The stove always served faithfully, but suddenly it started smoking. This is especially often observed when opening the ash pit or when the owner adds a new batch of firewood.

What is the reason why the stove smokes when the door is opened and how to properly heat it so that the smoke does not enter the living room. The most common reasons and advice from experienced stove makers.

Backdraft - Temperature and Humidity

Why does the stove smoke into the house?

The natural extraction of flue gases through the chimney is based on the laws of physics. Of primary importance here are the temperatures indoors and outdoors, as well as the difference between them.

Poor traction is the scourge of warm weather in the off-season. For example, after a summer of inactivity, it takes special skill to light the stove in the fall so that smoke does not enter the house.

Also, the air can “stay” even in cold weather if the owners left the house and it froze. If the temperatures inside and outside are equal, there will be no draft.

Humidity can also play a role. For example, when slanting downpours occur and water enters the pipe, this upsets the temperature balance and the draft worsens.

In warm weather, or in a frozen house, paper is burned for kindling. It needs to be placed as far into the oven as possible; if this does not help, then into the far well through the cleaning door. Closer to the pipe, make a small fire made of paper or small wood chips. This is necessary in order to warm up the brick. Warm air will rise and draft will be established.

In hot weather, it is extremely difficult to establish traction.

Prevention is important

The vast majority of the reasons described above can be prevented. Why spend effort and money on combating the entry of combustion products into a living space, if this problem can be completely prevented?

If you have a brick chimney, check the masonry once a year for cracks: inspect it carefully. Attentiveness will help you notice the slightest damage, repair it and protect yourself from brick collapse.

Clean the chimney at least twice a year - with a brush or a selected household chemical. Also, “unscheduled” check the exhaust channel for combustion products after a thunderstorm, heavy downpours, storms, prolonged snowfalls, hurricane winds, and also if you have not been to a country house or bathhouse for a long time. Just as regularly and thoroughly inspect the deflector/rotary turbine and the furnace itself.

Wind

A temporary cause of backdraft can be the wind, the direction and strength of which “drives” the smoke back into the chimney. Tall trees or buildings located near the house can contribute to this.

Install an umbrella or deflector on the top edge of the pipe. These devices significantly improve draft, protect from rain and prevent the wind from blowing smoke back into the chimney.

To date, many deflector designs have been developed. There are rotating models that are themselves installed by the force of the wind so that there is no interference with the smoke.

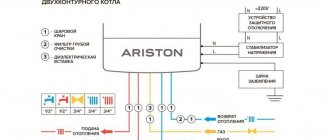

Many people are interested in the question: how to line an iron stove with bricks? Read useful information in our article. For information on self-repair of Ariston water heaters, see here.

Read about winter kits for air conditioners at this link.

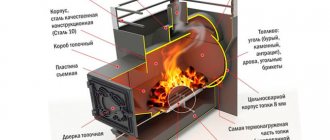

Application of technical means

To increase the traction force, you can resort to methods that do not involve changing the design of the chimneys.

There are several types of different technical solutions that can be installed directly on the finished pipe. One of them is the rotary turbine. Essentially, this is a fan that, due to the force of the wind, draws smoke from the chimney. True, it has a slight limitation on the temperature of the outlet stream. It should not exceed 200 degrees. Therefore, such solutions are used mainly to increase thrust in gas structures. A special tip that is able to turn the area where the smoke exits away from the wind can also help increase draft. Its operation is based on the operation of a conventional weather vane. In addition, its design is made in such a way as to avoid moisture getting inside the pipe.

The use of special electric smoke exhausters with an increase in draft force will be a good solution for private houses in windy areas. These devices are a fan that operates using electrical energy and physically “pulls” smoke out of the chimney.

Incorrect laying of a stove or well

An important condition for good smoke removal is sufficient chimney clearance. The pipe must be at least 15 cm in diameter (for a sauna stove - 10 cm).

During laying, the stove maker rubs the inner surface of all wells and pipes with a damp rag. If possible, all sharp internal corners are trimmed and turns are smoothed out. This creates a smooth inner surface along which smoke can easily move upward. This is done as the furnace is being laid. But you cannot plaster the inside of chimneys.

Any turn or additional well is another obstacle in the path of smoke. Therefore, the length of the pipe and its location on the roof must be adequately designed for the design of a particular stove.

It is also important that the entrance to the first well (inside the firebox) is not lower than the top edge of the door. Otherwise, there is a possibility that every time the fuel chamber is opened, smoke will flow into the room.

