Water heated floors are gaining popularity every year. The most important part of this design is the pipes. Today, the construction market offers a large number of pipes for heating water floor systems from different manufacturers. Therefore, in all this diversity it is difficult to choose the right contour for a warm floor.

This article will reveal all the pros and cons of each type. This will help you understand the features of the products and purchase a high-quality pipe at an affordable price for laying a heated floor in a “pie” in a private house or apartment.

Characteristics of pipes for water heated floors

The construction of a water heated floor is a complex and time-consuming process, especially when using a concrete screed and the need to reinforce the structure. Therefore, great demands are placed on the pipes that are planned to be laid in the “pie”.

Important! The use of standard PVC water pipes is prohibited.

Since they cannot withstand high loads that are formed due to high temperatures and pressure created in the pipeline.

The main requirement for a pipeline in a warm water floor, both in a private house and in an apartment, is durability and tightness. It is necessary that during a sharp temperature change the system does not depressurize.

After all, if there is a screed, it is difficult to find and eliminate the defect. In addition, it must withstand the effects of aggressive chemical compounds found in the coolant and mechanical loads. The elasticity of the contour is of no small importance - it should bend easily.

We should not forget about the level of thermal conductivity when choosing a coil for water-type underfloor heating; the higher this coefficient, the more efficiently the device works. And also, regarding the degree of expansion when heated, up to 0.25 mm/mK is considered acceptable.

Pipes are produced in coils with a certain footage. When purchasing, remember that the loops must be solid, without joints.

For your information! The pipeline for heated water floors must be marked to permit their use in heated floors.

Metal-plastic pipes

Metal-plastic meets many of the requirements for pipes described earlier.

This material:

- flexible and therefore the minimum bending radius is 8 diameters;

- it does not need to be heated during installation;

- elastic;

- has a low oxygen permeability.

The only drawback of metal-plastic is its service life, which does not exceed 30 years. There are also a considerable number of fakes on sale. The demand for metal-plastic pipes is explained by the convenient form of their production - they are sold in coils 25–50 meters long. Many companies accept orders for the manufacture of longer products.

Metal-plastic pipes with a diameter of 16 or 20 millimeters are used. Experts do not recommend installing heated floors from products with a different cross-sectional size. High-quality and branded metal-plastic pipe products are expensive, and their service life does not meet the needs of consumers. But the whole system turns out to be not too expensive, since in this case they try not to use fittings due to the high prices for them, but rather lay long sections of pipes, the cost of which is affordable for many property owners.

The best metal-plastic products for heated floors are those in which the foil layer is butt welded. Despite the fact that such pipes are expensive, they are more reliable. They are manufactured mainly in European countries, since this requires high-tech equipment.

Which pipes are suitable for heated floors?

Contours are made from various materials, the strength and cost are affected by its features and characteristics. Each model has positive and negative sides.

Polymer

Polymer is a common material; several types of pipes for water heating floors are made from it. It is chemically neutral, which makes it more resistant to high temperatures, up to +95 degrees.

For your information! Polymer pipes that are intended for installation in water-heated floors are marked PN 10. If available, the maximum temperature for such a pipeline is 55 degrees.

There are several types of polymer pipes:

- Cross-linked polyethylene is a new type of polyethylene in which the molecules are interconnected by cross-links. As a result, the material is obtained with a stable structure and improved quality characteristics.

Let's look at its properties:

- not subject to corrosion and chemicals;

- elastic - pipes made from it are flexible and can be easily bent at any angle, without the use of special equipment;

- has increased resistance to sudden temperature changes;

- The product has a small roughness coefficient inside - this reduces hydraulic resistance.

For your information! A coil made of cross-linked polyethylene has a structural memory - when heated, the product takes on its original shape.

This pipeline is available in several types, depending on the cross-linking technology:

- PEX-a - peroxide cross-linking, polyethylene is heated under high pressure in the presence of peroxides, the resulting material is strong and elastic, it can withstand heating up to 95 degrees;

- PEX-b - cross-linking is carried out using silane technology, polyethylene is exposed to chemicals, most often silane, which imparts resistance to oxidation and makes it rigid;

- PEX-c - the finished product is irradiated with electrons, little used on the Russian market;

- PEX-d is nitrogen-based; the production process of this type is complex, so it is not widespread.

