Eco-friendly, efficient, durable, for all types of structures - these are the insulation materials produced by the Isover company in recognizable yellow packaging. Like the price range, the range of its insulating materials is quite wide. Under the Isover brand they produce insulation based on quartz and basalt for various types of facades, ceilings, roofs, and partitions. The right product can be found for both private housing construction and serial construction.

What is Isover, release forms

The founder of the Isover brand is the international holding Saint-Gobain, whose roots were laid back in the 17th century. Currently, the corporation includes more than 100 manufacturing companies and research centers conducting research in the construction industry. The company appeared on the Russian market 20 years ago; currently, a plant for the production of insulation operates in Yegoryevsk, Moscow region. In 2011, the Saint-Gobain holding bought the Chelyabinsk Minervata plant, and it began producing insulation materials from rock basalt fibers.

Isover is produced by processing sand (quartz), glass cullet, and mountain minerals (basalt); after melting the raw materials in a high-temperature furnace, the mass is drawn into fibers using TEL technology to produce threads with a cross-section of 4 - 5 microns and 110 - 150 microns in length.

Hard fiberglass is placed in slabs, soft fiber is rolled into mats and rolls; products differ in thickness and dimensional dimensions, depending on the purpose and production technology.

The typical thickness of a single-layer or two-layer Izover is 50 - 100 - 150 mm, rolls are produced with a total area of 2 - 20 m2, their usual width is 1200 mm, length from 4000 to 12000 mm. The area of one Isover slab does not exceed 1 m2, its overall dimensions are kept within the limits of 600x1200 mm, the number in a pack is from 2 to 14 pieces.

Places for insulation of a private house

Application of mineral wool

As mentioned above, mineral wool has a wide range of applications. Depending on what kind of surface will be insulated and how much you are willing to spend on the construction process, choose the appropriate installation technology from the 4 existing ones:

- On a metal frame.

- On a wooden frame.

- On the staples.

- On the base profile.

Important! In order not to exceed your own estimate, take into account the manufacturer’s recommendations regarding the appropriate method of attaching Izover mineral wool. If you choose the right material option, you will definitely not have any difficulties with installation, even if you decide not to involve specialists, but to do all the work yourself.

Minvata Izover - characteristics

Before you buy Izover and install it, in order to obtain high-quality thermal insulation results in your own home, it is useful to know what mineral wool is and what its distinctive characteristics are.

Mineral wool is a fibrous material that is sold in the form of rolls, mats and slabs. The basis is taken from exclusively high-quality fiberglass, manufactured using TEL technology.

The technical characteristics of Izover mineral wool are as follows:

- Isover thermal conductivity. The value of this parameter is minimal - only 0.041 watts per meter per Kelvin. For this reason, such material retains air well and does not change its performance in different climatic conditions, which is the problem with many other types of insulation.

- Izover sound protection. Mineral wool from this manufacturer does an excellent job of protecting against external noise. The maximum possible parameters are achieved according to current standards due to the presence of an air gap between the fiberglass fibers.

- Density of mineral wool. This figure may vary depending on the specific type of product, but on average it is 13 kg/m3.

- Fire safety. The flammability of mineral wool is determined by the Isover density. Thus, slabs with values up to 30 kg/m3 belong to the group of completely non-combustible materials. This makes it possible to use Izover for buildings of any type - commercial and residential premises, cottages and apartments in high-rise buildings. Rigid and semi-rigid slabs with aluminum foil are low-flammable, so they can also be installed almost anywhere. The main condition when using Izover insulation is strict adherence to fire safety rules during the operation of the house.

- Vapor permeability. The indicator corresponds to 0.50 - 0.55 mg/mhPa. The accumulation of condensation inside the insulation system is a problem with any modern material used for insulation. The advantage of mineral wool in this case is that glass fibers very quickly give back the moisture that they have absorbed, and special water repellents help repel it. The main thing is to leave a gap of at least 2 cm between the wall during installation to remove moisture.

- Life time. In this regard, the restrictions have a very wide range - from 50 to 100 years, depending on climatic conditions and the building material used to construct the walls.

- Ecological cleanliness. The component composition of Izover mineral wool is absolutely safe for humans. During operation of the insulation system, no harmful fumes are generated, so you can safely take it if you put environmental friendliness as one of the first points when choosing a suitable insulation.

