In the modern world, technological progress does not stand still, but many homes still use simple stoves for heating. Despite the fact that this type of heating is one of the most popular and familiar options, it has some significant disadvantages. For example, the most significant of them can be considered the need to prepare coal or firewood, as well as a noticeable difference in air temperature during the heating of the stove and after it cools down.

In such cases, a real salvation will be a well-chosen scheme for heating a private house with a centralized heating system using electric or gas boilers.

Here you can see an independent comparison of different heating systems for a country house

Residential heating options

The well-known and most common way to heat your own house or apartment is to make a water system. Operating principle: the coolant is heated by a boiler or other source, then transferred through pipes to heating devices - radiators, heated floors (abbreviated as TP) or baseboard heaters.

Note. Water heating is used in 99% of apartment buildings and administrative buildings. There are 2 methods of supplying coolant - from a centralized city network or from an individual boiler house serving a specific building.

A heat exchanger placed inside the stove heats the water, directed by the pump to the batteries.

Now we list alternative heating options:

- Stove. A metal potbelly stove is installed or a full-fledged brick oven is built. If desired, a water circuit is built into the firebox or smoke channels of the stove (shown in the photo above).

- Purely electric - convectors, infrared and oil heaters, spiral fan heaters. A more modern method is to install underfloor heating using resistive cables or polymer film. The latter is called infrared, carbon.

- Air. The heat source warms up the filtered street air, which is forced into the rooms by a powerful fan. A simpler and cheaper option is to install gas convectors in residential premises.

- Combined - wood stove + electric heaters of any type.

Scheme for heating a bathroom with electric heated floors

To move on, you need to decide which type of heating is better - more profitable, more efficient, more convenient. We definitely recommend choosing a water system. Causes:

- to heat water, you can use any energy source or combine several types of fuel by installing 2-3 boilers;

- if there are high requirements for interior design, the piping is installed in a hidden way, instead of batteries, baseboard heaters or TP circuits are used;

- the ability to organize hot water supply (DHW) - install a double-circuit boiler or an indirect heating boiler (depending on the amount of water consumed);

- Alternative energy sources can be connected to the system - solar collectors, heat pump;

- if necessary, heating in a private house is made completely autonomous - pipes are laid according to a gravity (gravity) scheme, plus a boiler unit is installed that does not require connection to the electrical network;

- The system lends itself well to adjustment, automation and remote control via cellular communications or the Internet.

The only drawback of water networks is the cost of installation, equipment and shut-off and control valves. The purchase and connection of electric heaters will be cheaper, but restrictions in terms of fuel choice will lead to increased operating costs.

Construction of a brick kiln is an expensive and labor-intensive undertaking. An affordable iron potbelly stove will heat 2-3 adjacent rooms, so it is only suitable for a summer house or a change house.

Installing full-fledged air heating in a country cottage will cost even more than building a stove. It is necessary to purchase a ventilation unit with a recuperator, which plays the role of a blower, purifier and air heater. Then organize supply and exhaust - run air ducts to all rooms. An expert will talk about the pitfalls of air heating in the video:

Heating a country house using underfloor heating

Warm floors can be used not only in bathrooms. If you act correctly, you can use them to heat a country house completely. But, as you understand, the effectiveness of such a solution will be far from ideal. Heating with electricity (as well as with electric boilers, which we did not consider for the same reason) is not a cheap pleasure.

Diagram of a heated floor in a house

In addition, you will need serious thermal insulation of all walls and ceilings in the house. You will also need to install special double-glazed windows with enhanced thermal insulation and a special multi-chamber profile. As a result, you can completely abandon the traditional heating system; the air in each room will be heated by such a floor.

Conclusions. A competent heating project for a country house is a necessary technical document. It allows you to draw clear conclusions regarding the effectiveness of a particular type of heating. The project will require some investment, but it will pay off after the first winter.

A house whose heating system is built in accordance with competent technical calculations does not require a lot of money for maintenance and brings its owners the joy and warmth of home comfort.

Choosing an energy carrier

The main selection criterion is the cost of energy, depending on the country and region of residence. If in the Russian Federation the undoubted leader is natural gas, then in the rest of the states of the former USSR the picture is different - firewood, briquettes and coal take the first place. Don't forget about electricity supplied at half the nightly rate.

When choosing the right type of fuel, it is worth considering five factors (in addition to price):

- efficiency (efficiency) of heating equipment using this energy carrier;

- ease of use;

- how often the units will have to be serviced, prices for calling a technician;

- storage requirements.

Below is a comparative table showing the prices of various energy sources and how much a kilowatt of heat produced in real conditions costs. Building area – 100 m², region – Moscow region.

Note. The calculation results and prices are given as of February 15, 2018. Over time, the data becomes irrelevant, but the difference in the cost of 1 kW remains.

Based on the numbers given in the table, it is much easier to find a suitable option (or several). Just make an adjustment for the cost of energy in your region. Based on other selection criteria, we will give 4 tips:

- It is most convenient to use gas and electric heating equipment. There is no need to store anything, constantly maintain and bother with cleaning water heating devices.

- Burning coal and wood is the most economical way to heat. Saving money will have to be paid for with labor - sawing, carrying, loading the firebox, cleaning the chimney. It is more comfortable to burn briquettes and pellets, but the price of the boiler installation and the fuel itself increases. Plus you will need storage for storage.

- Diesel fuel or liquefied gas is the best solution for providing autonomous and at the same time comfortable heating when other energy sources are not available. The downside is the decent cost of fuel and installation of the fuel tank.

- A proven option is the combination of 2-3 energy carriers. A common example: solid fuel + electricity at night tariff.

Which fuel is best to use in specific conditions is described in detail in a separate material. We also recommend watching the video and listening to useful expert advice:

Heating boilers

At the heart of the heating structure is a heating unit, on which the source of energy received for heating depends.

Today, manufacturers offer consumers the following types of boilers:

- Gas appliances

. They are the most popular due to the low cost of operation and the presence of gas mains in many settlements. - Electrical units

. Heating using them is expensive. - Solid fuel devices

. Popular in those regions where there are problems with gas and electricity supply. A constant supply of coal or firewood is required for several refills per day. - Liquid fuel heating units

. For their operation, they use fuel oil and diesel fuel, which are inexpensive. But in this case there are problems: air pollution with waste products and the need to arrange a storage facility for liquid fuel. - Waste oil devices

. It is also a cheap source of energy, but currently the market for such fuel is not established. - Warm floor system

. Helps solve heating problems, but its cost cannot be called cheap.

