What is mining

Waste oils are engine oils that have lost their beneficial properties for a car. During the replacement process, used fluids are sent to waste, so you can purchase fuel for the furnace at a low price and in large quantities. For the convenience of obtaining oil, enter into an agreement with the nearest auto repair shop.

The flow rate is 2 liters per hour. Depending on the size of the room and method of operation, the figure may vary. An oil-fired stove is suitable not only as a heater for a work area, but also heats water for various needs.

Comparison with modern models

As for today's stoves, they are not at all similar to the old prototypes, with the exception of the potbelly stove, which retains the original principle of operation. In the sixties of the last century, the combustion of fuel to the state of carbon dioxide and water vapor was not considered something harmful, which cannot be said about the present time. Now any greenhouse gases are a dangerous enemy of the environment, so people are trying to abandon systems that pollute the environment. It is still impossible to ensure complete afterburning of the waste, but achieving maximum efficiency is quite possible.

Modern oil furnaces are different from the original ones

Also, in the distant past, there were no motor oils on the market with synthetic additives and clever additives, which can reduce the fuel consumption of internal combustion engines several times, but if burned incorrectly, they release carcinogens, toxic substances and mutagens. And people then were more resistant to various environmental influences, and the population was about 2.5 times smaller than now.

And in the end, Soviet engine oil was a natural petroleum product made on the basis of saturated carbons, which could not reach a high combustion temperature. This means that the appearance of harmful and dangerous nitrogen oxides in those heaters was practically eliminated. Modern installations emit such substances in significant quantities, which forces us to look for cleaner and alternative solutions.

Advantages and disadvantages

One of the advantages is storage, in which used oil outperforms wood fuel. The liquid takes up less space and does not deteriorate due to high humidity.

There are other advantages:

- High heat dissipation. In a short time it heats closed spaces: garages, workshops, greenhouses, premises for breeding animals.

- Safe design. No soot or burning when using the stove.

- Convenient and simple operation that requires special skills and effort.

- Fireproof. During the process, the oil itself does not burn, only its vapors burn. By following safety rules when using, no accidents will arise.

Like any design, a furnace using a gas cylinder also has disadvantages:

- Foreign impurities in the oil are explosive, and combustion waste from impurities clogs the filter and leads to premature wear of the furnace. To fix the problem, filter the fuel.

- It is necessary to regularly clean the chimney and stove chamber from combustion products, otherwise the efficiency will decrease.

- Increased noise during operation.

How to cut a gas cylinder

How does a furnace work during mining?

The principle of operation is as follows:

- The used oil is poured into the tank and set on fire. To make ignition easier, moisten the paper wick with diesel fuel.

- Using an air damper, the oxygen supply is regulated, which is convenient for changing the combustion intensity.

- Once the waste is heated sufficiently, it begins to release vapors, which release heat when burned.

- To quickly distribute warm air, a fan is attached to the top of the oven.

A diagram showing what a cylinder stove consists of.

A compact stove is easy to make with your own hands at home. This can be a furnace using an oxygen or gas cylinder.

Types of Russian-made waste oil burners

During the cold season, not only residential but also auxiliary premises need heating. Currently, devices using different types of fuel are used for heating, including waste or waste technical oil. On the Russian market you can find devices that process different fuel bases, as well as having a narrow specialization. Based on the type of fuel burned, such devices are:

In terms of functionality, burners used for testing are not only heating, but also welding and lighting.

- gas;

- liquid fuel;

- combined.

The simplest and most economical device for heating a room is considered to be an exhaust burner. According to functionality, burners are divided into 3 subtypes:

- welding;

- lighting;

- heating.

The operating principle of these devices was borrowed from primitive kerosene gas back in the 50s. Quite quickly, the simplest burners became popular; they began to be purchased for heating country houses and garages. In those days, any fuel was inexpensive, but over time, zealous owners, inventors and innovators began to look for a replacement for gasoline, diesel fuel and kerosene. Fuel oil and waste oil were used, which are now used as full-fledged fuel. Today, the device is still relevant, and is also an excellent way to preserve the environment.

Note! In a room where any liquid fuel device will be used, be it a homemade gasoline burner, a working unit, or a DIY diesel fuel burner, there must be a fire extinguisher! By type, burners for processing are liquid fuel, gas and combined

How to assemble it yourself

A gas cylinder is ideal for the combustion container. Let's look at the detailed instructions for assembling a stove based on it, having previously prepared the necessary equipment:

- Welding machine

- Grinder

- Drill and drill bits for metal

- Measuring tape

- Construction ruler for leveling

Next, we prepare materials for individual parts of the structure:

- 50 liter cylinder. The wall thickness should not exceed 1.5 centimeters, otherwise the fuel will not be able to heat up quickly and the exhaust vapors will not give the desired effect.

- Metal sheets. Needed for partitions and dampers, as well as oil fluid.

- Chimney pipe. The wall thickness should be 2-3 millimeters. The diameter depends on the size of the room and the oven itself.

- Additional connections for condensate and burner system.

- Metal corners for reliable stability of the structure.

After collecting the necessary tools and materials, you can begin to make a stove using a gas cylinder. It is important to strictly follow all instructions to avoid accidents.

