Coal is one of the most common types of fuel for use in a stove, providing even heating and heating of rooms for a long time (compared to wood).

However, kindling must be approached carefully, clearly understanding the nuances of heating a house, and observing fire safety rules. Improper ignition can damage the stove itself and reduce heating efforts to zero. But when all the nuances are followed and the fuel is selected correctly, there will be no problems, and stove heating will provide the house with warmth.

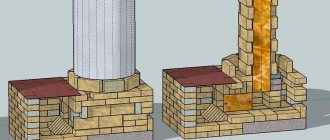

Furnace structure

Principle of operation

Due to the draft of the chimney, air enters the firebox and the fuel burns.

The resulting gases heat the walls of the firebox and transfer heat to the water circulating in the heat exchanger system. The heated coolant is supplied to the pipes, heats the house, and returns to the boiler. The gases then enter the chimney, where they maintain the temperature necessary to create draft. The most common coolant is water, but sometimes mixtures with antifreeze and antifreeze liquids are used. The smoke removal system includes thermally insulated pipes, which are sometimes supplemented with a forced ventilation unit.

Attention! It is forbidden to fire a regular wood-burning boiler with coal, since this type of fuel produces 2-3 times more heat than wood. Based on functionality, the equipment is divided into 2 groups:

Based on functionality, the equipment is divided into 2 groups:

- with one circuit - for heating the room;

- with two - for heating and organizing hot water supply.

Photo 1. Appearance and diagram with the operating principle of a coal-fired heating boiler.

There are classic (single-chamber) and pyrolysis boiler models. In the first case, traditional combustion of fuel in a chamber is implied, the efficiency of which is 70%. In pyrolysis models, coal and gases released during combustion burn in different chambers. The efficiency of such improved models reaches 92%. The fuel in them burns more efficiently with less soot and smoke.

Coal boilers are made of steel and cast iron. Steel models are most often bottom-burning devices and consist of welded elements. Cast iron - cast, characterized by high efficiency, less susceptible to corrosion and contamination. Long-burning devices have a vertical firebox, the fuel gradually burns from above, due to which they operate without additional loading for several days.

Algorithm of actions

In fact, everything is extremely simple:

- Initially, the furnace firebox is covered with a small amount of paper.

- It is necessary to put wood chips, small wood shavings or bark on top of it; it must be dry.

- For the next layer, take logs, but their thickness should be less than those that are already used in a burning oven. This amount of materials will be enough to warm up the heater.

- When the flame is sufficient, the firebox is filled with firewood, and its level should be 20 cm lower than the firebox. With this approach, the fuel will have time to burn out even before it enters the chimney.

- When the required amount of warm air has accumulated, you can begin to add coal, starting with small pieces and throwing in more and more.

Packing in bags is the most convenient

Types of coal

Such fuel is a rock consisting of a carbon compound and non-combustible components that, when burned, form ash. In different regions there are deposits with different amounts of impurities.

Depending on the level of specific heat of combustion, humidity and age of impurities, the following types of fuel are distinguished:

Lignite

A young type of coal with a specific calorific value of no more than 2.8 thousand kcal/kg. The raw material has a loose structure and a high percentage of ash formation. Lignite ensures the operation of industrial facilities - plants, factories, power plants, but is poorly suited for domestic use as fuel.

Brown coal

Product of the transition phase between black lignite and coal. During the combustion process, it forms a large volume of ash and coking derivatives. The calorific value of the fuel is 5 thousand kcal/kg. With an average humidity of 50%, the raw material is used for industrial boiler houses and chemical production plants. Due to the rapid clogging of the chimney system and heat exchanger, it is not recommended to burn household stoves and boilers with brown coal.

Coal

High-quality fuel with a calorific value in the range from 5 to 5.7 thousand kcal/kg. It is an intermediate link between brown coal and anthracite. It contains about 70% carbon and only 3% ash. Due to low humidity (20%), the raw material is not used for gas generating units, but is suitable for most models of household boilers and stoves.

Hard coal is divided into two groups:

- Long flame. The fuel is suitable for most domestic heating installations, provides a high flame and long-lasting combustion, and does not require additional blowing. You can use a small amount of wood or wood chips to light it.