The stove maker's mistakes come at a cost. Something in the design can be corrected only by moving part of the stove, or maybe by completely rebuilding it.

A tall, straight pipe with a smooth inner surface can be a salvation if minor miscalculations are made and the draft is weak:

- If located close to the ridge, the pipe should be at least 50 cm higher than it.

- When located 1.5 - 3 m from the ridge, the height of the pipe is allowed to be level with the ridge or higher.

- The pipe can only be slightly lower than the ridge if it is located more than 3 m from it.

- A chimney height of 5 m or more is capable of providing full draft.

- Under no circumstances should the chimney be assembled from elements of different sections!

It is advisable to make a pipe with a round cross-section. In the corners of rectangular smoke extractors, unnecessary turbulence is created, and soot formation occurs more readily.

Metal pipes “suffer” from deteriorating traction more often than brick and asbestos pipes. This happens because the metal heats up quickly and cools down just as quickly on a frosty day. Insulation with non-flammable material saves the situation.

Gas plugs

Reversible draft, air and steam plugs in the furnace, even in quite competent manuals on furnace business, are often considered one and the same phenomenon, although these are completely different things, which is already revealed by checking the total draft. If the draft is overturned, then the flame of the candle/match is blown out of the stove. If a gas plug is stuck in the stove or chimney, then there is either no draft at all, or there is a weak draft. Reversal of draft is provoked by external conditions, and gas locks are a disease of stagnant seasonal stoves (partly also bathhouses), i.e. survived the cold season unheated.

Air

An air lock is typical for any stoves with a non-insulated steel chimney connected to the stove through a hog in the attic. During the winter, the owners of country stoves close the view and all the doors of the stove to protect it from dust, which produces very harmful and difficult to remove carbon deposits during combustion. But not everyone knows that it is also necessary to plug the mouth of the chimney so that the plug does not fall into it during the winter. Or you end up with too little time when the November wind is already whistling.

It is clear that a column of cold air then remains in the chimney. If, as they say, the tubercles wilt a little in the spring, uncork the stove and let it ventilate for half a day, the cold air will flow down. But if a stagnant stove is started up for a long period of warmth after the weather has turned, it will be retained by its pressure in the warm air in the stove, which has warmed up along with the house. This is an airlock.

An air lock is determined by comparing the draft on the firebox/blower and on the cleaning door of the hog (which, by the way, must be present). If the draft here and there is approximately the same or absent, then there is an air lock. Additionally, you need to make sure that no foreign objects get into the chimney. If the stove has direct-motion dampers (see below), then they are simply opened: the draft does not work - there is an air lock. Or something unnecessary in the chimney.

Steam

The steam lock only sets in stagnant brick kilns; most often - in channel vertical circuits, i.e. with wells. During the winter the stove becomes damp; With heat, the moisture saturating it evaporates and partially remains in the structure of the furnace. Water vapor settles down, blocking the lower passes between the wells.

A steam lock is clearly diagnosed: if the draft during cleaning of the chimney is normal, or the general draft returns to normal when the forward dampers are opened, there is a steam lock. However, it is more difficult to expel it than the air one (see below). Prevention is better: in the winter, all the doors, visible cracks of the view, damper and valves are plugged (clogged) with rags or straw. This way, the oven won’t absorb much moisture over the winter, and the moisture it does collect will be easier to go back the way it came. The only main thing (don’t take it for formalism, this is for you): when leaving for the winter, hang a sign on the stove like: “Prepared for wintering. So many (number) doors and so many (number) gaps are clogged.” When uncorking the stove, do not dump the plugs into a common pile, but lay them out separately and, when finished, count whether the total amount adds up.

How to remove traffic jams

Any blockage, as well as slight backdraft, is eliminated by burning halves or quarters of a newspaper sheet or a handful of shavings one by one in the firebox with the door open. When the accelerating plug stops smoking and its flame reaches the hailo (exit hole) of the firebox, the furnace can be started. An air lock is expelled more easily: a torch made from a sheet of newspaper is burned in the chimney to clear it. If the steel pipe is up to 5 m high, half a sheet is enough.

Dispersing a traffic jam and returning traction in the traditional way is quite a tedious task. Sometimes it takes 2-3 hours to accelerate the steam plug, and it takes half a day or a day to return the thrust. If a home with a stagnant furnace is electrified, this process can be greatly simplified and sped up.

