- Where to place the stove in the house

- Russian with a high bed

Connecting to central heating is not always possible and economically justified. Especially when it comes to life in a dacha cooperative or a remote village. In such a situation, you can limit yourself to a beautiful brick stove for a private house; photos of the best options are in our article.

The main advantage of this heating option is the use of brick blocks. They accumulate heat and release it over a long period of time. The draft promotes ventilation of the premises, the walls of the building remain dry, which is especially important for wooden cottages.

If this is provided for by the design, you can cook food. Some models provide a special bed for resting and sleeping.

But we should not forget about the negative aspects. In particular, only the rooms directly adjacent to the heating equipment are heated. The further the room is from the firebox, the colder it will be. There is only one way to fix the problem - to equip several units. They may have combined or separate chimneys. If the cottage is compact (according to the five-wall principle), the stove is placed in the central part. From the living rooms one can admire the open brazier; in the kitchen one can cook dinner.

Types of brick stoves for the home - photos

All existing modifications belong to one of the basic variations. They are adjusted, modified in size and shape, taking into account the parameters of the room and the wishes of the customer.

Russian

The main differences from all other variations are the massiveness and the presence of a sleeping place. For pots and pans there is a wide firebox, closed with a damper. The walls are heated by smoke channels of considerable length.

Dutch

You won't be able to cook a roast on it. The main purpose is to heat rooms through special passages from bottom to top.

Heating appliances are relatively small in size. They are chosen by the owners of country houses, including two-story ones. The shape of the unit is not strictly regulated. It can be chosen based on personal preferences. One thing remains mandatory - the height exceeds the width.

Swede

It is smaller in size than the Dutch one, but in terms of efficiency and versatility it is comparable to the Russian one. You can cook food on it and dry wet shoes in special niches. The Swedish stove is a channel-type stove, but the flue gases burn out under the roof. The design is not intended for large cottages. Its power is only enough for neighboring rooms. Another application is as an addition to a standard heating system.

A significant disadvantage is the high cost of masonry due to the use of fireclay bricks. In addition, a significant part of the heat escapes through the lower part. This can be avoided if you spend money on thermal insulation.

Bell furnaces

They appeared relatively recently, but have already gained popularity due to their uniform heating and ability to retain heat for a long time. The main difference from all the previously listed options is the lack of channels.

When wood or coal is burned, smoke rises to the top of the dome. Here it slowly cools and falls down along the walls, warming them up. The internal space can consist of dozens of individual vaults, which significantly increases the efficiency of the equipment.

Bell-type structures are characterized by minimal masonry costs and the ability to quickly warm up, including in winter. The gas view will not allow the structure to cool quickly when the damper is open. The original version does not have a hob, but if necessary, it is quite easy to build it in.

Presence or absence of a long-burning system

So that you don’t get confused, let’s immediately define this: there are long-burning stoves (we wrote about them above), and there are those with a long-burning function.

Almost every modern stove has a long-burning function. Its principle is that we cover the supply of combustion air to the maximum (we remember from school that the combustion catalyst is oxygen - the less of it, the longer and less intense the combustion). Considering that the task of the stove is to generate heat, all modern stoves are equipped with this function (only “stove stoves” lack it).

Types of furnace equipment for gas movement

The brick warms up well and releases energy into the surrounding space for a long time. But this is not enough for high-quality heating of the kitchen or bedrooms. The heat capacity is increased due to the arrangement of special chambers that promote heating of the walls.

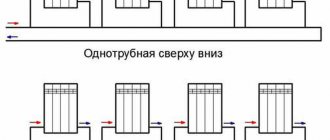

Without going into technical details, the movement of smoke through special channels occurs as follows:

- During the combustion of wood or coal, gases are formed that have an extremely high temperature. Under the influence of physical laws, they rise upward, but are delayed due to obstacles in the form of jumpers and valves;

- smoke begins to spread through the flues, heating the walls;

- the temperature of combustion products decreases. They go into the outlet pipe.

If the channels are laid horizontally, less time is spent on cooling than in analogues with vertical ones. The reason is the low air speed. The inevitable consequence is uneven heating of the rooms.

If we analyze all existing types of stoves, it is preferable to choose units with chimneys laid from the bottom up. No additional effort is required to move the gas. They inevitably move upward and warm up the surrounding space.

But equipment with a vertical chimney is not without its drawbacks. If, in the presence of horizontal channels, the space around the firebox warms up more, then here the heat accumulates in the upper part. The first option is more consistent with fire safety standards.