All types of PEX pipes can be used for underfloor heating systems. However, PEX-b and PEX-c are more popular, as they are more elastic and have a small bending angle. PEX-a has a high degree of cross-linking, so installation requires special equipment. In addition, this model costs much more than its analogues.

- Polyethylene with increased heat resistance PE-RT is a modified type, the main component is octene. The difference between this material and PEX pipes is that it is seamless, there is no need to additionally stitch it, since the structure has a stable molecular lattice.

A device with a PE-RT coil operates silently, even when coolant passes through it under high pressure. Able to withstand high negative temperatures. The service life of heat-resistant polyethylene is several decades.

This PE tolerates high temperatures and high pressure well, but not for a long time. In addition, it is not able to withstand aggressive substances and does not have structural memory.

However, PE-RT increasingly fits into the “pie” of a heated water floor, due to its affordability.

- Polypropylene - have a lot of advantages and are intended for water supply systems and radiator heating. But they cannot be used in heated floors, since they have:

- short length - not enough for floor hinges;

- poor ductility - almost impossible to bend at the desired angle;

- low thermal conductivity - it is difficult to ensure the necessary heat exchange between the circuit and the floor surface.

- Copper - not used often. Firstly, the cost of copper pipes for heated floors is much higher than other models. And secondly, laying a copper pipeline is a rather complex process, and it cannot be done without specialized equipment and strict adherence to technological rules. That is, you won’t be able to make a water floor yourself from these pipes.

In addition, they are subject to thermal expansion, even reinforced ones - when pouring screed, the pipes will experience increased internal pressure, which will affect their durability.

Therefore, despite the low price of polypropylene pipes, it is not recommended to install them in the construction of warm water floors, but if you still decide to install using polypropylene materials, read the article on the best way to install them.

Metal

Metal pipes are produced:

However, it is worth noting that copper coils have ideal characteristics for placement in the “pie” of a water-heated floor. Since, copper:

- excellent heat conductor - will provide high heat transfer;

- durable and not subject to corrosion;

- plastic - if the technology is followed correctly, the bending radius can be minimal;

- has high mechanical strength and is not afraid of high temperatures.

For your information! Many manufacturers cover the top of the product with a polymer film, which protects it from the aggressive effects of chemicals contained in the concrete screed solution.

- Corrugated stainless steel - this type appeared on the market recently, but has already proven itself on the positive side. Since the pipes are made of stainless metal, they are not subject to corrosion. In addition, they are equipped with an additional protective polymer coating.

It is worth noting the good flexibility of the pipeline and the ability to hold the laid bend, which is important when laying a complex circuit. In addition, due to the flexibility of the product, contour fracture is completely eliminated.

It is impossible not to mention the resistance of corrugated pipes to various types of influence: mechanical, temperature and chemical.

Pipes are produced in coils, 30 or 50 meters long. This is not always enough to make a complete loop. However, the method of connecting these pipes with fittings is so perfect that the nodes can be placed under the screed. This is the only type of pipeline whose joining areas are allowed to be filled with concrete.

The price for this model is quite high, which is why laying corrugation in heated floors is not popular.

For your information! VGP steel pipes should absolutely not be used when installing warm water floors.

Metal-plastic

The metal-plastic pipeline is all-welded, connected by laser or ultrasound. This type is often used in underfloor heating designs. One of the reasons is the excellent flexibility of plastic; it is easy to bend even without heating. It is durable, resistant to temperature changes and environmentally friendly.

The product goes on sale in bottles up to 50 meters, this allows you to lay solid loops in small rooms. For large areas, the bottles are supplied with a contour of up to 90 meters.

A plastic pipeline with a metal layer is a multilayer structure and consists of:

- inner layer - cross-linked polyethylene;

- metallized - aluminum foil of different thicknesses;

- external - a thin polymer coating to protect against mechanical damage.

For your information! This metallized design does not allow the formation of corrosion, since the inside surface is smooth, which does not contribute to deposits and reduces hydraulic resistance.

A variety of connecting fittings for metal-plastic pipes makes installation easy and quick. And if you follow the rules during installation and operation, the product will last more than 50 years.

Another advantage of metal-plastic products is their high thermal conductivity, in comparison with a hose made of cross-linked polyethylene, which allows you to quickly warm up the surface. The disadvantage is the possibility of the pipeline being broken, in which case it will be necessary to remove this section of the product, since there is no ability to restore its shape.

