The constant rise in energy prices is forcing country property owners to think about how to reduce heating costs. One option is to build an insulated house with minimal heat loss. The second step is to install a low temperature heating system. Third, heat the coolant with an air-to-water heat pump. At first glance, it seems that this is an unreasonably expensive solution, and an air source heat pump will not work efficiently in winter. Let's check if this is true using the example of FORUMHOUSE users who installed heat pumps in their house.

Renewable energy source

When energy bills start to rise, most of us wonder if there is an alternative.

Using renewable energy for heating is becoming a necessary step for homeowners, primarily because gas and electricity from fossil fuels are becoming increasingly expensive. Switching to green technologies such as (WHP) air-to-water heat pumps is often a no-brainer for those looking to cut bills and leave a smaller carbon footprint, but are they any good? As in any other business, it is important to take a balanced approach to the issue before purchasing, so let's look at the advantages and disadvantages of VTN.

There are different ways to compare a heat pump and boilers running on mains gas, diesel fuel or pellets. You can compare the dimensions occupied by the equipment in the boiler room, you can compare the ease of use, the color of the housing and the ease of settings. However, it is quite obvious that the first people begin to compare the complexity of installing different stakes, the necessary maintenance, obtaining permits and, most importantly, the costs of heating the house during the cold season.

Let's try to briefly consider the main aspects and subtleties that not everyone talks about.

Heating from natural gas.

Even though the decision to “supply gas to the house” is obvious, it is not always easy to do.

Natural gas, or as it is also called, Main gas in our oil and gas producing country is the property of the people, there is simply a huge amount of it (gas), it should cost just a penny, but the State should supply it to the house and practically free of charge! The slogan is correct, but in reality everything is somewhat different:

- The price of supplying gas to the fence of the site, as a rule, starts from 300 thousand rubles, but how much it will reach will depend on the distance of that very “cherished” main pipe. The amount could easily reach a million or even higher.

- It is necessary to draw up a project for gas supply to the house, and for this you need to obtain a cadastral passport of the site and, based on it, draw a project. The average project costs 60-70 thousand rubles.

- When laying a long pipe, 100-200 meters, on public lands, it is necessary to register the land under the pipe and the security zone of the gas pipeline for rent with the allocation of this land on the cadastral plan of the area. Such registration will take at least a year, no matter what they say.

- In addition to connecting the gas pipe to the fence, you also need to bring this pipe to the boiler room and separately to the kitchen with a gas stove (if, of course, you need a gas stove), and install a gas meter. This is a separate work and such work is carried out by individual commercial organizations, not always even from Mosoblgaz. The cost of laying a pipe along the site is from 150 thousand rubles.

- Installing a gas boiler in a house imposes its own requirements on the boiler room space and the glazing area of the boiler room (at least 0.03 m2 per 1 m3 of boiler room space). The door to the boiler room must open outward so that during a gas explosion there is room for air to expand :) Yes, there really is such a requirement.

- When installing a gas stake, separate ventilation of the boiler room is required. There are no outlets to the general house ventilation, bathroom ventilation or kitchen ventilation - only a separate pipe.

- It is necessary to ground the chimney (if it is a floor-standing gas boiler), and indeed the chimney itself. For a floor-standing boiler, a chimney costs about 100 thousand rubles (materials + labor). With a wall-mounted boiler it is somewhat simpler, but a coaxial chimney goes into the wall and will smoke at a level of 3 meters from the ground.

- Service contract. Without a service agreement, gas will not be allowed into the pipeline. The cost of annual maintenance for low pressure gas is 11.8 thousand rubles, for medium pressure gas (6 kg/cm2) - 24 thousand rubles. This is the cost of the contract, you still have to pay. It turns out you will have to pay 1000 rubles a month or 2000 thousand even if you don’t use gas at all.

Heating with liquefied gas from a gas tank.

