When arranging a private home, sooner or later the question of choosing a heating system scheme arises. Today there are so many of them that an inexperienced person can get confused and choose the wrong thing. Installers often recommend what is profitable for them to install. But since you came to this page, choosing a system in your home will be much easier. First, we will share the main varieties, and at the very end we will share our opinion and choice of heating scheme for the house.

The main principle of heating operation

Any type of heating system is closed. In a simple version, any wiring diagram can be considered as a ring consisting of pipes. It circulates hot liquid from the heating boiler to the heating devices, remaining in them for some time. The coolant releases thermal energy during circulation and is again directed inside the boiler for heating. The cycle repeats periodically.

Any heating scheme includes:

- Heating boiler

- Connecting system pipes

- Radiators or similar heating devices

- Armature

- Expansion tank

- Circulation pump

SNIP requirements

*

The general SNIP regulating ventilation and heating is registered under number 41−01−2003. There are other norms, among which are:

- SNiP 2.04.05-91 (clause 3.58). Regulates the installation of decorative screens and grilles on heating radiators.

- SNiP 41-01-2003 (clause 6.5.13.). Indicates the need to install shut-off valves, except in rooms with a high probability of coolant freezing.

- SNiP 3.05.01-8 (clause 3.18). Regulates the slope of the heating circuit with a pipe length of more than 500 mm.

- SP 40-108-2004 (clause 3.2.1). Regulates the connection of a copper pipe to a boiler with aluminum terminals.

Basic types of heating schemes

All types of schemes can be divided into 4 subtypes: open and closed, pump and gravity.

In the gravity system of a private house (system with natural circulation), the movement of coolant occurs through natural circulation. By following simple laws of physics, the system is installed in such a way that it does not require an additional pump. Well suited for small one-story houses

In the forced water heating scheme of a private house, liquid occurs due to the action of the circulation pump. When using such a system, pipes can be mounted in walls, in the floor, along the ceiling, and hidden from human eyes. With the correct selection of the pump, water heating will work successfully. Such wiring schemes are great for two-story houses.

An open system differs from a closed system by an expansion tank. A closed system uses a membrane tank. It allows you to maintain the required pressure in the system and compensates for the expansion of the coolant.

Now let's look at each scheme in more detail.

Modern home insulation technologies

Building a house today involves the use of new methods of insulating buildings with innovative materials.

Using thermal insulating paint Lic Ceramic

This modern material is popularly called nanopaint for insulation. Ultra-thin thermal insulation is the main quality of this material. It is used for insulation of walls, facades, roofs, floors. Innovative material saves heat in the room by 30%. For old buildings, the low weight of the material will be an advantage. There is no additional load on the walls.

Liquid penoizol

Old buildings require careful treatment. Penoizol liquid insulation is supplied under pressure. Fills voids inside walls, foundations and roofs. The appearance of the old building will not be affected. Using a foam-like material, small cracks and defects in the walls are filled. The insulation of the house is carried out with a high degree of reliability.

Penoizol has high sound insulation, low thermal conductivity, and increased fire resistance. House insulation will last 30-50 years.

Foam granule

These are solid foam balls. They call it “crushed foam.”

It is applied like this:

- Added to concrete. Concrete becomes lighter and has increased thermal insulation.

- The voids, for example, between brickwork, are filled with foam granules. No additional leveling of walls is required for insulation.

Gravity heating system, advantages and disadvantages

In this type of heating system for a private house, hot water, heated inside the boiler (usually solid fuel), moves upward, after which it ends up in the heating radiators. From them, heat goes into the room and is again sent to the return pipeline. From it it already goes into the heating boiler. The constant movement of heated water is ensured by the necessary inclination of the supply (direct) pipeline and return, as well as the use of pipes of different diameters. For the supply from the boiler, pipes of a smaller diameter are used, and for the return, the pipeline in which water is directed to the boiler, a larger one.