- Low caking. The raw materials are suitable for heating a private home, bathhouse or industrial facilities. It is characterized by high thermal conductivity and lack of caking. The combustion process takes place without flame or smoke.

Anthracite

The best type of fuel raw material with a dense structure and rich black color with a calorific value from 7.1 to 9 thousand kcal/kg. At a relatively low level of humidity (7%), anthracite forms a small amount of ash, which is removed from the heating equipment along with gases. It comes in different sizes: small as a seed, medium as a pea, and large as a fist.

As a result of the release of a large amount of heat, heating of rooms with anthracite occurs quickly and efficiently.

What to do if the coal in the boiler does not burn well?

It is difficult to say in absentia why coal burns poorly or does not burn at all, because this happens for many reasons, but some of them are more common:

- reduction in draft due to clogging of the chimney and grate;

- using the wrong grade or simply low-quality coal;

- the boiler power is too high, which does not correspond to the area of the house;

- loading a large volume of coarse coal, without preliminary kindling;

- malfunction of the automatic forced air supply system;

- violation of the integrity of the structure (the flame often goes out + smoke).

In the case of the latter options, a boiler repair specialist will be required, but other problems can be completely resolved by proper operation and cleaning.

Principles and rules of kindling

The rules for lighting a stove have been passed down from generation to generation. Over the centuries, the technology has been refined, and today it has reached perfection. Many stove operating procedures form the basis for servicing modern heating equipment, such as pellet boilers

Preparatory work

Before lighting the stove for the first time after completion of construction work, you will need to wait until the solution has completely dried.

The first stage is an external inspection, paying attention to the following points:

- Corresponding thickness of seams;

- correct execution of brick ligation;

- compliance with vertical angles;

- ensuring the accuracy of tile installation.

In this case, deviations are allowed: for masonry without cladding - up to 5.0 mm, and up to 2.0 mm when facing with tiles, vertical - no more than 2.0 mm per 1.0 m height.

Next, check the density of the masonry. Typically, a material with a high emission of black smoke is used for this. A trial fire is carried out for several days in a row with a normal load of firewood. When the furnace is operating, not only the uniformity of heating along the outer walls is determined, but also the uniformity of cooling. Next, the structure is checked for cracks and, if found, they are promptly repaired.

Stacking firewood

Before laying firewood, clean the ash chamber to allow the blast air to flow without resistance through the ash pan to the flame. The stove is lit only with dry wood.

After cleaning the stove from any remaining ash, they begin to place logs in the firebox. This is done in two ways: • a hut with a cone for a large combustion space; • in parallel, maintaining clearances of 8 to 10 cm.

Firewood is placed in the center of the firebox or closer to the door until approximately 2/3 of the firebox is filled. The top of the combustion space must remain free at least 18–25 cm. Firewood should not be stacked against the back wall.

Methods of igniting a flame

Next, push the view to the desired level and push the blower door a little. The paper is lit with matches in front of a pile of firewood. After igniting the wood, close the combustion door. When burning evenly, cover the view. The combustion process is adjusted by opening/closing the viewer and the blower.

The firebox door must always be closed. Open it only if you need to stir the coals with a poker or add firewood.

Control of the combustion process:

- White flames and noise in the smoke ducts indicate a high draft; it is reduced by using the blower door.

- A red flame with dark smoke from the chimney indicates low draft and you need to open the vent slightly.

- The yellow color of the flame characterizes the normal process of fuel combustion.

Nuances of choosing fuel

A home stove is actually a universal heating device, since it can operate on different types of fuel: wood, coal, peat. In modern conditions, fuel manufacturers offer new types, so-called Euro-firewood, and various options for pressed briquettes.

The traditional fuel for the stove is birch, which has a high lower calorific value. Its logs burn out completely, do not shoot or spark. The only drawback of birch is that if it is placed in a firebox higher than normal, a strong fire can lead to a fire.

In terms of calorific value, the best fuel is oak, which burns for a long time and produces a lot of heat. Its net calorific value is almost 20% higher than that of birch. But since the price of oak is also much higher, before choosing, you need to make a simple calculation of what will be more profitable for heating in a given climatic region.

