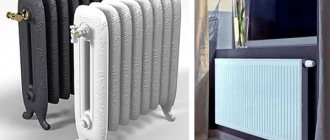

The best heating radiators for a private home will be aluminum or steel products. They have high heat dissipation and an elegant design. The former can withstand a working pressure of 10-16 atm, the latter - 6-8 atm.

Installing radiators in a house is quite a difficult task. The purpose of the article is to help decide which heating devices are best installed in your home, to provide the most complete information about the best battery manufacturers, where and under what conditions it is rational to install and when this can be done.

The modern design of autonomous heating systems in private houses consists of water heating equipment (solid - liquid fuel, gas and electric boilers), hot water pipelines and heating devices (radiators).

It is important that the characteristics of the batteries fully correspond to the operating conditions.

Features of an autonomous heating system

Installation of an autonomous heating system (AHS) for private housing construction allows you to take advantage of many of its advantages compared to a centralized analogue, despite some disadvantages.

Heating radiators for a private house.

Advantages

- One water heating boiler can provide a house with radiator heating, heated floors, and supply hot water to the kitchen and bathroom.

- The heating works fully regardless of seasonal shutdowns of the central heating system. This allows you to maintain a comfortable microclimate in the house during a sharp drop in temperature in the off-season.

- Closed heating and hot water supply circuits allow the use of clean coolant without harmful impurities. To do this, coarse and fine water filters are installed in heating systems.

- The owner of the house himself draws up a schedule and carries out repair and maintenance work to maintain the heating system of the house.

- An autonomous heating system is the only alternative to central heating for country cottages, large mansions and dachas.

- During the absence of the owners of a private house, you can set the operating mode of the heating system to the minimum heating temperature of a private house, which will save heating costs.

- The owner of the house can independently choose the class, type of heating radiators and determine their quantity.

- There is no threat of water hammer.

- Possibility of connecting to the Smart Home system.

Flaws

With all the advantages, autonomous heating has a number of disadvantages:

- you need to spend time and money on arranging the heating system, and apartment owners receive a ready-made heating system;

- maintenance and repair of ASO are the direct responsibility and concern of the homeowners, and in an apartment building this “lies on the shoulders” of the service company;

- You need to constantly monitor and regulate the temperature.

Pros and cons of metal-plastic

Let us make a reservation that metal-plastic pipes for heating should be compared with polypropylene pipes under equal conditions. Therefore, detachable joints on collapsible fittings are not considered - they are expensive and unreliable, although convenient for craftsmen without experience. Good tightness will be ensured only by the joint with the press fitting.

The condition also applies to the method of reinforcing the pipe; for comparison, let’s take metal-plastic and PPR reinforced with aluminum. Now about the advantages of metal plastic:

- Having special pliers, it is quite simple to install heating from metal-plastic parts.

- The pipe is bent and supplied in coils, and therefore is cut into sections of the required length, without any unnecessary joints.

- Thermal elongation of the material is insignificant and does not require a scrupulous approach when securing long sections.

- Can be installed in any weather.

- Laying in any hidden way is allowed, including under the screed along with the joints.

The reinforcing layer of the metal-plastic pipeline is only aluminum.

What is better in systems made of metal-plastic is the technology for connecting the elements. The end of the cut section is calibrated, pulled onto the fitting and crimped with pliers, and that’s all. A minimum of space is needed, since there is no need to insert a healthy soldering iron between the parts to be joined; the pliers are applied after joining. With the help of a spring, the metal-plastic bends well under a safe radius, which greatly simplifies the installation.

Separately, it is worth mentioning about heated floors, where it is customary to lay metal-plastic or cross-linked polyethylene, but not PPR. These materials do not need compensation and feel good inside the monolith, providing effective heating of the entire surface. It is worth imagining polypropylene in their place with its thick walls, extension and 90° joints, and it immediately becomes clear which pipes are best used in heated floors.