Top 5 articles

- Review of the cost of heated floors per m2, installation cost

- DIY installation of electric and water heated floors

- Which heated floor is better

- What flooring can be used for heated floors?!

- How much does underfloor heating cost per month?

Like and thank the author for his work!

- Popular

- Bestsellers

Film heated floor Hi Heat Standard 305/308/310

134.00 UAH.

Hemstedt single core heating cable

59.00 UAH

Single-core floor heating cable Therm EKO

37.00 UAH

DEVI Single Core Heating Cable

65.00 UAH

Perforated film Monocrystal

195.00 UAH.

Strip heating film Heat Plus

139.00 UAH.

DEVI floor heating mat

874.00 UAH.

DEVI Single Core Heating Cable

65.00 UAH

Heated floor pipe 14, 16, 17, 20 diameters, which one to choose

When faced with the question of choosing a pipe for a heated floor, the consumer comes across information about its different sizes; today on the market you can see pipes of 10, 12, 14, 16, 17, 18, 20 diameters. Which one is best suited for heated floors?

Find out which pipe is the best for water heated floors.

In our personal practice, we can confidently say that a 16 mm hose is better suited for heated floors in the home.

REMIND that the color of the pipe does not matter

It is not for nothing that it has won the largest market share, because as practice has shown, this particular size has the best heat transfer and works perfectly with standard manifolds and a pump. Such a pipe has a water volume of 110 g 1 p/meter, which has the most favorable effect on the hydraulic pressure in the system. Size 10, 12, 14

diameter is generally not used in heated floors, in most cases due to the small size, the hydraulic pressure is large, so even to make, for example, a room of 20 or 30 square meters, several 4-5-6 circuits will be needed, and this is a lot for such a small room.

The correct installation step in water and electric heated floors

Basically, diameter 14 is used in warm wall systems or in any other systems where a large heating area is not always needed. We repeat - the most favorable pipe has a diameter of 16, the wall should be 2 mm. Pipes of 17 diameter are also very popular.

, but this is a non-standard size, often manufactured by separate companies, brands have a fairly high price, which is why they are not profitable.

Pipes 18

The diameter for underfloor heating is generally considered to be too large and they are something between elements for home use and industrial pipes and do not fit either way. A pipe of 20 diameter already has a significantly larger volume of water in itself than a sixteenth diameter; the volume of a 20 mm pipe contains about 180 ml of water per 1 linear meter, which creates a greater load on the pump; the heat transfer of such a tube is, of course, higher.

Such a pipe

requires a wider laying step - 25 cm and a larger layer of screed.

That is, laying a 20 mm

step should be 25 cm, at home this will create a thermal zebra, and in industrial premises where the thermal zebra does not matter it is perfect.

Reinforced 16 diameter with walls 2.0 mm

However, do not forget that in addition to the external size there is also the concept of internal diameter, so pay attention to the wall thickness. For example, in a tube of 16-17 diameters the wall thickness is 2 mm, and in pipes that have a larger volume the wall thickness is even greater in order to withstand more pressure, and vice versa in smaller elements the walls are even smaller.

How to calculate the length of a pipe for a heated floor?

Watch the installation video on how to make calculations and which pipe materials to choose and why.

The size of the contour for a water floor should be determined when designing the structure. Its length depends on the laying step. The standard pitch ranges from 100 to 300 mm.

The simplest method to calculate the length of the pipeline is to take the average figure, per 1 m2 - 5 meters of contour, with a step of 200 mm.

A more accurate way is to use the formula

L = S / N * 1.1, where:

L—contour length;

S is the area of the room;

N—laying step;

1.1 - stock of product for rotation.

The calculation for each floor loop must be done separately, and then add up all the indicators. In addition, you should not forget to add the distance from the floor to the collector.

For your information! If the result obtained exceeds the permissible loop size - 120 meters, then the room must be divided into several loops.

You can simplify the calculation process by using an online calculator to determine the length of the pipeline.

The most effective step in installing underfloor heating! How not to make a mistake

XLPE pipes

This category is highly resistant to thermal influences, which allows for more intense heating of the room. Polyethylene structures are manufactured under high pressure. This manufacturing technology not only increases strength, but also allows the production of structures with different densities. The most stable and efficient firmware density is 55–80%. Note that the higher the density, the more the polyethylene pipe will cost.