- Weight of Izover mineral wool. This material is one of the lightest of the entire line of existing insulation materials, which means it can be used for installation even on surfaces with a small load-bearing load.

- Isover dimensions. As already mentioned, mineral wool of this brand is presented in various types on the market. Depending on the type of material, the thickness is 5-10 cm, the overall dimensions of the slabs on a standard grid are 1 * 1 meter, the rolls include a mineral wool area of 16-20 m2 with a roll width of 1.2 meters and a length of 7-14 m.

What is the material?

The name of the material “Isover” is a brand of the French concern Saint-Gobain, a manufacturer of various types of insulation. Since this concern began on the Russian building materials market by selling fiberglass mineral wool, the name “Isover” was firmly assigned to this material. The name "isover" comes from two French words - "isolation" - insulation and "verre" - glass.

Isover is a material made of fiberglass or basalt fiber with a porous structure; it is produced in the form of rolls and slabs of different hardness. It is used for sound insulation and insulation of walls, partitions, floors, roofs, air ducts and heating systems.

It is used in the design and construction of private, civil, industrial and transport facilities. It is used both in new construction and in the reconstruction of buildings and structures, for heating mains. In this article we will look at the technical characteristics.

Properties

Basic properties:

- high elasticity;

- low thermal conductivity - 0.041 watts per meter per Kelvin;

- good sound insulation due to the air gap between the fibers;

- Izover is much lighter than its analogues and is used for facades where excessive load is unacceptable;

- the presence of water repellents with water-repellent properties;

- service life of at least 50 years;

- all types of isover are considered non-flammable;

- low smoke generating ability;

- the ability to compress up to 60%, which is very convenient for transportation;

- environmental friendliness - no harmful substances are released during operation.

Basic composition

Isover consists of basalt or fiberglass with the addition of recycled sand, limestone and soda. The basis of isover is glass fibers about 5 microns thick and 150 microns long. In the production of isover, recycled materials are used, which ensures an affordable cost of insulation.

The material production technology consists of the following stages:

- mix quartz sand , soda, limestone, and other minerals;

- bring the composition to a temperature of 1300 degrees Celsius until liquid glass forms;

- From a special device, the plastic mass enters a container in the walls of which small holes are made. The container rotates at high speed and, thanks to centrifugal force, liquid glass is squeezed out of the holes in the form of thin, long threads;

- the resulting glass threads are mixed with yellow polymer glue, resulting in the formation of an adhesive mass;

- Then the mass is placed in a drying oven with rollers. Hot air dries the mass, and steel rollers level and form a layer;

- the finished layers are cut into the required sizes.

Release forms

Isover is produced in the form of rolls (mats) and slabs. Each type is used for specific insulation and sound insulation work. The slabs are produced in different hardnesses, they are treated with water-repellent compounds, with additives from extruded polystyrene foam.

Insulation rolls can be single-layer or double-layer; they are used for horizontal surfaces – floors, ceilings. Plates and rolls are packed in dense heat-shrinkable plastic containers.

Dimensions

The slabs are produced in different sizes, the maximum size is meter per meter with a thickness of 5 to 10 cm. Dimensions of the slabs are 610×1170 (dimensions are given in mm), there are 14 pieces in a package. Rolls are produced single-layer and double-layer with a width of 120 cm. The length of the roll varies from 7 to 14 m.

Single-layer rolls are produced with a thickness of 5 or 10 cm, double-layer rolls with a thickness of 10 cm, with the thickness of each layer being 5 cm.

What is Izover?

Izover brand insulation is mineral wool, which consists of glass thread (fiberglass). The components of mineral wool are exclusively environmentally friendly, which can be called a good advantage of this brand.