To the average person who has not experienced the heating of a country house, it sounds like main gas and gas in a gas tank are the same thing, after all, it’s GAS. In fact, they are completely different gases. Trunk/natural gas - methane, is obtained as an accompanying gas during the development of oil fields. The gas that is in the gas tank (at its core, a gas tank is just a large barrel) is a mixture of propane-butane. This gas is filled into gas cylinders of cars or cylinders for gas stoves.

The propane-butane mixture of gases is in a gas holder and cylinder in a liquid state; it is often also called LPG (liquefied hydrocarbon gases). For such “liquefaction”, it is necessary to build factories or gas liquefaction stations, so the cost of propane-butane will be completely different compared to methane.

Gas holder and gas boiler:

- The security zone from the house for a capacity of 5000 liters is 20 meters, if more than 5000 liters then 30 meters. No communications, not even sewerage, can be laid closer than 2 meters to the gas holder.

- Once every 10 years, it is necessary to dig up the barrel and check it for cracks or areas of corrosion. It would be a shame if the gas just started running into the ground. The talk of companies installing gas tanks about cathodic protection of the barrel material, unfortunately, remains just talk; they usually do not install cathodic protection. That is why recently a huge number of gas tanks “just dug up from military units” or simply “eternal” have appeared on sale - why would they be made of iron...

- The content of propane and butane in the mixture should be regulated by GOST R 52087-2003, but unfortunately in practice there is nothing that happens in this mixture. In Europe, propane-butane is sold by specific calorific value, but in our country it is sold per liter and it is not clear what is in it. We sell a lot of things like this: gas - in liters, chicken eggs in dozens :) The peculiarity of all liquid gases is that when its temperature changes, one kilogram of gas will occupy a different volume, so a liter in summer is one thing, and a liter in winter is completely different.

- The presence of separate ventilation in the boiler room, grounding of the chimney and everything else that is needed for gas boilers. Only permitting documentation from Mosoblgaz is not needed.

- The main difference between propane-butane and main methane is in price and calorific value. Heating a house with gas from a gas holder will cost almost 5 times more than with mains.

Heating with diesel fuel.

If, after listening to horror stories about exploding gas tanks and terribly greedy bureaucrats in Mosoblgaz, you decide to pay attention to a diesel boiler, then when choosing this type of heating there will be the following subtleties:

- A separate storage location for the diesel fuel container is required. Everyone who has placed containers in the house, even behind two doors, complains about the smell of diesel fuel in the living room. It is impossible to place the container on the street, in winter the diesel fuel becomes viscous and the dissolved paraffins included in the diesel fuel will clog the filter screens of the diesel burner of the boiler, but a separate building or boiler room will clearly not reduce the cost of installing diesel heating.

- It is highly undesirable to use “winter” diesel fuel; winter diesel fuel contains antifreeze, which the boiler burner does not react well to.

- A diesel burner, even from well-known brands and manufacturers, requires cleaning the nozzle and filters at least 2 times a year. For simple boilers like the Korean “Kiturami”, cleaning the burner makes almost no sense; it’s easier to change the entire boiler.

- Cleaning of the chimney is required, especially if the boiler is operating in part-load mode, “clocking”, so to speak, usually in the summer in the boiler heating mode. With such short operating modes, the burner and boiler furnace are simply not able to reach the operating mode - they do not have time to reach the desired temperature, the combustion of the mixture does not work in the correct mode, and so it smokes.

- Today, heating with diesel fuel is the most expensive of all types. Even direct heating with electricity is cheaper.

Heating with pellets.

Eco-friendly, economical heating that works autonomously for weeks - this is how pellet colas are usually described. What's it really like:

- Mandatory ventilation of the boiler room is required, both exhaust and supply. When the firebox or bunker is opened, smoke flies into the room; usually a ventilation “bell” is placed above the bunker so that the “aroma” does not escape into the house.

