The use of this type of heating, such as a heating system with natural circulation, is most common for country houses and cottages. Its advantages are availability, cost-effectiveness, ease of installation and operation. Creating a heating system with natural circulation does not require the use of pumps or additional equipment or power sources, since hydrostatic pressure arises spontaneously during the movement of the coolant.

Heating scheme with natural circulation

Many consider the disadvantage that the use of this system is permissible only in fairly small buildings. In particular, the radius of the system (horizontal arrangement) should not exceed 30 meters. In addition, not everyone prefers to use heating without a pump, since the network turn-on speed is also quite low.

Theoretical horseshoeing - how gravity flow works

The natural circulation of water in heating systems operates due to gravity. How does this happen:

- Take an open vessel, fill it with water and start heating it. The most primitive option is a saucepan on a gas stove.

- The temperature of the lower layer of liquid increases, the density decreases. The water becomes lighter.

- Under the influence of gravity, the upper heavier layer sinks to the bottom, displacing less dense hot water. Natural circulation of liquid begins, called convection.

Reference. The dependence of water density on temperature is not linear. The more the liquid heats up, the faster its density decreases, which is clearly visible on the graph.

Example: if you heat 1 m³ of water from 50 to 70 degrees, it will become 10.26 kg lighter (see below for a table of densities at different temperatures). If we continue heating to 90 °C, then the cube of liquid will already lose 12.47 kg, although the temperature delta remains the same - 20 °C. Conclusion: the closer the water is to the boiling point, the more active the circulation occurs.

In a similar way, the coolant circulates by gravity through the home heating network. The water heated by the boiler loses weight and is pushed upward by the cooled coolant returning from the radiators. The flow speed at a temperature difference of 20–25 °C is only 0.1…0.25 m/s versus 0.7…1 m/s in modern pumping systems.

Low speed of fluid movement through pipelines and heating devices causes the following consequences:

- The batteries have time to give off more heat, and the coolant has time to cool by 20–30 °C. In a conventional heating network with a pump and a membrane expansion tank, the temperature drops by 10–15 degrees.

- Accordingly, the boiler must produce more thermal energy after the burner starts. It is pointless to keep the generator at a temperature of 40 °C - the flow will slow down to the limit, the batteries will become cold.

- To deliver the required amount of heat to the radiators, it is necessary to increase the flow area of the pipes.

- Fittings and fittings with high hydraulic resistance can worsen or even stop gravity flow. This includes check valves, three-way valves, sharp 90° turns and pipe reductions.

- The roughness of the internal walls of pipelines does not play a big role (within reasonable limits). Low fluid speed means low frictional resistance.

- A solid fuel boiler + gravity heating system can safely operate without a heat accumulator and a mixing unit. Due to the slow flow of water, condensation does not form in the firebox.

As you can see, there are positive and negative aspects in the convection movement of the coolant. The former should be used, the latter should be minimized.

Design features

For a gravity system to work effectively, the following requirements must be met:

- the heat source is any non-volatile heat generator with outlet pipes with a diameter of 40-50 mm;

- at the outlet of a boiler or stove with a water circuit, an accelerating riser is immediately installed - a vertical pipe through which the heated coolant rises;

- the riser ends with an open-type expansion tank installed in the attic or under the ceiling of the upper floor (depending on the type of wiring and the design of the private house);

- tank capacity – 10% of the coolant volume;

- by gravity, it is advisable to choose heating devices with large internal channels - cast iron, aluminum, bimetallic;

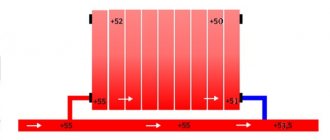

- for better heat transfer, heating radiators are connected according to a versatile pattern - bottom or diagonal;

- special full-bore valves with thermal heads (supply) and balancing valves (return) are installed on the radiator connections;

- It is better to equip batteries with manual air vents - Mayevsky taps;

- replenishment of the heating network is organized at the lowest point - near the boiler;

- all horizontal sections of pipes are laid with slopes, the minimum is 2 mm per linear meter, the average is 5 mm/1 m.

On the left in the photo is the coolant supply riser from a floor-standing boiler with a pump on the bypass, on the right is the return line connection

Note. Slopes perform 2 functions - they help the coolant flow in the desired direction, and the air rises through the pipelines and leaves through the open expansion tank. A caveat regarding the radiators used: if the system is built correctly, steel panels also heat well.

Gravity heating systems are made open and operated at atmospheric pressure. But will gravity flow work in a closed circuit with a membrane tank? We answer: yes, natural circulation will continue, but the speed of the coolant will decrease and efficiency will drop.

It is not difficult to substantiate the answer; it is enough to mention the change in the physical properties of liquids under excess pressure. With a pressure in the system of 1.5 Bar, the boiling point of water will shift to 110 °C, and its density will also increase. The circulation will slow down due to the small difference in the masses of the hot and cooled flow.