Another important point concerns furnaces with vertical channels. They should not be too long. The gas passing through them will cool down greatly. The result is uneven heating.

In bell-type heaters, it was possible to partially eliminate the disadvantages associated with heat distribution. Here, separate outlets open into a single chamber. The smoke passes through small-diameter holes and is collected in a hood under the upper ceiling. The combustion products partially cool and fall down. Then they rush into the atmosphere, obeying the natural forces of nature.

In terms of heat capacity, bell-type units are better than their analogues. They are chosen when it comes to heating a house of a large area. If you need to heat a small building at the dacha, a Dutch or Swedish one is enough.

Classification by heat capacity and wall thickness

We looked at once popular stoves by country of invention and their name. However, grouping by heat capacity is more practical - such heating devices are not designed for constant combustion, so their ability to accumulate and release heat is important.

Russian stoves are the most heat-intensive due to their massive construction.

Thin-walled stoves are about 6.5 cm thick. In most cases, the base of such structures is a steel frame, less often a case. No foundation is used, this allows the stoves to be installed on any floor, including wooden floors. The temperature of thin-walled species can reach 90 0C, but their heat capacity is low. The room will get colder 2-3 hours after the fire goes out.

Brick kiln performance

The task of any stove is to compensate for heat loss during the cold season. Cooking food and drying things are additional, albeit important functions. But when calculating power they are practically not taken into account.

The main parameter is the thermal characteristics of the building. To calculate them, energy losses through the floor, walls, ceiling, doors and windows are added up. If the building has ventilation ducts, they must be taken into account. The productivity of a Dutch or Swedish woman should exceed the obtained value by 10-15%. Otherwise it will be cold in winter.

During the use of stoves for a red brick house (pictured), the interdependencies between the area of a separate room and heat loss under different conditions, for example, in the presence of only one or two external walls, were experimentally established.

In the second case, the calculations become more complicated, since the height of the ceiling is taken into account. If the surfaces of the firebox face the rooms and are closed, correction factors are used. They allow you to correct the data.

Chimney installation

The main task when laying a chimney is to comply with fire safety.

The walls of the chimney should be made of two bricks, and the distance between the chimney and the roof should be about 70-80 cm. All cracks must be carefully sealed to avoid leaks.

How often should you light the stove?

Taking into account how often fuel has to be loaded, all units belong to one of the groups listed below:

- periodic action. Firewood or coal is added from time to time. The combustion temperature can reach 1000 0C. To avoid fire and premature destruction of the structure, the wall thickness should start from ¾ brick;

- continuous burning. Heat is not accumulated. The density of the walls does not exceed ½ stone. The firebox is of shaft type. In the standard version, firewood smolders for up to a day. Energy is released evenly, in relatively small portions.

The second type of firebox requires large volumes of oxygen to operate. They are recommended for homes with permanent residence. At dachas and cottages used only on weekends, it is better to choose designs with periodic action.

In relation to the previously discussed types of equipment, the following must be indicated:

- Russian stove. During the cold season it is heated continuously. The body should not cool down. Otherwise, condensation will accumulate in the channels. The brick gets wet and cracks during subsequent ignition. In the summer months, by moving the valves, the fumes from the firebox are directed directly into the chimney. There is no heating effect;

- Dutch. After ignition, it warms up in a few minutes. But it cools down just as quickly if you don’t close the view in time. Recommended operating mode: continuous smoldering;

- Swede. In winter, it cannot be cooled completely due to accumulating condensation. The masonry can completely collapse within a few months;

- bell-shaped Operation in any mode is allowed. Warm up in a few minutes.

Nuances of choosing a heater

When selecting a wood-burning stove, it is necessary to take into account working conditions, the specifics of the material, financial costs and personal preferences. Before purchasing a unit, you should pay attention to the following points:

- Brick structures are characterized by high heat transfer, but require financial investments in construction. Cast iron heats the room well and is installed without a foundation.

- Functional heating and cooking models are equipped with several burners and an oven.

- Pyrolysis devices ensure complete combustion of fuel.

- The optimal wall thickness of a furnace with a water circuit is from 75 mm.

- A unit with automatic fuel loading is loaded with circular sawn timber 10-15 cm thick.

- Due to their low efficiency, cooking and heating structures are suitable for rooms up to 25 m2.

- If you have a sauna or bathhouse, opt for a heater.

- The safest type of firebox is closed.

- It is easier to connect an expansion tank and heat exchangers to modifications with an oven.

Wood stoves require careful maintenance and compliance with operating conditions.

