The traditions of the Russian bath are slowly being restored and gaining great popularity. A sufficient number of private baths have already appeared in summer cottages and in the courtyards of private houses. Those who have recently built a bathhouse, but have never encountered the process of lighting a bathhouse, may have some difficulties in how to properly heat a bathhouse. Because preparing and lighting a bathhouse is an art. The main thing in this matter is to start, and experience will come with time.

The most important thing before you start heating the bathhouse is to clean it well and take out everything unnecessary. Sweep thoroughly so that there are no leaves or debris left anywhere, not only in all rooms of the bathhouse, but also in the woodshed. Wash the shelves in the steam room and benches with an antiseptic solution and a brush. Wipe the walls, floor and ceiling in the steam room and soap dish. Wash the stones. Ventilate everything well, open all doors, windows, vents wide.

How to heat a sauna

Heating a sauna is an art.

You need to know its subtleties: how to properly add firewood, what material to use, to what temperature it needs to be heated. The ideal, safe and profitable fuel is firewood.

Before taking bath procedures, you need to prepare it. Be sure to fill the boiler with water first.

First you need to put things in order. Wash floors, ceilings and all shelves using antiseptic agents. Ventilate the room well.

Preparation takes place in several stages:

Preparing the steam room for bath procedures

To start heating the bathhouse, you need to clean it thoroughly. We don't mean to say that everyone leaves a mess behind.

In a bathhouse, as in an auxiliary and non-residential premises, many things are left for storage, so putting things in order means removing from the room everything unnecessary and not related to bath procedures.

Check the floors of the room for wood chips left over from the firewood after the last visit to the steam room. The wood chips themselves are not harmful, but they can cause injury.

Please ensure that there are no soap residues on the floor. When water hits a soapy area, it turns it into a skating rink.

The secret of brick kilns

Traditionally, several types of stone stoves are used to heat baths. The more massive the stove, the more difficult the ignition process. For example, a Russian stove in a bathhouse, which is used a couple of times a month, is sometimes very difficult to light, especially if the building has been standing in the cold for a couple of weeks and is completely frozen, from the cap on the chimney to the foundation.

The easiest way to heat a sauna is with traditional Dutch ovens or fireplace stoves.

The mass of the Dutch oven is small, the wall thickness is at best half a brick. Therefore, it is enough to check the state of the draft in the pipe, and you can set fire to the wood.

Then everything is simple, two logs of wood are placed in parallel in the firebox, the driest ones that are available in the firewood supply. Wood chips are laid out on top of the logs, set on fire and the material is placed so that the lower logs warm up and begin to smolder. The rest of the firewood is loaded into the stove to capacity and waits for the first burnout.

After ¾ of the stored firewood has burned out, the firebox is loaded with a second portion, the valve is closed, and you can go steam.

Fireplace stoves are 2-2.5 times heavier than Dutch stoves; in addition, the fire in the hearth must be constantly maintained by adding a fresh portion of firewood. If the bathhouse is supposed to be heated with a fireplace, then a separate person will be required to manage the process - a stoker, whose responsibilities include managing the process of burning wood.

A fireplace stove has one advantage - very strong draft. When wood is burning in the hearth, there is a real draft in the dressing room. Therefore, to gain heat and heat in the heater, you can burn peat briquettes along with firewood. Only after the cast-iron mirror, screen and fireplace chimney have warmed up to maximum temperature, can you install a screen in front of the fireplace, close the damper and only maintain a small flame so that the draft in the chimney takes away smoke and carbon monoxide from the dressing room.

Pellets

Pellets are compressed wood waste (shavings, sawdust, etc.) in the form of granules. Their density is approximately 2 times higher than the density of ordinary wood. Only 1 kg of pellets can produce about 5 kW/h of heat, which is much higher than firewood.

Pellets help achieve the most efficient heating. The combustion process occurs as follows: first, the material itself burns with a significant release of heat, then the resulting gases burn out, which increases the efficiency of the furnace.

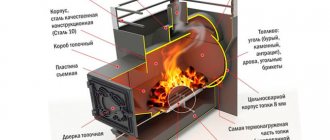

The difference between a metal and brick stove in a bathhouse

A metal stove warms up very quickly during combustion and can reach operating combustion mode within 15-20 minutes from the start of combustion. This allows you to heat the room as efficiently and quickly as possible. But this also brings with it some inconveniences.

For example, the consumption of firewood for long-term heating will be greater in a metal stove than in a brick stove. Let the brick oven warm up much longer and reach the operating combustion mode. But after the brick stove has warmed up, it can maintain a very stable temperature not only in the firebox, but also in the chimney.

How to level out these differences and add the positive aspects of a brick stove to the advantages of a metal stove? The simplest option is to use a brick shield with a metal stove, as well as install a brick chimney with a sleeve for a metal sauna stove.