Simplified gravity flow diagrams with an open and membrane expansion tank

Single-pipe and two-pipe heating schemes

When developing a heating scheme for a house with natural water circulation, it is possible to design one or several separate circuits. They may differ significantly from each other. Regardless of the length, number of radiators and other parameters, they are made according to a single-pipe or two-pipe scheme.

Circuit using one line

A heating system using the same pipe for sequential supply of water to the radiators is called single-pipe. The simplest single-pipe option is heating with metal pipes without the use of radiators.

This is the cheapest and least problematic way to heat a house when choosing natural coolant circulation. The only significant disadvantage is the appearance of bulky pipes.

With the most economical version of a single-pipe scheme with heating radiators, hot water flows sequentially through each device. A minimum number of pipes and shut-off valves is required here.

As the coolant passes through, it cools down, so subsequent radiators receive colder water, which must be taken into account when calculating the number of sections.

A simple one-pipe circuit (above) requires a minimum amount of installation work and investment. The more complex and expensive option below allows you to turn off radiators without stopping the entire system

The most effective way to connect heating devices to a single-pipe network is considered to be the diagonal option.

According to this scheme of heating circuits with a natural circulation type, hot water enters the radiator from above, and after cooling it is discharged through the pipe located below. When passing in this way, heated water gives off the maximum amount of heat.

When both the inlet and outlet pipes are connected to the battery at the bottom, the heat transfer is significantly reduced, because the heated coolant has to travel the longest possible path. Due to significant cooling, batteries with a large number of sections are not used in such circuits.

“Leningradka” is characterized by impressive heat losses, which must be taken into account when calculating the system. Its advantage is that when using shut-off valves on the inlet and outlet pipes, devices can be selectively turned off for repairs without stopping the heating cycle (+)

Heating circuits with radiators connected in this way are called “Leningradka”. Despite the noted heat losses, they are preferred in the arrangement of residential heating systems, which is due to the more aesthetic appearance of the pipeline.

A significant disadvantage of single-pipe networks is the inability to turn off one of the heating sections without stopping the circulation of water throughout the entire circuit.

Therefore, they usually use a modernization of the classic scheme with the installation of a “bypass” to bypass the radiator using a branch with two ball valves or a three-way valve. This allows you to regulate the water supply to the radiator, even turning it off completely.

For two or more storey buildings, variants of a single-pipe scheme with vertical risers are used. In this case, the distribution of hot water is more uniform than with horizontal risers. In addition, vertical risers are shorter and fit better into the interior of the house.

A single-pipe scheme with vertical wiring is successfully used when heating two-story rooms using natural circulation. An option has been presented with the ability to disable the upper radiators

Option using a return pipe

When one pipe is used to supply hot water to radiators, and the second to drain cooled water to a boiler or furnace, this heating scheme is called a two-pipe heating system. In the presence of heating radiators, such a system is used more often than a single-pipe system.

It is more expensive, as it requires the installation of an additional pipe, but has a number of significant advantages:

- more uniform temperature distribution of the coolant supplied to the radiators;

- it is easier to calculate the dependence of radiator parameters on the area of the heated room and the required temperature values;

- more efficient regulation of heat supply to each radiator.

Depending on the direction of movement of cooled water relative to hot water, two-pipe systems are divided into associated and dead-end. In associated circuits, the movement of cooled water occurs in the same direction as hot water, so the cycle length for the entire circuit is the same.

In dead-end circuits, cooled water moves towards hot water, so for different radiators the lengths of coolant circulation cycles differ. Since the speed in the system is low, the heating time can vary significantly. Those radiators whose water cycle cycle length is shorter will heat up faster.

When choosing dead-end and associated heating schemes, they proceed primarily from the convenience of installing the return pipe

There are two types of location of the liner relative to the heating radiators: upper and lower. With the top connection, the pipe supplying hot water is located above the heating radiators, and with the bottom connection, it is below.

With a bottom connection, it is possible to remove air through radiators and there is no need to run pipes from above, which is good from the point of view of room design.

However, without an acceleration manifold, the pressure drop will be much less than when using the top line. Therefore, the bottom liner is practically not used when heating premises according to the principle of natural circulation.

Calculation of gravity system

To calculate and design heating with natural circulation, proceed in this order:

- Find out the amount of heat needed to heat each room. Use our instructions for this.

- Choose a non-volatile boiler - gas or solid fuel.

- Develop a diagram based on one of the options proposed here. Divide the wiring into 2 branches - then the lines will not cross the front door of the house.

- Determine the coolant flow for each room and calculate the pipe diameters.

Note. There is no need to calculate slopes; take the standard value of 0.5 cm per meter of length. Deviations up or down in the range of 0.7…0.2 cm/1 m are allowed.