Press connection pliers are not a cheap tool; for 1-2 installations it is better to rent them

Reference. Cheap, low-quality metal-plastic is often found on sale; in practice, it often delaminates at bends. Fixing a leak under a screed is not easy; you can’t do it without opening it. Those who like to save on materials should think about using cheap metal-plastic pipes for heated floors.

Now about the disadvantages of metal-plastic, of which there are actually two:

- high cost of all elements;

- The range of pipes is limited to a maximum diameter of 63 mm (DN50).

Proponents of heating made from polypropylene constantly pay attention to another disadvantage of metal-plastic - a reduction in the flow area at connections where brass fittings are installed. They say that this leads to an increase in the hydraulic resistance of the network and the rapid “overgrowing” of passages when working in a central heating system, where the coolant can be dirty. The statement is true regarding collapsible fittings; in them, there is actually a narrowing of the diameter relative to the passage in metal-plastic.

High-quality fittings for press joining metal-plastic pipes also have a narrowing, but it is not so large as to significantly affect the hydraulics of the system. It is better to use them for heating, especially when laying hidden lines. Our expert Vladimir Sukhorukov shares the same opinion, whose video we recommend watching:

Heating radiator classes

The classification of heating radiators can be indicated by the following list:

- sectional;

- tubular;

- panel;

- lamellar.

Sectional

The design of this class of batteries is a combination of two or more hollow flow vessels (sections) in one radiator. The number of sections varies depending on the thermal design of the room. They come in both aluminum and cast iron models.

pros

The advantage of such heating devices is that you can always increase or decrease their heat output (see table) by adding or removing sections. To assemble the battery sections, you will need external thread fittings (nipples), O-rings, connecting pipes and a special wrench. Sectional heating devices can quickly be disassembled into separate sections or assembled into a reliable product.

Minuses

The structure, consisting of several elements, has many connecting points. Loose connections can result in battery leaks.

Tubular

Tubular radiators began to be installed back in the 30s of the last century. They have always been considered piecemeal devices. That is, they are supplied to the customer on an individual order. This class of batteries enjoys the greatest success among designers. Steel radiators can be either with horizontal or vertical tubes.

pros

Like all custom-made products, tubular steel appliances are in demand among owners of expensive country mansions.

The use of any bold design solutions makes it possible to install tubular radiators not only as heating devices, but also to make them one of the bright accents in the interior of any room. The thermal characteristics of steel products are high.

Minuses

The disadvantages of tubular heaters for an autonomous heating system include inaccessibility for most consumers due to the high price of the products, and “capriciousness” in relation to the quality of the coolant (coarse and fine filters must be installed).

It should also be noted that this class of batteries refers to non-separable devices, and partial replacement of individual segments is impossible.

Panel

Screen heaters are also non-separable devices. The look of solid panels, painted mainly in neutral tones, is in fairly high demand among ordinary consumers.

Rectangular steel radiators consist of 2 parallel steel planes welded to each other, inside which U-shaped tubes are located. Steel strips are placed along the perimeter of the ends of the battery. The panels can be either with a side or bottom coolant supply.

pros

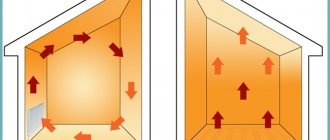

Panel steel radiators have high heat transfer characteristics, they are compact and their appearance harmonizes with any interior of the room. Panel appliances are especially popular in private homes with large window openings.

Long screen heaters are placed in niches or simply under windows so that they cut off the cold influx of the external atmosphere from penetrating into the premises.

Minuses

Panels that have been subjected to water hammer or mechanical damage with rupture of the steel surface cannot be repaired. Batteries cannot be disassembled and their dimensions cannot be adjusted. The devices look quite monotonous in appearance.