The gravity-flow wiring diagram for the water heating system of a private house has a specific device in the form of an open expansion tank connected to the outside space, mounted at the top of the pipeline. The tank is intended to take part of the water when it is heated, since this process is accompanied by an increase in the volume of coolant. An expansion tank filled with water creates the hydraulic pressure in the heating system necessary for fluid movement.

As water cools, its volume decreases. Some of the liquid from the open tank again enters the pipeline system. This ensures the necessary continuity of water flow circulation.

A gravity heating system has the following advantages:

- Uniform distribution of thermal energy

- Sustained action

- Autonomy from power grids

A gravity heating system also has disadvantages:

- Difficult installation. The slope angle of the pipelines must be observed

- Significant length of pipes

- The need to use pipes of different sizes

- Inertial system. It reduces the degree of control of the heating process

- The need to heat water to a relatively high temperature, which limits the use of polypropylene materials for pipes

- Significant volume of pipeline

- Inability to connect “warm floors”

Learning from other people's mistakes

How to avoid inefficient operation of the system and not make common mistakes will be discussed in the final chapter.

- The heating system diagram should be developed by professionals. In this case, the plumber may go on vacation, and the residents may experience force majeure. Therefore, not only the person who serves the system should know the scheme, the owner should also have it.

- Incorrectly selected pipes lead to unnecessary costs and system breakdown.

- It is better to purchase only parts that are homogeneous in material: they have similar thermophysical properties. If heterogeneity is unavoidable, then such parts are connected by protective connections or gaskets.

- In order for the equipment to work smoothly, install it according to the rules: free access, without overheating in the sun, without blowing. It is prohibited to install gas equipment in a hidden way.

- When a plumber recommends buying and installing valves, it is better to listen to him so that the system does not become airy and there are no heating problems.

- Safety is more important than savings. The equipment is installed for years. It is better to immediately prepare for the costs at the installation stage. Then there will be no repair costs or emergency situations in the future.

- You cannot buy a gas boiler with more power than you need, because... this will lead to increased gas consumption and additional costs. Let us remind you that for every 10 m2 of a house, 1 kW of power is planned. If the house is 250 m2, then we multiply 250 by 1 and divide by 10, we get 25 kW of power.

- Reduce heat loss when finishing the house. Insulate walls, upper floors, roof. Otherwise, the heat goes outside.

Single-pipe heating circuit

As a rule, this system wiring diagram is used in private one-story houses and is characterized by easy installation, low labor costs and low cost. Radiators are connected to the heating pipe in series. There is no provision for waste coolant removal. This water heating scheme has many disadvantages when heating a private house:

- loss of thermal energy - each subsequent heating device will heat up less than the previous one;

- the inability to regulate the heating intensity in one room without similar consequences for the rest. By reducing the temperature in one of the radiators, all subsequent radiators will inevitably cool down;

- the need to additionally equip the heating system with a pump to maintain operating pressure in it.

There are technological methods that can be used to partially get rid of these problems. You can improve the operation of a single-pipe wiring diagram using special equipment: thermostatic valves, radiator regulators, air vents, balancing valves. Their use will slightly increase the cost of installation, but will allow the temperature in one of the radiators to be lowered or lowered without undesirable temperature changes in the remaining heating devices.

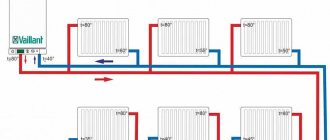

Two-pipe heating circuit

This water heating system is widely used in houses of any number of floors. Its peculiarity is that water is supplied to the radiator through one pipe, and drained through another. The heat exchangers are connected to the heating system not in series, but in parallel.

Main advantages:

- coolant with the same temperature is supplied to each radiator;

- it becomes possible to install a thermostat on radiators to set the desired temperature in each individual room;

- disconnection or malfunction of one of the batteries will not affect the operation of the others.