The first method is to close the blower, and open the gate and view completely. The furnace door is opened. A household fan is placed close to the firebox opening and turned on. It will be useful to apply a stream of hot air from a household hair dryer into its flow from behind. Return of thrust (except for reverse wind hurricane) occurs in 5-15 minutes. A dense vapor plug accelerates in 10-20 minutes. The oven is then started (melted) in the usual way.

The second method is to prepare the oven for acceleration, as before. case. The tip of a household hair dryer operating at full power is inserted into the hilo and blown for 3-10 minutes. Then they complete the acceleration of the plug or the return of the draft: 3-4 halves of a newspaper sheet or 2-3 handfuls of shavings are burned in the firebox one by one, and the stove is immediately (!) melted.

Note: if dispersal of traffic jams/return of draft is carried out with newspapers or other unglued paper (for example, toilet paper), it is first crumpled into a loose ball.

Soot and furnace wear

Why does the stove smoke in a private house? Other reasons

Even if the stove was perfect at the construction stage, over time the chimney clearance may narrow due to the build-up of soot. This is an inevitable process, so the oven is cleaned regularly. However, without wanting it, owners can significantly speed up the soot formation process.

What mistakes should you avoid:

- Do not use wet firewood, especially resinous wood.

- Do not over-burn large amounts of synthetic waste in the oven (cellophane, plastic, rags, rubber...).

- During the construction stage, do everything possible to ensure that the inner surface of the stove does not have protrusions, is smooth and uniform.

- Do not try to convert a regular oven into a pyrolysis oven.

Thrifty owners often strive to do the latter in order to save money. They limit the air supply, without opening the vent, but leaving only a small gap. The result is not combustion, but smoldering and decay. But a Dutch oven or a Swedish oven will never become pyrolyzed; by their nature, they should “hum” during combustion, and the vent can only be closed when there are coals left.

Particular attention should be paid to cleaning the stove for those stoves that are regularly fired with coal. This fuel quickly leads to the pipe becoming overgrown with soot (coal, like firewood, needs to be given a sufficient amount of oxygen to allow it to flare up properly).

By the way, the fact that it’s time to clean the stove can be indicated not only by the smoke in the house, but also by the sparks flying out of the chimney into the street. This happens when combustion does not occur in a furnace, but the soot itself burns in wells.

If after cleaning, the problem with traction remains or worsens, it is possible that soot fell on some area during cleaning, and the area remained uncleaned. With an aged stove, such a nuisance may occur as part of the brick falling off, which is not noticeable from the outside.

To be sure that the wells are clean along their entire length, you can make additional holes for cleaning. This is done using a hammer drill or a drill with a Pobedit drill bit.

Ventilation holes are not open enough

If the fire does not receive enough oxygen to burn the wood in your stove, it may begin to smoke due to inefficient combustion.

- Lack of oxygen can be caused by closed or insufficiently open furnace vents.

- All vents in a wood stove must be fully open before lighting the fire and remain fully open until the fire has engulfed the wood.

As the fire burns through the initial pieces of wood to form a layer of hot coals, larger and larger logs can be added to the fire to produce more heat.

To make a fire more efficient, keep the vents closed until the fire burns quietly through the wood without causing smoldering or smoke.

Presence of cracks

It's no secret that over the years the stove becomes covered with a network of cracks and cracks. Especially at the junction of clay and metal elements, for example, around a slab. Wells can also crack at the seams.

The cracks could remain in the place where a knockout brick is inserted for cleaning, or the vent and firebox doors have become loose over time.

Also, atmospheric phenomena sometimes destroy the outer part of the pipe on the roof.

It is possible and necessary to deal with cracks, because air is sucked in, its natural flow is disrupted, and at the slightest disturbance in draft for other reasons, smoke finds its way out, even with the door closed!

The cracks are sealed with clay mortar, similar to the one on which the stove is made. Deep cracks are widened using a knife or similar tool to allow the mortar to penetrate deeper between the bricks. Then the gap is moistened with water and sealed well. Small cracks can be whitened.

Where to begin

First of all, when smoke appears, you need to inspect the chimney and check if there are any foreign objects that interfere with proper operation. Some, in order to reduce the likelihood of objects appearing in the chimney, install special caps that protect the pipe.

If this was not the reason, then the pipe walls are checked further and the amount of accumulated soot is determined. The lack of proper draft force may be due to infrequent cleaning or a completely incorrect chimney structure.

In the case where the cause of smoke is a dirty pipe, it can be cleaned in several ways:

- Use special equipment. With its help, a strong water pressure is created, with the help of which plaque and foreign objects are removed from the chimney.