You must pay for private home heating system projects because they are not given away for free. This is quite a serious job that requires high qualifications.

Before starting design, the property owner will need the following information:

- floor plan of a country house;

- choice of pipe routing option - open or hidden, single or double circuit. It may be that in some rooms there is no need for heating because, for example, a fireplace is used in the living room;

- measures already taken to insulate the building;

- the place where the boiler is planned to be installed and the area of the room for its placement.

In a word, all the preferences and wishes of the owners of country houses are reflected in the document, which is called the “Technical Specifications”. It is advisable for the customer to record all relationships with design and contracting organizations on paper, formalizing them accordingly.

Creating a reliable and efficient heating structure requires a serious approach, and such work is entrusted to specialist heating engineers. It is the internal and external layout of the construction of the house that determines the features of the future heating system in it. The fact is that the design of heat supply for a country wooden cottage or a brick building will have significant differences. The heat carrier is usually water heated to a certain temperature by a boiler running on electricity (natural gas, coal, liquid fuel, etc.). The coolant circulates through pipes installed inside the building.

An example of a heating project for a private house consists of the following stages:

- development of a preliminary sketch;

- economic justification and necessary calculations;

- development of installation diagrams for pipes and heating radiators;

- creation of a working draft. This will allow you to avoid many mistakes that novice builders make during the installation process.

Schemes of water heating systems

We are moving on to the next step - developing a project for the future system, according to which we will purchase materials, fittings and thermal power equipment. The task is to choose the appropriate type of wiring, apply pipes to the layout of a private house, and arrange heating appliances.

Reservation. It is assumed that a place has already been allocated for installation of the heat generator - a furnace room, an extension, a kitchen or a corridor. We outlined the regulatory requirements for the placement of boilers in detail in another publication.

To deliver heated water to appliances and transfer heat to the air in rooms, the following schemes are used:

- single-pipe - horizontal “Leningrad” or riser system;

- two-pipe - dead-end, collector, associated ring (otherwise - Tichelman loop);

- water circuits for underfloor heating - heated floors (HF).

The first 2 types of wiring work in conjunction with radiators or other heating devices. The coolant movement is ensured in two ways:

- Forced, using an electric pump installed on the main pipeline or directly in the boiler.

- Natural circulation of water through the pipes (gravity flow) due to the difference in temperature and mass of the coolant between the supply and return lines. Cold liquid is heavier, so it tends to push hot liquid upward.

A gravity riser system with an overhead coolant distribution is suitable for a two-story house.

In the first case, the system does not communicate with the atmosphere and operates with an excess pressure of 0.6...3 Bar, depending on the degree of heating and the initial pressure in the network. The resulting excess expanding water is absorbed by a closed tank with a rubber membrane inside.

The gravity circuit is in contact with the atmosphere through an expansion tank located at the highest point of the system. In this way, airing is prevented - the bubbles formed in the pipes and batteries rise and go into the open tank. Effective air removal is facilitated by slopes of horizontal sections.

Let us consider each option separately and for clarity, we will give examples of typical schemes.

Single-pipe wiring - pros and cons

The supply and return of coolant in this system is organized through a single looped pipe. Accordingly, each radiator is connected to the main line using both connections. In the Leningrad scheme, this collector is laid horizontally, while the riser is laid vertically.

On the left is the connection of the radiator to the vertical riser, on the right - according to the Leningrad horizontal scheme

Negative aspects of single-pipe coolant distribution:

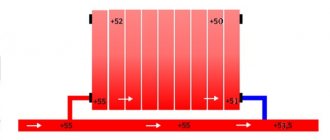

- due to the addition of cooled water, the temperature of the main line decreases by 1-2 °C after each battery;

- in order to ensure the required coolant flow in heating devices, the diameter of the main pipeline must be at least 25 mm throughout its entire length;

- when the number of radiators is more than 5 pieces, the cross-section of the collector increases to 32 mm;

- the last batteries receive cooled coolant, so they heat worse, the problem is solved by increasing the number of sections or increasing the size of the panels by 10%;

- “thanks to” the increased diameter of the line and the expansion of radiators, the costs of materials increase.

Note. The disadvantages of the Leningradka are listed here; with vertical wiring, the disadvantages are not so critical. There the problem is different - the risers that penetrate the ceilings are not easy to wall up inside the walls, the pipes stick out in plain sight. More details here: description of single-pipe heating networks.

Classic "Leningradka" closed type with a gas boiler

Positive points:

- Simplified installation - one pipe is easier to install than two.

- The Leningrad heating system for a private house, assembled from polypropylene pipes, is the most budget option. But if you use metal-plastic or cross-linked polyethylene, this advantage is offset by the price of the fittings.

- Single-pipe vertical risers are the best solution when installing a gravity system in a two-story house.

Taking into account the peculiarities of single-pipe schemes and the lack of installation experience of most homeowners, we recommend assembling the “Leningradka” in small country houses or residential buildings. If you want to save money, use polypropylene plus inexpensive steel radiators.

Methods for two-pipe battery connection

The main difference between these systems and single-pipe systems is the separate supply of coolant to the devices - hot water comes to the batteries through one line and returns through another. When installing heating, 3 types of schemes are used:

- Classic deadlock (shoulder). The coolant is supplied to the battery group, then moves back through the return pipeline. If necessary, the system is divided into several dead-end branches, and hydraulic equilibrium is established between them due to balancing. Two-pipe dead-end wiring with 4 branches for a two-story cottage

- Ring distribution with a parallel flow of forward and reverse water. The two-pipe loop is assembled in such a way that the coolant leaving the radiator does not change the direction of movement. The first heater on the supply line is the last on the return line and vice versa. In a two-story building, 2 Tichelman loops are laid out, connected to a common riser

- The collector circuit provides for individual connection of each battery to a common distribution comb, powered from the boiler. Each floor will need its own distribution manifold

Important point. The main advantage of two-pipe networks is the supply of water at the same temperature to all radiators. Hence the other advantages - distribution pipes of smaller diameter (15-20 mm), normal battery sizes and no restrictions on the number of devices.