The system has a number of disadvantages. Its installation requires a large number of pipes and connecting elements, which leads to an increased degree of complexity of installation work and a higher cost of the entire water heating system.

Choosing an energy carrier

The main selection criterion is the cost of energy, depending on the country and region of residence. If in the Russian Federation the undoubted leader is natural gas, then in the rest of the states of the former USSR the picture is different - firewood, briquettes and coal take the first place. Don't forget about electricity supplied at half the nightly rate.

When choosing the right type of fuel, it is worth considering five factors (in addition to price):

- efficiency (efficiency) of heating equipment using this energy carrier;

- ease of use;

- how often the units will have to be serviced, prices for calling a technician;

- storage requirements.

Below is a comparative table showing the prices of various energy sources and how much a kilowatt of heat produced in real conditions costs. Building area – 100 m², region – Moscow region.

Note. The calculation results and prices are given as of February 15, 2018. Over time, the data becomes irrelevant, but the difference in the cost of 1 kW remains.

Based on the numbers given in the table, it is much easier to find a suitable option (or several). Just make an adjustment for the cost of energy in your region. Based on other selection criteria, we will give 4 tips:

- It is most convenient to use gas and electric heating equipment. There is no need to store anything, constantly maintain and bother with cleaning water heating devices.

- Burning coal and wood is the most economical way to heat. Saving money will have to be paid for with labor - sawing, carrying, loading the firebox, cleaning the chimney. It is more comfortable to burn briquettes and pellets, but the price of the boiler installation and the fuel itself increases. Plus you will need storage for storage.

- Diesel fuel or liquefied gas is the best solution for providing autonomous and at the same time comfortable heating when other energy sources are not available. The downside is the decent cost of fuel and installation of the fuel tank.

- A proven option is the combination of 2-3 energy carriers. A common example: solid fuel + electricity at night tariff.

Which fuel is best to use in specific conditions is described in detail in a separate material. We also recommend watching the video and listening to useful expert advice:

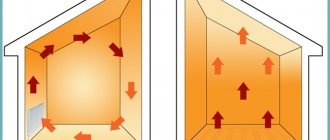

Heating scheme with heated floors

Heated floors provide horizontal thermal radiation, maintaining a higher temperature at foot level and reducing it to a comfortable level at higher altitudes. In areas with warm climates, the circuit can be used as the only source of heat. In northern latitudes it must be combined with the installation of a radiator heating system.

Structurally, the underfloor heating system is a network of pipelines. Heating can be done from any heat sources.

System advantages:

- uniform distribution of heat throughout the entire volume of the room;

- improving the aesthetic appearance of the room due to the absence of pipes and radiators.

Solid fuel

Coal.

Solid fuels include:

- wood;

- different types of coal;

- waste from wood processing and agricultural enterprises.

Solid fuel is burned to produce heat. Direct heating does not imply the use of an intermediate coolant; in the case of installing solid fuel boilers, heating systems with radiators are installed.

Stoves, fireplaces, potbelly stoves

It is advisable to consider stoves as the main heating system when building rarely visited country houses or bathhouses.

| Advantages | Flaws |

| Minimum equipment price | Rapid fuel burnout |

| Instant heat release from steel stoves and fireplaces after ignition | High cost of stone stoves |

| Long heating of brick or stone walls | |

| Low efficiency: 30% for potbelly stoves, 60% for the best stove models | |

| The need to arrange fuel storage areas | |

| Fire hazard of stoves and woodburners | |

| Danger of carbon monoxide poisoning | |

| Heating no more than 2-3 rooms |

The best options for heating stoves are of the bell-type type, when hot air passes several times through the smoke channels and is collected under a kind of hood.

Bell type furnace.

Steel stoves are chosen based on the same criteria: the gases must burn completely after passing through several smoke channels.

Solid fuel boilers with manual operation

Cutaway view of a modern Teplodar Kupper coal boiler.