Specifications

But below we present to your attention a list of technical characteristics of Izover insulation, which make it the leader in its market segment:

- since Izover belongs to the class of insulation, it has a rather low thermal conductivity at the level of 0.038;

- high level of sound protection, thanks to which Izover performs not only its main function, but also an auxiliary one;

- thanks to fiberglass, Izover is not susceptible to infection by fungus or other bacteria, and it is also not eaten by rodents and insects that are potentially dangerous to insulation;

- Izover also has a drawback - it is a high level of water permeability, which is typical for porous structures, including mineral wool. However, unlike other insulation materials that absorb water and do not release it, losing their thermal insulation properties, Izover dries quickly due to elevated temperatures and good ventilation. Therefore, it should be laid so that there is a void between it and the protective barrier for ventilation;

- low specific gravity, which can provide ease of use, transportation, installation and unloading of insulation. In addition, Izover is good because it can be installed independently, without the help of specialists;

- environmental friendliness;

- high level of resistance when exposed to chemicals that release lubricants and flammable substances;

- elastic insulation design that can compress by more than 70 percent;

- long service life;

- non-combustibility of insulation materials.

https://youtube.com/watch?v=4S-jFvQ8wIM

Areas of application

Izover insulation, thanks to its technical characteristics, is capable of providing thermal insulation for buildings of various designs, both inside and outside

However, when using it, please note the following:

- Izover can be used only where the temperature does not exceed 250 degrees, with the exception of residential buildings;

- the insulation must fit tightly to the structure that you plan to insulate;

- Before using Isover, prepare the surface by leveling it as evenly as possible.

The characteristics of Izover allow it to be used for the following purposes:

- construction of houses;

- exterior decoration of premises;

- external finishing;

- insulation of floor coverings;

- insulation of walls, attics and attics;

- protecting walls from wind.

https://youtube.com/watch?v=TMLhlO86hf0

https://youtube.com/watch?v=ot6KOR8biqg

Size and models

Today, Izover brand insulation products are available on the market in different forms:

- rolls;

- mats;

- slabs

They all have different purposes, but the technical characteristics are practically the same. There are single-layer models with different thicknesses, and there are two-layer ones. Roll models have a width of 120 cm and a footage of seven to fourteen meters. The characteristics of the rolls in terms of area can also be different.

Naturally, the model range of insulation is represented by insulation materials that have different purposes and characteristics:

- sound protection – model for finishing partitions and walls;

- frame – used for frame construction;

- pro - a model for insulating attics and pitched roofs in the form of rolls of different thicknesses;

- classic is a widely used insulation material that can be used to insulate floors, joists, attics and complex construction sites. It has a roll shape, but can be used for large areas;

- classic Plus - insulation of external and internal wall surfaces, has excellent thermal insulation characteristics.

As you can see, some models can be interchangeable, since they have universal characteristics and purposes, while others have only a narrow focus in application, for example, models such as “Sound Protection” or “Frame”.

Izover insulation

Advantages of Izover

Taking into account all the technical characteristics of Izover mineral wool described above, we can conclude that it has the following advantages:

- excellent level of thermal insulation;

- resistance to any, even extreme temperature conditions;

- fire safety;

- resistance to mechanical and chemical stress;

- easy delamination and no deformation during compression;

- tensile strength;

- moisture resistance;

- excellent noise absorption;

- absolute resistance to any biological influence, in particular to rodents;

- ease of installation.

Types of facades Izover

Ordinary mineral wool is not suitable for insulating facades, as it is soft and easily deformed. The manufacturer has developed the Facade series specifically for external wall insulation. It does not require additional finishing from above: the ventilated façade is covered only with reinforcing mesh and decorative plaster.

Izover Facade has all quality certificates. It does not change the properties listed in the characteristics description due to fluctuations in temperature and humidity.

There are several types of Izover facade insulation for different purposes. Single-layer insulation is used mainly when repairing facades. During construction, two-layer insulation is used: the inner layer retains heat, and the outer one protects from the wind.

Ventilated facade Izover

Ventilated façade Izover consists of two layers of insulation, which significantly increases the thermal insulation properties. It consists of mineral wool and fiberglass. On one side, the slab is covered with fiberglass, so Izover Optima is not afraid of wind and mechanical influences. The slabs are fastened using the tongue-and-groove type, so there are no gaps at the joints. It is used both in private construction and in the construction of high-rise buildings.

Ventilated façade Izover bottom

This type of insulation is used to finish the interior walls of a house in combination with external insulation. Its main purpose is to fill joints. Due to the elasticity of the material, the appearance of air pockets in the walls is eliminated. Has good heat protection and sound insulation.

It is unacceptable to install the bottom layer of thermal insulation with a gap of more than 2 mm. This leads to the appearance of “cold bridges” and reduces the efficiency of the entire structure. Installation with a gap between the wall and the mineral wool slab is also not allowed.