A novice developer installing heating with his own hands for the first time is recommended to choose the first option - shoulder wiring. It is simple and reliable, and the most affordable. A preliminary design for a one-story house is developed as follows:

- Mark the windows on the building plan and place radiators near these openings. If there is no glazing, the device is placed near the coldest outer wall.

- Place a heater on the drawing - a boiler, a furnace with a water heating circuit, a heat pump.

- Run along the outer walls from the boiler pipe to the radiators. To avoid crossing the doorway, divide the net into 2 arms of approximately the same length.

- If there is a second floor, make 1-2 additional branches laid upstairs. It is better to lift the second floor branch directly from the boiler room.

An example of a heating project for a one-story building with an area of 100 square meters.

Pipe diameters for a building of 100...200 m² (closed system): from the boiler - DN20, arms (branches) - DN15, connections to the heaters - DN10. The indicated sections are taken from practice; there is no need to calculate water flow and hydraulics. The exception is houses of complex configuration, large number of floors and area.

Reference. The designation “Du” indicates the diameter of the internal passage in millimeters (rounded). For example, the diameter of a plastic pipe 26 x 2 mm is 20 mm.

It is convenient to make a collector system during the construction process - the connections to the batteries are hidden in the floors. The Tichelman loop helps out in a situation where you need to “plant” 10...20 radiators on 1 line. On our resource there is a separate material devoted to the consideration of two-pipe wiring methods.

About underfloor heating circuits

The advantages of water heating over other heating methods are obvious:

- uniform heating of the room, starting from the lower zone;

- efficiency - due to lower water temperature (35...55 degrees versus 60...80 °C on batteries);

- aesthetics - heaters and pipelines are not visible;

- convenient regulation using automation - distribution manifold servo drives and room temperature sensors.

Along with the impressive advantages, we note the main disadvantage of TP - the high costs of purchasing materials and installation. The circuits will require a decent amount of quality pipe (metal-plastic, copper, cross-linked polyethylene), a manifold with flow meters and a mixing unit. Add the layout of the hinges and the installation of a cement floor screed - a considerable number will come out.

Advice on reducing the cost of construction. In a country house or apartment up to 150 m², you can save on the purchase of a manifold and mixing unit - make a TP comb yourself from the tees, and install RTL thermal heads to limit the temperature of the coolant.

Minor disadvantages of floor contours:

- Inertia. When heated, the concrete monolith absorbs a lot of heat, which continues to be released after the heating is turned off. And vice versa, “overclocking” cooled TP takes 4...6 hours.

- If a pipe breaks inside the screed, repair is very difficult. It’s unlikely to do without calling the experts, because you need to find the defect, open the monolith and properly fix the leak.

- A power supply failure in an apartment building is a real problem. You will have to repair your own home plus your neighbor’s flooded one (from the bottom floor).

An example of a TP layout on the first floor of a house.

The comb is located in the center of the building, large rooms are divided into 2 water circuits. The inertia of warm water floors is “overcome” with the help of traditional radiators that quickly respond to changes in the temperature of the boiler water. For ease of adjustment, 2 systems are installed - TP and batteries, which is not cheap. How to independently arrange heating heating circuits, read our other guide.

Where to order a heating project for your apartment

OVK-Group specialists have been working in the field of design and installation of engineering systems of buildings for many years, they will ask you questions, and after receiving answers to which they will be able to design a system that best suits your requirements.

Basic data required for an apartment heating project:

- Apartment layouts

- Desired type of heat generator

- Desired type of heating devices

- Information about the availability of heated floors

- Plan for placing furniture in rooms with heated floors

- Desired location of the boiler

- Desired location of fan coil units when using an air heating system

This information is already enough to get started; during the design process, additional or clarifying questions may arise and be resolved along the way. If necessary, we provide sketches for approval for the designer or related design organizations. In addition to apartments, we also deal with cottages, so if you need a ventilation and heating project for a swimming pool, we can help you, in addition, we carry out heating, ventilation and air conditioning projects for various industrial facilities.

Equipment, components and materials

The next step after developing the scheme is the selection of all heating elements:

- heat generator;

- radiators, underfloor heating collector;

- pipes;

- expansion tank, circulation pump, fittings and heater piping parts.

Clarification. Wall-mounted gas boilers and some floor-standing models are equipped with a pump and expansion tank located inside the unit. If you plan to purchase such a device, still make sure that the tank volume is sufficient for your system.

Let’s immediately make a reservation that we will consider a hot water boiler as a heating unit. You will not be able to install an air or geothermal heat pump without the help of specialists, and connecting the water circuit of the stove is carried out in the same way as connecting a solid fuel heat generator.

How to calculate the capacity of the expansion tank, choose the right pump and fittings:

- The useful volume of the tank must be at least 10% of the total amount of coolant circulating in the heating network. The water jacket of the boiler is also considered.

- If the building area does not exceed 150 m², then circulation will be provided by a pump with 25/40 or 32/40. The first number is the diameter of the threaded connection, the second is the developed pressure. The 25/40 unit is equipped with a 1” pipe thread and is capable of delivering a pressure of 0.4 Bar. The most common model of pumping unit 25/40 from the Grundfos brand

- For a large cottage and floor circuits, it is better to select a pump according to the algorithm.

- Shut-off ball valves are installed in front of the heat generator, expansion tank, pumping unit and on the make-up pipe. Additional equipment - a buffer tank, an indirect heating tank, a solar system - must also be cut off by taps.

- Each heating radiator is equipped with a thermostatic valve at the inlet and a balancing valve at the outlet. In the unregulated version, a ball valve is installed on the battery supply pipe.

The final list of components is compiled after selecting the main elements - a thermal power plant, batteries and a pump with a tank. Accordingly, we will next consider the issue...

What should the project include?

The photo shows a real working sketch of the boiler room.

Now let’s look at what exactly a professionally compiled project should include.

According to SNiP, the instructions require that the customer receive the following documents:

- Title page with the title of the work and the seal of the design organization, as well as the names of responsible persons and signatures;

- A copy of the license (if necessary) to carry out such work;

- Explanatory note to the drawing and calculations;

- General layout plan for all communications;

- High-altitude plan of communications distribution;

- Instructions for the work performed;

- Estimate for all materials and equipment used;

- Specification of materials and equipment;

- The most detailed sketch of the project;

- Technical drawing with all dimensions and precise detailing of all circuit components;

- Communications laying plan indicating the connection points of nodes and devices.