The process of installing all parts. Diameter and dimensions may vary depending on the heated area

Work on preparing the cylinder

Even after prolonged ventilation, condensation remains in the gas cylinder. To remove it, you need to remove the valve and gearbox and leave it in fresh air for several days.

Then a hole is drilled in the bottom of the cylinder. To prevent sparking, the drill is moistened with oil. Since it is not easy to make a hole in thick metal, it is better to start the work with a small diameter drill, and then it can be increased to 10–16 millimeters.

Next, the balloon is filled with water and drained after 24 hours. Since condensate has an unpleasant, pungent odor, it should be carefully poured away from your home. The procedure is repeated if necessary.

Step-by-step assembly instructions

First, let's prepare the cylinder so that during operation, the remaining propane gas does not lead to an explosion.

The method for assembling a furnace from an oxygen cylinder will be identical

- Drain the remaining condensate from the cylinder and rinse thoroughly with water. The procedure should be repeated several times.

- Place the container vertically, completely filling it with water.

- We draw markings for the cut in the upper area of the cylinder.

- Carefully cut the balloon with a grinder until water appears. As soon as the water has drained to the cut point, cut off the top to the end.

- The upper cut part will be used as a lid for the container, and combustion will occur in the lower part. After dividing the container, drain all the remaining water in it.

- We weld steel corners 250 mm high at the bottom of the container for stability.

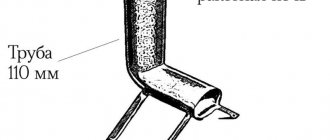

- Having retreated 100 mm from the top of the container, we cut out a hole for smoke removal. A 400 mm long pipe is inserted into it.

- We weld a 4-meter long vertical pipe to the pipe and take it outside.

- We make a hole at the bottom of the cylinder to allow air to enter. We install a damper so that we can regulate the oxygen supply.

- We hermetically weld a piece of pipe 100 mm long and 140 mm in diameter onto the bottom of the cylinder. Such a chamber will serve as a container for liquids. For sealing, we cut out a lid from an iron sheet with two holes: for the pipe and for filling with oil.

- Then the pipe coming out of the cylinder is connected to a metal blank of the same diameter as the combustion container. From the outside it looks like a barbell.

- In the connecting pipe we drill holes with a diameter of 9 mm in several rows. We insert the rod into the cylinder and weld the lid to the walls.

After complete assembly, you need to conduct a test fire in the open air.

Increasing the number of pipe bends

Increasing the bends of the potbelly stove chimney

The tank at the outlet of washing machines will retain a certain amount of heat, but it will not be able to retain all the heat. A large amount of heat will continue to escape into the chimney.

Therefore, one of the improvements that provides additional heat retention is to increase the length of the outlet pipe. A long pipe running through the room, but with good exhaust, ensures the transfer of heat from its surface, which was previously lost.

Materials and tools

- several elbows that can be easily placed in the room after the potbelly stove,

- brackets for fastening pipe elbows,

- welding machine and metal processing tools.

Instructions

First you need to mark the location of the pipe. It can pass with a large number of bends and zigzags, thereby ensuring maximum heat retention, without forgetting about the loss of exhaust draft. After marking the pipe laying location, it is necessary to install pipe mounting brackets

Particular attention should be paid to the joints of pipe elbows and corners. Brackets must be made of heat-resistant materials. Lay the pipes to ensure a tight, hermetically sealed connection, and, if necessary, modify the elbows to ensure the pipe is laid along the marked route. Firmly secure the elbows in the brackets, check the working draft (burn newspaper in front of the pipe), check the tightness of the connections, connect the inlet elbow to the stove.

Operating rules

When heating a room with a waste oil stove, you must strictly follow safety precautions:

- Install the stove on a stone floor or a special tray

- Avoid drafts

- Flammable substances and objects must be located no closer than 5 meters from the stove

- It would be a good idea to decorate the walls closest to the structure with heat-resistant metal material.

- Do not leave the oven unattended during operation.

It is not difficult to make a furnace for testing yourself; the main thing is to correctly calculate the required dimensions and draw up your own diagram according to the presented drawings. Fuel economy and high heat transfer will be felt after the first kindling. In the regions, the average price for used oil starts from 5 rubles per liter and does not exceed 15 rubles - a strong argument for choosing this furnace.

Combined potbelly stove

If you slightly modify the design of a classic potbelly stove, you can make a universal stove that will work not only on waste fuel, but also by igniting solid materials.

To do this, you need to make several additional elements. When igniting wood, the pipe must be sealed, so four plates must be made of steel that can close the pipe from air penetration. To do this, you should make several fastenings for bolts on the pipe so that additional elements can be easily screwed on.

A grate or steel grate is placed on the base of the lower tank. It is necessary to design an additional container that will be placed in the lower tank. It is necessary to ensure that the container can be easily installed through the removable top of the stove. It will serve as a reservoir for used oil.

The more removable elements there are in a potbelly stove, the easier it is to clean the stove after using used oil. You should also handle the stove with care. To ensure that the oil burns evenly, without bubbling or hissing, several important points must be taken into account. The tank must be filled no more than two-thirds with spent fuel. It is best to use machine oil and let it sit. Oil that was drained from a car several hours ago will not burn well.