Ventilated façade Izover up

This type of thermal insulation is used to insulate the external walls of houses in combination with internal insulation. It has a low thermal conductivity coefficient, which means it retains heat well in the house. Another advantage is good wind resistance, which allows you to use Izover Facade Top in different climatic zones.

Supplied in sheets of optimal size, which reduces installation time by half and the number of fasteners by 40%.

The top layer slabs must overlap the joints of the bottom insulation layer. Fastening is carried out with disc anchors. They provide a tight fit of the slab to the wall surface.

Types of isover insulation

Isover insulation has nine popular varieties:

- Isover KL34 – slabs 5 or 10 centimeters thick, suitable for any surface;

- Isover KL37 – slabs are produced in pressed packages;

- Isover KT37 – roll material;

- Isover KT40 – two-layer mats; .

- Isover STYROFOAM 300A – solid boards with the addition of extruded polystyrene foam;

- Isover VENTITERM – slabs treated with a water repellent;

- Isover “Pitched roof” – used for roof insulation;

- Isover “Ventfacade” – two-layer facade slabs;

- Isover “ Sound protection” – available in the form of plates and rolls, used for sound insulation.

Many types of insulation can be interchanged with each other.

Application of isover insulation

Izover is used for insulation of internal and external walls, roofs, floors of residential, public and industrial buildings. It is also used to minimize noise in wall, ceiling and floor structures.

Isover KL34 is used for any surfaces: horizontal, vertical, with any angle of inclination. To install the slabs, a frame is used in which the isover is mounted, and no additional fastenings are needed.

Isover KL37 is used for interfloor slabs, walls and roof slopes. Available in the form of pressed slabs and packaged. This type of insulation must be pressed tightly against the working surface; installation does not require additional fasteners.

Isover KT37 is produced in roll form, used mainly for horizontal surfaces, but can be used for internal walls and partitions and roof insulation. The material does not require additional fastenings; it must be pressed tightly to the surface.

Isover KT40 is a two-layer roll material used for horizontal surfaces. During installation it does not require additional fastenings.

Isover STYROFOAM 300A has improved thermal insulation and moisture resistance properties thanks to additives in the form of extruded polystyrene foam. The material is produced in the form of rigid slabs and requires additional fastenings. Depending on the base, the slabs are fastened with: plastic dowels, special mastics based on cold bitumen, or polyurethane foam glue.

Isover VENTITERM and Isover VENTITERM PLUS

boards are new products from the Isover concern, with dimensions of 1000x600 mm, with a thickness of 50, 80, 100 mm.

They are used in single-layer and two-layer facade insulation systems. Isover VENTITERM is produced in the form of dense slabs and is used for external insulation of facades, ventilation and water supply pipes, for sound and thermal insulation of ventilated facades.

Isover VENTITERM PLUS is available in slabs with the same dimensions as Isover VENTITERM . The main difference is the improved helicopter protection properties, due to the fact that on one side these plates are covered with special fiberglass.

Isover “Pitched roofing” is used for structures with changes in humidity conditions. It is also a good sound and heat insulator, used in any climatic conditions. It is used for pitched roofing and soundproofing of internal walls and partitions. The dimensions of the Isover “Pitched Roof” slab are 610x1170 with a thickness of 100 mm.

Isover “Ventfacade” is available in the form of slabs of different sizes, with a thickness of 50, 100, 150 mm. Consists of two layers, but can be used as a single layer material. Thanks to its elasticity and elasticity, it fits tightly to the base and does not require additional fastenings.

Isover “Sound Protection” is produced in the form of slabs with dimensions 610×1170 and a thickness of 50 mm. This material reduces noise levels and is used for sound insulation of roofs, facade walls, internal walls and partitions. Can be used in any climatic conditions.

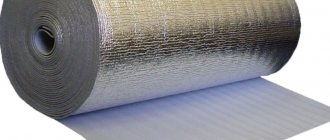

Isover “Sauna” The product is intended for insulating walls and ceiling structures of saunas and baths from the inside. The foil product is also good for

insulating

other damp areas. ISOVER SAUNA also works as an effective heat insulator.

Isover “ Optimal”

– stone wool slabs for frame structures. The product is recommended for thermal insulation of the roof, walls, and floors of the house.

Isover “Facade- Master”

is a high-tech facade insulation for low-rise and private construction.

Isover “ Classic”

Used in lightly loaded horizontal structures.