The document is prepared in at least two copies, and an electronic copy is also kept. As a customer, you have the right to request all of these copies.

The contractor is required to report on any issues that arise with the customer, especially when choosing specific equipment or the type of system organization. The customer has the right to know the final cost of the project, the consumption of materials and the number of necessary installation activities.

A feasibility study will help you understand why such materials and equipment were chosen.

Important! A good indicator of the quality of the designer’s work will be the presence of a feasibility study for the design and equipment configuration he has chosen, the materials used and pipe routing methods.

How to choose a heating unit

Factors influencing the choice of a boiler (or several water heating devices):

- energy carrier used;

- heat generator power;

- dependence on external energy sources;

- price;

- functionality, ease of use.

Note. The heater selection criteria are arranged in order of priority. It is important for the user that the unit consumes cheap fuel and produces enough heat. Price plays a secondary role; comfort and functionality come in third place.

All household boilers are usually divided into groups according to the type of fuel (energy carrier) burned:

- gas;

- electrical;

- solid fuel;

- liquid fuel, consuming diesel fuel and waste oil;

- universal, operating on 2-3 types of energy carriers.

Each of the listed groups is divided into varieties according to the operating principle, installation method and other criteria. We will review existing boilers and give a number of useful recommendations.

Types of gas boilers

To organize heating in private homes, 3 types of units using natural gas are sold:

- Atmospheric. The combustion chamber is open, combustion air is taken from the boiler room. The operating efficiency is in the range of 86...88%.

- Supercharged (aka turbocharged). Air is forced into the closed firebox by a fan controlled by an electronic circuit. Boiler efficiency is 90...93%.

- Condensation. Structurally similar to turbocharged heaters, but the heat exchanger and burner are designed in such a way that in a certain mode the boiler uses the latent heat of combustion of the fuel. Efficiency – 95%.

Reference. All heat generators are capable of burning 2 types of fuel - natural gas and liquefied propane-butane mixture (LPG). To switch to LPG, the fuel jets are replaced and the automation is adjusted.

Boilers are manufactured in wall, floor and parapet versions. The first group is ready-made mini-boiler rooms, equipped with their own expansion tank and pump. The second type is high-power units, or those that do not depend on electricity. Parapet models are placed near the outer wall, the chimney goes directly to the street.

Among the large assortment of gas water heaters, it is not easy to make the right choice. Our recommendations are:

- If you are on a limited budget, purchase an atmospheric wall-mounted boiler. But remember - open-chamber heaters require a traditional chimney.

- To work together with the gravity system, you will need a non-volatile floor-mounted atmospheric unit. Floor-mounted non-volatile heater equipped with a single-stage burner, mechanical automatic safety system EuroSIT and a cast iron heat exchanger

- It is better to install a forced-air heat generator in an apartment or cottage without a ready-made chimney. Organize the removal of combustion products through a coaxial pipe laid through the outer wall.

- To supply hot water to 1-2 consumers, buy a dual-circuit model. If the consumption in the DHW network is high, you will need an indirect heating boiler connected to a conventional single-circuit heater.

- Read the detailed description of all gas heaters presented in a separate article.

A condensing boiler is the most economical among gas-using devices. The disadvantage of the unit is the complexity, high price of the equipment and its repair.

Electric hot water installations

A feature of electric boilers of any type is their high efficiency, reaching 99%. The second positive point is the low installation costs and purchase of the heaters themselves. The units should be used as auxiliary heat sources, operating at night at half the light tariff.

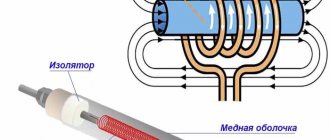

There are 3 types of electric boilers (all are available in wall-mounted versions):

- With traditional tubular heaters - heating elements. Modern devices are equipped with an expansion tank and a circulation pump.

- Electrode. Heating of the coolant occurs due to a chemical reaction resulting from the passage of current through the water layer between the 2 electrodes.

- Induction. Here the coolant is heated by the steel core of a sealed coil, which creates eddy currents in it.

Sectional view of a heat generator with tubular heaters (TEH)

To install electric heating, it is better to take a classic heating element boiler that does not require serious piping. The device is reliable and easy to repair - you can always replace a burnt heating element yourself. An induction heat generator is expensive and cannot be repaired in the event of a breakdown, and an electrode heat generator is highly dependent on the salt content in the coolant.

Advice. Don't listen to salespeople who call induction boilers energy-saving. All electrical installations heat water equally efficiently - losses do not exceed 2%, the rest of the energy is converted into heat.

Classification of solid fuel boilers

For heating country cottages, 3 types of solid fuel units are used:

- direct combustion - atmospheric and turbocharged;

- pyrolysis;

- automatic pellet and coal.

There are many myths about the efficiency of TT boilers. Manufacturers of pyrolysis heat generators claim an efficiency of 85-86%, pellet heat generators - up to 90%. In reality, the figures are much more modest: traditional wood-burning units - 75%, pyrolysis units - 75%, boilers using pellets and coal chips - up to 86%.

Construction of a direct combustion boiler with a fire tube heat exchanger

Reference. In addition to the listed types of heaters, there are long-burning TT boilers with an increased size of the firebox. How to distinguish such installations from classic wood-burning heat generators, read the corresponding publication.

Recommendations for choosing a solid fuel boiler:

- A steel direct combustion apparatus equipped with a chain draft regulator is perfect for burning wood, coal and briquettes. Turbocharged examples are automated and burn wood better, but rely on electricity.

- Pay attention to the volume of the firebox of a traditional boiler - the duration of combustion depends on this indicator.

- Automated pellet units are a good solution for lovers of comfortable heating. You don’t have to chop and carry wood, remove coal dust, just clean the firebox and burner weekly.

- Do not mess with pyrolysis TT boilers, they are a priori more expensive than conventional ones, demanding on the quality of fuel, and in addition they consume electricity.

- Avoid models with water-filled grates if you plan to burn with coal. The temperature difference forms a hard crust on the surface of the grate, which is not easy to knock off.

Grate of a TT boiler made of pipes filled with coolant

When choosing a heat generator, remember the old saying “the miser pays twice.” It is better to take a high-quality classic device with a cast-iron heat exchanger than a cheap “pellet generator” with electronics of unknown origin.

