Despite the huge number of ways to obtain heat using natural resources, homeowners are increasingly turning to using electric heating units to heat their homes.

Boiler systems operating using electricity are environmentally friendly , since combustion products that appear when burning petroleum products, gas, coal and even firewood are not released into the atmosphere.

Another option for an induction boiler

There is another option for creating an induction boiler with your own hands.

Such induction heating boilers, of course, will cost a little more, but their operating efficiency will be higher. Making such a boiler will be a little more difficult than the previous option. You will need skills in working with a welding machine, a three-phase inverter, which would preferably be permanently mounted, as well as some tools.

Homemade induction boiler

Note that the design of this version of the induction boiler will consist of two pipes that will be welded into each other. If you look at it from the end, this design will remind you of a donut. At the same time, the device will be both a core that will create an electromagnetic field and a heating element.

The copper winding is wound directly onto the boiler body. Thanks to this, increased productivity will be achieved, while the relatively small size and weight of the device will be maintained. To supply and remove coolant, special pipes are welded into the inductor.

When you assemble such induction boilers for heating your home, you should consider several recommendations and installation requirements:

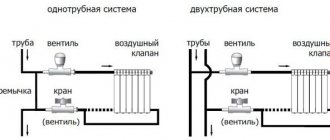

- A device such as an induction boiler can only be installed in closed heating systems that are equipped with a circulation pump.

- The device can also be installed in systems that use plastic pipes.

- There must be at least 30 centimeters of free space between the induction heating system and the walls (or pieces of furniture, household appliances). And such devices are placed at a distance of 80 centimeters from the ceiling and floor.

Of course, you will have to work a little more and more complexly on this version of the boiler, but the effect that will be achieved in the future will please you. Such an induction boiler, as reviews show, is a truly productive device that can not only provide you with high-quality home heating, but will also serve you for at least 25 years without maintenance.

Homemade induction boiler connected to the heating system

Using induction heating boilers provides users with many advantages. Among them, several should be noted:

- First of all, it is the ability to work with alternating and direct current.

- In such a device there are simply no heating elements that will wear out.

- The design of the device is extremely simple.

- There is no need to take a separate room for installation. All induction boilers belong to class 2, according to fire safety.

- The efficiency of both homemade and factory-made induction boilers is almost 100% (usually 98-99%). Compared to traditional heating systems, this is simply an excellent result.

- You can use several types of heat carriers, and the induction boiler will not suffer any harm. So, you can use not only water, but also work with oil and antifreeze.

- Making an induction boiler yourself will not be difficult for you, and the cost will be very low.

Thus, modern induction boilers are devices that belong to the new generation of technology. These are not only practical devices, but also powerful and economical. They are capable of heating not only an ordinary country house, but also a large industrial premises. With all this, you do not spend money on complex installation and maintenance of such devices.

Advantages and disadvantages

The real advantages that induction boilers have for heating a home or industrial building are as follows:

- High, as with all water heating installations, operating efficiency is in the range of 97-98%.

- Durability due to the absence of moving parts and simplicity of design.

- Small dimensions allowing heating equipment to be placed in a room of any size.

- High heating rate of the coolant and lack of inertia when it is turned off.

- Comfort during operation, an induction electric boiler does not require constant attention from the owner of the house, and the frequency of its maintenance depends entirely on the quality of the water used in the system.

Vortex heaters are supplied with automatic control kits, which makes it possible to connect heat generators with other climate systems at home.

Sectional view of the heater

This equipment also has disadvantages. The main one is the high cost, especially for heat generators of the Sibtekhnomash type. While using these units for industrial purposes is quite acceptable, induction heating of a private home may turn out to be unreasonably expensive.

The experience of practical use of vortex heaters by homeowners and maintenance personnel of service companies is not yet very extensive, but at the moment there are no significant complaints about the equipment.

Conclusion

There are no obvious advantages of induction heating over other types of heating systems, given its high price.

