Having a portable stove on hand in an unfinished home or garage is a big deal. You can finish the work put off since the fall without haste. True, such a stove is very expensive, and it weighs almost a hundred kilograms, so how mobile is it? But even in such situations, there is a way out - to make a stove yourself, for example, from old gas cylinders. Moreover, such creativity will cost much less than buying a cast iron potbelly stove, because all the work can be done independently, and the materials can be collected at any metal collection point for almost nothing.

What are the benefits of potbelly stoves?

To begin with, it would be nice to understand the features and advantages of potbelly stoves.

The main advantage is extreme simplicity. If you have a gas cylinder available, then the assembly can be completed in a matter of hours. The main thing is to have a welding machine, which is impossible to do without. A cylinder, a door, a chimney pipe - and an excellent homemade heating unit is ready to receive the first portions of firewood to give its owners warmth. Omnivorous - a stove made from a gas cylinder is suitable for burning any type of fuel. This can be firewood, compressed eurowood, wooden waste or pellets. Throw into it everything that can ignite and burn - the potbelly stove is undemanding when it comes to the quality of fuel. The main thing is to let it flare up, and then you can burn anything in its interior.

Affordability – a potbelly stove made from a cylinder is extremely cheap. You can use a new cylinder for it or get an old one from somewhere. If you live in a rural area where there is no gas main, then there will be no problems with the search. And if you cannot get a cylinder, adapt sheet iron, an old barrel or any other suitable container under the potbelly stove.

Other features and advantages of potbelly stoves assembled from gas cylinders:

You can adapt any battered, but more or less whole, gas cylinder to a potbelly stove.

- Versatility in use - if you need a stove for a bathhouse or for a garage, use a potbelly stove. Its production will not take much time, and you will have an excellent heating unit at your disposal;

- A potbelly stove made from a cylinder does not require special maintenance - you only need to periodically clean the ash pan and check the condition of the chimney;

- Easy to install - simply mount the stove on any suitable base or weld metal legs to it;

- Ease of modernization - a cylinder stove can be made more efficient if you use some technical tricks;

- Relatively high heat transfer - thermal power, depending on the volume of the stove, will be from 2 to 7 kW (heated area from 20 to 70 sq. m);

- A stove made from a cylinder is characterized by stable operation in any conditions - you just need to build a decent chimney with a height of at least 3-4 meters;

- Easy self-assembly - if you know how to work with a tool, then after 2-3 hours of work you will have the most effective potbelly stove made from a gas cylinder at your disposal;

- Several modifications for consumers to choose from - the stove body can be vertical or horizontal, large or small volume.

There are also some disadvantages. The first of them is its unsightly appearance. But if you put in some effort, you will be able to build a nice, compact potbelly stove with good appearance. The second drawback is not the highest efficiency. For such units it is about 70%, but this figure can be improved by implementing afterburning of combustion products with secondary air.

All the main ways to increase efficiency will be discussed in the corresponding section of our review.

Simple and convenient “ash pan”

In a long-burning potbelly stove, an ash pan is not needed; a small amount of light ash after combustion remains directly in the firebox. But you can still adapt the stove for easier cleaning, especially if you plan to add coal to the firewood.

1. Stops from the corner. 2. Grate over the ash pan

If the potbelly stove is positioned horizontally, you need to cut out the same plate that was used to form the upper chamber. Instead of a partition, it has a regular 35 mm corner welded transversely. In the front part, a handle is made from a thin rod. The plate is installed on two guide angles welded along the body. To ensure a tight fit of the plate and avoid strong air leaks, it is recommended to do the following:

- weld the corners under the bottom of the plate with the shelves up on small tacks that are easy to break off;

- insert the plate into the body and weld the corners to the walls, filling the thick weld seam well;

- insert a crowbar into the lower chamber and undermine the plate, if possible, clean out the weld marks.

Through small cracks, the minimum amount of oxygen required for combustion will enter the chamber.

1. Disc. 2. Holder made of reinforcement. 3. Side of the “ash pan”

For a vertical potbelly stove, you need to cut out another flat disk and weld a piece of thick steel reinforcement to it in the center. A side made of steel strip is bent and welded along the perimeter of the circle. In both cases, ash removal is carried out after the potbelly stove has cooled: the ash pan is removed, cleaned and replaced before a new filling.

Design features and principle of operation

Like any other direct combustion solid fuel stove, the unit, made from a gas cylinder, consists of several parts:

- firebox combined with the body;

- grate;

- blower chamber;

- chimney.

The blower is located at the bottom of the stove and is a small chamber (essentially a channel) necessary to supply oxygen to the combustion zone. To regulate the amount of air, monitor the process and remove ashes, the ash pan is equipped with a door.

Simple design is one of the components of the success of cylindrical potbelly stoves

In the middle part of the furnace there is a combustion chamber, which is separated from the ash pan by a grate. Being the main module of the heating device, the firebox simultaneously plays the role of a loading compartment and a heat exchanger. Like the vent, the firebox is equipped with a door through which firewood is placed into the potbelly stove and ash is removed.

The chimney is a channel necessary to remove combustion products from the working area. A damper must be installed in the chimney, which is closed after the wood burns out. This prevents heat from escaping from the room when the stove is not in use.

The operation of a heat generator from a gas cylinder is not difficult. After the firewood is placed on the grate, they are set on fire and the combustion chamber door is closed. The blower must be open at this time - air passes through it to the fuel. The intensity of combustion is controlled by closing or opening the bottom door. Heated gases are removed through the chimney.

To increase the efficiency of heat exchange, the potbelly stove is equipped with additional elements that allow the residual heat of the flue gases to be removed. To do this, an air heat exchanger or a water jacket is installed on the chimney. Often the modification consists of lengthening the part of the chimney that is located in the room.

