can be compared with them, and even those are inferior in thermal conductivity. The purpose of this article is to determine all the pros and cons of copper pipelines, and also to consider all the ways in which copper pipes for heating are installed.

Selection of heating pipes

Having figured out which heating boiler will heat the water in your home, you can choose pipes for heating radiators and the system as a whole. Traditional materials for heating pipes:

- steel;

- copper;

- plastic.

Quite expensive and requiring the invitation of professionals for welding, steel or copper pipes are increasingly being replaced in practice by metal-plastic or polypropylene pipes.

Metal-plastic pipes

The connection and installation of metal-plastic pipes can be done using crimp and press fittings.

To make a connection using compression fittings and subsequent connection of heating pipes, you will need:

- spanners;

- flarer;

- springs for bending pipes.

The main disadvantages of connections on compression fittings are:

- their cost is quite high;

- fragility of rubber gaskets under high temperatures;

- periodic “downtime” of heating pipes in the summer, which also does not have a very favorable effect on the durability of rubber parts.

As a result, the need for preventive work to tighten joints may occur every five years or more often.

Rules for connecting metal-plastic pipes using a press fitting

A reliable, permanent connection with press fittings allows you to install heating with plastic pipes, hiding them directly in the walls. These pipes will last for many years without replacement if the temperature of the heating water flowing through them does not exceed 80°C.

The only disadvantage of using this type of connection is the need to purchase special equipment for installation

Polypropylene pipes

Recently, a leading place among suitable water and heat supply equipment has been occupied by a pipe for a heating boiler made of polypropylene. The use of polypropylene is due to the fact that it is very durable, is not afraid of system defrosting, and has a very affordable price.

Polypropylene pipes can be bent quite evenly (unlike metal-plastic). They will last quite a long time if all operating rules are observed.

Their only drawback is the need to use a special tool for welding.

There are the following features of connecting polypropylene pipes by welding:

- It is more convenient to weld polypropylene pipes together with a partner. The main condition for a high-quality connection of plastic pipes is the choice of the correct heating time, so as not to overheat them, and precise fixation, which does not allow shifts and displacements along the axis in the first few seconds after connecting the heated parts.

- Welding and installation of heating pipes is carried out at positive ambient temperatures - above +5 °C. When working in winter, it is necessary to create a “heat zone” where polypropylene pipes are welded.

To carry out high-quality work on soldering polypropylene pipes, it is necessary to comply with all the requirements of the instructions supplied with the device.

It would be a good idea to carry out several test welds on individual short sections of pipe using inexpensive couplings to gain at least some initial skill in handling the welding unit.

Advantages and disadvantages

It must be said that systems assembled from copper pipes are closest to the ideal, since they have numerous advantages with a minimum of disadvantages:

- corrosion resistance and durability;

- ability to withstand high temperatures. Copper will withstand environmental temperatures up to 300 ºС for a long time, although the maximum temperature in centralized heating systems does not exceed 115 ºС, and when we mean heating a private house, even less - 95 ºС;

- resistance to pressure drops and water hammer. In accordance with GOST R 52318–2005, a drawn copper pipe is destroyed at a short-term pressure of at least 220 MPa. Standard products are designed for a working pressure of 25 MPa (250 Bar). Similar technical characteristics of copper pipes allow them to be used in any heating systems;

- low weight compared to steel pipes;

- high thermal conductivity. An uninsulated copper pipeline passing through the room is also a heating device; this must be taken into account when selecting radiators and the number of sections must be smaller;

- solid and remarkable appearance;

- plastic. Thanks to this property of the material, copper pipes and fittings can withstand several defrost cycles.

A little about the shortcomings. You have to pay a lot of money for the high quality and reliability of copper systems, but they are worth it because they will last as long as the house itself costs. This material is suitable not only for installing radiator heating and heated floors; boiler piping with copper pipes is also considered one of the most durable.

Installation of expansion tank

When heated, the density of water changes and it expands. If there is not enough space for the coolant, pressure begins to increase, leading to an explosion. If there is a tank, excess coolant goes into it. This approach is a way out to maintain pressure stability. The size of the tank also matters.

Inexperience allows the wrong choice of expansion tank. It is worth keeping in mind that they differ in purpose and color. The heating system uses a red tank.

When connecting the system, you should create the required pressure in the tank - the factory parameters usually do not correspond to the norm.