Lamellar

They can, in some cases, be classified as bimetallic types of batteries and converter devices. The idea of the design is that a steel pipe with coolant is placed through a set of thin steel, aluminum or copper plates.

pros

The more petals, the larger the heat transfer area. Therefore, a small-looking device in a private house will heat a room just as effectively as its much larger panel, sectional or tubular counterparts. The trouble-free service life is 20 years or more.

Minuses

The main disadvantage of plate heaters is that the plates, with their area, increase not only the heat transfer of the device, but also attract a large amount of dust.

Accumulations of lightly suspended particles in a private home can cause allergic reactions in people present in the room. Therefore, batteries of this type need to be cleaned regularly with a vacuum cleaner.

Disadvantages of PPR pipes

Unfortunately, polypropylene has more disadvantages than advantages. Practical experience of experts and reviews of the material say the following:

- It is difficult to weld and install propylene; the contractor is required to strictly adhere to the technology;

- pipelines, even those reinforced with aluminum, tend to significantly elongate when heated;

- it is impossible to control the quality of joints;

- due to the fact that the pipes do not bend and are supplied in 4 m long sections, joints on the highways can occur in the most unexpected and inconvenient places;

- It is not recommended to assemble the system at low temperatures, and in frosty conditions it is prohibited;

- greater wall thickness makes a polypropylene pipe larger than a metal-plastic pipe of the same diameter;

- Thickened tees, elbows and other fittings take up a lot of space.

A significant difference between polypropylene and other polymer pipes is the large wall thickness

Note. The disadvantage of propylene’s flammability is not specifically mentioned, since it is also inherent in metal plastic. Permanent connections are also not one of the disadvantages of PP-R, because it is better to join metal-plastic pipes by pressing. These joints cannot be disassembled later.

The most controversial statement that causes a lot of dissatisfaction among propylene supporters is the complexity of installation. On all Internet sites they are trying to prove that it is very easy to learn how to solder polypropylene parts; a 15-minute training session is enough for a beginner to master the technology.

This is demonstrated in the video, where a worker famously joins PPR fittings to pipes, placing a soldering iron on the table. In real life, everything is much more complicated; connections will have to be soldered on the fly, in hard-to-reach places, while simultaneously holding the welding machine and the pipe section with your hands.

Trusted manufacturers

On the Russian heating engineering market there is a wide range of heating radiators, the manufacturers of which are known for their quality products.

The best radiators are presented by several well-known manufacturers.

Aluminum

Among products of this type, two manufacturers worth noting are Global ISEO and Royal Thermo Revolution.

DO NOT BUY Radiators Until You See THIS!!!

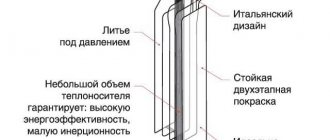

Global ISEO

The Italian company Global ISEO has been manufacturing aluminum radiators for more than fifty years. Elegant products fit harmoniously into window sill niches and look great in the open. The model range is represented by devices with different numbers of sections. The average price of a radiator of 8 sections is 5.2 thousand rubles, of 10 sections – 10.2 thousand rubles.

Royal Thermo Revolution

This brand has established itself as a manufacturer of reliable products at an affordable price. Impeccable design, increased power, resistance to water hammer and a 10-year warranty - all this indicates the high quality of aluminum batteries. The average price of a Royal Thermo Revolution radiator with 10 sections is 10.8 thousand rubles.

Steel

The best steel radiators are represented by manufacturers such as Kermi and Buderus.

Radiator in the heating system of a private house.

Kermi

The Kermi brand presents one of its best steel batteries, the Kermi FKO 22 with side connection. German products are made from high-quality low-carbon steel. Thanks to this, radiators are characterized by high performance.

All devices are supplied with a complete set of brackets, plugs and an air valve. The average price of a 500 x 800 mm panel is 6.3 thousand rubles.

Buderus

The German company is one of the manufacturers of high-quality products such as steel panel heating radiators. One of the best models, Buderus Logatrend VK-Profil 22, is made by roller welding.