But if we draw a portrait of its ideal consumer, it will be the owner of a country estate located in a non-gasified area, who needs a remotely controlled heating system for infrequent and moderate use.

And it is possible to install an induction boiler in the basement so that it does not emit too much harmful fields toward the residents, but, on the contrary, repels mice, moles and rats.

Durability and lack of periodic maintenance will really be a plus for such a consumer and will justify all costs in the long term. No tags for this post.

Should they be used for heating a private home: let’s look at known misconceptions

As we said earlier, the use of induction electric boilers is justified only in industry. However, it is worth confirming the words by analyzing all the known myths in more detail.

Efficiency and profitability

An example of compact piping of an electric induction boiler in the heating system of a private house.

Despite sellers’ assurances of high efficiency, all modern electric boilers have about 99%. This means that, for example, at maximum load, a boiler producing 9 kW of thermal energy will consume 9.091 kW of electricity. However, over time, due to scale formation, the efficiency of heating element models decreases to 90 or even 80%, since more time and power are required to ensure the same heat transfer through the scale layer. In induction boilers, scale does not form and the efficiency remains unchanged.

But even in heating element models the problem can be almost completely solved:

- filtering the coolant being poured;

- installing softening filters;

- using the same coolant without draining it every season. Minerals will settle once on the heating elements and turn into an insignificant layer of scale, which practically does not affect the heating efficiency, after which they will simply have nowhere to come from.

We will deal with it later, but for now we can conclude that the efficiency of all modern electric boilers is the same, and the absence of scale is not worth an overpayment of more than 50%.

Reliability

Another frequent argument in favor of electric induction devices is their reliability: the design is as simple as possible, which means there is simply nothing to break in it.

This is true, but it applies to absolutely all high-quality electric boilers, since, unlike gas boilers, the only element that can fail under proper operating conditions is the heating element. But even with cleaned and soft coolant, they last at least 5-7 years.

Safety

Even with modern models, safety is not easy, since powerful inductive electric boilers create a serious load on the electrical network and distort the sine wave. It is necessary to connect the boiler unit only if the wiring is in excellent condition, preferably through a voltage stabilizer. In addition, the magnetic field is not isolated in any way, which can negatively affect the operation of nearby electronics.

Automatic and temperature control

Typical control cabinet for an induction boiler.

An induction electric boiler is controlled using a separate control panel, which has fairly precise settings, but does not imply programming the operation of the boiler for the next day or week.

In well-known heating element models, the temperature is controlled more precisely: by degrees, thanks to a temperature sensor. In addition, in many models it is possible to install a room thermostat, which allows you to more efficiently and correctly regulate the operation of the boiler according to the temperature of the air in the room, and not the coolant at the outlet.

Weight and dimensions

An example of using several low-power electric boilers in one system.

The dimensions of induction boilers are really small, which allows you to install them almost anywhere in the house. However, this is not such a significant advantage over the already compact heating element models or extremely small electrode boilers, slightly larger than the main pipe.

Differences between heating element boilers and induction equipment

Such devices convert electrical energy into thermal energy. At the same time, their efficiency approaches 100%. It is for this reason that many consumers find it difficult to make a choice.

People often pay attention to the high cost of induction units. However, they do not take into account the fact that over 5–7 years of regular use, equipment costs seem to be the same

This is explained by the fact that heating element boilers require regular repairs, namely the replacement of burnt-out elements.

In fact, making a choice between these types of equipment is not easy, because they heat the room in the same amount of time. However, induction units are considered more preferable, because scale does not form here, and it is also possible to use various coolants. At the same time, you don’t have to worry about noisy operation and don’t worry about the need for regular maintenance.

No heating element

First, the electric boiler is induction, supposedly there are no heating elements. But in a heating element, sometimes there are more than a dozen of them, which means there is a high probability of them breaking, maybe several at once.