- The operation of the boiler very much depends on pellets: initially, pellets as raw materials for boilers must undergo the procedure of resin distillation and drying, but in the harsh Russian realities, distillation costs money, and it is much more convenient to mold a pellet with resin, but in practice, due to resin sublimation and sedimentation on the supply pipe from the bunker to the firebox, the pellets simply stick and create a dull “plug” - the boiler stops.

- You need a special place to store a supply of pellets. The promise about 400 liters of bunker and “stay away from the boiler for a week” does not correspond to reality. To store pellets you need a room the size of a garage, dry with ventilation and without access of rodents, yes, mice really like to live in sawdust and pellets.

- The boiler needs to be cleaned and the ash removed.

- The story with the chimney is the same as with the diesel boiler - periodic cleaning is required. The problem is aggravated by the specifics of the boiler operation - vapors of resins deposited on the inner surface of the pipe. Such growths can begin to burn directly on the pipe, raising its temperature, and as a result, the pipe can burn out in sections. In principle, this is a problem with all solid fuel boilers, not just pellet boilers.

- It is not possible to greatly change the boiler power. Of course, there is a forced air fan, there is a smoke exhaust fan, and the boiler can control them, but it cannot significantly reduce the power - it will simply go out.

- In terms of heating costs, a pellet boiler will be cheaper than a diesel boiler and a gas boiler from a gas holder, but only if the pellets are of high quality.

What is an air source heat pump?

Air-to-water heat pumps for heating a home are truly a stroke of genius. The question is, why, having such good characteristics, are air-to-water heat pumps not installed in every home?

The monoblock, about the size of a washing machine, fits harmoniously against the outside wall of your home and magically converts cold outside air into hot water and heating.

It is capable of transforming the negative temperature atmosphere and supplying hot water to the house for further use, and during the summer months it can work as an air conditioner. Often people use an air-to-water heat pump for a swimming pool to heat the pool water with it.

Installing an air-to-water heat pump takes only a couple of days, and they last up to 20 years. The devices require minimal maintenance and need to be cleaned once a year.

VTN is able to replace all the advantages of a traditional gas boiler, and it does this with minimal energy consumption, without harm to the environment. There is no need to buy fuel as it simply does not consume any.

Types of equipment by design type

Air heat pumps are:

- monoblock (all components are located in one housing);

- split systems (the device is divided into two blocks - external and internal, which directly interacts with the home heating system).

In turn, monoblock ones have versions with:

- internal installation;

- external installation.

Split systems are:

- with an intermediate heat exchange circuit;

- with a split circuit filled with refrigerant.

Monoblock heat pumps

Monoblock heat pumps with internal installation imply installation of equipment indoors. The advantage of this option is the protection of equipment from destructive external factors, including precipitation and weather. The disadvantage of this installation option is that it is necessary to provide large openings in the wall of the room where the unit will be installed for sufficient air flow. Monoblocks with external (external) installation are more often used when there is no room for a boiler room in the house. Placing all elements in one heat pump housing outside the house has the advantage of reducing noise levels. In addition, in this case there is no need to make air supply channels in the walls. The disadvantages are obvious:

- outdoor placement may lead to freezing of the system in case of inactivity;

- The street block must be insulated and protected from precipitation.

Split systems

Split air heating systems, which have a separate refrigerant circuit, are somewhat similar to household air conditioners. Main advantages:

- simple installation;

- there is no risk of the system freezing, since the main unit is located in the house;

- in the boiler room you don’t need a lot of space for the indoor unit (it is compact, since some of the equipment is located outside);

- The noise source is installed outside the house.

There are several disadvantages of split systems with a separate circuit:

- the need to insulate the pipeline connecting the external and internal blocks;

- strict requirements for the distance of placement of the external unit (the closer, the better, since there is less travel heat loss);

- forced intervention in the working fluid circuit.

Systems with an intermediate heat exchanger provide for the installation of an additional heat exchange circuit that heats the incoming air or maintains the temperature of the refrigerant. This design makes the heat pumps universal and reduces the risk of freezing. The main disadvantage of this equipment is that additional costs are required for installing an additional circuit.