Isover “ Pro”

, judging by the characteristics and reviews, is the most durable material in this line.

Isover “Ruf N” is a non-flammable basalt insulation. Made from stone fiber with the addition of a synthetic binder. High-density material can withstand significant loads. It is used as a bottom layer when insulating flat roofs in private housing construction.

Isover Venti

a special product for insulation systems for ventilated facades.

Advantages of Izover thermal protection

Practicality

Due to its shape retention, the material does not change during installation

Firmly attached to the frame or wall, preventing the penetration of cold

Due to its elastic properties, no additional fasteners are required for installation

Thrift

Saving utility costs up to 70%

Does not require much space for transportation as the material compresses well

Safety

Vapor permeability allows the insulation to “breathe”

There is no dust when working with insulation

When heated, it does not evaporate toxic substances

Eco-friendly, does not harm the environment and human health

Fire resistant material

Disadvantages of isover

According to safety precautions, when working with materials containing fiberglass, you need to use protective equipment: gloves, long-sleeved workwear, safety glasses, gauze bandage. If safety precautions are not followed, skin irritation may occur.

To prevent glass dust from entering the room during internal insulation, a special film is laid between the isover layer and the finishing material (lining, drywall).

Also, if the isover is installed incorrectly or the finishing layer is deformed, insects or mice sometimes appear in the insulation. Isover does not have mechanical strength, so it should not bear the load.

Despite its shortcomings, Izover is not inferior to its competitors, such as Ecover, Knauf, TechnoNIKOL, Rockwool.

Varieties

The manufacturer Izovera produces mineral wool in rolls, mats and slabs.

Plates

Slab models come in the following types:

- Isover Optimal whose density is 28-37 kg/m3. It is used for frame structures and installation of sound insulation for interior partitions and floors. They can insulate roofs, floors, and walls. Slab dimensions - 60*100 cm, thickness - 5 cm or 10 cm, in a package of 4 slabs (10 cm) or 8 slabs (5 cm);

- Isover Standard. It is used to insulate external walls before finishing them with siding or facing bricks. The geometry of the plates is identical to Izover Optimal. Among the characteristics of Izover Standard, it is worth noting low compressibility under a specific load of 2 kPa - 10%;

- Izover Façade, whose density is 145 kg/m3, is used for facades with a thin layer of plaster. Fire resistance, as well as the absence of the influence of rodents, are the undoubted advantages of this model when insulating a building.

Rolls

Among the many roll options for this insulation, the following can be distinguished:

- Isover Warm Roof. The technical characteristics of this model allow it to be used for pitched roofs, since this material has high water-repellent properties;

- Isover Warm House is convenient to use on large horizontal surfaces. It allows you to save on heating your home by 64%;

- Isover Sauna combines a steam barrier. The presence of a layer of foil allows you to maintain a high room temperature for a long time;

- Isover Frame-M37 is used for serial construction;

- Isover Frame-M40-AL has a layer of aluminum foil, which allows you to increase the rate of heating of the room and save heat for a long time;

- Isover Frame-M40 is used for thermal insulation of floors.

Mats

Pro - used indoors and outdoors, a universal material that is popular. Thickness 50, 100 and 150 mm. Classic – thickness 50 mm, 2 mats wound in a roll. It is used for insulation of floors, roofs along joists, and ceilings along lathing. M37 frame - thickness options 40, 50, 60, 100 and 150 mm. It is used to fill the space between walls when insulating frame houses. Frame M34 – thickness 50 mm, less dense than M37. Frame M40AL – foil insulation with a thickness of 50, 100 and 150 mm.

Description and Application

The presented material has many advantages and disadvantages of mineral wool. And this is not surprising, since their properties are quite similar. It is produced in the form of slabs, which can be either rigid or semi-rigid. There is also the opportunity to buy Izover in the form of rolls and mats. They are used in the arrangement of the roof and facades of the house, ceilings, walls and floors.

Izover is based on glass fibers, the length of which reaches 100-150 microns and the thickness of 4-5 microns. It is these parameters that allow the Izover heat insulator to obtain high levels of elasticity and resistance to loads. Competition may come from the technical characteristics of TechnoNIKOL insulation.