Diesel and combined models

This heating equipment is used much less frequently than gas, wood and electric boilers. Diesel fuel is more expensive than other energy sources, and waste oil is a specific fuel that is clearly unsuitable for the average homeowner. Accordingly, such heating devices are operated only in certain conditions when access to other resources is limited.

Multi-fuel boilers from different manufacturers combine 2-3 energy sources, for example, wood + electricity, gas + coal. Advantage: you buy one heat generator and get two. Disadvantage: the unit cannot boast of high efficiency and functionality. The most popular option is shown in the photo - a TT boiler, equipped with a heating element unit for electrically heating water after the flame in the firebox has died out.

Electric wood heater from the Russian company Teplodar

Heat generator power calculation

To select a boiler based on performance, you should find out the load on the heating system of the house. That is, calculate the heat losses of the building. We propose to calculate this indicator in a simplified way:

- If a living room is separated from the street by one wall with 1 window opening, then 0.1 kW of heat is consumed to heat a square meter of area.

- A room with two external walls (corner) and 1 window – 0.12 kW/m².

- The same, with 2 light openings - 0.13 kW/m².

An important nuance. The calculation is performed for each room separately, then the results are summed up.

The algorithm is suitable for buildings with floor heights up to 3 meters. If the ceilings are higher, heat consumption is calculated based on the volume of the room. Accordingly, in a room with 1 fence and a window, the volume value is 35 W/m³, in a corner room – 40 W/m³, in a corner room with two openings – 45 W/m³.

Having determined the need for thermal energy at home, we select the power of the boiler installation according to the instructions:

- The performance of a unit operating only for heating is taken with a margin of 20%. That is, we multiply the found amount of heat by a factor of 1.2.

- The heat generator providing hot water supply must be taken with a reserve of 50% (coefficient 1.5).

- For TT boilers, the increasing coefficients are 1.5 and 2, respectively.

If you live in an area with a mild southern climate, then the coefficients should not be used. Conversely, residents of the northern regions should increase the initial heat loss figure by 1.5-2 times.

Calculation of heat losses by volume of residential premises

Beam system with collectors

Radiant heating system using a collector.

This is one of the most modern schemes, which involves laying an individual line to each heating device. To do this, collectors are installed in the system - one collector is the supply, and the other is the return. Separate straight pipes diverge from the collectors to the batteries. This scheme allows for flexible adjustment of heating system parameters. It also makes it possible to connect heated floors to the system.

The radial wiring diagram is actively used in modern homes. The supply and return pipes here can be laid in any way - most often they go in the floors, after which they are suitable for one or another heating device. To regulate the temperature and turn on/off heating appliances, small distribution cabinets are installed in the house.

According to heating engineers, this scheme is ideal, since each heating device operates from its own mains and is almost independent of other heating devices.

Advantages and disadvantages of beam systems

There are many positive qualities:

- the ability to completely hide all pipes in the walls and floors;

- convenient system setup;

- possibility of creating remote separate adjustment;

- minimum number of connections - they are grouped in distribution cabinets;

- it is convenient to repair individual elements without interrupting the operation of the entire system;

- almost perfect heat distribution.

When installing a radiant heating system, all pipes are hidden in the floor, and the collectors are hidden in a special cabinet.

There are also a couple of disadvantages:

- high cost of the system - this includes the costs of equipment and installation costs;

- difficulty in implementing the scheme in an already built house - usually this scheme is laid out at the stage of creating a home ownership project.

If you still have to put up with the first drawback, then there is no escape from the second.

Features of installation of radiant heating systems

At the project creation stage, niches are provided for laying heating pipes, and installation points for distribution cabinets are indicated. At a certain stage of construction, pipes are laid, cabinets with collectors are installed, heating devices and boilers are installed, a test run of the system is carried out and it is checked for leaks. It is best to entrust all this work to professionals, since this scheme is the most complex.

Despite its complexity, a radiant heating system with collectors is one of the most convenient and efficient. It is used not only in private homes, but also in other buildings, for example, in offices.

Types of heating batteries

Water heating devices are divided into types based on the material they are made of:

- steel;

- aluminum;

- cast iron;

- bimetallic.

Construction of stamped steel heaters

Reference. The name “aluminum radiators” is conditional. In fact, batteries are made from an alloy of aluminum and silicon - silumin.

Steel radiators are available in the form of flat panels and individual sections connected by threaded nipples. Batteries made of cast iron, silumin, bimetal - sectional. The latter type of devices is also made of an alloy, but a frame made of iron pipes is inserted inside, withstanding high pressure and protecting the aluminum walls from corrosion.

Connecting a sectional battery with nipples

How to choose heating radiators:

- Select the type of batteries for a private home at your discretion; any will do - cast iron, iron, aluminum. Focus on your own budget, appearance, quality of products.

- In an apartment in a high-rise building with central heating, do not take steel panel radiators and cast iron “accordions” of the old MS-140 model. They are designed for a working pressure of 9-10 bar, and in the heating network there can be 12.

- When laying hidden pipelines under floors, use batteries with bottom connections.

- The number of sections or size of a panel radiator is based on heat transfer indicators, using a simplified method.

Bimetallic radiator - a steel core made of pipes is embedded in the silumin housing

District heating design

Heating scheme for an apartment building

It is much more difficult to design a heating system for an apartment building. Difficulties are associated with adapting the system to the central pipeline, as well as uniform distribution of the coolant among all consumers.

Until recently, the organization of heat supply to multi-storey buildings was carried out in only one way - by connecting to the central heating main. This entailed the impossibility of changing the temperature regime of the system by apartment residents, as well as a direct dependence on the quality of services of the management company.

Special engineering bureaus are engaged in the design of heating systems for apartment buildings. The following factors are taken into account:

- Number of storeys of the house, its area. Parameters for residential and non-residential premises are calculated separately;

- The degree of thermal insulation of walls and window structures. In this case, the calculated temperature of the outside air for heating design must be compensated by the heated air inside, taking into account the heat losses of the building;

- Thermal operating mode. To reduce losses when hot water passes through external pipes, its temperature can range from +90°C to +110°C. To reduce this indicator, an elevator unit is installed in each house, which is also taken into account when drawing up technical specifications for heat supply design.

Taking into account all these features, most residents of apartment buildings refuse central heating services at the first opportunity. As an alternative, autonomous heating systems for an apartment building are designed, which are almost completely similar to those described above.

Over time, the performance of a home may deteriorate. Accordingly, it is necessary to either improve the thermal insulation of external walls or increase the level of air heating in apartments.