How to choose a stove for a red brick house - photo

If we are talking not only about heating, but also about complementing the interior, you can give preference to a round Irish stove. The thickness of the walls is ¼ stone. To give additional strength and increase heat transfer, a metal frame is “put on top”. It will strengthen the masonry and allow you to decorate the outer surfaces with forging.

If there are always people in the building, and there is a desire to cook food on wood or coal, you should choose a square or rectangular design, for example, Russian or Swedish. If you need a fireplace more as a stove for your home, pay attention to thin-walled Dutch or round Irish stoves. They are ideal if you don't need a special cooktop. And the front surface can be decorated with elegant tiles. They can become both an addition to the interior.

Do you want to stop using a gas stove? Variations of the Swede are at your service. They will warm you up and allow you to brew coffee over an open flame. The main thing is to correctly lay out and select the source materials.

Where to place the stove in the house

The main focus is on the design phase. The quality of the drawings determines the safety, performance properties, and aesthetic appeal of heating equipment. If you don’t have your own drawing skills, it’s better to turn to professionals. When choosing a place for placement, both the type of heater itself and the area of the cottage or part of it that is planned to be heated are taken into account.

Selection of working tools

Then you can move on to the tools. For work you will need:

- jointing With its help, concrete is poured into the seams;

- trowel;

- pick;

- shovel for mixing and supplying the solution;

- special line.

Materials

The next stage is purchasing the material. The heat transfer of the stove and its durability will depend on the quality of the brick. The rules are as follows:

- the outer surface is made of brick (grade M-500). They do not crack, do not lose their consumer properties during periodic heating or cooling;

- Only refractory bricks are suitable for the combustion chamber.

In addition, you will need sifted sand and high-quality clay.

Laying the foundation

Materials have been purchased. You can move on to the construction stage. It is important to understand that the stove must stand on a strong and high-quality foundation. It is better to lay it at the same time as the base of the entire house.

If the decision to build a Dutch or Swedish one is made only now, you will have to:

- dig a hole. On each side there should be at least 20 cm to the walls;

- level the bottom and fill it with sand, followed by thorough compaction;

- lay a waterproofing membrane;

- install formwork;

- pour concrete (1 part cement x 2.5 parts sand x 4 parts small crushed stone) to ground level. The surface of the foundation must be strictly horizontal;

- wait 5-6 days for the concrete to harden. After this, you can disassemble the formwork and lay waterproofing.

If, as a result, the foundation ends up below the floor level, it is leveled by additional pouring of concrete mixture. In the latter case, the formwork is rebuilt. The entire space around the foundation is filled with soil and thoroughly compacted.

Masonry process

First, a mixture of sand and clay, previously soaked, is prepared. It fills the gaps between the outer and inner walls. They are displayed separately, but there should be no spaces between them. The lowest rows are only made of solid brick and with a sling. Then the brick is cut taking into account the selected modification. The chopped side faces the inside of the masonry. To build a chimney you will need red burnt stones. Knowing the “castle” layout will not be superfluous. A brick chimney must be lined with a FERRUM stainless steel chimney to prevent the formation of condensation and premature destruction.

Is the oven built? There is no need to rush to melt it. You must wait at least 3 weeks.

Exterior finishing method

- decoration with tiles and/or ceramic and fire-resistant tiles; equal gap between bricks between rows and between strips - jointing; rubbing bricks against each other - the old way; whitewashing, painting; lack of finishing - not recommended, as it can cause delamination of the mortar and the appearance of cracks .

Sources:

- www.stroitelstvo-new.ru

- ostroymaterialah.ru

- www.portaltepla.ru

There are no similar posts, but there are more interesting ones.

Three options for laying a stove with orders

Below is information regarding the construction of the main body of heating equipment. Laying the foundation is discussed in detail in the previous paragraph of this article. The most popular modifications are selected as examples.

Russian with a high bed

Settles in regions with cold and temperate climates. It is heated once/twice a day.

Below are descriptions of the rows:

- The first should be continuous using cement or lime mortar.

- Starting from the 2nd to the 4th, they begin to build a semblance of a well. On the front side there is a hole for baking. A prerequisite is the presence of a dressing.

- 5th - beginning of the arch. To lay it out, you will need shaped formwork, and the heels of the bricks will have to be pulled off. The operation continues in lines 6 and 7. In the 8th the vault closes.

- Rows 8 to 10 are laid out in one stone. At 11, the cold stove turns off. A layer of sand is poured on top. It should slope towards the rear.