Installation of copper pipes

The assembly of a heating circuit or boiler piping from copper pipes is made from straight sections and connecting parts - fittings. The latter are made of brass or copper, depending on the connection method. And these methods are like this:

- soldering of copper pipes;

- crimp connector;

- crimp press connection.

In turn, soldering joints can be performed using two methods: soft and hard solder. But, regardless of the chosen method, you must first make preparations. It consists of measuring a section of the required length, cutting the pipe itself and cleaning the joint before joining. It is recommended to cut the material with a special manual or mechanical pipe cutter; it allows you to maintain a clear 90º angle and leaves a minimal burr, and high-quality installation of heating from copper pipes depends on this.

The joint is cleaned with sandpaper to remove a thin film of copper oxide from the surface. The best option is to use soft sponges containing abrasive instead of sandpaper. Before cleaning, you need to remove the burr by removing a small chamfer from the inner surface. To do this, you can use a special device or an ordinary triangular-shaped shoe knife. When you plan to install copper pipes by soldering, you also need to clean the fitting from oxide.

Two-pipe circuit with horizontal wiring

It is also suitable for one-story houses. However, it can be implemented with your own hands in houses with an area greater than 100 square meters. m. The number of radiators may exceed 5.

Its features (they can be seen in different photos) are as follows:

- The supply line is either under the ceiling or runs under the windowsill. In the first case, there is no need to include an accelerating manifold in the pipe distribution, because the hot water is already at a high altitude. In the second option, such a collector is necessary.

- The coolant supply line and radiators are connected by vertical pipes. Depending on the design option, they can be long or very short.

- The return line is located below the floor. It is also connected to the battery by a separate pipe.

- Both lines are placed at an angle. The feeder is inclined towards the batteries, the second - towards the boiler.

How to solder copper pipes

To solder using the most popular method - using soft solder - you will need a gas torch or soldering iron, as well as a brush and flux. A layer of flux is applied to the cleaned joint from the outside with a brush, and the length of the section should correspond to the depth of immersion of the pipe into the fitting. It is recommended to measure it in advance and mark it with a marker. Like copper pipes for a heating system, the inner surface of the fitting is coated with flux, after which the parts are joined manually.

The next step is to warm up the interface with a gas torch or electric soldering iron. Here it is important to get to the point so that there is no overheating or underheating; an inexperienced installer will need preliminary training. Knowing when sufficient temperature has been reached is quite simple.

While working, you need to apply a solder wire to the surface of the pipe and at the moment when it starts to melt, start applying solder to the joint, moving the burner a little further. How to properly solder a heating system with copper pipes is shown in the video:

Features of operation and installation of pellet boilers

Although pellet boilers are classified as solid fuel equipment, they are an order of magnitude better than traditional units that burn wood or coal, because:

- dry pellets burn, giving off much more heat, which significantly increases the efficiency of the unit;

- during operation, a minimum amount of fuel combustion products is produced;

- loading pellets into the bunker is carried out much less frequently than when using firewood or coal.

This effect is achieved thanks to the special design of the equipment, as well as through the use of highly efficient pyrolysis combustion processes. An important point when operating a pellet boiler is the humidity of the fuel, which should be less than 20%. If this requirement is not met, the power of the equipment will subsequently decrease and condensed moisture will enter the system. And this can very soon lead to serious equipment breakdowns.

There are combined pellet boilers, which have two fireboxes: one for burning pellets, the other for conventional solid fuel. The efficiency of such units is somewhat lower than that of boilers that operate only on pellets, and the requirements for installation and piping remain quite high.

When installing a pellet boiler, it is necessary to install a hopper, a burner and a screw mechanism for feeding pellets. Experts often recommend using a special buffer tank, the volume of which can be 50 liters for each kW of pellet boiler power. All this significantly increases the size of the boiler room in which the equipment will be installed and connected.

Detachable and press connections

To make a press connection, you need a specialized tool - crimping pliers. They are available both manual and electric. After stripping the pipe and fitting, they are combined, pliers are applied to the joint from the outside and crimping is performed. The connection is considered permanent and quite reliable.

Detachable coupling is done following the example of metal-plastic pipes, since the principle of combining a brass fitting with a pipe is exactly the same. Accordingly, the cost of the connector is several times higher than that of a soldering fitting. But for installation you only need 2 wrenches. Details of the work are presented in the video:

Heating and water supply pipes

All instructions and standards state that the connections of water pipes and heating pipes with a gas boiler must also be rigid. This means that you can use any pipes to connect a gas boiler, and the connection of the heating and water supply pipes with the gas boiler is made through metal pipes.