In this case, more firewood can be added and the burning time will be extended. The process of heating the steam room in the bath will take a little longer, but the heating will be more uniform. Not only will the area of the room next to the stove warm up, but the farthest corners will immediately warm up as well.

Let's give the country coal

The use of coal for heating a bathhouse is a very delicate, if not scrupulous, issue. On the one hand, coal, especially high-quality anthracite, is a very high-calorie fuel that maintains the temperature inside the coal cake for a long time. In addition, anthracite and semi-anthracite produce relatively few volatile substances during combustion; they form soot plugs in chimneys.

On the other hand, truly high-quality anthracite is not always available and is almost always not cheap. Ordinary gas coals are prone to the formation of flue gases saturated with solid soot particles, which radically pollute smoke exhaust systems.

And finally, the combustion of coal is associated with the formation of a large amount of ash, which requires disposal, and the combustion process itself is accompanied by the characteristic and unpleasant smell of coal tar. In general, coal cannot be classified as an environmentally friendly fuel and therefore, when solving the problem of what is the best way to heat a bathhouse, coal should be considered last.

The dilemma of how to properly heat a bathhouse with a metal stove with coal is in most cases solved in budget establishments that provide bathing services on a commercial basis. Due to their specificity, heating with wood, and of high quality, is quite a costly undertaking, sometimes eating up all the profit.

Fuel selection

When kindling, you can use firewood from different types of wood:

- Thuja, pine, spruce. They are inexpensive and burn out quickly. The main disadvantage of the fuel is the content of resins, which settle on the walls of the chimney and do not burn out.

- Birches. They flare up quickly, burn long and evenly. When burned, they release a pleasant fragrant aroma that fills the bathhouses. It is recommended to use fresh, dried wood.

- Duba. This breed has a high heat transfer rate. Prepared logs can be stored for a long time without loss of quality. Burns for a long time and heats evenly. The disadvantage is the high price.

- Acacias. High thermal conductivity. Provides uniform heating.

- Aspen, poplar, linden. They have low density and burn out quickly. Do not provide strong heat.

- Hornbeam. They have a high thermal conductivity. The flame is smokeless, the burning is long, even, the heat is strong.

A separate type of solid fuel that is gradually gaining popularity is pellets and briquettes. The first are granules that are made from sawdust by pressing. The latter are similar to bricks, made from sawdust of different sizes. The main advantage of these types of fuel is long burning and intense heat.

Firewood or coal?

At first glance, coal appears to be an attractive fuel. However, coal burns differently than wood. Having caught fire, the briquette gives off the first portion of heat with lightning speed, and then smolders for a long time. This pace is suitable for heating a house, but not for bathing procedures.

Compared to coal and gas, wood is almost ideal. They are not explosive, give a uniform, long-lasting combustion, and are relatively inexpensive. Firewood can be replaced with other solid fuel, but not coal, but wood products - for example, fuel pallets.

Most commonly used types of wood

Each type of wood has its own density and calorific value. These indicators affect the amount of fuel burned that is necessary to achieve the desired temperature in the room.

If we compare tree species growing in Russia in terms of heat release, then the hornbeam has the highest value, and the poplar has the lowest. Consequently, to warm up the steam room to the required temperature, less hornbeam firewood will be required, and more poplar wood. From this we conclude that the best firewood for a bathhouse is hornbeam.

However, it does not grow everywhere. Therefore, you should pay attention to what kind of wood is common in the area where the bathhouse is located. Let's give an example: hornbeam has the highest calorific value. But if the bathhouse is built in a place where it does not grow, then a lot of money will be spent on purchasing hornbeam firewood. Therefore, to fire a stove in a sauna, you should choose wood with the highest heat transfer value among those that are common in the region where the sauna is located.

The most common species are birch and alder. Burning occurs evenly with the release of beneficial essential oils. Also, spruce and pine grow in all regions, but if there are other options, it is better not to use them. They burn quite quickly and release resins that can clog the stove chimney.

You can heat a sauna with the following types of wood:

- Hornbeam has the highest calorific value. Burning takes a long time and no smoke is produced.

- Linden , aspen and poplar have a relatively low density. What is the reason for their fairly rapid combustion without the formation of coals, they have a low calorific value.

- Acacia - has a good calorific value and maintains a constant temperature in the combustion chamber.

- Oak is a good fuel for a sauna. As it burns, the steam room is filled with a pleasant forest aroma. Harvesting firewood from oak begins in late spring (others - at the end of winter or early spring). It has a high heat transfer rate, but its cost is also high. Such firewood can be stored for quite a long time without changing its quality and performance.

- Spruce , pine, thuja - grow everywhere, their price is low, and are used only if it is not possible to use other species. The main disadvantage of conifers is their resin content. They do not burn completely and fall on the walls of the chimney, as a result of which it becomes clogged.