How does an air-to-water heat pump work?

The air heat converter runs on 75% renewable energy from the air and 25% from electricity. There are two main types of VTN:

- An air-to-water heat pump is a device in which heat is generated from the heat of the atmosphere for the coolant, and then supplied to traditional heating systems such as radiators and hydronic heated floors. Since underfloor heating operates at a lower temperature, around 35°C, it is considered an ideal system for heat pump operation.

- An air-to-air system generates a warm stream of air and then pumps it through fans that distribute the heat throughout the home.

Recommendations for system maintenance

The heating system using such heat pumps is automatically regulated and does not require constant monitoring. At the same time, seasonal and annual maintenance still needs to be carried out - this will help to timely detect points requiring repair. During maintenance you need to pay attention to several nuances:

- Filters must be cleaned regularly. If necessary, they must be changed immediately.

- It is important to control the temperature of the oil in the compressor - it must be warm.

- Do not allow the external unit to become dirty as this may reduce the performance and efficiency of the system. Temperature sensors should also be kept clean.

- The wiring braid must be intact, without traces of decay or creases.

- Hoses and pipes, including at joints, must not have leaks or defects.

- The moving parts of the external unit must be periodically lubricated - this eliminates jamming and reduces noise during operation.

Advantages and disadvantages

The use of air heat pumps for heating a private home is effective. At the same time, this heating option, of course, has advantages and disadvantages.

System advantages

- Air is a free, renewable resource that is available everywhere, so an air heat pump can be used everywhere - be it a densely populated city like Moscow or a suburban village.

- Air heat pumps can operate both as the main heating source and as an auxiliary heating source.

- To install the external circuit (block), there is no need to carry out excavation work or lay a tubular heat exchanger. This makes installation cheap and quick.

- The external unit does not take up much space. Therefore, such a system is suitable for installation even in small local areas.

- Low installation costs guarantee a quick payback for the heating system.

- The equipment corresponds to a high energy efficiency class (up to A++).

- The air heat pump control can be automated. Some models even allow remote control.

- Inverter heat pumps allow you to smoothly regulate compressor performance and reduce starting currents (to increase service life).

- The equipment is environmentally friendly. There is no need to burn fuel, there is no release of harmful substances, it is safe for the residents of the house.

- To install and use air-water heat pumps, you do not need to obtain a permit or other documents.

Disadvantages of the system

- Air heat pumps are dependent on the outside temperature. The colder it is outside, the lower the COP (if there is no temperature-compensating heating element).

- When placed outdoors, the external unit of the air heat pump is constantly exposed to temperatures, moisture, precipitation and other factors. Therefore, it wears out faster than the external heat exchanger of geothermal heat pumps.

- An outdoor heat exchanger unit requires periodic defrosting. It happens unpredictably. Often during defrosting the heating does not work.

Conclusion

An air-to-water heat pump is one of the effective and cost-effective ways to heat a home. To use this alternative heating source, you do not need complex installation, fuel, large garden areas or permits from special organizations. Of course, this heating option has disadvantages, but they are insignificant and are fully compensated by the efficiency, high efficiency and prospects for using the system.

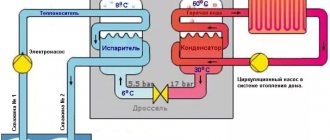

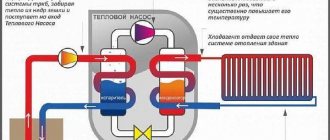

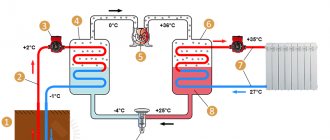

Operating principle of an air-to-water heat pump

The principle of operation is quite simple. Energy is produced by sucking atmospheric air into an evaporator heat exchanger. The air is used to heat the freon gas, similar to how a refrigerator works, but in reverse. After freon has received low-grade heat from the air, the temperature of the refrigerant increases due to compression, which is carried out by the compressor. The compressed, now heated gas is condensed in an intermediate heat exchanger called a condenser. After which the accumulated heat is transferred to the coolant of the heating system.