But if there were no heating element, then how would the boiler heat the water? The same coil essentially performs this role, only without contact with the liquid. Therefore, this element is present in any such unit.

But as for the high probability of heating elements failing, this directly depends on the product and manufacturer that you buy.

There are specialists who have installed more than 500 heating element boilers over the years of their work, and have not changed a single element under warranty during all this time.

Advantages of an induction heating boiler

- Low operating costs (up to 30% lower compared to traditional boilers).

- High efficiency, which does not decrease during the entire service life and reaches 98%.

- Possibility of using any coolant (water, oil, glycerin, antifreeze...).

- The coolant must be replaced every 10 years.

- Lack of heating elements.

Note! In electric boilers, heating elements require maintenance and replacement.

- Environmental friendliness of the system (no emissions of combustion products).

- There is no need to equip a special boiler room and fuel storage warehouse.

- No scale.

- High degree of fire and electrical safety.

- There is no need to install a ventilation system and chimney.

Advantages and disadvantages of an induction boiler

Induction boilers have the following advantages:

- High efficiency;

- No consumables, reliable design;

- Small overall dimensions;

- Easy installation and operation;

- High heating rate;

Induction-type boilers have an efficiency of up to 99%, exceeding the efficiency of heating elements and electrode units. The boiler efficiency of 20 - 30%, declared by manufacturers, contradicts the principles of the law of conservation of energy.

But some savings can still be achieved due to the lack of scale. The fact is that the core, when exposed to electromagnetic induction, not only heats up, but also acquires a stable microvibration. The formation of deposits and scale under such conditions is almost impossible.

In heating element and electrode boilers, scale formation is a stable, constant process. Lime deposits have a certain thermal resistance and reduce the heat transfer coefficient from the heating element to the coolant. Scale 0.5 mm thick impairs heat transfer by 8 - 10%. In induction boilers there is no such obstacle and electrical energy is spent more efficiently.

The presence of vibration also allows the use of water in the heating system even with a high content of hardness salts. In general, untreated water, antifreeze, even oil can be used as a coolant when operating inductor boilers - that is, there are no requirements for the chemical composition that are inherent in other electric boilers.

Induction boilers do not have wearable elements (heating elements, electrodes) in their design. The service life of the equipment is stated to be 25 years (with a 2-year warranty). Regular replacement of heating elements is not required - this reduces the cost of operating the equipment.

Domestic boilers are small in size (height does not exceed 1 meter) and can be located in any room. Installation of the product does not require obtaining any permits; installation can be done independently. A prerequisite for installation is to ground the device to prevent electric shock.

Separate mention should be made about the independent production of an induction type boiler. The implementation of this task is possible if you have a welding machine and certain skills. But knowledge of electrical equipment and devices is a prerequisite, because any complex equipment requires a serious security, control and management system. Self-assembly of the control unit and security systems is not within the capabilities of everyone.

Induction boilers can be called multifunctional. They can be used not only for heating, but also for producing hot water in instantaneous water heater mode.

Induction boilers practically do not have any serious disadvantages. We can only note that according to user reviews, there are complaints about the noise of the product during operation. This is caused by the presence of vibration. This negative factor can, in principle, be eliminated - the boiler should be mounted with shock-absorbing inserts (rubber, etc.), which will prevent the transmission of vibration to building structures.

It can also be noted that uncontrolled coolant leakage poses a serious danger. If the flow control system fails, the equipment will be destroyed and will become beyond repair. And one more significant drawback inherent in all electric heating equipment is the very high cost of electrical energy.

Induction heating boilers are high-quality and efficient equipment from a technical point of view. In their design, they are more advanced than heating elements and electrode electric boilers. In the absence of other energy sources other than electricity, equipment of this type may eventually become more popular for heating private houses and cottages.