Pipes for connecting radiators and heated floors

For homeowners without installation experience, we recommend the following options:

- If you want to save on materials, take reinforced polypropylene pipes (PP-R) with fittings. In addition, buy an inexpensive Chinese soldering iron - it will definitely be enough to assemble 1 system.

- Without special tools, you can install heating pipes from metal-plastic pipes on compression fittings, tightened with open-end wrenches. The disadvantage is the high cost of parts.

- The best solution is to assemble the system from cross-linked polyethylene or metal-plastic with press fittings. You will have to rent special pliers.

The structure of the polypropylene pipe - to prevent thermal elongation, aluminum reinforcement is laid between the layers of plastic

Important note. Polypropylene is not suitable for installing heated floors due to the thick walls and joints that fall inside the screed. Use metal-plastic or polyethylene PE-X, PE-RT.

Polypropylene pipelines are welded according to technology, the main thing is to accurately maintain the heating time. It is strictly not recommended to wall PP-R joints in floors and walls to avoid the consequences of leakage.

Beginners should not use copper, stainless or galvanized pipes. High-quality installation will require certain skills - welding, proper cutting, crimping. Metal is reliable, but inferior to plastic in price.

On the left in the photo are pipes made of metal-plastic, on the right - cross-linked polyethylene

Checking and configuring the system

After all heating equipment has been connected, you should make sure that the work done is correct. To do this, the system is filled with coolant, after which you need to monitor it and check for leaks.

Then the boiler starts. Heating the liquid will allow you to finally verify that the circuit has been assembled correctly and that there are no violations.

If a mistake was nevertheless made and a leak was discovered somewhere, then for this you need:

- drain the coolant;

- correct the defect;

- check again.

The final stage is sealing the grooves where the pipes were laid. If the installation was carried out on the floor, then the best solution is a screed. When the pipeline is installed on a wall, putty or plaster is used. Next, you can do finishing work.

Boiler installation instructions

Strict requirements are put forward only for the installation of gas-powered heaters. But we recommend following these rules when installing any heat generators:

- Equipment with a power of up to 60 kW can be placed in a kitchen with ceilings of 2.5 m (minimum). More powerful units are moved to a technical room - internal, attached or free-standing.

- The requirement for furnace ventilation is threefold air exchange, that is, the amount of supply and exhaust air is equal to three volumes of the room in 1 hour. The kitchen window is equipped with a window.

- When placing a floor-standing boiler, observe the minimum technological passages - 1.25 m in front, 60 cm on the side, 250 mm in the back from the nearest building structure, as shown in the photo.

- The distances from the wall-mounted heat generator to the walls or cabinets are 20 cm on the side, 45 cm on the top, 300 mm on the bottom. Before hanging, a protective sheet of roofing steel is laid on the wooden wall.

- The height of the chimney is 5 m, calculated from the grate or gas burner, not from the ground. The head of the pipe should not fall into the wind support zone of the roof.

- The maximum number of turns of the chimney is 3, the distance from the chimney to combustible structures is 0.5 m.

Clarification. Double-walled sandwich-type chimneys can be placed at a distance of 38 cm from wooden walls and ceilings.

The heat generator piping depends on the fuel consumed. High efficiency boilers - gas, diesel - are connected to the system directly through shut-off valves. Floor-standing versions are additionally equipped with an external expansion tank and pump.

Typical wiring diagram for a double-circuit wall-mounted heat generator

Solid fuel units must be protected from cold return flow and condensation; accordingly, a small boiler circuit with a three-way mixing valve is provided. Please note: the pump is always installed inside the circuit, on the supply or return line - it makes no difference. Detailed wiring diagrams are shown in the instructions for connecting TT boilers.

Important! In a closed system operating under pressure, there is always a safety group - a pressure gauge, an automatic air vent and a safety valve. The installation point is the supply pipe at the boiler outlet. To prevent dirt and sand from getting inside the heat exchanger, a filter - a mud filter - is placed on the return line in front of the heater.

Selecting a Heat Source

The source of heat in the house is a heat generator, which heats the medium to the required temperature and thereby creates comfortable living conditions for people. Ideally, the heat generator can maintain the set parameters for 24 hours.

Good to know! Having drawn up a single heating project for a two-story house, experts claim that it is ideal to purchase a gas boiler with a power of 28 kW, equipped with a closed combustion chamber, comfortable for people with electronic ignition.

Experts often advise using combined heating in houses with 2 floors. For example, you can choose from:

- heating boilers;

- ovens;

- infrared emitter;

- fireplace;

- solar collector;

- thermal pump installations;

- and so on.

Interesting fact! It has been proven that the use of a minimum set of solar collectors pays off in three years.

In all houses, regardless of number of floors, the following heat sources are used:

- electrical;

- gas;

- solid fuel;

- liquid fuel.

Important! Electric and gas sources are considered economically profitable.

How does an electric boiler work?

The operating diagram of an electric boiler looks like this:

- the boiler heats up to the set temperature;

- heat passes through the pipes to the radiators;

- partial cooling occurs;

- under the influence of the pump, the heat goes back into the boiler.

Tips for installing a home heating system

The heating installation begins with the installation of radiators in pre-prepared places under windows or on corner external walls. The devices are hung on special hooks attached to the structure itself or the plasterboard finish. The unused lower outlet of the radiator is closed with a plug, and a Mayevsky valve is screwed in from above.

The pipeline network is installed according to the assembly technology of certain plastic pipes. To protect you from mistakes, here are some general recommendations:

- When installing polypropylene, take into account the thermal elongation of pipes. When turning, the knee should not rest against the wall, otherwise, after starting the heating, the line will bend like a saber.

- It is better to lay the wiring in an open way (excluding collector circuits). Try not to hide the joints behind the sheathing or embed them in the screed; use them to secure pipes.

- Mains and connections located inside the cement screed must be protected with a layer of thermal insulation.

- If for any reason a loop has formed in the pipeline, facing upward, install an automatic air vent on it.

- It is advisable to install horizontal sections with a slight slope (1-2 mm per linear meter) for better emptying and removal of air bubbles. Gravity flow schemes provide for slopes from 3 to 10 mm per 1 m.p.

- Place the membrane expansion tank on the return line near the boiler. Provide a valve to shut off the container in the event of a malfunction.