It will not be possible to split it into 2 branches right away. This means that the ring pipeline will definitely pass under the threshold of the front door. To withstand all the slopes, the boiler will have to be placed in a pit.

The calculation of the diameter of the pipes in all sections of the gravity two-pipe system is done as follows:

- We take the heat loss of the entire building (Q, W) and determine the mass flow rate of the coolant (G, kg/h) in the main line using the formula below. The temperature difference between supply and return Δt is taken equal to 25 °C. Then we convert kg/h to other units - tons per hour.

- Using the following formula, we find the cross-sectional area (F, m²) of the main riser, substituting the value of the natural circulation speed ʋ = 0.1 m/s. We recalculate the area of the circle into diameter, we get the size of the main pipe suitable for the boiler.

- We calculate the thermal load on each branch, repeat the calculations and find out the diameters of these lines.

- We move on to the next rooms and again determine the diameters of the sections based on heat costs.

- We select standard pipe sizes, rounding the resulting numbers up.

Let's give an example of calculating a gravity system in a one-story house of 100 square meters. The layout below already shows heating radiators and indicates heat losses. We start from the main boiler manifold and move towards the last rooms:

- The amount of heat loss at home is Q = 10.2 kW = 10200 W. Coolant flow in the main riser G = 0.86 x 10200 W / 25 °C = 350.88 kg/h or 0.351 t/h.

- The cross-sectional area of the supply pipe is F = 0.351 t/h / 3600 x 0.1 m/s = 0.00098 m², diameter d = 35 mm.

- The load on the right and left branches is 5480 and 4730 W, respectively. Amount of coolant: G1 = 0.86 x 5480 / 25 = 188.5 kg/h or 0.189 t/h, G2 = 0.86 x 4730 / 25 = 162.7 kg/h or 0.163 t/h.

- The cross section of the right branch is F1 = 0.189 / 3600 x 0.1 = 0.00053 m², the diameter will be 26 mm. Left branch: F2 = 0.163 / 3600 x 0.1 = 0.00045 m², d2 = 24 mm.

- Lines DN32 and DN25 mm (rounded up) will come to the nursery and kitchen. Now we calculate the sizes of collectors for the bedroom and living room + corridor with heat losses of 2.2 and 2.95 kW, respectively. We get both diameters DN20 mm.

To connect small batteries, you can use DN15 connections (outer d = 20 mm), the plan shows DN20 dimensions

Attention! The diameters obtained as a result of calculations indicate the size of the internal passage of pipelines (designation - DN or DN).

All that remains is to pick up the pipes. If you make heating from steel, the boiler riser will be Ø48 x 3.5, the branches will be Ø42 x 3 and 32 x 2.8 mm. The remaining wiring, including connections to the batteries, is done with a 26 x 2.5 mm pipeline. The first digit of the size indicates the outer diameter, the second - the wall thickness (range of water and gas steel pipes).

Do-it-yourself installation recommendations

To lay the main natural circulation lines, it is better to use polypropylene or steel pipes. The reason is the large diameter, polyethylene Ø40 mm and more is too expensive. We make radiator hoses from any convenient material.

Advice. When assembling a gravity heating network made of metal-plastic, do not install compression fittings - they greatly reduce the internal passage.

An example of installing a two-pipe wiring in a garage.

How to make the wiring correctly and withstand all slopes:

- Start with markings. Mark the locations for installing batteries, connection points for connections, and routes for highways.

- Mark the routes on the walls with a pencil, starting from the distant batteries. Adjust the amount of inclination using a long building level.

- Move from the outer radiators to the boiler room. When you draw all the routes, you will understand at what level to install the heat generator. The inlet pipe of the unit (for cooled coolant) must be located at the same level or below the return line.

- If the firebox floor level is too high, try moving all the heaters up. Horizontal pipelines will rise next. As a last resort, make a recess under the boiler.

Laying a return line in a furnace room with a parallel connection to two boilers.

After marking, punch holes in the partitions and cut grooves for a hidden gasket. Then check the routes again, make adjustments and proceed with installation. Follow the same order: first secure the batteries, then lay the pipes towards the combustion chamber. Install an expansion tank with a drain pipe.

The gravity pipeline network is filled without problems; Mayevsky’s taps do not need to be touched. Just slowly pump water through the fill valve at the lowest point, all the air will go into the open tank. If any radiator remains cold after warming up, use a manual air vent.

Pipe selection

Also, the choice of material is greatly influenced by the boiler, since in the case of solid fuel, preference should be given to steel, galvanized pipes or stainless steel products, due to the high temperature of the working fluid.

However, metal-plastic and reinforced pipes require the use of fittings, which significantly narrows the clearance; reinforced polypropylene pipes will be an ideal option at an operating temperature of 70C and a peak temperature of 95C.

Products made from special PPS plastic have an operating temperature of 95C, and a peak temperature of up to 110C, which allows use in an open system.