The use of wood or coal boilers is recommended in areas where it is impossible to connect to a centralized gas supply or where it is not possible to equip a gas holder.

Table. Advantages and disadvantages of heating with wood and coal boilers.

| Advantages | Flaws |

| Fuel of any quality is suitable | Instability of calorific value - depends on the moisture content of the fuel, type of coal, type of wood, difficulty in calculating the fuel required for the season |

| Complete independence from power supply when installing a gravity system | Requires constant monitoring and maintenance - loading fuel, removing ash |

| Low price of 1 kW of energy | Low average efficiency |

| Possibility to use free or cheap wood processing waste (often wane can be removed for free, paying only for transport services) | Cooling of radiators with high hot water consumption (in double-circuit boilers) |

| Availability of automated boilers with adjustable combustion speed and supply of pallets or granules | Fire hazard in fuel storage areas |

| Difficulties in organizing a “warm floor” system |

The price of the most popular boilers with a capacity of 14-20 kW ranges from 25 to 70 thousand rubles.

Advice! To maintain the temperature of the coolant at night and during the day, when the owners are absent, they purchase boilers with built-in electric heating elements, which turn on when the fuel burns out and the temperature drops.

Justification for the purchase of high-tech solid fuel boilers

In an effort to increase efficiency, manufacturers resort to various technical solutions:

- create conditions for complete combustion of fuel;

- air charging fans are built into the design to ensure fast or slow combustion;

- install automatic dampers that reduce the air supply when the coolant is overheated.

This is what a pre-installed air charge fan looks like.

Automatic damper on a TT boiler.

Pyrolysis is the separation from fuel by heating it of gases that burn at high temperatures. The process requires precise stabilization of the operating mode.

The operating principle of pyrolysis coal boilers using the Geyser VP model as an example.

It is technologically difficult to achieve the effect in boilers less than 50 kW, but this power is enough to heat a house up to 500 m2.

The offered boilers up to 50 kW can only conditionally be called pyrolysis. Usually these are two-chamber devices. In the first chamber, direct combustion of wood (coal) occurs, and the second is an afterburning chamber, where the remaining organic substances are burned.

The price of such boilers is 2-3 times higher than usual, so part of the profit received by the manufacturer can be used for advertising.

Important! The purchase of so-called “pyrolysis” boilers of low power (up to 40 kW) allows you to increase the efficiency of installations by 5-20%, but you will have to pay 2.5-3 times the cost for the equipment.

In order to talk about the payback of high-tech pyrolysis boilers relative to conventional ones (direct combustion), it is necessary to calculate the costs incurred.

Example. To heat the house, a 25 kW boiler is required. A direct combustion device costs about 35 thousand rubles, a “pyrolysis” device costs about 90 thousand.

For example, the consumption of firewood in a regular boiler per season will be about 20,000, in a “pyrolysis” boiler it is 5-10% less, i.e. 18–18.6 thousand rubles. The savings will be 1.4–2.0 thousand rubles. Boilers up to 25 kW must be equipped with a fan with a power of 50 W or more, which will consume 800–900 rubles worth of electricity per season. Thus, the net benefit from installing a long-burning boiler will be no more than 1000 rubles per season; we can talk about payback in 30-40 years.

Payback of truly pyrolysis boilers within 10-15 years of operation is possible with equipment power of 40 kW; in such devices, combustion efficiency can be increased by 20%.

Efficiency and selection criteria for modern pyrolysis solid fuel boilers

The best manufacturers of solid fuel boilers

Solid fuel boilers are produced by many brands. Based on the number of sales and user reviews, the following companies' products stand out:

- Teplodar;

- Rommer;

- TMF;

- Zota;

- Heiztechnik;

- Thermocraft.

The choice is made according to the required power and available fuel.