Heating heat generator operating technology

In the working body, the water must receive increased speed and pressure, which is done using pipes of various diameters, tapering along the flow. In the center of the working chamber, several pressure flows mix, leading to the phenomenon of cavitation.

In order to control the speed characteristics of the water flow, brake devices are installed at the outlet and progress of the working cavity.

The water moves to the nozzle at the opposite end of the chamber, from where it flows in the return direction for reuse using a circulation pump. Heating and heat generation occurs due to the movement and sharp expansion of the liquid at the exit from the narrow opening of the nozzle.

Positive and negative properties of heat generators

Cavitation pumps are classified as simple devices. They convert the mechanical motor energy of water into thermal energy, which is spent on heating the room. Before building a cavitation unit with your own hands, you should note the pros and cons of such an installation. Positive characteristics include:

- efficient generation of thermal energy;

- economical in operation due to the absence of fuel as such;

- An affordable option for purchasing and making it yourself.

Heat generators have disadvantages:

- noisy pump operation and cavitation phenomena;

- materials for production are not always easy to obtain;

- uses decent power for a room of 60–80 m2;

- takes up a lot of usable space in the room.

Air source heat pump efficiency

VHPs are effective both in winter and summer, thanks to the COP (conversion coefficient). The COP of a heat pump is a way of measuring its efficiency by comparing the power input required to produce heat with the amount of heat output.

The COP is adjusted based on the time of year. To be able to compare heat pumps based on how much they are affected by these changes, seasonal COP (Seasonal Coefficient of Performance) is used.

The VHP receives energy from the surrounding air, but as the ambient temperature decreases, the efficiency also decreases.

What to buy - top 5 best pumps

Purchasing a heat pump is an important and responsible procedure. It is possible to give any recommendations in this area only if you have specific information about the size of the house, the material of the walls, the degree of insulation, the configuration of the premises, the type of heating system, etc. Without this data, it is pointless to talk about the best pumps. However, we can consider the most well-known manufacturers who supply high-quality equipment to the market and are leaders in this field:

ALTAL GRUP

The company is based in Ukraine, Russia and Moldova. Equipment production is focused on the conditions of Russian regions and can be used in harsh conditions

NIBE Industry AB

The Swedish company has been on the market since 1949 and is rightfully a leader in its field. Production is carried out according to the most advanced developments, the best materials and components are used

Viessmann Group

One of the oldest European companies - the company's foundation dates back to 1928. German specialists have gained extensive experience and achieved the highest quality of their products

OCHSNER

An Austrian company that was one of the first to begin serial production of heat pumps and has received recognition from users due to the quality, reliability and durability of the equipment

Heliotherm

Another Austrian company producing heat pumps and other equipment. Products are sold in Europe, high quality, reliability and wide functionality of heating systems are noted

VTN for cold climates

It is important to know the thermal load of the object and the characteristics of the heat converter; the higher the required supply temperature to the home heating system, the lower the final COP will be.

Even though efficiency may be reduced, this does not mean that HHPs do not work in cold weather. It is known that they can extract heat from air at temperatures down to -25°C, and with an additional source, such as an electric boiler, etc. HHPs work even in the cold climate of Siberia.

But to get the most out of it, you need to make sure your home is well insulated.

Methods for organizing geothermal heating

Geothermal heating systems are classified according to several criteria:

- Combinations of the external circuit laying medium and the type of coolant of the internal circuit.

- The method of laying thermal probes (circuits) in soil or water - vertical or horizontal.

The first parameter is specified by the equipment manufacturer. For example, a conventional split system will belong to the air-to-air class, taking heat from the outdoor air and releasing it into the premises.