- Birch flares up quickly, combustion occurs evenly and for a long time, while substances are released that clean and disinfect the steam room, and also fill the air with a pleasant aroma. The best firewood is one that has been recently dried, as the aroma is significantly reduced 3 years after the tree is cut down. When using birch firewood, the air dosage must be observed. If smoke is generated, tar will begin to be released, resulting in the chimney becoming clogged.

Safety precautions

Safety regulations:

- Damaged ovens must not be used.

- It is necessary to regularly clean the chimney to prevent smoke from entering the bathhouse.

- It is prohibited to use chemicals or liquid fuel for kindling. Compositions for igniting stoves are allowed for use.

- Firewood cannot be stored or dried close to the walls of the stove.

- There should be a sheet of metal under the ash hole to protect the floor from coals falling out.

- Do not leave the oven door open during combustion.

- Bathrooms should have proper ventilation.

- After each fire, you need to clean out soot and ash from the combustion chamber and ash drawer.

- You cannot fill the firebox to the very top.

The following cannot be used to light stoves:

- painted boards;

- old clothes, rags;

- plastic products, rubber;

- rotten, rotten logs.

Garbage not only clogs the firebox and chimney faster, but also emits a pungent, unpleasant odor.

What kind of wood to heat the bathhouse with?

You can heat a sauna with a variety of wood types. We have all sorts of trees, and each of them behaves differently in a sauna stove. In order to heat the stove perfectly, the wood must burn for a long time, produce a lot of heat and little smoke.

Bad, rotten, moldy firewood can simply ruin the entire sauna process. The bathhouse can become completely saturated with unpleasant aromas.

Be reasonable, do not use painted boards and other wooden rubbish for the firebox, I assure you, it will not bring any benefit! Old junk can be toxic and unsafe for you and for the queen of the stove herself!

Oak firewood

Young oak will give a wonderful aroma in the bathhouse and create a unique atmosphere, but there will be no real heat from such firewood. Old oak wood is also not suitable for a stove; it is too decrepit and old, and produces ash rather than heat. The air in the bathhouse will be heavy and don’t expect light steam.

If you choose oak as a sauna fuel, then opt for a middle-aged tree. Firewood must be strong, dry and under no circumstances rotten!

Rotten firewood does not provide heat, it only smokes. But strong oak logs will heat up the bathhouse properly!

Oak is famous for its hard structure, it burns for a long time and produces a lot of heat. Oak firewood is economical; to properly heat a bathhouse, its consumption will be much less than other firewood.

Birch firewood

The most popular fuel in the sauna world is birch firewood! They heat a sauna perfectly, light up easily and burn evenly, their coals retain heat for a long time.

The birch heat from the stove disinfects the air in the bathhouse, making it light and soft. In a bathhouse heated with birch firewood, hot air is inhaled much easier.

Birch firewood has excellent heat transfer, it is almost 30% higher than the amount of thermal energy that pine or aspen provide when burning.

Wood and birch bark are extremely rich in tar, which is nothing more than a carbon compound. It is birch tar that allows you to quickly build a fire and burn logs well.

Birch bark replaces paper for lighting the bulk of firewood in the stove.

Birch fuel has only one drawback - it quickly deteriorates and deteriorates. Rot appears inside the logs; there is no heat from such firewood. The service life of harvested birch firewood is no more than two years.

Alder firewood

Alder firewood is very similar to birch firewood. The spirit of alder firewood in the sauna will make you cheerful and energetic. And popular beliefs say that a sauna heated with alder is an excellent anti-cold remedy.

Alder is a good wood for a sauna stove. Firewood produces almost no smoke, produces a lot of heat and can be stored for quite a long time. When burning, this tree emits beneficial fumes, which perfectly clean the chimney of soot.

Alder firewood dries well and does not require special drying conditions.

Linden firewood

Linden is a special tree and can also be used to heat a sauna stove. It’s just that you’re unlikely to be able to light the wood quickly.

Linden logs light up slowly and difficultly, but then burn well, heating the sauna stove perfectly.

There is no secret that linden is a healer! In ancient times, warriors who were wounded in battles with foreigners treated their wounds in a hot bathhouse heated only with linden wood. After the bath we drank linden honey and quickly recovered.

Linden firewood, like birch firewood, has a limited shelf life (no more than two years). After this period, the firewood quickly deteriorates.

Aspen firewood

Aspen firewood is not the best option for high-quality heating of a bathhouse. There is no excellent heat in aspen! However, aspen has an amazing property. When burning, wood does not produce soot or smoke and emits (like alder) special fumes. It is these fumes that are super-disintegrators of soot in the furnace chimney.

The soot simply falls into the furnace and the furnace vent, where it can be easily cleaned out. Thanks to this amazing ability, aspen wood must be used to fire the stove.