The devices have an elegant appearance and are designed for 50 years of trouble-free service. The average price of this model measuring 500 x 600 mm is about 5 thousand rubles.

Cast iron: MS-140 and GURATEC Apollo 970/05

The budget version of cast iron products is presented by the Lugansk Foundry and Mechanical Plant. They are preferred to be installed in public places and non-residential premises. The cost of one battery from section 5 of MS-140 with a height of 800 mm is on average 2.7 thousand rubles.

The German company Guratec is considered one of the best foreign manufacturers of cast iron batteries. The products are made in retro style. The products are expensive because each device is a unique work of art with painting and monograms in a wide color range. A cast iron radiator GURATEC Apollo 970/05 will cost the buyer about 90 thousand rubles.

Bimetal: SIRA GLADIATOR 500x4 and ROYAL Thermo Revolution Bimetall 350

In the heating engineering market, the Italian company Sira Group is known for its high-quality Gladiator bimetallic radiators. The wide range of products includes models Alfa Bimetal, Gladiator, RS Bimetal, etc. The average price of a bimetallic radiator model SIRA GLADIATOR 500x4 is about 3.6 thousand rubles.

Bimetallic devices ROYAL Thermo Revolution Bimetall 350 are of high quality. The main advantage is a seven-layer anti-corrosion coating, which allows the batteries to be used in rooms with high humidity levels (gyms, swimming pools, etc.). The average cost of a 60 x 415 mm radiator is 8.3 thousand rubles.

Vacuum: EnergyEco

The Russian company EnergyEco is considered one of the best manufacturers of vacuum heating radiators. The devices are made of 1.5 mm steel. The heat output of 1 section is 170 kW. The average price of a lithium bromide flow radiator of 10 sections is 7 thousand rubles.

Quartz: TeplEco

Judging by the 2022 ratings, the Russian company TeplEko was named the best manufacturer. Quartz panels can be installed in rooms with high humidity. For a bathroom, a 400W stove will provide a comfortable air temperature. A quartz monolithic slab measuring 600 x 350 x 25 mm costs an average of 2.6 rubles.

Characteristics of bimetallic batteries

Bimetallic radiator

The main difference between bimetallic radiators is the use of two different metals in the manufacturing process - steel to create the core and aluminum to assemble the body. Thanks to this, the rod is very strong. Another advantage of such products is their high working pressure, which can reach 50 (!) atmospheres. Moreover, steel works well even with water that contains various impurities, while aluminum heats up quickly and gives off maximum heat.

Technical characteristics of bimetallic heating batteries

The main advantages of bimetallic radiators

In short, the use of two metals at once made it possible to obtain radiators that have the advantages of each of them. Therefore, it is quite obvious that the cost of these devices is the highest among all possible options.

Bimetallic radiator in section

Attention! Bimetallic batteries are used primarily for heating industrial and public facilities. In residential buildings they are rare due to their high cost.

The service life is 20-25 years, which is quite normal.

Bimetallic radiator Rifar Base Ventil 500 5 sections (bottom connection)

Table 2. Comparison of bimetallic radiators

| Manufacturer/Model | Working fluid temperature, ᵒС | Weight, kg | Volume, l | power, kWt | Operating pressure | Section dimensions, cm |

| 1. Sira Group/Gladiator-500 | 110 | 1,6 | 0,42 | 0,185 | 30 | 8x8x42.3 |

| 2.Gordi/Gordi-500 | 100 | 1,7 | 0,3 | 0,181 | 30 | 8x8x57.2 |

| . Rifar/Rifar Monolit-350 | 135 | 1,5 | 0,18 | 0,136 | 100 | 8x10x41.5 |

| 4.Tenrad/Tenrad-500 | 120 | 1,44 | 0,22 | 0,161 | 24 | 7.7x8x55 |

| 5.Global/Style-350 | 110 | 1,56 | 0,16 | 0,125 | 35 | 8x8x42.5 |

All the advantages of using bimetallic radiators are clearly expressed in the design of STOUT Space heating devices. These radiators are easy to install, they are suitable for rooms of any design and have a reliable design. The maximum pressure that a heating device can withstand is 100 atmospheres. Production is Russian, the largest in the country. Service life - 25 years, warranty from the manufacturer - 10 years. The number of sections is available from 4 to 14 - you can complete any object and select a radiator for a room of any size.