- In the 12th, a continuous surface of refractory stone is laid out over the poured sand. This part of the firebox will be in direct contact with the fire. It is desirable that the floor is perfectly level. Does not work? You can add sand and sand the outer surface.

- Rows 13 to 16 are a crucible. Blocks - 3/4, with a sling. No masonry mortar is required at this stage. To make castles, the stones are cut to 450.

- Starting from the 17th line, the mouth and posterior surface are formed. The cooking chamber is being built. A brick with hewn heels is placed on its edge.

- 18th. The furnace walls are laid out. To fill the free space between the individual chambers you will need sand. You can add cut heels to it.

- 19th - laying out the vaulted opening above the pole. Behind it is the mouth.

- 20th - the walls are leveled. The hole above the pole is reduced. A cross-pipe is formed.

- The 21st row is no different from the 19th.

- 22nd - the vault closes. On the right is a chamber in which soot will accumulate. The view is also located here. With its help, the chimney is blocked so that the heat does not escape into the atmosphere too quickly.

- Lines 22 to 32 - laying out the overpipe, laying the view and building a chimney channel. The cross-section of the latter is 26x26 cm.

After this, all that remains is to remove the outer pipe and mount an additional damper. It will require a steel corner or strip 3 mm thick.

Semicircular chambers can be replaced with ordinary rectangular ones.

Improved "Teplushka"

All brick ovens have one common drawback - the walls heat up unevenly. Builders are trying to solve this problem by introducing changes to the design. This is how “Teplushka” appeared. After fuel combustion, part of the gas leaves the house immediately through the chimney. The remainder goes into the channels and is intended for space heating.

Heat transfer in comparison with the classic Russian modification increases immediately by 2.5 times. Structurally, “Teplushka” is closer to its bell-type analogues. The chamber is divided into 2 parts: food is prepared in the upper part, fuel is burned in the lower part. The floor itself is supported by pre-installed posts. Additionally, there are 4 openings on the sides to allow combustion products to pass through. The minimum chimney height is 5 meters. The countdown is from the bottom of the firebox.

The main differences from the traditional version are the displacement of the channel relative to the firebox. To remove cooled gas, special holes are laid at the bottom of the channel.

Important! The damper must be closed during cooking. You can use a special peephole.

The orders for the "Teplushka" are presented in numerous diagrams. The main requirement is that to increase heat transfer, the ceiling installed in line 21 is carefully covered with a mixture of sand and debris.

Simple stove with shield

This option is for those who want to build a stove at their dacha or in a small country cottage (no more than 20 square meters) with minimal costs, including temporary ones. The firebox is made of fireclay clinker, optionally red solid (provided that only coal will be used as fuel).

Cooking and burning fuel are in separate chambers. Gases pass through the cooking chamber and pass into the chimney. Photos of brick stoves for the home allow you to see in detail all the necessary masonry sections.

A horizontal channel is installed at the very bottom. Thanks to it, the air near the foundation warms up well. A microclimate favorable for humans is created in the room.

Various functional purposes

First you need to decide on the functions that the device will perform.

This could be a stove:

- only for cooking;

- exclusively for heating the house;

- to perform both of these functions, i.e. combined option.

A hob is most often installed in small free-standing kitchens. The heat from burning wood is abundantly enough not only for cooking, but also for heating such a room.

A small cooking stove is suitable for an unheated kitchen, it will provide enough energy for cooking and will warm the surrounding area

Therefore, the device is placed next to two external walls so that excess thermal energy moves outside. In this case, the chimney is strictly vertical and small in size.

Heating stove . The design provides for maximum retention of thermal energy within the house. Such a device has neither a stove nor an oven, but the oven array is equipped with an extensive smoke circulation system.

Heating brick stoves are necessarily equipped with a massive chimney in order to retain as much thermal energy as possible within the house

A bulky chimney is necessary so that combustion products do not leave the house too quickly and have time to heat the brickwork, which then gives off heat to the air inside the premises. Such a stove is placed as close to the center of the house as possible so that individual rooms are heated evenly.

Detailed information about the installation of stove heating in a private house is presented in this article.

A brick hob with a metal oven can be an excellent alternative to conventional gas equipment if there is no gas or electricity

Combination oven . For its installation, both a hob and a branched chimney are used. They place it in the kitchen, but not near the outer walls, but next to the inner ones. The chimney is also, if possible, shifted towards the living rooms in order to provide them with sufficient heat.