The connection of pipes in the piping is carried out according to the standards of simple plumbing connections, namely:

- Metal threaded connections are made with sealing winding;

- Polypropylene pipes are connected using special welding;

- Polyethylene pipes are connected using compression fittings;

- Metal-plastic pipes are connected by collet joints or compression fittings;

- Copper pipe connections are soldered or connected with a collet.

Indirect water heaters

An indirect water heater will ensure stable and efficient operation of the entire heating system.

The wiring diagram for a solid fuel heating boiler using an indirect heating boiler is not the simplest, but not the most complex either. Here, consumers are faced with the task of ensuring the supply of hot coolant from the heating circuit to the coil. To do this, a hydraulic arrow is installed in the system, distributing flows into two or more directions. Two pipes extend from the arrow - one goes to the batteries, and the second to the boiler.

Two circulation pumps are installed behind the hydraulic switch - the complexity of the piping scheme gradually increases. One pump sends coolant to the radiators, and the second pumps it to the boiler. The operation of the second pump is regulated by a thermoregulation system built into the water heater. This ensures the maintenance of a stable temperature in the DHW circuit.

Using a three way valve

When creating a wiring diagram for a solid fuel boiler with your own hands, you should consider the need to install a three-way valve. A properly designed heating system should not show the greatest difference between the water temperature in the return and supply pipes - it usually fluctuates between 20-30 degrees. But sometimes this parameter goes beyond the norm, which causes the temperature in the “return” to drop.

It would seem that there is nothing wrong with this, since the solid fuel boiler will in any case bring the coolant to the set temperature. But in practice, this often leads to the formation of condensation, which causes corrosion. A three-way valve helps neutralize this phenomenon. It is installed between the supply and return pipes, mixing hotter coolant from the supply into the “return”.

As a result of mixing, the temperature in the heating return pipe rises, making condensation impossible. Together with the three-way valve, a temperature sensor is supplied that measures the return temperature. As soon as its temperature reaches normal, the addition of hot coolant will stop.

Please note that in this wiring diagram for a solid fuel boiler, the circulation pump should be located between the valve and the heating unit, and not somewhere else.

Boiler connection procedure

Connecting the boiler

The classic diagram for connecting the unit recommends adhering to two main indicators that can ensure the reliable functioning of the system as a whole and the heating installation in particular in the future.

The device is connected according to the diagram. The document indicates how to properly connect the product and what type of fuel will be most optimal. A schematic diagram of the connection is included with each product.

Unit safety features

The most important thing is to install a safety group right at the outlet of the supply pipe. In the future, the task of this group is to automatically relieve pressure if this indicator increases above the norm. This issue is regulated by a safety valve, as well as an automatic air duct and a pressure gauge. Any shut-off valve can be installed on the section of the air duct between the safety group and the boiler.

How the circuit works

The operation of the equipment is based on a standard algorithm:

- at the initial stage, the wood should flare up;

- the water begins to move in a small circle;

- when the temperature reaches 50-55 degrees, the thermal head presses on a special valve;

- the valve opens and gradually cold water enters the boiler, mixing with hot water.

- as mixing progresses, the temperature reaches a critical level, after which the valve opens completely, mixing the incoming water with hot water.

This procedure is the simplest and its installation can be done with your own hands.

Copper wiring

Another significant point is the location of the circular pump. It is best to place it exactly where it is indicated in the diagram - on the return line, in front of the boiler running on wood fuel. In general, the pump can be placed on the supply side, but when steam appears, the likelihood of a possible explosion from the accumulation of steam can increase significantly.

Schematic diagram of the strapping

Heating efficiency depends on the accuracy of the connection. The general wiring diagram for boilers of all types, including solid fuel and condensing types, is simple and looks like this:

- Boiler.

- Radiator.

- American nuts - for attaching the boiler to the heating system.

- Ball valves - to disconnect the boiler from the system.

- Filters for cleaning - protect against non-standard water fractions.

- Thermal heads, tees, Mayevsky taps

- Angles and tees.

- Valves: straight through, separating, air and safety.

- Expansion tanks.

- Heat meters.

- Pressure gauges, thermometers, hydraulic separators, circulation pump.

- Clamps and other fastening parts.