Oak firewood

Pine and spruce firewood have a heat transfer even lower than that of birch and oak. For the heating season, they are purchased 20-30% more. The presence of resin in the logs not only causes a strong crackling sound, they also shoot and can throw pieces of ash onto the floor; if it is wooden, a fire may occur. Therefore, when using this type of firewood, it is recommended to place a metal sheet in front of the stove.

Aspen and alder firewood are highly valued because in addition to providing heat, they clean the chimney of soot, which is why they are rightfully considered “royal” firewood.

Euro firewood performed well when firing a Russian stove, with a complete combustion process and low ash yield. Their price remains high, equal to the cost of coal, but their calorific value is approximately the same.

Some rules

Those people who have never lived in a private house or rural area, finding themselves in such conditions, may wonder how to properly heat a stove with coal, because such a skill can be useful at any stage of life.

During the entire period of fuel combustion, care must be taken to ensure that the materials burn evenly. To do this, they will need to be turned over about 2-3 times using a poker. If the coal or firewood is not mixed, the stove will simply go out. In addition, it is necessary to close the vent flap and chimney pipe in time (approximately after 2 hours).

At the moment when the coal is just burning out, these parts of the furnace should be partially closed. After adding the required amount of fuel materials, you should wait a certain time until they need to be mixed. This process should begin after approximately 50% of the fuel has already burned well.

View from the firebox

When the main volume of the bookmark comes, it’s time to lay the remaining logs and coal. All materials that remain in the firebox are moved to the side, then new firebrands are placed in the middle and heat is applied to them.

During this period, you need to remember to do less cravings. At the moment when the burned embedded materials are almost completely burned out, a light appears in which blue color predominates. This indicates that carbon monoxide is being released, and it has no place in the house. To get rid of it, you need to even out all the heat over the surface, and also open the chimney pipe for about 10 minutes.

Types of coal for heating the furnace

Depending on the material

Material for coal-fired stoves is the main criterion for choosing fuel and stove. Let's look at these qualities in more detail.

For cast iron stove

Cast iron, due to its characteristics, easily tolerates high temperatures, so such stoves, including brick ones, are better suited for burning coal. Coals designated by the letters:

- "A" - anthracite;

- “D” - long-flame;

- “DG” is long-flame gas coal.

Expert opinion Pavel Kruglov Stove maker with 25 years of experience

This stove charcoal is better than other types. Furnaces equipped with long-burning systems are recommended to use long-flame and similar gas types. “DG” fuel is most suitable for pyrolysis types of furnaces - they have an increased formation of exhaust gases when burning fuel from an oxygen-depleted furnace atmosphere.

Brown coal types are not suitable for cast iron stoves - a high ash content will require cleaning the chimney after 20-25 days of operation.

For brick kiln

The best coal for stoves and boilers is the type marked “A”. But some stove makers recommend heating such stoves with long-flame coal nuts. After the temperature has risen, anthracite is poured in.

This option allows you to maintain the temperature in the room and save expensive anthracite. This bookmark lasts until the evening. At night, add a seed, which maintains the temperature in the house for 8-10 hours.

Important! Boilers and stoves of different designs may change their tastes, so go to the forum and ask what fuel is suitable for your equipment.

This way you can not only save money, but also allow the heater to work normally. When choosing, a lot depends on your capabilities. You can purchase grade A fuel and provide yourself with anthracite with excellent characteristics.

Expert opinion Pavel Kruglov Stove maker with 25 years of experience

But for heating small garden houses it is better to buy coke or even brown coals. They will cope with their task no worse than anthracite, but are much cheaper. The low price of lingite makes this fuel in demand among summer residents or rural residents.

For steel furnace

It is recommended to use expensive anthracite, but coke fuel is also suitable. It is more important to choose the size of its fractions and apply a mixed use scheme.

Let us note right away that such furnaces must be made of thick and only heat-resistant steel. If you make a potbelly stove from an old barrel, it may not be completed until the end of the heating season. High temperatures when burning fuel will require the purchase of expensive stoves with parts 8-10 mm thick. This increases the mass and its price.

If you purchased a steel coal stove, be sure to read the instructions. In it, manufacturers indicate its brands and types.