Poplar, Willow, Ash firewood

I combined these three trees into one story of firewood for a bathhouse. The fact is that they are in no way suitable for the queen of a sauna stove. They burn out quickly, do not produce heat and are of low quality.

Willow and ash smoke is very acrid and bitter, if it gets into the steam room - disaster!

Conifers

All coniferous trees are rich in resin, so they burn well, evenly and quickly. Coniferous wood is rich in essential oils; they create this unique forest aroma in the steam room. But in order to heat the bathhouse hotly, you need quite a lot of such firewood.

The downside of pine wood is that when it burns, it produces a lot of smoke, which clogs the chimney. When burning, conifers crackle and sparks fly from them, therefore you need to monitor fire safety in the bathhouse.

Finishing the conversation about firewood for the bathhouse, I would like to add that it is advisable to choose even logs for the stove, without knots. Knots on logs are future firebrands that burn out for so long that all the heat from the bath will fly out of the stove and onto the street!

Not all logs are good for kindling.

Much in the bath business depends on the choice of firewood. It is better to give preference to hardwood species: oak, ash or maple. Birch brooms steam well, and the logs of this tree give off good heat in the oven. Therefore, it is also recommended to take a closer look at this option.

The efficiency of firewood from fruit trees is slightly lower, and it is not harvested on an industrial scale. But if there is an opportunity or you decide to get rid of apple trees or pear bushes on the site, they are also good for heating stoves in the bathhouse.

Coniferous woods perform poorly in generating heat. In addition to the fact that they quickly burn out and release tar deposits, increased formation of soot negatively affects the chimney, clogging it. Also, you need to discard the following firewood:

- old logs give off an unpleasant odor when burning;

- Rotten wood produces little heat, but a lot of ash;

- old impregnated boards are completely unsuitable for a bath;

- Young oak logs do not have high heat transfer.

Knotty firewood also does not show its best side. Typically, this type of wood burns faster. But if these are birch logs, then they can be used for the initial ignition.

Bath procedures will be beneficial only if the kindling technique is followed correctly. Follow the recommendations given and then no carbon monoxide or high temperatures will spoil your “sacred ritual”.

What is the best way to heat a new sauna for the first time?

It is not recommended to heat the steam room too much for the first time. It is better to heat it little by little over several times so that the stove dries out and “adapts” to work. The next five times should be done “increasingly.”

| The steam room should warm up to a level of 50 - 60 degrees and about 60% humidity. |

How to efficiently heat a relaxation room in a bathhouse in winter?

Heating option No. 1 - simply open the doors in the sink, steam room and relaxation area while the stove is firing, and the room will warm up. This volume of heat should be enough for the period of bath procedures.

Option No. 2 – gas convector. Relatively easy to install, fits organically into the bath design.

Option No. 3 – an exclusive stove with a glass door similar to a fireplace. It costs more, but it looks stylish. Even when the stove in the steam room cools down, the relaxation room will be warm and cozy.

| In the case of a new stove, “running in” the structure is important, and sudden kindling is not necessary. |

Useful recommendations for high-quality kindling of a sauna stove

- At the very beginning, open the blower to the maximum - for a more effective flow of fresh air;

- Use firewood wisely. After about 5 - 8 kindlings you will understand how much wood is needed. In the future, simply cook this volume to avoid overheating.

- To control temperature and humidity in the steam room there must be a thermometer and a hygrometer. Update them regularly.

- If you have not heated the steam room for a long time, it will take a little longer to warm it up. With regular heating, it takes about a third less time to warm up the steam room.

Preparing the walls

Above, we determined what the distance to the flammable wall should be, and there we came to the conclusion that it is much more practical to decorate them with refractory materials, so as not to waste the space of the steam room. Now it's time to talk about how this is done.

Budget-friendly, but not the best option, a sheet of galvanized sheet nailed to the wall

So, we have three and a half options:

- We attach the refractory sheet to the wall;

- plastering the wall;

- we make a brick casing for the stove;

- replacing part of a wooden wall with brick.

Let's explain why 3.5 - often they hang the refractory on the wall and build the casing. Moreover, the latter is installed not only for the purpose of fire safety, but also simply for safety, as well as for heat redistribution. You will learn more about why it is needed and how to make it in this article.

As for refractory, you can use mineralite - these are sheets of cement with fillers, reinforced with fibers. Excellent fire resistance. You just need to attach it correctly.

If the stove is located almost flush against the wall, then you will need two layers of mineralite with an air gap between them, which you will create using 3-centimeter ceramic bushings. The first layer is directly adjacent to the wooden wall, then there are bushings and a second layer of mineralite.

If the distance is larger, you can limit yourself to one layer, but it should not touch the wall - the same bushings are used to attach it to the tree.

Note! In a new log bathhouse, the refractory cannot be rigidly attached. Due to shrinkage that lasts for years, rigid fastening can cause the refractory material to rupture

Therefore, make grooves for the fastening to slide. Over time, the shrinkage will be completed, then secure it tightly).