The ground-water pump takes the heat from the earth and heats the liquid coolant of the heating system. The “water-air” parameter implies a design solution in which the external circuit is located in water (an external reservoir or in a well), and heat is distributed throughout the house by flows of heated air.

The choice of one method or another depends on the operating conditions.

Justification for choosing the equipment class

One of the main parameters that people pay attention to when purchasing heat pumps is the heat transformation coefficient COP (coefficient of performance). It can be equal to from 1 to 7, in other words: 1 kW of electricity is converted into 1-7 kW of thermal power. It is important to understand that the actual coefficient of geothermal heat pumps will be less than that stated in the passport, since operation will require electricity costs for pumping coolant through the external circuit, and the longer it is, the greater these costs will be.

In practice and according to user reviews, you should count on a COP of 2.5-3.2 if you keep records throughout the entire period of operation - the temperature of the soil and water gradually changes depending on climatic conditions.

To a large extent, the choice of the medium from which heat will be taken depends on the climatic conditions of the region and the geological features of the construction site.

Another alternative way to organize geothermal heating using a reservoir.

Equipment with an external circuit located in water is selected if:

- the pond is a private pond;

- The depth of the well to groundwater does not exceed 20 meters (in some regions up to 45 meters).

If these conditions are not met, then a license for the right to use subsoil is required. If the license is not found during inspection by regulatory authorities, the equipment will have to be stopped and a fine of up to several million rubles will be paid.

In addition, the distance from the reservoir to the house is important; if it is more than 25-30 meters, then the efficiency decreases sharply - additional costs will be required for pumping the coolant and insulating the pipeline.

Placing the external circuit in the ground on your own site is not prohibited, but you should choose the correct method of pipe placement - horizontal or vertical.

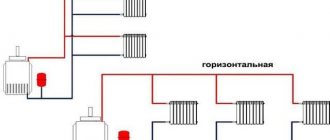

Horizontal and vertical external contours.

Depending on the composition of the soil, up to 50 W of thermal power can be removed from one meter of horizontal pipe. However, this is true for clay soils. Sandstones and loams can produce from 12 to 25 W/m, and a 10 kW heat pump may require an external horizontal circuit with a length of 200 to 700 m. To accommodate it you will need

. Accommodation

not effective, since the coolant cools the soil around it and the neighboring rings simply will not warm up effectively.

Efficient placement of external circuit pipes.

Inefficient but compact arrangement of pipes in rings.

Important! During the winter, the soil gradually freezes, becomes colder and the COP drops by February-March, since the coolant heats up less.

According to reviews from owners of plots in the area where the horizontal circuit of the heat pump is located, after several years of operation the soil structure changes, vegetable plants grow worse and the soil is used only for lawns. Trees with a powerful root system, which can destroy pipes, should not be planted in such places.

A vertical system of punctures or wells, in which several contours are placed, diverging in different directions, is considered optimal. At great depths, the temperature of the earth is more stable and depends little on climate. For pipe outlets, a well is equipped in which collectors are placed. Wells are drilled at an angle to the horizon and placed in a circle - this reduces the influence of each contour on each other.

Well for pipes.

External contour well.

Is it possible to do everything yourself?

In theory, it is possible to assemble a geothermal heating system with your own hands, but in practice it is difficult, if not impossible.

A large amount of excavation work will be required when laying the contour horizontally. The pipes are placed at least 0.5 meters below the soil freezing level, i.e. In total, you will have to dig the ground to a depth of 2-2.5 m. The soil must be stored somewhere and placed while the pipes are being laid.

Drilling wells with a total depth of up to 200 m will require special, expensive equipment; it is impossible to do such a volume of work with your own hands. It is advisable to start laying the circuit yourself only if you have technical means in use: an excavator, dump truck, bulldozer or drilling rig.

Which air-to-water heat pump should you choose?

The higher the COP, the better.

For example, an air-to-water inverter heat pump operates at COP 4 when the outdoor temperature is 0°C and the supply temperature is 35°C. This means that the efficiency of the air-to-water heat pump is 400%. That is, for every kW/h of electrical energy consumed by the fans and compressor, 4 kW/h of heat is generated.