Important! Regardless of the material of the stoves, before lighting the unit, be sure to open the air damper on the chimney, the firebox door and the ash pan, and pull out the ash collection box. Only after making sure there is sufficient draft can you fill the firebox

To do this, it is recommended to use firewood for kindling, then pour a “nut” into the compartment and use a “seed” before night.

Depending on the purpose

This fuel can be used to heat a house, greenhouse or bathhouse. Let's look at the main installation locations and the choice of types for them.

For baths and saunas

If you like the smell of burnt wood, then this fuel is not for you. Coal burns without smell or flashes of fire. Coal for the stove in the bathhouse provides heavy and moist steam for the steam room. Let's also add the high level of toxicity of ash to humans.

These are the disadvantages of such fuel for a sauna. But high temperature in a short period of time is an advantage for large baths. For a small steam room, it is better to use old, time-tested fuel - firewood.

For home heating

The choice depends on the size of the room. For a small garden house, coke or even brown coal is suitable, but you will need to clean the chimney more often.

This fuel has a lower heating temperature than anthracite, but costs an order of magnitude lower. Long-flame and long-flame gas coal is preferable for heating medium and large houses. But the highest performance is achieved by using anthracite.

The choice depends on the money you can allocate to purchase fuel. Using the mixed coal stowage described above, you can significantly reduce the cost of purchasing coal. Unlike stoves in a bathhouse, the house needs to be heated constantly.

Therefore, you will need to accurately calculate the entire annual supply of coal and purchase several types of fuel.

Why close the damper?

Closing the damper in the furnace in the house is necessary to preserve heat and regulate draft. It is installed in the upper part of the stove, under the ceiling, at the beginning of the chimney pipe. If you leave it open, the oven will cool down quickly.

When the damper is open, ventilation occurs inside the stove: cold air from the house enters the inside of the stove through the blower, warm air comes out through the pipe. Accordingly, the bricks cool quickly.

This does not happen when the damper is closed. On the contrary, the walls of the stove heat up more strongly; it can hold heat for up to two days, providing a comfortable temperature in the house. Allows you to use the stove more efficiently and save on fuel.

Technology for lighting a coal boiler - how to fire it correctly

Coal boilers are operated using the following technology:

- First of all, dry kindling material - rolled up newspaper or paper - is placed in the firebox. A small layer of wood chips is placed on top, and even higher - small firewood (for example, birch). It is best to lay out the firewood in a hut or in the form of a well so that it burns better.

- The paper placed in the firebox is set on fire. The boiler door closes and the ash pan opens. Using a blower, you can regulate the intensity of combustion - increasing the supply of oxygen directly affects the rate of burning of wood.

- A layer of small coal is placed on top of the completely burnt wood, which has turned into smoldering ash. The thickness of the coal layer is about 15 cm. Each time the door is opened, the ash pan must be completely closed.

- After the first layer of coal burns out, another layer is laid directly on top of it, but a coarse fraction is used for it. The thickness of the main fuel layer should be about 60 cm. Before laying a new batch of fuel, it is better to stir up the previous one a little to increase the intensity of air movement and prevent the coal from sintering into one large piece.

- Low-quality fuel may coke during combustion. To avoid this phenomenon, it is advisable to dilute the main coal layer with small layers of firewood - this will give the boiler the opportunity to warm up normally and ensure maximum heat transfer. The presence of a layer, among other things, will also greatly simplify the process of cleaning the boiler after fuel combustion.

- Proper lighting of the boiler requires that natural circulation is used to burn out the paper and wood chips, which is achieved if the ash pan is open. Due to this effect, the chimney will warm up, and the draft will increase gradually, and at a certain point you will only need to close the ash pan and turn on the fan.

Stages of the combustion process

The heat entering the room appears as a result of wood combustion

It is important to organize the combustion process in such a way as to achieve maximum efficiency and safety at each stage. Combustion does not occur instantly

This is a fairly long period that can be divided into two stages.

Ignition

The wood is placed in the combustion chamber and set on fire. First, the wood is heated or pyrolyzed, during which flammable or pyrolysis gas is released. Gradually it ignites, heating the fuel material even more.

Combustion

The temperature of firewood heated by burning pyrolysis gases increases to the combustion level. The entire bookmark ignites and burns evenly.