You can put, for example, heat-resistant tiles on top of the mineralite (it is placed on heat-resistant mastic) or come up with another decorative design. As an option - mirror stainless steel. Its sheets perfectly reflect heat, but at the same time heat up themselves. Therefore, stainless steel is attached to a layer of any refractory - mineral wool, ceramic fiber, superisol, etc.

In principle, you can plaster a flammable wall (a layer of at least 2.5 cm) or use fire-resistant plasterboard.

Those who decide to bring the firebox into the dressing room either immediately put up a brick wall, or then cut out part of the log house or timber. In the brickwork, space is left for the combustion tunnel with a reserve, where a heat insulator, for example, mineral wool, is then clogged. The heat insulator is also used in places where the brickwork contacts the wooden wall. If you don’t want to replace the entire wall, make a portal - at least a meter long.

How to properly heat a sauna with a metal stove?

Owners of such heating devices should remember the main advice - to lay logs often, but little by little. Otherwise, you will cause the oven to overheat, after which it will take a long time to cool down.

Distinctive features of the iron stove:

- It warms up quickly. Such settings reach optimal mode within 20 minutes after igniting the wood.

- Heating of the room begins as soon as the device itself warms up.

- An iron stove requires more fuel. Firewood or briquettes burn much faster than in a classic brick heater.

- Such stoves do not always maintain the same temperature in the chimney and combustion chamber.

A metal heater can be supplemented with a brick shield. Some lovers of Russian baths do just that - they line the appliances with bricks, thus increasing the time of heat release.

The technology for lighting a metal stove includes the following steps:

- Place some paper on the bottom of the firebox.

- Place the logs on the paper (not too tightly).

- Fill the combustion chamber two-thirds full.

- Light the paper with a match.

- Add new logs only after the previous ones have completely burned out.

Avoid the following common mistakes:

- excess firewood overflowing the combustion chamber,

- excessively dense arrangement of logs,

- closing the stove vent too early.

It should also be remembered that the flame in such a heater should not be too strong. It is much better when the firewood smolderes slowly, releasing heat evenly into the room.

Features of operation

When operating cast iron products that are subject to strong, constant heat, it is necessary to remember fire safety rules and carefully follow them. This will help not only avoid fire, but also extend the life of the stove.

The main disadvantage of cast iron is that it is susceptible to corrosion. Therefore, the installation of the product is carried out in a room devoid of sources of moisture. If damage has been caused or there are cracks on the product, they must be repaired in a timely manner to avoid damage to the unit.

You should also use the correct fuel for your stove. In Russia, summer residents most often lay firewood. There is no point in buying peat or pellets, since firewood is the most affordable type of fuel.

The type of logs must also be taken into account. Firewood should not protrude beyond the firebox, as this can lead to fire and untimely damage to the stove.

It is imperative to monitor the level of ash and clean the unit from it as often as possible. This extends the life of the cast iron stove and helps keep it looking beautiful and presentable. A cast-iron wood-burning sauna stove with a water tank requires careful treatment and it is highly not recommended to clog it with ash, dirt and debris.

The cast iron sauna stove is very easy to install and is ready for use immediately after installation. It significantly outperforms its brick and steel counterparts due to its strength, quick heating and independence from the season, which is ideal for use in our conditions.

How to heat a sauna with an electric heater?

Heating devices of this type do not require such serious preparatory work. For the first testing, it is enough to install a new stove in a suitable place outside the bathhouse and load the required volume of stones (this should be specified in the instructions for the specific model). After this, start the electric heater according to the following scheme:

- Press the main switch at the bottom of the case.

- Set the oven heating temperature to 50 °C.

- The device will operate for an hour and then turn off.

When turned on for the first time, the electric heater may emit foreign odors, which is quite normal. However, if they do not disappear after 2-3 uses, you should contact customer service. Perhaps you haven’t fully figured out how to properly heat such a stove.

The second switching on of the device also has its own characteristics. The temperature here needs to be set at 80 °C to warm up the stove even more. This time you cannot pour water on the stones yet: this can lead to their premature destruction. Follow the operating instructions and carefully monitor the operation of the oven. If after 2-3 test runs you do not notice anything alarming, then the device can be safely placed in a Russian bathhouse and used for its intended purpose.

Advantages

Cast iron wood-burning sauna stoves have positive properties resulting from the original production material - cast iron.

- Environmental friendliness. Iron, carbon, graphite contained in cast iron ensure their safe and environmentally friendly use. Iron, carbon, graphite.

- Durability. By choosing cast iron, you provide heat in your home for at least 30 years. The material is reliable and resistant to corrosion. The design does not require welding; the absence of irregularities and seams significantly increases the service life of the product, outperforming brick and steel products.

- Heat resistance. Cast iron is not afraid of deformation due to high temperatures and changes.