Gravity system "Spider"

The vertical heating circuit of a private house with a top spill without the use of a circulation pump is called “Spider”. The main advantage is complete autonomy from gas or electricity, which is especially in demand in rural areas or in holiday villages. In the circuit, the coolant moves due to the temperature difference at the inlet and outlet of the heating device. In the absence of gas and electricity, it is best to use a solid fuel boiler.

The operating principle of the “Spider” is based on the laws of physics - hot water rushes upward, displacing cold water downward. As a result of heating, the water rises from the boiler along the riser to the radiator, gives it part of its thermal energy and moves to the next one until it returns back to the boiler. The functioning of the system depends on the accurate selection of pipes and compliance with slopes. Water intake must be carried out above the level of the heat exchangers. The boiler should be located lower. The main disadvantage of the scheme can be considered quite complex installation work .

How to choose a heating unit

Factors influencing the choice of a boiler (or several water heating devices):

- energy carrier used;

- heat generator power;

- dependence on external energy sources;

- price;

- functionality, ease of use.

Note. The heater selection criteria are arranged in order of priority. It is important for the user that the unit consumes cheap fuel and produces enough heat. Price plays a secondary role; comfort and functionality come in third place.

All household boilers are usually divided into groups according to the type of fuel (energy carrier) burned:

- gas;

- electrical;

- solid fuel;

- liquid fuel, consuming diesel fuel and waste oil;

- universal, operating on 2-3 types of energy carriers.

Each of the listed groups is divided into varieties according to the operating principle, installation method and other criteria. We will review existing boilers and give a number of useful recommendations.

Types of gas boilers

To organize heating in private homes, 3 types of units using natural gas are sold:

- Atmospheric. The combustion chamber is open, combustion air is taken from the boiler room. The operating efficiency is in the range of 86...88%.

- Supercharged (aka turbocharged). Air is forced into the closed firebox by a fan controlled by an electronic circuit. Boiler efficiency is 90...93%.

- Condensation. Structurally similar to turbocharged heaters, but the heat exchanger and burner are designed in such a way that in a certain mode the boiler uses the latent heat of combustion of the fuel. Efficiency – 95%.

Reference. All heat generators are capable of burning 2 types of fuel - natural gas and liquefied propane-butane mixture (LPG). To switch to LPG, the fuel jets are replaced and the automation is adjusted.

Boilers are manufactured in wall, floor and parapet versions. The first group is ready-made mini-boiler rooms, equipped with their own expansion tank and pump. The second type is high-power units, or those that do not depend on electricity. Parapet models are placed near the outer wall, the chimney goes directly to the street.

Among the large assortment of gas water heaters, it is not easy to make the right choice. Our recommendations are:

- If you are on a limited budget, purchase an atmospheric wall-mounted boiler. But remember - open-chamber heaters require a traditional chimney.

- To work together with the gravity system, you will need a non-volatile floor-mounted atmospheric unit.

Floor-mounted non-volatile heater equipped with a single-stage burner, mechanical automatic safety system EuroSIT and a cast iron heat exchanger - It is better to install a forced-air heat generator in an apartment or cottage without a ready-made chimney. Organize the removal of combustion products through a coaxial pipe laid through the outer wall.

- To supply hot water to 1-2 consumers, buy a dual-circuit model. If the consumption in the DHW network is high, you will need an indirect heating boiler connected to a conventional single-circuit heater.

- Read the detailed description of all gas heaters presented in a separate article.

A condensing boiler is the most economical among gas-using devices. The disadvantage of the unit is the complexity, high price of the equipment and its repair.

Electric hot water installations

A feature of electric boilers of any type is their high efficiency, reaching 99%. The second positive point is the low installation costs and purchase of the heaters themselves. The units should be used as auxiliary heat sources, operating at night at half the light tariff.

There are 3 types of electric boilers (all are available in wall-mounted versions):

- With traditional tubular heaters - heating elements. Modern devices are equipped with an expansion tank and a circulation pump.