( , 2 today)

We recommend reading:

Autonomous water heating of a private house

Cascade connection of boilers

Do-it-yourself toilet replacement

Replacing a heating radiator in an apartment

Electric boiler for heating a private house

Water supply system for a private house from a well

Operating principle

Induction heating is the heating of materials by electric currents that are induced by an alternating magnetic field. Consequently, this is the heating of products made of conductive materials (conductors) by the magnetic field of inductors (sources of alternating magnetic field).

Induction heating is carried out as follows. An electrically conductive (metal, graphite) workpiece is placed in a so-called inductor, which is one or several turns of wire (most often copper). Powerful currents of various frequencies (from tens of Hz to several MHz) are induced in the inductor using a special generator, as a result of which an electromagnetic field appears around the inductor. The electromagnetic field induces eddy currents in the workpiece. Eddy currents heat the workpiece under the influence of Joule heat.

The inductor-blank system is a coreless transformer in which the inductor is the primary winding. The workpiece is like a secondary winding, short-circuited. The magnetic flux between the windings is closed through the air.

At high frequencies, eddy currents are displaced by the magnetic field they themselves generate into thin surface layers of the workpiece Δ (skin effect), as a result of which their density increases sharply and the workpiece heats up. The underlying layers of metal are heated due to thermal conductivity. It is not the current that is important, but the high current density. In the skin layer Δ, the current density increases in e

times relative to the current density in the workpiece, while 86.4% of the heat of the total heat release is released in the skin layer. The depth of the skin layer depends on the radiation frequency: the higher the frequency, the thinner the skin layer. It also depends on the relative magnetic permeability μ of the workpiece material.

For iron, cobalt, nickel and magnetic alloys at temperatures below the Curie point, μ has a value from several hundred to tens of thousands. For other materials (melts, non-ferrous metals, liquid low-melting eutectics, graphite, electrically conductive ceramics, etc.) μ is approximately equal to unity.

Formula for calculating skin depth in mm:

Δ=103ρμπf{\displaystyle \Delta =10^{3}{\sqrt {\frac {\rho }{\mu \pi f}}}},

where ρ

is the specific electrical resistance of the workpiece material at the processing temperature, Ohm m,

f

is the frequency of the electromagnetic field generated by the inductor, Hz.

For example, at a frequency of 2 MHz, the skin depth for copper is about 0.047 mm, for iron ≈ 0.0001 mm [ source not specified 463 days

].

The inductor becomes very hot during operation, as it absorbs its own radiation. In addition, it absorbs thermal radiation from the hot workpiece. Inductors are made from copper tubes cooled by water. Water is supplied by suction - this ensures safety in the event of a burnout or other depressurization of the inductor.

Installation of a simple circuit

- Place a metal mesh at the bottom of the plastic pipe.

- Fill the entire space of the body with steel pieces and cover the top with a piece of mesh.

- Wind copper wire evenly in a spiral around the plastic pipe. In total, you should get from 90 to 100 turns with the same distance between them.

- Install the resulting inductor into the heating circuit using adapters. To do this, you need to remove part of the pipe from the general system and place the coil in the resulting cut. Solder the first adapter to the body.

- Connect the ends of the copper wire to a high-frequency inverter.

- Fill the system with water and start it up.

To increase the safety of a homemade heat generator, it is advisable to insulate the open areas of the coil

When choosing a material to protect copper wire, you need to take into account its electrical and thermal conductivity

The considered circuit of an induction boiler, made by hand, is inexpensive for the manufacturer and can significantly increase the rate of heating water in the heating system. The disadvantages include the small size of the equipment and nondescript appearance.

A little about the induction cooker

This miracle stove is not like ordinary stoves in that:

- Automatically recognizes suitable cookware (only made of ferromagnetic metals and with a flat bottom), and does not even turn on unsuitable ones.

- Heats up faster than gas or electric, therefore, food is prepared more quickly.

- Heats a strictly defined zone equal to the diameter of the dish. The rest of the stove remains cold.