- Easy installation and portability. Thanks to its small size and relatively moderate weight, you will not need to make any extra effort to install the stove. If desired, the unit can be easily transported and installed in another location. The structure is made of individual elements fastened to each other using locks. Therefore, if parts break, they can be easily replaced with new ones.

- Excellent heating. Cast iron heats up quickly, accumulating heat and takes a long time to cool down. Therefore, during long-term operation, the device melts a large bath within 2-3 hours. A one-time stack of firewood heats the room for 8-9 hours.

- Safety. The “cast iron” cannot catch fire: the wood burns completely, and there is no chance of a fire.

- Aesthetics. Wood-burning cast-iron sauna stoves do not take up large areas; they fit beautifully into the interior of any sauna. The main fuel for cast iron stoves is wood. And this, in turn, is a pleasant and familiar smell, creating an excellent atmosphere in the bathhouse.

Cleanliness is the key to a healthy microclimate!

First, regardless of the stove you choose for the bath, you need to clean up the room where it is located. Actually, after each procedure, the floors are washed and the remaining leaves are swept away. You need to clean up especially carefully around the stove itself. Immediately before the procedures, the room is ventilated for half an hour.

Any stove in a bathhouse is an individual mechanism. Even despite the external similarity and the same functionality. This is characterized by the fact that each stove maker approaches work in his own way. According to this, almost all of them are heated differently, but the principle of operation is the same.

There are certain rules for kindling, compliance with which will allow you to avoid unpleasant situations, such as:

- carbon monoxide poisoning;

- getting heatstroke;

- possibility of fire.

Preparatory stage

Before starting the bath ritual of lighting the stove, let's prepare it for this. Using a special scoop, empty the ash chamber (in common parlance - the ash pan), as well as the grate part. Remains of combustion products are removed from the premises. Then we prepare firewood (preferably birch) and store it at a safe distance from the stove.

Examine the heater. If it is open, rinse with water. But only if this was not done before during 5-6 bath rinses. We check the water supply in the boiler and, if necessary, replenish the missing part.

It is imperative to determine the presence of traction. We completely open the ash pan, the combustion door and the damper on the chimney. We light a match and bring it to the door. Everyone knows how to determine the presence of traction from school lessons and personal experience in lighting street fires. If everything is in order, we proceed to the following procedures. If there is no draft, you need to check the chimney. The reason for the absence may be clogging of the pipe with ash, bird nests (and they love to huddle in such places) or a malfunction of the deflector on the chimney .

For ignition you will need paper or you can use special flammable mixtures, but not gasoline. If for some reason you forgot to purchase them, follow the old “old-fashioned” method - split off the birch bark from the logs - it burns well, no worse than newspaper sheets.

Next, you need to select 4-5 dry, small logs and chop them into small wood chips. If there are none, use an ax to split the wood blanks. Now we’ll make a “seed” on the grate to ignite the fire faster. To do this, follow these steps:

- We place two logs on the grate parallel to each other, with a gap of 10 cm, immediately behind the first ash holes;

- between them we pour kindling: paper or birch bark;

- pour a small mound of wood chips on top of them;

- We press it all down on top with two more logs, placing them in the opposite direction relative to the first two pieces.

Let's make a fire

This procedure was also performed by every man. In this case, it is necessary to observe safety precautions. It’s easier if there are tiles on the floor in the bathhouse; they don’t burn; on wooden floors, you need to be careful and prepare water just in case.

Use matches to light paper or whatever you use for ignition. We wait 2-3 minutes until the fire “takes up” thoroughly and close the stove door. After 4-5 minutes, when the wood burns, you will hear the characteristic hum of the flame. We cover the vent, but not completely, but leaving a small gap, and open the valve to the water boiler.

That's it - the wood has caught fire, now you need to turn up the heat to heat the bathhouse.

You need to start adding firewood after 10 minutes, when the logs laid first begin to burn. Open the door, use a poker to slightly level the heads of the grate, and throw in 5-6 logs. Don't try to push them deep into the oven. The ends should be located immediately beyond the outermost border of the grate. Depending on the type of stove and its dimensions, you will need a different amount of firewood. But in any case, put enough to fill the space by two-thirds.

The job is done - all that remains is to wait for the temperature to rise to the required level. Again, depending on what the bathhouse is built from, its dimensions and the correct insulation, the time intervals for this will need different.

You can repeat the procedure for adding firewood, depending on how long you will be washing. Check the combustion of the stove periodically. When the firewood “settles”, level the coals over the internal space, and again throw in a few logs.

After complete warming up, you need to constantly maintain the temperature. Close the valve on the pipe slightly. When the bathhouse is thoroughly heated, there is no point in constantly adding firewood. Just level the coals on the grate and enjoy the procedures.