Disassembly type

Attic stairs are classified according to the method of disassembly. Let's consider the basic mechanisms.

Manual

Using a special cane mounted in the ceiling, the assembled structure is hooked onto a special hook and pulled towards itself. Often it is not necessary to apply much force to get the ladder into working position.

With drive

Electric ceiling products allow automatic extension of the stairs using a remote control.

Features of gas heating in the apartment

Before you begin dismantling the old heating system and purchasing the components of a new one, you should obtain permission to install a gas boiler for heating the apartment from the gas service, fire supervision and BTI. This is quite a troublesome matter and the applicant may be refused. Therefore, only after receiving all the necessary documents should you begin purchasing the unit and other elements of the system.

Choosing a gas boiler for an apartment

First, choose a gas unit. By the time official consent is received for the installation of this device, it is already determined which gas boiler to choose for heating the apartment, since for approval it is necessary to provide technical documentation for the proposed device.

For placement in an apartment, a wall-mounted unit with a closed combustion chamber is usually chosen. Depending on the need for hot water, choose a single-circuit or double-circuit device

It is also important to correctly calculate the required power of the unit in accordance with the area of the apartment, the degree of wall insulation, and the availability of hot water heating

If the owner wants to connect additional systems to the unit, for example, “warm floor”, then it is better to purchase a condensation model

It is able to work very economically at a coolant temperature of 50-60°C and produce an efficiency of 97-99%. Important! If the temperature of the coolant in the condensing unit heats up above 60°C, then it already operates with the efficiency of a convection boiler

Selection of radiators and pipes

Gas heating wiring can include both metal and plastic pipes. If the owner is going to install the heating system with his own hands, then a plastic pipeline is an easier option. Only a professional can install metal pipes.

There are several schemes for organizing a heating system. The most common and most suitable for apartments are single-pipe and two-pipe schemes. The first option is more economical, but if the pipe is clogged, the entire system will become worse at heating the apartment. For two-pipe heating it will be necessary to spend more material, but if a problem occurs in one pipe, the coolant will be able to circulate through the second. With a single-pipe version, a diagonal connection is ideal, then the coolant will be in contact with the inner surface of the radiators.

For one-room and two-room apartments of standard size, a single-pipe system is suitable, and for large living spaces, a two-pipe system is suitable.

When installing a heating system made of plastic, it is allowed to use only reinforced polypropylene pipes. Unlike conventional products, this material is not subject to corrosion and expansion from exposure to high temperatures. These types of pipes are reinforced with aluminum foil or fiberglass. Thanks to this, polypropylene products can withstand heating up to 70-90°C.

…Important! Antifreeze or water acts as a coolant for gas heating. When choosing a radiator, in stores you can find products made of cast iron, steel or bimetallic (mixtures of steel and aluminum)

It is the latter that have the best performance, so consumers often opt for such batteries. In this case, it is important to correctly calculate how many elements will be needed to heat each room.

What is it for?

To find out for what purposes a hydraulic arrow is used, you need to understand the operating principle of the simplest heating system with forced circulation of coolant.

The main components of the above diagram are:

- boiler;

- radiators or convectors that are placed on the same circuit (the number of heating devices may vary);

- pump - a device with which the coolant circulates through the main line.

In addition, the system includes other elements, for example, an expansion tank, but we will not focus on them, since they are not so important for explaining the principle of operation of the hydraulic gun. The scheme described above is suitable for a summer house or a small house, but if the building has a large area or several floors, then a more complex heating system using a collector circuit will be required. The scheme described above is suitable for a country house or a small house, but if the building has a large area or several floors, then a more complex heating system using a collector circuit will be required

The scheme described above is suitable for a summer house or a small house, but if the building has a large area or several floors, then a more complex heating system using a collector circuit will be required.

The diagram shows that the following devices are connected to the collector:

- Circuits with different numbers of heating radiators. There may be several contours and their length may also differ from each other (in diagram P).

- Systems of water heated floors, to which other temperature parameters of the coolant are presented. In addition, the length of heated floors is much longer than the contours, which increases the level of hydraulic resistance (in the STP diagram).

- Indirect heating boiler. The purpose of this equipment is to provide hot water supply. The boiler also has completely different requirements (in the Bgvs diagram).

You don’t need to be a specialist to understand that one pump cannot cope with all the components of an autonomous heating system, even if it is of sufficient power. It is worth considering that a pump that is too powerful will create increased pressure, and this will have a detrimental effect on the operation of an expensive boiler and will lead to a reduction in its service life.