Installation trick. Do not fill the TP screed until you fill the circuits with water and warm up the system. The goal is to increase the pressure in plastic pipes and force them to lengthen, that is, to put them into operating mode. Then the material will not bend under the weight of the monolith and will not float up if the solution turns out to be liquid.

Installation procedure

A one-pipe system is assembled as follows:

- In the utility room, the boiler is installed on the floor or hung on the wall. Using gas equipment, the most reliable and efficient single-pipe heating system for a two-story house can be installed. The connection diagram in this case will be standard and will allow you to carry out all the work, if desired, even independently.

- Heating radiators are hung on the walls.

- At the next stage, the “supply” and “return” risers are installed on the second floor. They are located in close proximity to the boiler. At the bottom, the outline of the first floor is connected to the risers, and at the top – to the second.

- Next, the connection to the battery lines is made. A shut-off valve (on the bypass supply section) and a Mayevsky valve should be installed on each radiator.

- An expansion tank is mounted in the immediate vicinity of the boiler on the “return” pipe.

- Also, on the “return” pipe near the boiler, a circulation pump is connected to a bypass with three taps. A special filter is installed in front of it on the bypass.

At the final stage, the system is pressure tested in order to identify equipment malfunctions and leaks.

As you can see, a single-pipe heating system for a two-story house, the design of which is as simple as possible, can be a very convenient and practical equipment

However, if you want to use such a simple design, at the first stage it is important to make all the necessary calculations with maximum accuracy

When thinking about installing heating, we first determine what type of fuel will be used

But at the same time, it is extremely important to decide how independent the planned heating will be. So, a heating system without a pump will be truly autonomous, which does not require electricity to operate. To operate effectively, all you need is a heat source and properly positioned piping

To operate effectively, all you need is a heat source and properly positioned piping.

A heating circuit is a set of elements designed to heat a home by transferring heat to air. The most common type of heating is a system that uses boilers or boilers connected to a water supply as a heating source. Water passing through the heater reaches a certain temperature, and then is sent to the heating circuit.

In systems with a coolant that uses water, circulation can be organized in two ways:

Boilers are used as a heat source for heating water. Their principle of operation is based on the conversion of a specific type of energy into heat and its subsequent transfer to a coolant. Depending on the type of heating source, boiler equipment can be gas, solid fuel, electric or fuel oil.

Depending on the type of connection of circuit elements, the heating system can be single-pipe or two-pipe. If all the circuit devices are connected in series relative to each other, that is, the coolant passes through all the elements in order and returns to the boiler, then such a system is called a single-pipe system. Its significant drawback is uneven heating. This is due to the fact that each element loses some amount of heat, so the difference in boiler temperatures can be significant.

A two-pipe type system involves parallel connection of radiators to the riser. The disadvantages of such a connection include the complexity of the design and twice the material consumption compared to a single-pipe system. But the construction of a heating circuit for large multi-storey premises can only be done with such a connection.

A system with gravity circulation is sensitive to errors made during heating installation.

Selecting a heating device

When drawing up a heating scheme for a two-story, three-story or one-story house, specialists will definitely discuss with the customer which heating devices are preferable to use. It can be:

- convectors;

- radiators.

Radiators are ideal for central heating systems. They operate on a combined principle. This makes them perfect for installation in 2-story houses.

Radiators are made from different metals: cast iron, steel or aluminum, they can be forged and ceramic.

Normative documents

When creating a project, you need to focus on GOSTs and SNiPs. Here are the main ones:

SP 54.13330.2011 “Residential multi-apartment buildings” SP 60.13330.2016 Heating, ventilation and air conditioning.

SNiP 41-01-2003 “Heating, ventilation and air conditioning”

SP 7.13130.2013 “Heating, ventilation and air conditioning fire safety requirements”

Single-pipe schemes

The easiest way to calculate and assemble a heating system is with a single-pipe piping scheme for the coolant. The heated water in it sequentially passes from the boiler through all the radiators in the house, starting with the first and ending with the last in the chain. At the same time, each subsequent radiator receives less and less heat.

There are four main advantages of such a heating installation in a private house:

- Ease of implementation;

- Small cubic capacity of coolant;

- Hydraulic stability of the system;

- Low consumption of materials.

Installing a pipeline according to this scheme and connecting it to the boiler with your own hands, even if you have minimal skills, can be completed in two to three days. Plus, the costs of creating a water heating system in a house for single-pipe wiring are minimal compared to other options.

Few fittings, fittings and pipes are required here. The savings on materials are significant. And it doesn’t matter whether laminated timber or brick is chosen for the construction of the cottage. If the home is well insulated, then even a simple one-pipe system for heating it will be more than enough.

Among the weak points of this heating scheme are:

- Inability to accurately regulate the heat supply in each room;

- Limitation on the total length of the pipeline throughout the house (no more than 30 m);

- Small amount of thermal energy in the battery furthest from the boiler;

- Vulnerability to defrosting and gusts.

To mitigate the shortcomings, a circulation pump has to be built into a single-pipe system. But these are additional costs and potential equipment breakdowns. Plus, if there are any problems in any section of the pipe, heating of the entire cottage stops.

Single-pipe horizontal

If a private house is small and one-story, then a single-pipe heating system is best done in a horizontal design. To do this, a ring of one pipe is laid in the rooms around the perimeter of the cottage, which is connected to the inlet and outlet of the boiler. Radiators cut into the pipeline under the windows.

Single-pipe horizontal design - ideal for small spaces

The batteries are connected here using a bottom or cross connection. In the first case, heat losses will be at the level of 12–13%, and in the second they are reduced to 1–2%. It is the cross installation method that should be preferred. Moreover, the coolant supply to the radiator should be done from above, and the outlet from below. So the heat transfer from it will be maximum, and losses will be minimal.

Single-pipe vertical distribution

For a two-story cottage, a single-pipe vertical heating system is more suitable. In it, the pipe from the water heating equipment goes up to the attic or second floor, and from there it goes back down to the boiler room. In this case, the batteries are also connected in series one after the other, but with a side connection. The pipeline for the coolant is usually laid in the form of a single ring, first along the second and then along the first floor, in such a heating distribution in a low-rise building.

Single-pipe vertical design - saving on materials

But an example with vertical branches from a common horizontal pipe at the top is also possible. That is, first a circular circuit is made from the boiler up, along the second floor, down and along the first floor back to the water heater. And between the horizontal sections, vertical risers are laid with radiators connected to them.