In the photo Izover insulation

How it is made

So, what is Isover insulation? The characteristics of any insulating material depend primarily on how accurately the required technologies are followed during its production. Isover insulation is manufactured as follows:

Quartz sand, cullet, limestone, soda ash and other minerals are thoroughly mixed in advance.

The resulting mixture melts at a temperature of 1300 degrees. until a homogeneous fluid plastic mass is obtained. In a special installation, this liquid glass is fed from a great height into a bowl rotating at high speed, the walls of which have small holes. Under the influence of centrifugal force, the hot mass is squeezed out in the form of long thin threads. The fibers are mixed with yellow polymer glue. The resulting sticky mass is fed into a special oven, where it is rolled between steel shafts and blown with hot air. As a result, the glue sets and the layer itself is leveled. The finished glass wool is fed into circulation saws to be cut into slabs of the required size.

Stamps

Isover's lines of thermal insulating products include several dozen items and are designed to solve specific problems. They all differ in delivery form, thickness, density and size.

Please note: since all brands have the same base, they are interchangeable.

For general construction work

Izover Profi. A universal material with increased elasticity. Provides the highest level of thermal protection among the brand's retail materials.

Supplied in rolls, plate thickness – 50, 100 and 150 mm. Does not require additional fasteners during installation; can be installed by surprise. Received positive reviews from builders.

Used for insulation and sound protection:

- external walls inside and outside the house;

- pitched roofs;

- interfloor ceilings;

- frame walls;

- internal partitions;

- ventilated facades.

Classic. Supplied in rolls, material thickness – 50 mm. Can be installed by surprise.

Application area:

- insulation of suspended ceilings;

- interfloor ceilings - the material lies between the joists;

- attic spaces.

Isover Classic stove. The shape of mineral wool is slab. Size – 610*1170 mm, thickness 50 and 100 mm. Packaging 5 and 10 m2.

Application area:

- insulation of frame walls;

- insulation of walls from the inside;

- insulation of ventilated facades.

Isover kl 34. Release form – slab with a thickness of 5 and 10 cm. Does not require additional fasteners during installation.

Application area:

- ventilated facades;

- frame walls.

Isover kl 37. Release form – plate. It is used for insulation and sound protection of roofs and interfloor ceilings.

Isover kt 40. Two-layer roll material. Thickness – 10 cm, each layer is 5 cm. Used for insulation of horizontal planes.

Isover Sauna. Supplied in rolls, mat thickness 50 and 100 mm. The main feature is the presence of a vapor barrier layer. Suitable for rooms with high humidity. Refers to moderately flammable materials. It is used for insulation of walls, floors and ceilings in baths and saunas.

Izover Uteplyaev. Universal mineral wool, available only for Siberia and the Far East.

Special solutions

The Izover product line includes special insulation materials with characteristics optimized for solving specific problems.

- Isover Pitched Roof. Has increased moisture resistance.

- SoundProtection. Provides a high level of noise protection.

- Frame P32. Designed for insulation of frame houses. Provides savings on heating costs of up to 25% compared to the basic product.

- Frame M40-Al. Min wool with one-sided aluminum coating. Designed for wet rooms, can be used without additional finishing.

- Izover Plaster Facade. The material is of high density and has low vapor permeability.

- Vent Facade Top and Vent Facade Bottom. They are used for two-layer insulation systems for ventilated facades.

- Floating Floor. Designed for insulation and sound insulation of floors. Has increased elasticity and density. It is made using tongue-and-groove technology.

- Isover OL-P. Special solution for flat roofs. Has ventilated grooves to remove moisture. Made using tongue-and-groove technology, which increases the tightness of the mineral wool layer.

Specifications

Isover is a heat and sound insulating material; it is used to insulate any structural elements inside and outside the building. It is necessary to level the surface under this insulation, since the main condition for using this insulation is a tight fit to the surface.

Main characteristics:

- low thermal conductivity;

- high level of sound insulation;

- resistance to infestation by fungi, small insects, and rodents due to special impregnations;

- ease of transportation and installation ensures the light weight of the material, its density is 13 kg/cub.m;

- elasticity of the material;

- resistance to chemicals;

- long service life.

Thermal conductivity

For thermal insulation materials, thermal conductivity is the main characteristic. For various types of isover it ranges from 0.035 to 0.044 W/mK, which is much less compared to other analogues.

Provided the installation technology is followed, this characteristic will not change over time. This ensures the prevention of heat loss through the load-bearing and enclosing structures of the building.