In winter, when the temperature drops, throw in a few pieces of wood to keep the fire burning. 3-4 logs are enough for the coals to engulf them in flames. Don't overdo it with firewood. Coals from birch logs give no less heat to the stove than an open flame.

How do you know when the sauna has warmed up?

This question is asked by all those who first encountered lighting a stove. Having correctly completed the above steps, you need to wait about two hours. Then we go into the steam room, open the door and ventilation, fill a ladle with warm water and splash it on the heater. When the oven is heated, the water will immediately evaporate, producing a sharp hissing sound. In this case, it is better to turn away, because with the first supply of water, a layer of ash will fly off the stones, falling on them during kindling.

Now we close all the windows and ventilation, splash another ladle of water on the heater and set off to prepare for the “sacred procedures”. While you are collecting bath accessories, the steam room will warm up thoroughly. When starting to steam, open the ventilation, but not all the way, so that the cold air does not “drown out” the still fragile streams of hot steam. After about an hour, you can open the vent a little more.

What temperature should be in the steam room

After the firewood of the last stack has burned out and the surface has become grayish, when the coals move, the flames are red in color, without blue flashes (carbon dioxide has not yet completely escaped, if blue tongues appear), which means you can close the half-door and firebox, open the valves.

By this time, the stones should already be well heated and the water should boil (the temperature in the steam room should rise to +50-+60°C).

The next step is to ventilate the bathhouse. Open everything that can be opened, rinse the entire steam compartment and stones with boiling water. After ventilation, everything is closed, leaving only a window in the steam compartment. This allows you to heat the bath evenly in an hour and a half. Then close the window after this time. The steam room is ready and you can steam to your heart's content.

Detailed instructions for heating an iron stove in a bathhouse

Adding fuel to the stove

Properly heating a sauna with wood and an iron stove is very simple. There is a special algorithm:

- Place 5-7 crumpled newspaper sheets on the bottom of the firebox, cleared of ash. There is no need to crumple the paper tightly; you should leave small layers of air between the natural folds.

- We begin to lay out small firewood (chips) on newspapers so as to cover the entire surface of the stove bottom. Between the logs of the bottom row you need to leave small gaps, about the width of a finger - this way, during kindling, air from the ash pit will flow more efficiently into the stove.

- We continue to lay the logs one on top of the other, placing birch chips slightly protruding forward between them. Any dry wood chips will do, but birch wood is easiest to light. Stop filling when the firebox is about 80% full to leave room for gas circulation. Now you can set fire to the wood.

- When adding firewood during the fire, you need to wait until the previous batch burns down to the state of bright red coals, and only then lay the next batch of logs.

The oven is lit, you can use it

Using the gate

A damper is a damper on a stove chimney. Its task is to prevent heat from leaving the room through the chimney when the combustion process is already completed.

How to use the gate correctly? The only important rule when using a damper is to close the chimney only when the combustion has already completed. Otherwise, even if there is no fire in the stove, but only active smoldering, there is a risk of carbon monoxide leakage.

Adviсe

- You can hang a thermometer and a hygrometer in the steam room - this will allow you to control the atmosphere in the bathhouse even before it completely melts and understand when you need to stop adding firewood to the stove.

- You can, by trial and error, calculate how many logs are needed to create a comfortable atmosphere in the bathhouse, and at all subsequent times simply prepare the required number in advance to avoid overheating.

- Bath brooms can be prepared in the summer and used throughout the season if stored correctly. The ideal condition for a broom during storage is hanging with the spine down.

- At the beginning of the kindling, the vent should be open as much as possible for a better flow of oxygen.

Common mistakes

- Too much firewood at once. If the firewood in the stove, especially one that has not yet been lit, is placed too tightly, there is a risk of smoke in the room, because there will be no normal circulation of gases in the firebox of the stove.

- Blower/gate valve closed too early. In both cases, violation of the order of using the stove leads to difficulty in the circulation of gases during the combustion process.

Lords of Stone and Fire

Now it’s worth considering the algorithm for the problem of how to properly heat a stove. In general, the entire process can be divided into several main stages, such as: preparation, combustion and completion of combustion. Previously, any housewife knew thoroughly how to heat a Russian stove and, most importantly, how to properly heat a Russian stove. And a complex sauna stove is in many ways similar to a Russian house stove. And for such a housewife, the problem of how to flood the bathhouse is not a problem at all. There would be firewood. Well, we’ll start with the ABCs, with the very basics.

On your marks

At the preparatory stage it is necessary:

- Conduct an external inspection of the stove, ducts and chimneys to ensure there are no visible damages or malfunctions.

- Check traction. To do this, just light a crumpled sheet of paper in the firebox and watch the behavior of the flame. It should steadily deviate deeper into the firebox, towards the smoke channel. It is also useful to cover the ash flap and monitor how the level of natural draft drops by the behavior of the same flame.