- Electrode. Heating of the coolant occurs due to a chemical reaction resulting from the passage of current through the water layer between the 2 electrodes.

- Induction. Here the coolant is heated by the steel core of a sealed coil, which creates eddy currents in it.

Sectional view of a heat generator with tubular heaters (TEH)

To install electric heating, it is better to take a classic heating element boiler that does not require serious piping. The device is reliable and easy to repair - you can always replace a burnt heating element yourself. An induction heat generator is expensive and cannot be repaired in the event of a breakdown, and an electrode heat generator is highly dependent on the salt content in the coolant.

Advice. Don't listen to salespeople who call induction boilers energy-saving. All electrical installations heat water equally efficiently - losses do not exceed 2%, the rest of the energy is converted into heat.

Classification of solid fuel boilers

For heating country cottages, 3 types of solid fuel units are used:

- direct combustion - atmospheric and turbocharged;

- pyrolysis;

- automatic pellet and coal.

There are many myths about the efficiency of TT boilers. Manufacturers of pyrolysis heat generators claim an efficiency of 85-86%, pellet heat generators - up to 90%. In reality, the figures are much more modest: traditional wood-burning units - 75%, pyrolysis units - 75%, boilers using pellets and coal chips - up to 86%.

Construction of a direct combustion boiler with a fire tube heat exchanger

Reference. In addition to the listed types of heaters, there are long-burning TT boilers with an increased size of the firebox. How to distinguish such installations from classic wood-burning heat generators, read the corresponding publication.

Recommendations for choosing a solid fuel boiler:

- A steel direct combustion apparatus equipped with a chain draft regulator is perfect for burning wood, coal and briquettes. Turbocharged examples are automated and burn wood better, but rely on electricity.

- Pay attention to the volume of the firebox of a traditional boiler - the duration of combustion depends on this indicator.

- Automated pellet units are a good solution for lovers of comfortable heating. You don’t have to chop and carry wood, remove coal dust, just clean the firebox and burner weekly.

- Do not mess with pyrolysis TT boilers, they are a priori more expensive than conventional ones, demanding on the quality of fuel, and in addition they consume electricity.

- Avoid models with water-filled grates if you plan to burn with coal. The temperature difference forms a hard crust on the surface of the grate, which is not easy to knock off.

Grate of a TT boiler made of pipes filled with coolant

When choosing a heat generator, remember the old saying “the miser pays twice.” It is better to take a high-quality classic device with a cast-iron heat exchanger than a cheap “pellet generator” with electronics of unknown origin.

Diesel and combined models

This heating equipment is used much less frequently than gas, wood and electric boilers. Diesel fuel is more expensive than other energy sources, and waste oil is a specific fuel that is clearly unsuitable for the average homeowner. Accordingly, such heating devices are operated only in certain conditions when access to other resources is limited.

Multi-fuel boilers from different manufacturers combine 2-3 energy sources, for example, wood + electricity, gas + coal. Advantage: you buy one heat generator and get two. Disadvantage: the unit cannot boast of high efficiency and functionality. The most popular option is shown in the photo - a TT boiler, equipped with a heating element unit for electrically heating water after the flame in the firebox has died out.

Electric wood heater from the Russian company Teplodar

Heat generator power calculation

To select a boiler based on performance, you should find out the load on the heating system of the house. That is, calculate the heat losses of the building. We propose to calculate this indicator in a simplified way:

- If a living room is separated from the street by one wall with 1 window opening, then 0.1 kW of heat is consumed to heat a square meter of area.

- A room with two external walls (corner) and 1 window – 0.12 kW/m².

- The same, with 2 light openings - 0.13 kW/m².

An important nuance. The calculation is performed for each room separately, then the results are summed up.

The algorithm is suitable for buildings with floor heights up to 3 meters. If the ceilings are higher, heat consumption is calculated based on the volume of the room. Accordingly, in a room with 1 fence and a window, the volume value is 35 W/m³, in a corner room – 40 W/m³, in a corner room with two openings – 45 W/m³.