Advantages of a brick kiln

The main advantage of Swedes and bell-shaped variations is their heat capacity. If you choose the right place for placement and lay it out without errors, you can maintain a comfortable temperature in 4 rooms at once using one device.

Additional advantages include:

- independence from central heating;

- environmental cleanliness. If you don’t throw plastic yogurt jars into the firebox, a minimum of harmful substances will be released into the atmosphere;

- unpretentiousness in care and maintenance;

- the ability to choose a completely unique exterior design.

Another important aspect is the creation of a favorable microclimate in the rooms. The air does not dry out, and the walls warm up well.

Operating rules

A fireplace, a small sauna stove or a wood-burning model with a steam generator should not create fire situations. The operation of wood heaters involves:

- Installation next to the combustion chamber of a metal sheet 2 mm thick. The length of the protective product is 30 cm, the extension beyond the brick structure is 15 cm.

- Installation of smoke exhaust systems for metal structures made of acid-resistant materials.

- Use for burning dry firewood stored indoors.

- Dense fuel laying - thick lumber is on top.

- Use thin dry twigs for ignition.

- Laying firewood with a gap of 1/5 of the height of the firebox to the roof.

The second batch of fuel can be added after at least 1 hour, for long-term combustion models - after 3-4 hours.

Tips from the professionals

A brick stove in a wooden house will create an aura of warmth and comfort - interior photos confirm this. But its masonry should be treated with special attention.

On specialized websites, experts and amateurs share their experiences and present ordering schemes. You can also find plenty of finishing tips.

To summarize the most frequently encountered recommendations, we can highlight the following:

- special attention to the dressing and thickness of the seams. The last parameter must be the same throughout the array;

- brick blocks are pre-soaked in water;

- for cutting you will need a grinder with diamond wheels;

- In the smoke ducts on the walls, no cement should be visible from the seams.

Main advice: if you have no experience in construction work at all, it is better to initially contact a specialized company.

I made a foundation for the fireplace stove, tied to the main tape. Am I right?

No. The stove, like a cat, loves to walk on its own, and the foundations for heating structures must be autonomous. This will protect the foundation from frozen groundwater, movement and any lateral loads.

Exceptions are made in two cases:

- quicksand soil;

- piles.

In the case of an abutment, a soft insert is installed between the furnace foundation and the tape. But not a wooden shield, for example, or sand. The simplest soft insert around the perimeter of the foundation under the stove can be made from a foam plastic board 5 cm thick.

If you nevertheless decide to make a common foundation for the house and the stove, you need to take into account the uneven load and install additional reinforcement in the concrete monolith between the main perimeter and the platform along the foundation of the stove.

Video description

Another option for creating a stove is shown in the video:

- Further, in the twelfth row, exactly 18 bricks are used.

With their help, the door of the cleaning compartment is closed and the formation of the rear wall of the fireplace chamber continues.

- At the next stage - for the thirteenth row, 19 bricks are used.

When using blocks in a fireplace compartment, they are pulled out and cut away. The same row allows you to raise the walls of the open hob.

- Also 19 bricks are used in the next, twentieth row.

They begin to form a shelf above the fireplace insert. To do this, each brick is pushed 3 cm not only forward, but also to the side. The result is an overhanging row over the firebox.

- Further, in the twenty-first row, 20.5 bricks are used.

With their help, the walls of the cooking compartment are completed and the construction of the fireplace mantel continues.

- Then, in the twenty-second row, 15.5 bricks are laid.

They are reinforced with a steel angle above the cooking chamber. Metal strips are also used above this compartment. They are installed in the middle and rear part, the so-called ceiling of the cooking chamber. The elements are needed to subsequently cover the entire tier.

Video description

You can clearly see one of the options for arranging a Swedish stove without a fireplace compartment in the following video:

- The next, tenth row is created with bricks in the amount of 17.5 pieces.

They cover the front part of the place where the oven will be. The blocks are mounted directly on metal strips. Their installation allows you to combine the space above the firebox and oven. In this case, cutouts are first made at the top of the bricks used. They will allow you to subsequently lay the cast iron hob.

On a note! At the same stage, a place is designed where in the future a small door will be installed, allowing the upper part of the fireplace chamber to be cleaned.

- For the next, eleventh row, use 18.5 bricks.

From these they begin to build the walls of the brewing compartment, where there is already a cast iron panel. The brick blocks laid on the right should close the gap between the fixed cooking plate and the already created wall. At the same time, the blocks that are used to create the back wall of the fireplace chamber are pushed forward 4 cm and then pulled together. This allows you to continue creating the inclined surface.