You need to know that without a sufficient supply of oxygen, pyrolysis gases burn out very quickly and exit through the chimney. In order for the combustion to be long and uniform, it is necessary to maintain an optimal temperature in the firebox, ensure the supply of oxygen, and ensure that the pyrolysis gas burns out completely.

Features of the combustion chamber of different types of furnaces

There are several types of stoves, depending on the material:

- Made of stainless steel;

- Cast iron;

- Brick.

How to properly heat a metal stove?

More often, these heating devices are found in bathhouses, but there are often cases when residents of ordinary rural houses build them for themselves. It is imperative to take into account the temperature in the wood burning stove when working with such a structure. Although such stoves are small in size, not every owner knows how to heat them in order to maintain heat in the room for a long time.

The general rules are identical for all types of stove structures, so do not be afraid of this matter - there is absolutely nothing complicated in it, every master can do it if desired:

It is important to remember that when working with metal stoves, there are several important restrictions that must be met immediately when starting work. First of all, in order to properly light the stove with wood without wasting it, you should not use flammable mixtures sold in stores to water the wood. This has an extremely negative impact on both the environment and the general health of the stove maker - an excessive abundance of chemicals, as well as the forced need to breathe their vapors for a long time, have not benefited anyone. Prefer to these auxiliary products special alcohol tablets, sold in the same section of the supermarket as lighter fluid - they burn for a long time

Thanks to them, firewood ignites quickly, easily, and also has a much lower level of toxicity. They can be used if there is a need to work with poorly dried firewood.

Features of working with a cast iron stove

One of the main rules for working with such a stove is to keep the doors and the blower structure tightly closed. The device for regulating the air draft must remain wide open - this is the only way to ensure the best quality of work with a stove of this type. In order to properly stack firewood in the stove, without fear of getting thermal burns, purchase special gloves to protect the skin of your hands, and an apron so as not to contaminate your clothes with soot. Be sure to take precautions during work - when loading each new portion of firewood, you must carefully open the doors, in no case in a hurry - the intra-stove pressure must certainly return to normal.

Properly heating a brick stove

In the first half hour of operation, such a structure must be heated very intensively, exactly until the optimal air temperature in the room is reached.

When the desired value is reached, a draft regulator should be installed to avoid a further decrease in temperature. The temperature in the firebox of a wood-burning stove must be stable. This will help significantly reduce raw material costs.

Brick stoves have the largest dimensions compared to other types of heating devices, so only physically resilient people who do not have health problems can work with such a structure. To ensure the smooth functioning of such a stove, you often have to lift heavy objects.

How to properly heat a brick stove with wood in winter?

In order to ensure maximum heat production in a brick kiln during the cold winter period, certain operating conditions must be observed. Keep in mind that in this case you simply need to know how to properly place firewood in the stove - each new load of firewood must take place at intervals of at least forty minutes.

Step-by-step instruction

Sooner or later, each of us faces the problem of wet firewood, and the situations can be very different. For example, when you need to light a fire in nature to keep warm, cook fish soup, shish kebab, baked potatoes, or when you need to heat the house, prepare a bathhouse to steam and wash. It is much more difficult to light wet firewood, but with the right approach this task can be easily accomplished. Let's consider at the same time how to heat a stove with raw wood and how to light a fire with it in nature.

To implement a simple plan for lighting firewood, we will need:

- a good ax, a sharp knife;

- wet firewood;

- fine salt;

- a stack of ordinary newspapers;

- lighter or matches.

First of all, we need to chop some of the firewood into small pieces, chips. Small pieces of wood will quickly dry out and catch fire, while large logs, on the contrary, will negatively affect our fire. A good ax and a sharp knife will allow you to do the work quickly.

Winter version of a small fire

Note that the firewood inside may well be dry, so we make chips and splinters from the middle part of the logs. If we are dealing with birch firewood, then we remove the birch bark from the blanks. On logs, birch bark will not immediately dry out and catch fire, but separately, on the contrary, it will easily ignite and give the necessary fire.