Having determined the need for thermal energy at home, we select the power of the boiler installation according to the instructions:

- The performance of a unit operating only for heating is taken with a margin of 20%. That is, we multiply the found amount of heat by a factor of 1.2.

- The heat generator providing hot water supply must be taken with a reserve of 50% (coefficient 1.5).

- For TT boilers, the increasing coefficients are 1.5 and 2, respectively.

If you live in an area with a mild southern climate, then the coefficients should not be used. Conversely, residents of the northern regions should increase the initial heat loss figure by 1.5-2 times.

Calculation of heat losses by volume of residential premises

Scheme "Leningradka"

“Leningradka” is one of the simplest, but nevertheless quite effective and economical heating schemes for wiring a private house. It is similar to a single-pipe scheme, that is, the coolant sequentially passes through all the radiators of the room, gradually losing its heating temperature. The main pipe is placed along the floor and loops the circuit from the heating device. It is best to use Leningradka in one-story houses so that all batteries are on the same level. In this case, the system can operate with natural circulation, but when installing it in two-story houses, it is necessary to use a forced supply of coolant.

The advantages of this scheme are:

- economical consumption of materials;

- easy installation;

- long-term reliable operation;

- the ability to hide the main pipe under the floor covering to improve the aesthetics of the interior.

Leningradka" is not without significant drawbacks:

- inability to maintain the same temperature in all rooms;

- horizontal wiring does not allow connecting heated floors or heated towel rails;

- a large area of the room requires the use of a circulation pump to ensure operating pressure in the system.

Using the built-in boiler pump

This scheme involves the use of boiler equipment with a built-in pump, the power of which is up to 35 kW. It creates a pressure at the outlet of the tank in the range of 20 - 25 kPa, with a water flow of 1000 - 1500 liters per hour.

The installation process is similar to that of a conventional heating element, but an additional pump for underfloor heating is not required.

To fully utilize the potential of the device and create coolant circulation in the heated floor and radiators, it is necessary to correctly connect the device to the circuits.

This can be achieved in this scheme by ring combination - the boiler with the TP, and with the radiator. These two rings are united by a small common area with low hydraulic resistance, thereby one circuit does not affect the other.

In this scheme, the slant filter acts as a slag catcher, and there are air vents in the boiler, radiator and floor circuit.

The essence of the functioning of the ring circuit is that water flows from the container where it is heated into the pipelines. Pressure surges in the supply and return pipes lead to the movement of liquid through the lines and its return back.

Radiant heating scheme

The radial water heating wiring diagram is newfangled. When using it, hot water is evenly distributed throughout the room through the collector. The degree of heating of the home is regulated by changing the heating of the water and the speed of its movement through the pipes.

It is an improved version of the two-pipe circuit. To distribute the coolant, the same collector is used as in a warm field.

The main advantages of the beam wiring scheme include:

- Jointlessness. There are no joints inside the screed. The likelihood of leakage is significantly reduced

- The ability to turn off each device individually on the collector without harming the entire system

The only drawback is the price. Due to the use of a collector and an additional number of pipes, the price of the system also increases.

Gas boilers

An excellent option is to install heating that operates on main gas. In general, hot water gas boilers are very reliable and efficient. The efficiency of the simplest energy-independent unit is at least 87%, and the efficiency of an expensive condensing unit is up to 97%. The heaters are compact, well automated and safe to operate. Maintenance is required no more than once a year, and trips to the boiler room are needed only to monitor or change settings. A budget unit will be much cheaper than a solid fuel unit, so gas boilers can be considered generally available.

Just like solid fuel heat generators, gas boilers require a chimney and supply and exhaust ventilation. As for other countries of the former USSR, the cost of fuel there is much higher than in the Russian Federation, which is why the popularity of gas equipment is steadily declining.