- If the soot layer does not exceed 2 mm, then powder or liquid mixtures with a chemical composition can be used.

- When the soot deposit is more than 2mm, you should resort to mechanical cleaning. Such cleaning on a day without rain or wind. Clean the build-up with a scraper, then use a brush. If this method does not bring much results, then a weight tied to a cable that needs to be thrown into the chimney opening will help.

Ventilation

The chimney itself is a natural exhaust hood. In order to create upward movement of warm air, a full influx from the outside must be ensured.

Oven ventilation

However, often, when installing a forced ventilation system, owners only perform forced exhaust (in the kitchen and bathroom, for example). If some factors have influenced the reduction in draft in the chimney, powerful forced exhaust through a separate channel will become an additional obstacle to the normal movement of smoke from the stove.

The second floor may compete with the chimney. If there is a staircase nearby and an opening to the top, air sometimes rushes there more readily, especially if at those moments when a window on the second floor opens.

Temporarily turn off the hood, close the windows on the second floor, open a window or door at the level of the stove so that fresh air enters the room. However, the other extreme should not be allowed - drafts.

Checking the draft quality in the chimney pipe

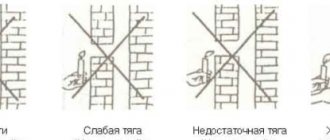

To determine further measures to eliminate smoke from the stove, it is necessary to check the quality of draft in the smoke exhaust system. Verification is carried out in one of the following ways:

- Using an anemometer. High-precision professional device for determining smoke draft.

- Ignition of flammable material. The burning material is brought to the chimney grate - with good draft, the flame is directed upward, with poor draft or its absence, it remains motionless.

- Visual check. If, when lighting the stove, the flame acquires a dark red tint, this indicates a decrease in draft. Good draft provides a light, almost white flame.

- Presence of a strong smell of smoke. If strong odors appear when the firebox is open, this indicates a mechanical blockage of the chimney system.

The full list of reasons why a heating stove starts to smoke is quite long. In each individual situation, it is necessary to take into account: the nature (temporary or permanent) and duration of smoke, indoor temperature, weather conditions, design features and equipment service life.

Other reasons

Smoke can enter the house if there is too much wood in the firebox and the entrance to the wells is blocked, and the fuel has not yet had time to ignite.

What to do here is decided according to the circumstances.

If the firewood is just starting to burn, you can carefully pull out several large logs (if they give off smoke, take them outside).

When the fuel is filled, a poker is used to try to stir up the pile and lay it down more compactly.

Many people ask the question: which brick stove to choose for a summer house when building it yourself? In our article you will find a lot of useful manufacturing options. Read about DIY waste oil stoves here.

Conclusion

So, the full list of reasons why the stove smokes is quite impressive. In each specific case, you need to consider: is this a rule or an exceptional case; what is the current weather and temperature in the house; how old is the stove and other factors.

What to do if the fireplace smokes

Stovemaker Master

Understanding the reasons why a fireplace smokes and then eliminating them can be difficult. Below we will consider the most likely of them. These may be design and installation errors, as well as improper operation.

Design errors

- – Poor design of the smoke collector. If the volume of the smoke collector, or hail, is small, the smoke does not go completely into the chimney. The same thing happens if the cross-sectional area of the chimney is insufficient. If the volume of the high is too large, insufficient vacuum is created. The smoke collector needs to be modified.

- - Firebox. The depth of the firebox should have a ratio with the height of the fireplace portal from 1/2 to 2/3. If the firebox is too deep, you can lay it down; if it’s shallow, you can increase it. If the smoke tooth is positioned too low, the fireplace may also smoke. An additional row of bricks placed on the smoke tooth may solve the problem.

- – Chimney design. The height of the chimney for a fireplace should be higher than for a conventional stove. The cause of smoking may be a narrowed pipe head, or the lack of wind protection on it. The cross-section of the chimney must correspond to the size of the fireplace. If the damper narrows the passage for smoke, it should be replaced.

The fireplace pipe can be connected to an existing chimney. In this case, all connections and turns should not have right angles, thereby creating additional resistance.

To eliminate smoke, the chimney needs to be modified. In this case, joints made at right angles are disassembled. It is recommended to make vertical pipe joints at an angle of 60° from the horizontal.

It may be necessary to install additional purifiers to remove soot.

Poor vent design can also be the reason why the fireplace smokes. It's all about the reverse thrust that the blower can create. In this case, it will be enough to close it.