The coldest battery in such a heating system for a private house will again be the last one in the chain - at the bottom of the boiler. In this case, there will be an excess of heat on the upper floor. It is necessary to somehow limit the volume of heat transfer at the top and increase it at the bottom. To do this, it is recommended to install bypass jumpers with control valves on the radiators.

Leningradka

Both schemes described above have one common disadvantage - the temperature of the water in the last radiator turns out to be very low, it gives off very little heat to the room. To compensate for this cooling, it is recommended to improve the single-pipe horizontal heating option for a private house by installing bypasses at the bottom of the battery.

Leningradka - improved single-pipe system

This wiring was called “Leningradka”. In it, the radiator is connected from above to a pipeline running along the floor. Plus, taps are placed on the outlets to the batteries, which can be used to regulate the volume of incoming coolant. All this contributes to a more even distribution of energy across individual rooms in the house.

Natural and forced heating circulation

It doesn’t matter whether gas, wood, coal or electric heating is planned to be installed in a private house. In any case, there is a boiler (furnace or water heater) for heating the coolant, as well as pipes for its movement along the circuit. In this case, water in pipelines can flow naturally under the influence of gravity and convection or forcibly using a pump.

Scheme of types of heating circulations

The first example is cheaper and quieter than the second. However, forced circulation can greatly improve the performance of the entire heating system. Often, heating a private home cannot be done without a booster pump. Due to the large number of radiators, pipe turns and fittings, the hydraulic resistance in the pipeline is too high. And this can only be compensated for by the operation of pumping equipment.

Choice of one- or two-pipe option

The supply of hot water and the removal of cooled water for the heating system of a private house can be done using one or two pipes. Each option has positive and negative sides, as well as features of use depending on the type of wiring.

From an interior design perspective, the presence of a second pipe does not have any effect on the appearance of the heating system due to the lower option for connecting the system to radiators and the ability to reduce pipe diameters

Using a one-pipe connection diagram

A water heating scheme for a private house using one pipe for supplying hot water and discharging cooled water is called single-pipe. The main advantage of such a system is to minimize the length of the pipes.

The main advantages of the option:

- lowest costs for purchasing heating system elements;

- the simplest and fastest installation;

- lowest risk of accident.

The main disadvantage of single-pipe heating is the gradual decrease in the temperature of the water, which passes sequentially through all radiators in the circuit.

Therefore, it is necessary to use a slightly larger surface area of the latest radiators (more elbows), which often offsets the cost benefit from minimizing the length of the pipes.

In addition, due to this disadvantage, there are restrictions for one circuit on the number of connected radiators. If there are too many of them, then the latter will practically not emit heat along the flow of the coolant.

In addition, a problem arises when calculating heat transfer. Here it is necessary to take into account that disconnecting the first radiators from the heating system leads to an increase in the temperature of the incoming water for subsequent devices.

It makes no sense to use single-pipe circuits with vertical bottom wiring, since the length of the pipes will be the same as the two-pipe version, which eliminates all the advantages, but leaves disadvantages.

If the coolant returns along the same route as the supply, then the total length of the pipes in both options is almost the same

The heating device is usually connected through a bypass in order to be able to turn off any of them without stopping the water circulation through the circuit.

To save on taps, you don’t have to bypass the water through the tap, but then you will have to stop the operation of this part of the system and drain the water if it is necessary to replace or repair the radiator.

The most economical option is to use one steel pipe with a diameter of 1.5-2 inches without heating radiators. The absence of taps and fittings makes this system also the most practical because it minimizes the risk of leaks or water breakthroughs.

Read more about calculating a single-pipe heating system in this article.

Application of two-pipe heating option

The heating circuit diagram, when one pipe is used to supply hot water to heating devices, and the second to return cooled water, is called two-pipe.

Its main advantages:

- the temperature of the water supplied to all radiators is the same;

- turning off one or more radiators does not affect the temperature of the water supplied to the remaining heating devices;

- restrictions on the number of radiators for one heating circuit depend only on the throughput volume of the pipes.

The main disadvantage of such wiring is a slight increase in pipe footage.

This leads to some additional disadvantages:

- the costs of purchasing and installing heating system elements increase;

- integration into the interior of a private home becomes more difficult.

The number of fittings and taps for a two-pipe system is almost the same as for a single-pipe system.

For a parallel flow pattern of the coolant, the total length of the pipes when using a two-pipe system increases by the distance between the first and last radiator. Sometimes it is insignificant compared to the entire length of the contour

Depending on the relative movement of hot and chilled water, two-pipe wiring diagrams are divided into two types:

- incidental;

- dead end.

Related scheme. Both flows move in the same direction and, thus, the length of the coolant circulation cycle for each radiator is the same. In this case, they heat up at an equal rate when the heating system starts.

Dead end option. The direction of movement of hot and chilled water is counter. Radiators closest to the boiler heat up faster.

The lower the water speed, the more noticeable this effect is, therefore, with natural circulation, heating of some rooms will occur much more slowly than others.

If a circulation pump is used or the distance between the first and last radiator in the circuit is small, then the effect of uneven heating with a dead-end two-pipe wiring is invisible. Then the choice in favor of one or another option is determined solely by considerations of the convenience of installing the return pipe.

Selection of coolant

It is not enough to draw up a diagram of heating boilers and decide on a heat source; it is important to make the right choice of coolant.

For houses that have an electric, fireplace or stove heating system, a coolant in the form of heated air is well suited. But it has its drawbacks:

- low heat transfer; insufficient density;

- insufficient heat capacity.

Liquid substances do not have these disadvantages. They absorb the body well and also release it well, retaining heat for some time. Therefore, most experts believe that water is the best coolant of all existing ones. The main thing is to ensure continuity of the process through circulation.

It is important to know! Experts warn that in order to prevent the pipes from becoming coated from the inside, and the heating system to remain operational longer, you should “run” it through a filter for purification before using water as a coolant.

If the house is intended for seasonal use, antifreeze should be used as coolants. It does not freeze in the cold season, so the heating system is always in working order.

Electric

To heat your home, you can use electrical appliances: convectors, long-wave infrared heaters or “warm floor” systems. Also, to achieve maximum effect, it is recommended to combine several electrical appliances.

With any of these methods, large payments for energy consumption cannot be avoided, so it is recommended to install them in cases where there are no alternative heat sources.