Processing methods:

- Silane gas. The technology allows you to create structures with a density of up to 65%;

- Peroxide (density 75%);

- Magnetic irradiation (maximum firmware density is 60%).

Polyethylene structures are sealed using special fittings. A ring is put on the end of the hose, then its diameter is expanded and the fitting is inserted inside. After this, the connection is clamped with a mounting ring.

Selection of the optimal diameter

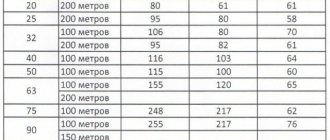

When choosing the diameter of the circuit, you should proceed from the length of the loop and the thermal conductivity of the material. Common sizes used in the construction of heated floors are 16, 20 and 25 mm.

When determining the diameter of the product, the following points must be taken into account:

- the smaller the diameter of the pipes, the higher the hydraulic resistance increases, and the level of heat transfer decreases;

- The larger the cross-section, the thicker the screed must be made, which increases the load on the floors and reduces the height of the ceiling.

Important! If the length does not correspond to the diameter of the circuit, this may lead to the hydraulic resistance exceeding the technical capabilities of the circulation pump.

With a pipeline length of 70 meters, it is recommended to take a pipe diameter of 16 mm. For a loop size of 90 meters, the appropriate cross-section is 20 mm, and for 120 meters, 26 mm.

When choosing the diameter of the product, it is necessary to take into account the level of heat transfer of the pipe material. When laying a copper or metal-plastic coil, it is better to use a contour with a cross-section of 14 or 16 mm. When using polymer pipes - 20 or 25 mm.

Initial parameters

Reducing the coolant speed will lead to a decrease in the temperature of the returning liquid and an increase in its heating time in the boiler. Accordingly, fuel consumption will increase. Increasing the speed increases the hydraulic noise of the entire system.

When designing a heating system, decide in advance on the type of coolant. Water and antifreeze have different viscosities. The designed underwater system may not work effectively with non-freezing liquids.

We calculate the heating power required by the house. The basic value is 60 W/m³ internal volume. The sources of cold air are windows and street doors. Each window adds up to 100 W of thermal power to the need, and the entrance door adds 200 W.

Regardless of the window material, do not change this indicator in the calculations.

For example, let’s calculate the diameter of the heating pipes of a private house measuring 6×8 meters with a ceiling height of 3 meters. The house has 5 windows and 2 doors. Location - Voronezh.

It is necessary to round up.

According to this table, the optimal pipe diameter for heating is 15 mm, with a coolant speed of 0.8 m/sec.

Depending on the material of a pipe of the same outer diameter, the inner diameter differs significantly.

Which pipe is best to use for heated floors?

Which pipe to choose for a heated water floor depends on the characteristics of the material and the room, as well as your financial capabilities. If the means and design of the floors allow, then the ideal option is copper.

Testing underfloor heating pipes

However, more often when constructing water heated floors, metal-plastic or PEX pipes are used. If we compare both types, they have almost the same characteristics:

- the elements are connected without the use of tools and extensive experience in this work is not required;

- the installation process is not long;

- the pipes bend well.

It is worth noting that a product made of metal-plastic has greater thermal conductivity and heats up quickly, but its cost is an order of magnitude higher than that of cross-linked polyethylene.

When analyzing the reliability of both types, cross-linked polyethylene takes first place, since the joints are fixed with special sealed sleeves. For metal-plastic circuits, the connection areas of pipes and fittings are open, which can lead to leaks during floor operation.

Cross-linked polyethylene also leads in terms of strength. For example, periodic defrosting and freezing of a floor with PEX pipes will not affect the circuit in any way, but a metal-plastic pipeline can break.

For your information! When constructing heated floors, heavy steel pipes cannot be used; they will increase the load on the floors.

Material characteristics

The best material for a heated floor contour is copper. The thermal conductivity of metal is much higher than that of plastic. It can withstand any changes in pressure and temperature. Operating temperature of copper 200 0C, pressure 67 bar; With high-quality soldering, it can withstand water hammer.

Operating steel temperature 150 0C, pressure 15 bar. Copper and steel do not allow oxygen to pass through and do not react with chemicals in concrete and coolant. Disadvantages include the difficulty of doing it yourself, the high cost of materials, and the high weight of the products.

Plastic equipment costs less than metal equipment. It's easier to use. The highway is easy to install with your own hands. No special skill is required to connect the circuit. What plastic pipes should I use for heated floors?