Soundproofing

The structure of Isover insulation, consisting of thin glass fibers and an air layer, and low dynamic rigidity create effective noise insulation. It is used to provide sound insulation in structures where the soundproofing material does not bear the load.

Flammability

According to the current GOST 30244-94 “Construction materials. Combustibility test methods", isover belongs to the class of non-combustible materials. Therefore, it is used for insulation and sound insulation indoors for various purposes and in low-rise construction.

Isover is also used as an effective insulation in log, frame or panel wooden residential and public buildings.

Vapor permeability

The vapor permeability of isover is 0.50 - 0.55 mg/mchPa and is one of the main disadvantages of this material. In the absence of a vapor barrier, the quality of the insulation will decrease as moisture accumulates.

When the humidity level increases by 1%, the level of thermal insulation decreases to 10%. But under the influence of temperature or sufficient ventilation, the material dries quickly.

To prevent moisture absorption, a vapor barrier is used, and a ventilation gap of 2–4 cm is left between the isover and the wall.

Life time

The heat and sound insulation qualities of the material do not deteriorate over time if the installation technology is followed. For 50 years, the thermal insulation parameters of isover in building structures have not deteriorated.

Environmentally friendly and harmless

Izover is made from natural materials and does not contain harmful substances such as artificial resins or formaldehydes. This is a hypoallergenic material that is safe for human life. Based on the research, it was revealed that there are no harmful emissions during operation.

Insulation weight

What is the weight of the insulation? The weight of isover is much less than similar insulation materials. The specific gravity of isover is 2.5. Therefore, it is used for insulating buildings made of wood, slag concrete, and thin-walled brick.

Release form

Isover is produced in the form of slabs and rolls in packaging. The elasticity of the material allows it to be compressed in packaging, which is very convenient for storage and transportation. After opening the package, the isover quickly acquires its initial dimensions. Roll sizes are 7-14 meters long, 1.2 meters wide.

Other characteristics

Double-layer rolls can be divided into layers before installation. Isover cannot be used at temperatures above 250 degrees Celsius

In a humid environment, isover:

- has water-repellent properties;

- slowly absorbs moisture and water.

These Isover insulation materials have a certificate of conformity and meet all safety standards listed in the requirements of the Customs Union.

Types of thermal insulation

All materials produced under the Isover brand differ from each other in functional purpose and physical properties. Industrial and household categories of insulation are supplied separately. There are several of the most popular varieties of products from Saint-Gobain.

Types of thermal insulation Izover:

Minvata Izover KL 34

This is a mineral plate 5 or 10 centimeters thick. It is used in frame construction and does not require additional fastening with dowels. These products are characterized by high elasticity, which maximizes the scope of application.

The insulation is packaged in a bag. After opening, it instantly takes on its original appearance and is ready for installation. Another advantage of this modification is low shrinkage. Among the technical characteristics it should be noted:

- Thermal conductivity – 0.034 W/μ.

- Vapor permeability – 0.53 mg/mchPa.

- Nominal compression at 2 thousand Pa – 60%.

- Return to normal state – 98%.

Thermal insulation of walls and floors:

Pitched roof

This modification is intended for use as roof insulation. Available in the form of mats measuring 117x61 centimeters and 5-10 cm thick. It is almost one hundred percent hydrophobic. This is its main advantage over its competitors - the ability to use it in conditions of high humidity without loss of properties.

This type of Izover product is characterized by the following indicators:

- Thermal conductivity - 0.035 W/mK.

- Steam conductivity - 0.55 mg/mchPa.

- Absorbency with partial immersion - 0.08 kg/m² in 25 hours.

- A density of 15 kg/m³ is combined with sufficient return and deformation properties.

The advantages of the material make it number 1 in the Russian markets.

Non-combustible thermal insulation for pitched roofs Izover is sold in packages with an area of 14.72 m² and a weight of 10.8 kg.

Product category KT37

This insulation is available in rolls 630 cm long, 60 cm wide and 50 or 100 millimeters thick. Double compression packaging allows for convenient and economical transportation of the material to the construction site. If the volume of insulation in the package is 0.16 cubic meters, then after opening it increases to 0.71 m³. The scope of its application is the insulation of concrete, brick, and wooden buildings from the inside. It is not prohibited to install floors and interfloor ceilings as thermal protection.