We build the hut on a pedestal of newspapers, additionally covering the chips on all sides with newspapers. When placing newspapers inside, you should crumple them and give them some volume. If there is birch bark, also lay it deep in the hut. Sprinkle fine salt on top of the structure. Being a good adsorbent, salt will draw out some of the moisture from the wood chips.

Carrying out preparatory activities before lighting the fire

Note that in a brick-lined stove it is very easy to assemble such a structure and light it. At least it’s more convenient and better to light such a stove than to work with a shapeless gray hole. For many stove owners, the memories of the difficulties they overcame during the construction stage, when they erected the stove, covered it with bricks, and covered it, are still fresh. All the efforts of that time were not in vain; now you can quickly and easily light a fire in the firebox, even from damp wood.

The preparatory measures have been completed, it’s time to set fire to our original structure

At the same time, try to pay attention to whether the wet wood-burning hut made of wood chips will catch fire from the newspapers. If you fail to light a fire the first time, repeat the procedure.

In this case, the dried wood chips will flare up better. If the fire catches on, it’s time to put in a couple of larger logs. This should be done so as not to block the access of air to the fire.

When the fire becomes more confident, you can add more wood. Try not to push too much, clutter the flame, or block the air (oxygen) access to the fire. Large logs can only be laid when you already have a sufficient amount of good coals. If you had to heat the stove with raw wood, then monitor the intensity of the fire, do not let it weaken too much, because if there is not enough heat for new raw logs, then everything may simply go out. Starting a fire requires patience, especially when you are dealing with raw fuel.

Decorative elements accompanying the stove

In order not to think about whether it is possible to heat the stove with raw wood, do the preparatory work, bring some firewood home and dry it near the stove for the future. Dry firewood stacked near the stove and ready for use will allow you not to think about such problems in the future. In addition, a stack of firewood can make a very original decorative item for the home.

Owners' opinions

Below are some reviews from stove consumers.

“We purchased a stove for the Rus bathhouse with a fireplace door. It looks great and very presentable. And it works even better - a couple of clutches, and the steam room is already 110°C. Comfortable warmth without the feeling of suffocation. Economical fuel consumption coupled with a stylish design and an affordable price - Teplodar with both hands!”

Zarina Radina, Sverdlovsk region.

“The most affordable option for our home was the opportunity to buy a Teplodar gas stove. We doubted for a long time whether this would be an effective solution. But in reality everything turned out to be very simple and functional. The latest design of the stove allows you to steam comfortably after just 30 minutes of intense heating. No worse than wood heating. Thanks to the manufacturer, we were satisfied."

Sergey, Moscow.

“Based on feedback from friends, I decided to purchase a Rus stove from the manufacturer Teplodar. Outwardly, it is presentable; I was attracted by the increased manufacturer’s warranty of up to five years. Well constructed - thick, good steel. It’s a pity I didn’t immediately buy a tank for heating water; then I had to run around looking for a suitable one. I haven’t found any complaints in operation yet.”

Mikhail Badin, St. Petersburg.

“Our bathhouse is small, we only have enough money for it, so an electric stove is enough for us. We purchased a very inexpensive and practical option from the Teplodar company. We steam with pleasure, just like in a real Russian bathhouse. Installation is simple and consumes little electricity. Considering that we use the bathhouse once a week, the operating costs are quite reasonable. Overall, the result exceeded all expectations.”

Peter, Ekaterinburg.

Price

You can buy sauna stoves in many dealer stores, as well as on the website of the manufacturer Teplodar. The table shows the price of equipment without taking into account the cost of additional installation of a gas burner.

| Name | Dimensions (WxHxD), mm | Steam room volume, m3 | Price, rubles |

| Blast furnace 25 LC | 615x995x705 | 10-25 | 26000 |

| Cascade 18 LP Panorama | 380x920x770 | 10-18 | 20500 |

| Kuban 20 L | 500x865x700 | 10-20 | 19900 |

| Laguna 12 TK | 855x330x690 | 6-12 | 15000 |

| Teplodar Rus 18 LNZP Profi | 335x810x790 | 10-18 | 22600 |

| Rus Panorama 27 LNZP | 440x930x800 | 18-27 | 30800 |

| New Rus' 18 L (2004) | 395x815x805 | 10-18 | 13800 |

| Sahara 16 LRK | 785x380x755 | 8-16 | 17500 |

| Siberian cliff 20 health care facility | 835x565x730 | 10-20 | 26500 |

| Siberia 20 LRK Panorama | 785x375x750 | 10-20 | 23200 |

| Taiginka 10 TU | 405x330x705 | 4-10 | 8500 |

| Electric heater SteamFit 3 | 560x400x240 | 12 | 16700 |

| SteamGross 3 oven | 580x530x643 | 26 | 41000 |

When can you light the stove after repair?