If there is insufficient oxygen supply, the combustion of wood will be sluggish and the flame will have a dark color.

Poor quality installation

The use of low-quality materials for masonry mortar can cause the formation of cracks in the chimney, or burnout, especially in the attic. Air leaks will worsen traction. The chimney may be clogged with construction debris and mortar.

Uneven chimney walls will additionally collect soot. Insufficient chimney insulation in the attic can also cause smoke. To eliminate it, you need to carefully examine the pipe and seal the cracks.

Plastering the pipe will additionally insulate the chimney.

Operational reasons

The cause of smoking will be damp, rotten and dirty firewood, or drafts. Avoid opening windows and slamming doors excessively. Perhaps the chimney has not been cleaned for a long time, and it is clogged with soot.

Practical tips for eliminating smoke

If the size ratio of the fireplace portal and chimney is not met, you can try the following. An asbestos-cement strip is taken, the width of which is slightly greater than the width of the fireplace portal, and is applied on top of the smoking fireplace. The area of the portal decreases and the fireplace stops smoking.

Now you should lift the strip up, gradually increasing the area of the portal until smoke appears. Thus, the optimal position of the strip is found when there is no smoke and the portal has the largest cross-section.

Now all that remains is to install a stationary decorative curtain made from a strip of metal instead of a strip of asbestos cement.

It is possible to eliminate smoke by changing the upper section of the smoke collector, or by installing a metal plate on the smoke tooth. It is possible to install a metal heil of appropriate dimensions.

To increase the cross-sectional area of the chimney, you can try to saw off the edge of the tooth - this technique is quite risky and is used as a last resort. To determine where the smoke goes during combustion, use a mirror.

If the room has supply and exhaust ventilation, this may cause smoke. Turn off the ventilation and look at the result.

This solution can be effective if the pipe height is insufficient, but it has a number of disadvantages. The danger is that in the event of a power outage, a non-working fan will create additional resistance to the exit of flue gases.

Smoke in a brick stove

Why does a brick potbelly stove smoke when the door is opened? The reasons largely coincide with the malfunctions of a conventional oven and are eliminated by analogy with it.

Poor quality solution

The use of ordinary cement-sand mortar for ordinary repair work is unacceptable. It does not withstand strong thermal loads and aggressive environmental influences. And carbon monoxide, which will penetrate through the cracks of the masonry, is dangerous to human life. It is prohibited to use the oven in a faulty condition. Eliminating such mistakes results in a complete refurbishment of the furnace or endless cosmetic repairs.

For normal operation of the furnace, the following is required:

- lime mortar - for the foundation and chimney;

- clay;

- masonry sand.

Much attention is paid to the preparation method, the balance of components and solution consumption. Each element and design model has its own proportions.

Large seams when laying

The use of old dry bricks or large seams during the construction of a furnace contributes to the rapid destruction of the furnace structure. The adhesion between the materials is initially weakened, cracks appear, which have to be checked and strengthened every season. The same problems occur in new ovens that are not sufficiently dried before use.

Lack of lining

The absence of a lining reduces the maintenance-free service life of brick kilns if the firebox is made of cast iron or steel. The consequences are not critical. Such potbelly stoves are simply inspected more often and any problems that arise are eliminated.

Cracks

The cracks of a brick potbelly stove are first cleaned with a metal brush to a hard brick surface. The space is covered with a margin, especially in the case of a network of cracks.

Cracks in a brick stove

Work order:

- surface treatment with a primer - cement is diluted with water to a liquid state;

- the solution is applied to the surface;

- cracks are filled with high-quality adhesive or other suitable composition;

- After drying, the surface is plastered and the planned types of finishing work are carried out.

For combustion sections, fire-resistant mixtures and sealants are used;

For the rest - heat-resistant solutions.

Cracks in metal structures are permissible on metal that is not yet subject to fracture, with a width of no more than 5 mm. In these cases, a patch is welded. In other situations, damaged parts must be replaced and the elements must be reassembled.

How to solve a problem

If the stove still smokes even with the fire door open, you should think about the competence of the stove maker who installed it. The most common mistake of inexperienced craftsmen is not wide enough

. Its dimensions depend, in particular, on the power of the heating unit. For example, for a stove with a power of 3.5 to 5.2 kW, the chimney diameter must be at least 189 mm, and the cross-sectional area (if rectangular) must be at least 0.028 m². Otherwise, carbon monoxide will tend to escape not only through the pipe, but also through the firebox.