The design of such a stove in different brands may differ significantly, but its basic structure is the same for all models:

- Glass ceramic surface.

- There is an insulating layer underneath.

- Under the insulation is an induction coil.

- Under the coil there is a control unit and a frequency converter.

The primary circuit in such a transformer is the coil inside the stove, and the secondary circuit is the cookware itself.

On the Internet you can even find funny diagrams of homemade heating systems using induction cookers. But they do not stand up to criticism.

Induction cookers operate at ultra-high frequencies from 20 kHz to 60 kHz. Carrying out measurements of radiation, it was revealed that part of it is absorbed by the slab itself, and the rest act strictly within a radius of 30 cm from the center of the slab. Still, despite proven safety, people with pacemakers are strongly advised not to use such stoves in order to avoid cardiac arrest. What about harmful radiation from an induction boiler? After all, it also operates at frequencies from 25 kHz and higher.

Or is it better to buy

On the modern heating equipment market you can find many models of induction boilers. If you don’t want to bother creating it yourself, just purchase an induction boiler to heat your home or industrial premises.

If this cost scares you, then just make an induction boiler yourself. After all, most of the components and materials necessary for this are always available to the owner and home craftsman.

Industrial induction boiler

If we examine the domestic market of induction boilers, they are represented by such manufacturers as SAV, VIN. As for power, single-phase boilers have a range from 2.5 kW to 7 kW, and more powerful three-phase boilers - up to 60 kW.

It should be remembered that when you select the necessary parameters of an induction boiler, the power of the device will not decrease throughout the entire period of operation. The standard ratio is 60 W per 1 sq.m of area that is heated. But in order to more accurately calculate the power, it is necessary to take into account the parameters of the room, that is, the place where this boiler is located. If the thermal insulation leaves much to be desired, and the insulation too, then the calculated ratio should be higher. That is why it is best to entrust such calculations to specialists.

So, you don’t need a very powerful model; you will need to install a 6 kW boiler for a room of 100 sq.m and for a temperature of about 15 degrees. The maximum permissible pressure in the system will be no more than 0.3 MPa.

It is worth noting that an electronic operating mode programmer unit can also be additionally supplied to the basic package. Such a device programs the operation of an induction boiler for a period of a week, or is used to remotely control the entire heating system.

Boiler programmer

When choosing a boiler, you also need to pay attention to such a thing as the thickness of the steel core. The thicker the walls, the longer it will not be subject to corrosion.

Water heaters type VIN

The heart of the unit is a coil consisting of a large number of turns of insulated wire, and placed vertically in a cylindrical housing in the form of a vessel. A metal rod is inserted inside the coil. The housing is hermetically sealed at the top and bottom with welded lids, and the terminals for connection to the electrical network are brought out. Cold coolant enters the vessel through the lower pipe, which fills the entire space inside the body. Water heated to the required temperature goes into the heating system through the upper pipe.

Coolant heating circuit

Due to its design, when connected to the network, the heat generator constantly operates at full power, since it is irrational to supply the heating installation with additional voltage regulation devices. It is much easier to use cyclic heating and use automatic shutdown/on with a water temperature sensor. You just need to set the required temperature on the display of the remote electronic unit and it will heat the coolant to this temperature, turning off the water heating induction element when it is reached. After the time has passed and the water has cooled by a few degrees, the automation will turn on the heating again, this cycle will be repeated constantly.

Since the heat generator winding provides a single-phase connection with a supply voltage of 220 V, induction-type heating units are not produced with high power. The reason is that the current in the circuit is too high (over 50 amperes), it will require laying large cross-section cables, which in itself is very expensive. To increase power, it is enough to put three water heating units in a cascade and use a three-phase connection with a supply voltage of 380 V. Connect a separate phase to each device in the cascade; the photo shows a similar example of the operation of induction heating.