- “PEx-a” – made of cross-linked polyethylene; the “flex” variety has a silvery tint; single-layer material, operating temperature 95 0C, pressure 9 bar; covered with a protective layer of "EVOH". “stabil” products have an internal layer of aluminum; the optimal temperature in the system is 70 0C, pressure 10 bar. PEX-a pink color - the material was created specifically for the production of water circuits of the heating system. The red pipe for underfloor heating is designed for liquid 95 0C, which is supplied under a pressure of 10 bar.

- “PErt” – the material holds its shape well when hot water circulates in the main; the optimal liquid temperature is 95 0C, but the product does not deform at 110 0C. Optimal pressure up to 9 bar. "PErt" can be multilayered, with an oxygen barrier.

- "PPR" is polypropylene. For underfloor heating systems, multilayer propylene with aluminum or fiberglass is used. Operating temperature 70 0C, pressure 6 bar. They function well at 95 0C. Softening of the material occurs at 110 0C. Warm floors made of polypropylene pipes will last 30-50 years.

Manufacturers rating

In addition to the characteristics, when choosing a pipe product, you need to pay attention to the brand and manufacturer. It is better to give preference to proven brands that are popular in the market.

The main and well-established manufacturers include:

- Rehau - country of origin: Germany. Specializes in the production of PEX pipes for underfloor heating and water supply, with noise-absorbing properties and an anti-oxygen barrier. The company produces products in several series, which differ in color: white, red, orange. The warranty period is 10 years, and with proper use it will work for more than 50 years. Products of this brand have high thermal insulation, strength and elasticity.

- Sanext (Italy) - produces multilayer PEX contours. They have protective properties against noise and gas penetration. The warranty period is 10 years. The permissible bending diameter is 10 cm. The company promises uninterrupted operation of the circuit for up to 50 years.

- Uponor is a Finnish manufacturer. The range is huge - metal-plastic and polyethylene reinforcement products that are not subject to corrosion and destruction under the influence of chemicals. Protective layers protect pipes from mechanical stress.

- Emmeti (Italy) - produces metal-plastic and PEX-polyethylene pipes. The company monitors the technological process, all products have quality certificates.

- Valtec is a joint production between Italy and Russia. The company produces kits for standard conditions, and has also developed fittings for non-standard premises. Kits from this brand for underfloor heating are easy to install on your own. The product is an excellent heat conductor and is not affected by chemicals.

Purchasing high-quality material guarantees efficient and durable functioning of the heated floor. In addition, with the right choice, you can create an economical and visually aesthetic floor heating system in your apartment.

Minimum mandatory requirements for pipes

Before visiting a store to purchase a hydronic floor heating kit, you should carefully study the minimum requirements for water pipes operating under pressure in the screed. This is a necessity that is not discussed. Too specific operating conditions.

1. There should be no pipe splices in the laid “warm floor” circuit. Any type of connection: fittings, flanges, welding, gluing has been and remains the most vulnerable point in any pipeline. Therefore, the risk of leaks is very high. And this means complete dismantling of the floor with large financial expenses.

2. The second logically follows from the first requirement - the length of the pipes must be sufficient for one circuit. There should be a bay, not footage.

3. Steel pipes are immediately rejected: there are many reasons, but the first three are deadly:

- You can’t do without welding;

- are susceptible to corrosion, including those made of stainless steel - the alkaline environment of the cement-sand mortar slowly but surely corrodes the metal;

This is what a metal pipe looks like inside after 10-15 years of operation.

- the coefficient of linear expansion does not coincide with the concrete screed when heated - microcracks appear.

4. The walls of the pipeline should not allow oxygen to pass through, which oxidizes divalent iron (Fe2+) dissolved in water. Over the course of a year, up to 4 kg of rust can appear in the coolant (circulates along with the liquid). Exactly the same process occurs with ferric iron (Fe3+). Only there is more rust - up to 12 kg and it settles on the walls of the pipes.

5. The pipe material must withstand temperatures of about +90oC. Such emergency situations arise when the control equipment fails and hot liquid flows directly from the boiler into the circuit.

6. When the circuit material is heated, it elongates. The screed prevents this and, in turn, compresses the pipes, which is why deformation and destruction are possible. The problem can be solved in two ways: the material must have a small coefficient of linear expansion under the influence of temperature, or it must have sufficient strength and elasticity to resist the resulting stress.