Bimetallic radiators STOUT Space

Prices for bimetallic batteries

Bimetallic batteries

Which is the best heating radiator for a private home?

Radiators are the final devices in the autonomous heating system of a cottage, large mansion or any private home. The choice of radiators of a certain class and type largely depends on what building material the building is constructed from.

If we take into account that houses are made of stone, brick, reinforced concrete and wood, then the requirements for batteries will differ.

Choosing a heating radiator// FORUMHOUSE

Stone, brick, block, reinforced concrete

Houses made of masonry building materials have a high degree of fire safety and moisture resistance. It is better to install radiators of an autonomous water heating system in them. Gas and electric boilers have greater efficiency than solid-liquid fuel equipment.

In this case, it is better to choose panel, sectional steel and aluminum water radiators.

With boiler equipment running on solid and liquid fuels, tubular, bimetallic and plate batteries will be quite suitable for heating.

Wooden private houses

Water heating is not installed in frame-panel houses and log houses. This is due to the fact that in the event of a pipeline break, the wood will quickly become saturated with moisture and eventually become completely functionally unusable.

Although there are exceptions, despite the great risk. Therefore, electric radiators are used for heating wooden housing constructions.

These include electric vacuum batteries and quartz panels.

Installation method

This parameter depends not only on the personal taste of the owners, but also on the characteristics of the wall. After all, there are structures (for example, made of plasterboard) on which heavy metal samples simply cannot be hung. There are also special models of cast iron products, which initially have a floor arrangement.

In this case, they are mounted on special brackets that are attached to the floor, and a radiator is placed on top. The leg can have a fixed or adjustable height.

If a wall connection is used, then it is necessary to install four fasteners, so that two of them hold the upper part, and two hold the lower part. To save money, some people use only top holders, and this causes the battery to wobble. In this case, the main load falls on the upper brackets, so they should be given special attention. The lower ones perform supporting and fixing functions.

Installation Rules

The installation of heating batteries largely depends on several of the following factors.

- Area of premises.

- Availability of a coolant source.

- Number of storeys.

- Number of window openings.

- Types of connection.

Room area

For each type of heating radiator, the manufacturer indicates in the technical specifications the calculated heating area per unit of its product. So, for example, one section of the MS-140 battery is capable of heating 4.5 sq.m. For a room of 18 m2 you will need to install radiators with a total of 18 sections. Screen (panel), tubular and plate heaters are also calculated.

Availability of a coolant source

Water as a coolant can be supplied to a water heating boiler either from a reservoir, a well, or a centralized water supply. If the coolant is not completely clean, then it is better to choose cast iron sectional and steel appliances. With the installation of filters in the autonomous heating system, almost all types of heating radiators are installed.

Number of storeys

Several floors affect the length of heating mains, which in turn affects logistic heat losses, which is compensated by increasing the power of the boiler pump. As a result, there is a risk of high pressure in the ASO. If heating radiators for a private house with a gas boiler on two or three floors will often be subjected to a maximum pressure of 16 atm. and higher, it is better to install steel appliances.

Number of window openings

According to the rules of heating engineering, radiators must be installed under each window. If, according to calculations, it is enough to install a panel radiator with an area of 1.4 x 0.5 m to heat a certain room, and there are two windows in the room, then panels measuring 0.7 x 0.5 m are mounted under each of them.

The same applies to sectional devices. In this case, you have to select the number of sections for each battery.