- Remove from the pre-furnace space all flammable objects that could serve as a source of ignition near the stove as a result of inadvertent sparks.

- Clean the ash pan and grates from ash to ensure normal air circulation during the combustion process.

- If the furnace design has water boilers and jackets, check that they are at the required level to prevent them from burning out.

- Open the chimney valves and open the ash door.

- Let's check the heater insert. As is known, for normal heat transfer, the ratio of the volume of working stones in the heater in relation to the volume of the steam room should be within 1:50.

Attention! Wood ash is an excellent organic fertilizer and a source of such an important element in plant nutrition as potassium. In addition, local application of ash under fruit trees has some disinfecting properties. Naturally, the ash must be cooled. When applying on a large scale, control the acidity of the soil, since ash has a pronounced alkaline reaction.

Ignition

Now, a few words about the quality of firewood, or more precisely, about its humidity. Firewood, like gunpowder, should always be kept dry. For this purpose, even in the simplest bathhouse design, without a dressing room, a canopy was provided above the entrance for storing clothes and firewood. It is better not to know how to heat a stove with raw wood, since raw wood shoots, smokes and does not burn, or rather, it burns, but poorly. The size of the firewood matters. Logs of various sizes are needed at certain stages of heating the stove. This trend is clearly visible directly during ignition:

- We fill the firebox with seed, that is, small firewood, birch bark, wood chips, paper, which ensures reliable ignition.

- As the flame sets the seed and begins to burn confidently, we add small logs “staggered”, that is, leaving free space between them for air circulation. We make sure not to “lock” the flame in the firebox with excessive quantity or size of firewood. At the same time, it is very important not to look through the flame, to prevent the seed from completely burning out.

- At this time, the firebox door can be kept ajar for a better supply of air oxygen to the combustion site.

Important! There is a large selection of special alcohol-containing liquids for lighting barbecues on the market. The fire department strongly does not recommend using them for a colorful show like how to quickly light a stove, in order to avoid uncontrolled burning of high intensity. Consuming them internally is also not recommended, but by the Ministry of Health.

Everything is fine, we're on fire

As the seed burns out and the first load of firewood begins to burn confidently, you can perform the following actions:

- We put standard size firewood into the entire volume of the firebox, but leaving a gap of 200-250 mm to the upper arch of the firebox. Modern science has not yet figured out how to heat a stove with a firebox filled with wood right up to the vault. This rule must be observed throughout the entire process of heating the bath.

- Open the ash door. The firebox door must be tightly closed.

- We monitor the air temperature in the steam room and the water in the boiler, if the stove is equipped with one. Visually monitors the temperature and condition of the stone backfill by its appearance.

Depending on the quality of the stove, the thermal insulation properties of the bath structure and other individual conditions, the time to reach the operating air temperature of 60 degrees Celsius can take about 2-5 hours. Approximately the same algorithm of actions applies to the question of how to properly heat a bathhouse with an iron stove.

A word from Experienced! When laying firewood, follow the direction of laying the logs, which should be parallel to the long side of the firebox. In addition, a prerequisite is the need to leave a gap between the firewood and the firebox door. As a rule, 10-12 cm is enough. During combustion, control the stability and quality of draft. Clean the grates if they become clogged.

Finish of the furnace firing

Once the air temperature in the steam room reaches operating levels, the stove can be extinguished. But, as in the question of how to light a stove, there is also a certain algorithm of actions and its own nuances:

- If you are sure that further burning of the stove is inappropriate, then the addition of firewood stops;

- The stove vent is closed and the chimney damper is closed;

- At this time, in conditions of insufficient oxygen supply to the firebox, the formation of very dangerous carbon monoxide is possible - carbon monoxide, the insidiousness of which lies in its lack of color and odor.

Attention! A sign of fuel combustion under conditions of a significant lack of oxygen is the coloring of the flames yellow with a purple rim.

- Visually inspect the color of the stone backfill in the heater again;

- The bathhouse is thoroughly ventilated and steamed with the first steam.

A visual table reflecting the calorific value of various types of firewood, both dry and freshly cut, will help you learn how to heat a stove in a bathhouse correctly and effectively:

| Wood name | Specific heat of combustion, kW h/kg | Nominal combustion heat for dry firewood at 18% humidity, kWh/cub.m. | Nominal combustion heat for freshly cut firewood at 55% humidity, kWh/m3. |

| Beech | 4,2 | 2200 | 1900 |

| Oak | 4,2 | 2100 | 1850 |

| Ash | 4,2 | 2100 | 1850 |

| Birch | 4,3 | 1900 | 1670 |

| Elm | 4,1 | 1900 | 1670 |

| Maple | 4,1 | 1900 | 1670 |

| Alder | 4,1 | 1500 | 1300 |

| Poplar | 4,1 | 1400 | 1230 |

| Pine | 4,4 | 1500 | 1300 |