The factor that each individual circuit differs in pressure and other technical characteristics is also taken into account. Therefore, using one pump, it is impossible to achieve coordinated operation of the system.

For the normal operation of several circuits, maximum precision in setting the pumps is necessary, but it is impossible to achieve such an effect. This is explained by the fact that quantities such as pressure, productivity and degree of heating are variable. There are many situations in which one circuit can affect the state of another. They can manifest themselves in different ways. For example, the pressure or temperature of the coolant changes sharply, but in any case, the effect will be negative. Such disorders will have a detrimental effect on both the operation of the pump and the condition of the boiler.

It is known that the manifold is responsible for the separation of hydraulic systems. But is it possible for the boiler circuits to be autonomous? This means that the boiler must supply a certain amount of coolant for each circuit, and the circuit, in turn, would receive a certain amount of liquid.

This task is quite realistic. To do this, it is necessary to select a small boiler circuit, which is done using a hydraulic distributor. That is, this element can change the direction of the coolant when required for the correct operation of the heating system.

Placement of the system and its individual elements

The boiler is the main element of the heating system. Its design has a significant impact on the strapping device.

Wiring diagram for a floor-standing gas boiler

The piping scheme for a floor-standing gas boiler should be created so that the heat generator is installed on the floor or at a small height, but not at the highest point of the pipe distribution. Otherwise, air pockets will accumulate inside the boiler.

When using a boiler that does not have air exhaust, the supply line should be positioned strictly vertically. The presence of air exhaust can be determined by the pipes located at the bottom of the installation. The supply line and return pipe are connected to them. Typically, such pipes are found in gas and electric equipment placed on the wall. This structural feature must be taken into account when creating a piping scheme for a wall-mounted boiler - the ability to independently remove accumulated air greatly simplifies the operation of the device.

In some cases, the boiler is sold without additional accessories. In this option, the necessary devices must be purchased separately.

When purchasing, you should pay attention to the compatibility of devices and purchase the necessary adapters. Additional devices are often not required when the system has natural circulation

Water guns and collectors

The use of hydraulic arrows and manifolds in the piping schemes of solid fuel boilers makes it possible to ensure the supply of coolant in several directions - to radiators, heated floors, heated towel rails and boilers. The collectors distribute the coolant evenly, at each outlet it has the same temperature. Next, the coolant is picked up by circulation pumps and carried away in the required direction.

Water arrows allow you to distribute the coolant by temperature. If there are two collectors in the heating system (one is placed on the supply pipe, and the second on the return pipe), then the hydraulic arrow is installed alone and connected to two pipes at once. Inserts are made in it to allow coolant to be taken in at different temperatures - for example, heated floors do not need too high a temperature, so it can be taken closer to the return pipe.

Using long-burning boilers

To avoid frequent loading of the firebox and increase the interval between them to 12-18 hours, you can use boilers for heating with long-burning wood. They work on the principle of burning wood “from top to bottom”, using natural draft or forced air injection. The dimensions of the chamber make it possible to load a large amount of firewood into it, and the burning method will increase the operating time so much that loading will need to be done a couple of times a day.

The design features of such heating installations do not allow logs to be thrown into the firebox until the entire previous portion is completely burned. And it’s not a fact that this will happen during the day and not at night. In the latter case, there will be no one to load a new portion, which means that the backup of an electric boiler will not hurt in any case. Therefore, following the previous recommendations, a long-burning wood-burning boiler must be connected in parallel with an electric one. Due to the long burning of a solid fuel boiler, its electric assistant will turn on quite rarely, this will provide additional electricity savings.

Advantages of the polypropylene option

Polypropylene is widely used for the manufacture of strapping, which is explained by its significant advantages, such as:

- Easy to install - all you need is a special soldering iron and a supply of keys.

- Speed of work - the wiring of the heating system of the entire house is completed in 1–7 days.

- Resistance to heat - ensured by a layer of thermal fiber, which creates a kind of frame and protects the pipe from expansion during the passage of coolant.

- Minimum thermal conductivity, as a result of which the heat supplied from the boiler to the radiator is not lost.

- Resistance to deposits - due to the smoothness of the inner surface of the pipes, which is also responsible for the rapid circulation of the coolant.

- Long service life of 40 years. The material can withstand pressure up to 25 atmospheres.