Heating with induction boilers

Design features of heaters of the “Sibtekhnomash” type Using the same effect of electromagnetic induction, another company develops and produces water heating devices of a slightly different design that deserves attention. The fact is that the electric field created by a multi-turn coil has a spatial shape and spreads from it in all directions. If in VIN units the coolant passes inside the coil, then the Sibtekhnomash induction boiler device provides a spiral-shaped heat exchanger located outside the winding, as shown in the figure.

The winding creates an alternating electric field around itself, eddy currents heat the turns of the heat exchanger pipe in which water moves. Coils with coils are assembled in a cascade of 3 pieces and attached to a common frame. Each of them is connected to a separate phase, the supply voltage is 380 V. The Sibtekhnomash design has several advantages:

- induction heaters have a separate, collapsible design;

- in the zone of action of the electric field there is an increased area of the heating surface and a larger amount of water due to the spiral circuit, which increases the heating rate;

- Heat exchanger piping is accessible for cleaning and maintenance.

An example of connecting an induction boiler

Despite the differences in the design of the heat generator, its operating efficiency is 98%, as in heaters of the “VIN” type, this efficiency value is declared by the manufacturer itself. The durability of the units in both cases is determined by the performance of the coils, or more precisely, by the service life of the winding and electrical insulation; manufacturers set this indicator within 30 years.

How much electricity does an air conditioner consume for heating?

It is important to understand that there is no absolute calculation formula. The point is the impossibility of accurately predicting the street temperature and the required temperature value in the room

In addition, it is difficult to understand how often the user will turn on the device. It is possible to find out approximate indicators.

Heating uses less electricity than cooling. Here the COP coefficient is used for calculation. For class A it is approximately 3.60. With a heating power of 2.2 kilowatts, it will take approximately 0.61 kilowatts per hour. Judging by the above calculations, heating a room with a split is more profitable than with a heater. The latter consumes an approximate number of kilowatts, as in the case of rated power.

Per month

To find out how much an air conditioner consumes per month, you need to know how many hours the system has worked. In hot weather, the device can operate for no more than 10 hours. If the air conditioner is class B and needs 0.78 kilowatts per hour to operate, then in 10 hours it needs 7.8 kilowatts per day. For a month of continuous operation in the specified mode, 234 kilowatts will be required. With a tariff for electricity of 14.04 rubles per day, per month you will need to pay 421 rubles per month. This calculation is schematic and inaccurate, since the final amount will depend on the size of the room, heat inflow, desired cooling or heating parameters, and other things.

You can also use the second calculation method, based on the indicator of hourly electrical consumption and specific air conditioning operation, a typical split operation scheme. So, in a few hours, the type B inverter model will work with 100% performance. Within 3 hours this figure will be 75%, within 4 hours - 50%, and 5 hours - 25%. Then per day a figure of 5.85 kW/hour will be obtained. The monthly cost will be 758.16 rubles.

Considering this indicator in one way or another, you need to know that each air conditioner has several characteristics of consuming and heating power (cooling and heating capacity). These values are specified in the device passport and may vary depending on specific conditions. The higher the number of heat and cold indicators, the lower the consumption will be. It is also interesting that any device consumes 3 times less electricity than it produces. The point is the cost of freon circulation and its conversion.

It is worth understanding that these figures, written with the help of the manufacturer, may differ from the real ones. This can only mean one thing - they are approximate. In the conditions of the enterprise there were no factors influencing the increase in the indicator. In practice, conditions are not ideal.

Revealing the main myth of induction heating

Lately they have stopped saying that the efficiency of induction heating is 2-3 times higher than the efficiency of a heating element boiler. But supporters of the induction boiler claim that a heating element boiler quickly loses its properties and goes out of use because scale grows on it!

They say that during the year the power of a heating element boiler decreases by 15-20%. Is it really?

Yes, heating element deposits are indeed present, but you should never confuse the heating system and the water supply system. For example, scale actually forms in the water supply, just as it forms in the kettle that we see in the kitchen every morning. This never interferes with our work; we know, and there is no doubt, that water boils in a kettle in any case.