Clean the chimney

Chimney cleaning must be carried out regularly, even if expensive firewood is used. To carry out the procedure, use a brush with a weight (no more than 2 kg) on a strong cable. A weight helps knock pieces of brick to the bottom, and a brush cleans soot from pipes and wells.

Important! If the owner leaves the house for a long time, it is necessary to close the pipe damper, which will prevent the deposition of soot inside the structure. When craftsmen make design inconsistencies, the stove quickly fails and begins to smoke

Such violations are costly for the owner, since correcting the problem requires relocating the stove. Only a specialist can perform such complex work.

When craftsmen make design inconsistencies, the stove quickly fails and begins to smoke. Such violations are costly for the owner, since correcting the problem requires relocating the stove. Only a specialist can perform such complex work.

Cracks that appear as a result of overheating or long service life can be repaired yourself. To do this, use stove mortar, which is usually used for laying Russian brick stoves.

The procedure is as follows:

- Make a solution of sand and clay in a 1:1 ratio. You need to add a few teaspoons of water to the mixture. The solution should be thick.

- Moisten each crack with water before sealing.

- You should seal the gap inside the stove with your hand so that the mixture does not spill inside the structure. You can use a piece of metal for this.

- From the outside, the gap is sealed with mortar using a brush and spatula.

Clean the oven

Before use, you only need to remove the film. The log is placed in the fired oven. The desired cleanliness effect is achieved in 2 hours.

Pulls, but not there

If the stove has not been used for a long time, a “backdraft” effect may occur - a cold air plug accumulated in the chimney does not allow the warm flow to pass through, and smoke enters the room. What to do? Raise the temperature in the pipe! To do this, before adding fuel, open the dampers and throw burning paper through the cleaning door. The smoke exhaust duct will warm up, the heated air will rise, and the draft will be restored. If this does not happen, the operation must be repeated again. But now the paper must be thrown directly into the pipe directly from the roof. After the fire goes out, light a torch in the firebox and see where the smoke goes. If it’s outside, that means you can lay firewood. A special attachment, a deflector, will help prevent backflow. This is a cylindrical metal product that is installed on top of the chimney. Thanks to its design, the device creates an area of low pressure, increasing traction. In addition, the deflector prevents air turbulence from appearing inside the pipe. Thus, it protects the chimney from strong gusty winds, which can also cause carbon monoxide backflow.

Installing a deflector on the chimney. Photo from refite.ru

Pulls, but not there

If the stove has not been used for a long time, a “backdraft” effect may occur - a cold air plug accumulated in the chimney does not allow the warm flow to pass through, and smoke enters the room. What to do? Raise the temperature in the pipe! To do this, before adding fuel, open the dampers and throw burning paper through the cleaning door.

The smoke exhaust duct will warm up, the heated air will rise, and the draft will be restored. If this does not happen, the operation must be repeated again. But now the paper must be thrown directly into the pipe directly from the roof. After the fire goes out, light a torch in the firebox and see where the smoke goes.

We suggest you read: The best way to paint a bathhouse inside

If it’s outside, that means you can lay firewood. A special attachment, a deflector, will help prevent backflow. This is a cylindrical metal product that is installed on top of the chimney. Thanks to its design, the device creates an area of low pressure, increasing traction.

Troubleshooting solid fuel models

Solid fuel boilers may have the same causes of smoke associated with the chimney as gas appliances described above. When burning, it is necessary to use well-dried raw materials. It should be stored in well-suited places with low humidity. Do not use synthetic materials as fuel.

Wood-burning boilers such as Buderus Logano SW, Stropuva S and Zhitomir D should be heated only with dry wood. To be able to use different types of fuel, you need to purchase combined devices such as KST or Dymok. You can experiment with the degree of opening of the gate in air-heating models, such as. If smoke appears, make the chimney opening larger.

Ensure air flow into the boiler room. For safety reasons, the window must be open constantly while the boiler is operating during the heating season. The device operating on solid fuel must be cleaned regularly. This is especially true if it is coal or diesel, running on exhaust, since these types of fuel clog the burner especially quickly.

Wind influence

Air currents generated by the wind penetrate the chimney at high speed, bending around its edge and causing turbulence. If the force of this flow turns out to be greater than the force of the smoke exit, the latter has no choice but to return back to the room. In other words, if the wind is very strong, the likelihood of smoke will be greater.

The effect of wind on draft can be eliminated using a special windproof cap, which should be mounted on the main chimney. It will separate the air flows so that they do not cause turbulence and do not penetrate inside the chimneys.