Power and efficiency

If for geothermal and water heat pumps the efficiency practically does not depend on the time of year, then with air heat pumps the situation is different. Performance directly depends on the outside air temperature; the colder it is, the lower the COP (efficiency).

Many people believe that the power of a heat pump determines how much heat it can produce, but this is not true. It characterizes energy consumption, and the amount of heat received depends on the efficiency. Accordingly, it depends on the air temperature outside the house.

Advantages of VTN

Unlike a gas boiler, an air source heat pump does not produce carbon when operating. Although they consume electricity, VHPs can be combined with solar photovoltaic panels to produce clean electricity.

For the home, air-to-water heat pumps have low operating costs, especially compared to fuels such as propane, diesel or direct electric heating.

Installation cost

Installation and commissioning work is carried out at different prices, depending on the scope of work, the equipment and machinery used, volumes and other factors. An equally important circumstance is the general economic situation in the region and the state of the purchasing power of the population.

In any case, the cost of installing and launching the system will require approximately 20% of the total cost of the equipment , which will significantly affect the user’s wallet.

The high cost of installation work often becomes the reason for installing and launching the system yourself, which makes minor repairs and maintenance possible without the involvement of specialists. However, one must keep in mind that many companies refuse warranty or service if the installation was carried out by strangers.

Impact of VTN on the environment.

In addition to the financial benefits of installing a HVAC system, upgrading your HVAC system has a number of positive environmental impacts.

High conversion efficiency means you'll use less fuel to heat or cool your home. This means that power plants produce less energy from fossil fuels such as coal and oil, reducing the amount of greenhouse gases and other pollutants released into the atmosphere.

You can further reduce your carbon footprint by switching all your energy consumption from fossil fuels to solar energy. Installing solar panels on your roof allows you to power your VHP system (and your entire home) with free electricity with zero CO2 emissions.

Economics and ecology

When choosing heating pumps, also take into account environmental aspects, which are inseparable from the efficiency of the system. The less energy required, the cheaper it is and the less harmful it is to the environment. Each of us should take care of the environment.

Choosing a good pump starts with energy-efficient houses, because only if they are properly equipped is it worth investing in the project. If the equipment will be installed in an old house that is not class A, then you need to heat it first, and then talk to specialists about choosing a suitable scheme for the house.

It is dangerous to install the unit yourself. Proper installation requires special skills, so leave the job to professionals who can guarantee that everything from A to Z is done correctly. Self-installation is dangerous because there may be malfunctions, the elimination of which will be expensive. An incorrectly connected system will not last long, will quickly fail, and maintenance will require additional costs.

About Thermex Energy

Thermex Energy is a Russian manufacturer of heat pumps created taking into account the characteristics of the Russian market and climate. The company is part of the Thermex Corporation and relies on 70 years of experience in the development and production of advanced thermal equipment and energy-saving products. The assembly of heat pumps is carried out in the city of Tosno, Leningrad Region - the main production site of Termex in Russia.

The Thermex Energy team has more than ten years of experience in implementing complex heat supply projects for residential, commercial and industrial facilities using heat pumps. The production team includes members of the WorldSkills national team in the “Refrigeration and Air Conditioning Systems” competency.

The production capacity of serial models of geothermal heat pumps with a heating capacity from 6 to 56 kW is up to 700 units per year. Individual development of high-power industrial heat pump units is possible. In 2021, it is planned to launch our own line of air source heat pumps, buffer tanks and indirect water heaters for heat pumps, as well as a line of low and medium power chillers. In 2020, the Thermex Energy Compact series of geothermal heat pumps was recognized as the best energy-efficient heat pump produced in Russia according to the World of Climate and Cold 2020 competition, and in 2021 the company became the winner of the Aquatherm Moscow Awards competition in the Energy Efficiency and Energy Saving category. .