On the contrary, in the heating system we know, impurities rarely enter the water. The deposit layer is very thin and does not pose any significant obstacle to heat transfer.

If energy leaves the network somewhere, it does not completely disappear anywhere. It turns into absolute heat and the coolant heats up, which, in turn, heats up with exactly the same efficiency as it was heated before and as it will always heat up. If it were not so, then the heating element would be torn apart by excess energy.

As soon as scale appears, heat exchange occurs at a higher temperature. There can be no talk of any reduction in efficiency, no matter what the temperature in the heating element.

Decrease in electric boiler efficiency

Another argument for comparison is that an induction boiler does not lose its original power during operation. But with heating element, due to scale formation, this happens as a matter of course.

Even sometimes calculations are given, according to which, within just one year, the power of a heating element decreases by 15-20%. This means that its efficiency also decreases.

Let's look at this in more detail.

Almost any electric boiler has an efficiency exceeding 98%. And even boilers operating at ultra-high frequency currents from 25 kHz and above, what can they change for you? Add an extra one and a half percent, but at the same time jump the price by 100%?!

As for deposits on the heating element element, they are indeed present.

What happens where there is no constant supply of impurities? A small layer of deposits may settle on the heating element, however:

this layer is not thick enough

it does not in any way interfere with heat transfer

And accordingly, the boiler in no way loses its original efficiency.

That is, in fact, both on a clean heating element and on a dirty one, the same amount of energy is transferred, only at different temperatures.

Pros and cons of induction boilers

Factory assembled induction boiler

Is this type of heating really as effective as the manufacturers advertise it? When reading reviews about induction heating, one cannot draw an unambiguous conclusion. Many consumers complain about high energy consumption; some homemade boiler models are clearly dangerous to operate.

Before making an induction heating boiler with your own hands, selecting components and components for it, it is recommended that you familiarize yourself in detail with the pros and cons of this type of heating supply.

- Rapid increase in coolant temperature to the required level. Unlike the operation of heating elements, induction heating of water for heating does not require additional insulating materials. Those. thermal energy from the rod is transferred directly to the coolant;

- Long service life. This is due to the absence of moving parts and the high reliability of manufacturing materials;

- Small design dimensions;

- There is no scale formation on the internal walls. This is due to the slight vibration of the rod during its operation. However, if you read reviews about induction heating boilers, no one complains about the high noise level.

But along with this, it is necessary to take into account the negative aspects of operating heating boilers of this type:

- High cost of factory models. Truly high-quality electric induction heating boilers are made using modern materials, the cost of which largely determines the high price. Therefore, homemade models are significantly inferior in quality and technical parameters to factory ones;

- To install boilers with a power of more than 7 kW, it will be necessary to install a 380 V electrical network. Otherwise, the load will not allow the equipment to operate in normal mode;

- If there is no water during operation of the induction heating furnace, it will overheat and fail. Therefore, the design must include pressure sensors that are connected to the circuit breaker. If the pressure drops, the device will automatically turn off.

Having decided that you still need to do induction heating yourself, you can begin to select the optimal boiler design and calculate its parameters.

The induction heating principle has been used in the steel industry for heating metal for decades. It was from this industry that induction heating boilers came.

Who invented the induction heating unit

The marketing argument about the innovation of the induction boiler does not stand up to criticism. The principle of induction was discovered back in the first third of the 19th century by Michael Faraday, a researcher known to us from a school physics course.

And at the very beginning of the 20th century, the first induction melting furnace for the metallurgical industry was released into the world in Sweden.

Of course, engineers and scientists were still considering induction for heating boilers in everyday life. But, having studied the pros and cons, we considered this option irrational.

Induction heaters for home and everyday use began to be used throughout the CIS in the mid-90s. Before this, high-power induction boilers were used in the USSR only in heavy industry for metal smelting.