The repair process takes some time. Upon completion of the masonry, a period of time is required for drying. Only after it has completely dried can you melt it for the first time. Several features of this process:

- How long does drying take? The natural drying process lasts from 3 to 5 days. Many will ask why the unit cannot be heated during this period? The answer is simple: during this period, intensive removal of moisture from the structure occurs. Heat drying lasts about 2 weeks. In total, the entire process will take up to 3 weeks.

- Why can’t it be used immediately after repair? It contains a large amount of moisture when it comes to brick. Heating will cause the system to crack, and bricks may fall out and become deformed. In this case, all the work will not make sense, and everything will have to be redone.

Don't miss: Do-it-yourself Russian oven and mini oven: step-by-step instructions, drawings and order (+ best Photo projects)

At this stage, the owners may have a question: why is the coal not burning in the stove, because the repairs have been completed and everything is ready to go. This means that it has not dried completely and the material does not burn through. The danger is that if drying is insufficient, carbon monoxide and smoke can enter the room through the cracks formed and cause harm to health.

What are the main differences in heating systems using coal and wood?

Coal is still a fairly cheap product, and coal boilers are the cheapest of all modern devices.

Coal burns slowly, releasing enough heat so that the problem of loading a new batch into the boiler does not bother you too often. Coal boilers can also burn wood, but with less efficiency. Coal in the house is a constant source of dirt. Burning coal is harmful to the environment. Wood is considered an environmental fuel; when burned, no harmful compounds are formed. The cost of firewood can be very low. However, the price of certain types of wood fuel - briquettes or pellets - is still quite high. Harvesting firewood is a rather labor-intensive and time-consuming process. Wood boilers are more expensive than coal boilers. Modern boilers running on pelletized wood fuel are almost completely automated and do not require special maintenance.

A coal boiler is right for you if...

There is coal mining in your region, or for some other reason, coal is cheap and ordering it is relatively easy. In regions where coal is not traditionally used for heating, the use of such a boiler is completely unjustified. When both coal and wood are available and you are looking for an inexpensive automated boiler, a coal boiler is definitely your choice. Automated boilers for pellets and briquettes are still quite expensive, unlike the same coal boilers

Such a choice will allow you not to spend a lot of effort and time loading fuel, which is quite important for a rural resident.

A biofuel boiler is right for you if...

- You prefer cleaner fuel. Having a coal boiler in the house, you have to put up with constant pollution of the space with coal dust. In this case, even purchasing specially prepared portions of coal will not save you. It is clear that cleaning the boiler room is not a priority, not to mention the fact that we breathe this dust, which does not improve health in any way. Even simple firewood that sheds sawdust and bark is much more pleasant to use than coal. Pellets and briquettes do not pollute your home at all and do not emit harmful compounds into the air. Ash from wood combustion, unlike waste from the coal combustion process, is a valuable mineral fertilizer.

- You have access to cheap wood. In the “forest” regions of Russia, getting cheap firewood is not a problem. You can completely minimize costs if you prepare firewood yourself. Each household has the right to receive a plot of firewood once a year for very little money, however, this right is rarely used, since purchasing standing timber involves a considerable expenditure of time and effort. It’s easier to buy already chopped firewood, which will be delivered to your gate. If money is not an issue, then it is better to use pellets or briquettes for heating.

- Your priority is ease of maintenance of your heating system. Although coal boilers are automated, pellet devices are much more technically advanced. Some pellet boilers can be loaded once a week. Lighting such a boiler is quite easy - due to its small size, the granules ignite well. Most boilers are equipped with electric ignition, which is controlled by a controller, a sophisticated air supply system to the burner, and even an automatic device for removing combustion waste.