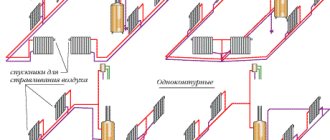

Types of connection

Radiators are made with side and bottom connections to pipes with coolant. Lateral wiring is arranged by connecting batteries in series on each floor.

If hot water pipes are laid on the floor or under it in a one-story house, then the batteries are installed with lower outlets.

How defects occur when welding polypropylene

According to the technology, the polypropylene pipe needs to be cut, the depth of immersion into the fitting must be marked with a pencil, degreased and soldered, heating both elements for a certain time. The duration of heating depends on the diameter of the pipeline. If you hesitate for a couple of seconds or ignore degreasing, the connection will become unreliable. This is not determined visually, the joint will undergo hydraulic tests, and a leak will appear after 2 weeks or a year.

An example of correct soldering - the plastic did not spread and did not block the cross-section of the pipeline

Overheating of polypropylene is easier to detect than underheating. A rim of molten plastic forms outside near the tee or coupling. The same defect will appear inside the joint; it will partially or completely block the passage of the coolant.

But you can see this trouble on a cut pipe, that is, cases of underheating and overheating cannot be clearly controlled after installation work is completed. And these defects arise due to inconvenient soldering conditions and the inability of the “masters” to qualitatively join polypropylene in any hard-to-reach place.

“Welded” joint – the cross section is half blocked due to overheating

When working in extreme cold or frost, the probability of underheating of the parts being connected is very high, so it is always better to install PPR at a temperature not lower than +10 °C.

Due to the impossibility of monitoring connections, experts do not recommend making polypropylene heating hidden, walling it into walls or laying it under a cement screed to install heated floors. If there is a need to lay a PPR line in the wall, then this must be done using thermal insulation.

The reason is thermal elongation of the material, which affects the method of pipeline installation. It should slide inside the fastenings, and the ends should not rest against the walls. The best polypropylene heating pipes are guaranteed to bend if they have nowhere to expand while warming up.

Where can I buy

You can purchase heating radiators in the following stores:

- TuT plumbing – more than 7,500 models;

- MirCli – all types of coolants;

- AllTools – fast delivery and low prices;

- Ulmart - products from 8 major manufacturers;

- Ozon – classic sectional samples are presented;

- Baucenter – when purchasing Buderus products, additional points are added to the bonus card;

- RAIBT – for the convenience of the buyer there is an information, service and delivery service;

- Leroy Merlin – various products: aluminum, steel, bimetallic.

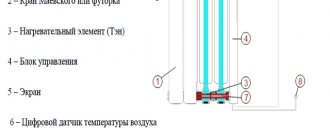

Thermostat

Thermostat is a device that is installed on the radiator. It is designed to reduce room heating during the heating season.

You may be sure that such an addition is unnecessary. After all, many people think only about how not to freeze, and naively believe that a room that is too well heated can always be ventilated. But, as a person who lives in an apartment where in winter it is always at least 30 degrees, I assure you that this is a bad idea. Keeping the window open all the time means creating a constant flow of icy air, and this is uncomfortable. Moreover, after closing the window, the heat returns very quickly. So my personal requirement No. 2 for new devices, right after the material, is the presence of a thermostat.

But here you need to be more careful in your choice, since there are several regulatory structures. Without delving into technical issues, we can cite the following advantages and disadvantages of different types:

- Shut-off valves are a simple ball valve, opening and closing which shuts off the flow and limits the supply of coolant. Cons: it has only two positions: “open” and “closed”, and frequent tugging causes leakage. Obviously, using it to adjust heating is not the best solution.

- Shut-off and control valves are valves that can be manually opened and closed, thus regulating the flow force. But it is necessary to manually monitor changes in indoor climate.

- The control device is a needle valve with a thermostatic head that automatically maintains the set temperature. However, their reliability often leaves much to be desired, since the disadvantages of heat supply, which we have already mentioned, do not allow them to work correctly: instability of water heating and many impurities lead to incorrect settings and blockages.