Due to the density of 15 kg/m³, it is not recommended to use KT37 in structures with high mechanical loads. Thermal conductivity of 37 W/μ is sufficient to create an effective coating even in one layer. In this, Isover competes with Rockwool Wired Mat 80 slabs. However, the roll form of the product allows you to insulate large areas much faster with the help of a non-combustible product from Saint-Gobain.

Roof insulation:

Material indexed KT40

It is classified as wall insulation. Isover KT40 is supplied in rolls and is intended for frame, brick houses and for insulating free building cavities. The roller, which is 10 cm thick, can be easily divided in half thanks to its two-layer structure. Its remaining dimensions are: 7 meters in length and 61 cm in width. Covered area - 17.8 m².

Izover roll insulation: Its thermal insulation properties are slightly worse than those of other Izover materials - 0.04 W/mk. However, high vapor permeability (0.5 Mg/mPa) makes it possible to effectively insulate buildings made from any raw material with its help. To improve moisture absorption, which amounts to 15% of the weight of the product, it is recommended to install additional waterproofing. GOST 30225 classifies KT40 as non-combustible thermal insulation.

Basalt mass

Russian factories, in addition to fiberglass slabs, produce materials in the form of stone wool. Similar varieties have the following differences:

- Higher cost.

- More durable, stronger and denser than traditional mineral wool.

- Less elasticity. Packages are larger, increasing the cost of storage and transportation.

- High moisture and heat resistance.

Basalt insulation is more expensive, but of the highest quality

Classification of basalt insulation:

- Optimal - for pitched roofs in the form of sound and thermal protection.

- Light - for frame house construction.

- Acoustic - for sound insulation.

- Floor - from impact noise.

- Ruf V, Ruf N - for flat roofing.

- Plaster and Facade-Master are designed for facades under plaster.

- Venti - with improved vapor permeability.

- The standard applies to multi-layer brickwork.

Testing basalt wool for combustion:

Basalt insulation Isover

Izover insulation materials of this group are made from natural raw materials of volcanic origin. It belongs to the basalt group, which determined the name of mineral wool thermal insulation. Isover basalt insulation is not presented in such a wide range as quartz. But even among them, materials are distinguished by purpose and type of construction.

Mineral wool for walls and frame structures

Basalt mineral wool has improved strength characteristics, vapor permeability and resistance to the negative effects of moisture.

For frame structures, external and internal walls, Izover offers:

- Izover Frame House. Universal insulation for any frame structures both in the house and in the apartment.

- Isover Master of Warm Walls.

- Isover Optimal. Universal insulation for walls, roofs, interfloor ceilings, floors along joists, partitions. Elastic, holds its shape well and does not require the use of additional fasteners.

- Isover Light. This is mineral wool for partitions, frame structures, suspended ceilings. Provides additional sound insulation and is characterized by increased elasticity.

- Isover Flor. At the same time, it serves as heat and sound insulation for floors, reducing the level of impact noise to 35 dB .

The standard thickness of these insulation materials is 50 or 100 mm. And only Izover Floor has 25 mm.

Basalt thermal insulation for facades

Due to their properties, Izover basalt insulation materials are ideal for insulating ventilated facades and facades under plaster, siding, and brick. Thus, Isover FACADE-MASTER is designed for insulating external walls under a thin-layer plaster facade. Features high adhesion .

Isover Facade are slabs with high mechanical strength and uniform structure. The thickness of the slab can reach 200 mm. Isover Standard is used for insulation of external walls under brick, block house, siding. It is characterized by high elasticity and chemical resistance to elements of the insulated structure. Isover Venti and Isover Venti Optimal are suitable for ventilated facades.

Basalt mineral wool for roofing

Izover produces insulation for both pitched and flat roofs.

For a pitched roof, you can use one of the universal insulation options or a special one - Isover Master of Warm Roofs. Plates of this material help minimize heat loss during the cold season and keep rooms cool in summer.

For insulating flat roofs, Isover has the Isover Roof series. These are slabs of various sizes that are compatible with most building materials and can withstand loads of up to 7 tons per 1 sq.m.

The production of insulation from two types of raw materials and a naturally large assortment make Isover a leader in the market of thermal insulation materials. Not only professionals, but also inexperienced craftsmen who want to do the insulation work themselves can find the right solution.