Making a heating unit with your own hands from a cylinder

A thrifty owner carefully insulates his home, trying to reduce heating costs. In addition, there are a number of objects that need to be heated periodically: workshops, garages, outbuildings. It is necessary to regularly heat greenhouses or winter gardens.

Therefore, home craftsmen are constantly developing and implementing additional heating units of various designs. The most popular are products made from gas cylinders. The reason for this is the convenient shape and almost ideal proportions and characteristics of the material.

The efficiency of cylinder stoves reaches 85–90%, which is a very high figure in comparison with homemade stoves of other forms. The rounded shape is ideal for intensive pyrolysis of fuel and allows you to arrange openings for smoke exit and oxygen supply to the combustion zone at the lowest cost.

A simple and effective gas cylinder stove will last a long time

Features of operating a mobile stove

Before lighting the stove, the blower valve is fully opened, after which scraps of paper or cardboard are placed in the firebox. Firewood is laid on top of them in a “hut” or “well”. After igniting the fuel, the combustion door should be slammed shut. As soon as a stable flame appears in the chamber, close the blower damper. By adjusting it, you increase the operating time of the heating device from one load and set the desired temperature. As it burns, add 3-4 logs to the working chamber.

If pizza or flatbreads will be baked in the oven, then a ceramic tray is placed on the roasting pan. After ignition, the wood is given the opportunity to burn thoroughly. Since smoke will enter the baking chamber during cooking, use only hard wood. For cooking, it is best to prepare a supply of “noble” fruit wood from cherries, plums, apricots, pears, etc. In this case, you will be able to obtain baked goods with an incomparable aroma. And, on the contrary, you should not use pine, laminated timber and various waste wood building materials for these purposes, since the substances released during their combustion can be hazardous to health.

There is nothing tastier than pizza baked “smoky” in an oven you built yourself.

The temperature in the mobile oven can be adjusted in two ways. The first is the reduction in air flow through the blower described above. The second is a change in heating carried out by rotating the furnace hood relative to the opening for the exit of flammable gases. The closer the chimney is to it, the more heat will go into the chimney. Heating is controlled using a thermometer. For baking, a temperature of 200 to 260 degrees will be sufficient.

The simplicity and accessibility of the design described above allows you to build a stove with your own hands, spending one day on it. This unit is well suited for heating utility rooms and cooking food at the same time. Be sure to take advantage of the opportunity to make such a stove. It will be enough to take her out into the wild once and cook meat or smoky pizza for friends to ensure her reputation as a skillful host and unsurpassed cook for many years to come.

Requirements

If the oven is used for cooking food, then one important problem arises. There must be a surface where food will be placed. At the same time, the heat flow in this place should be sufficient for high-quality cooking.

If, first of all, the tasks of heating the room are important, then other features come to the fore. Here the following are of particular importance:

- long burning;

- fuel efficiency;

- high requirements for fire safety.

The last requirement plays a vital role in the operation of various types of furnaces. However, when heating, the stove, in fact, can be left without direct supervision for a long time. This greatly increases the risk of an accidental fire. Another important issue is the possibility of legalizing a self-made stove. This process is not simple or easy.

Calculation of basic parameters: drawing and recommendations

To make an optimally efficient potbelly stove, an all-metal cylinder with a volume of 50 liters is suitable.

A standard 50 liter cylinder will be sufficient

Finding such a cylinder is usually not difficult. They are often used in households and industry.

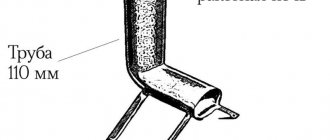

To equip such a stove with a chimney, a pipe with a diameter of 100–125 mm and a thickness of at least 3 mm is used to make the chimney pipe. The chimney itself should be positioned vertically, but deviation from the axis is also allowed (slope no more than 30 degrees). The slope is made for greater efficiency of heat transfer from the chimney pipe. Although the location of the pipe directly depends on the local conditions for installing the potbelly stove.

For ease of operation, the firebox and ash pan compartments are equipped with doors with a locking mechanism. With the doors closed, the combustion process improves and the risk of fire hazardous particles falling into the room is reduced. And also by adjusting the gap with the ash pan door, you can regulate the intensity of air supply to the firebox.

The doors are made of any shape. The main thing is to take into account the standard size of firewood and the convenience of loading it.

An important part of the potbelly stove is the grate. The grate serves to support fuel (wood) and at the same time helps to separate loose combustion products

The combustion process takes place on the grate. Therefore, the metal from which the grate is made must be strong enough and resistant to high temperatures. It is better to make a grate from reinforcement rods with a diameter of at least 12 mm. Such rods are cut to the dimensions of the inside of the cylinder (width) and assembled into a grid with a gap width of 10–15 mm. The rods are connected by welding.

Potbelly stove from a cylinder

The approximate assembly diagram of a horizontal solid fuel stove is applicable to a gas cylinder.

The diagram is applicable for a gas cylinder

A little more about the chimney

It is worth noting here that thanks to the design of the stove, which consists of two sections, a chimney pipe that is too long will not “steal” heat - an increase in draft will only contribute to increased combustion and an increase in temperature. The main thing is to secure it so that the wind does not uproot it. But it’s worth thinking about the deflector (protective cap). If there is snow or a blizzard at night, the pipe may become completely clogged. In this case, lighting a potbelly stove will be quite problematic. In the photo below you can see that I raised the chimney quite high. However, when this photo was taken, the deflector had not yet been installed.

This is the chimney pipe I got

Preparatory work

Before you start building a furnace, you need to carefully plan all stages of the work. In particular, you need to prepare a gas cylinder and select a place to install the heating device. As for the technology, using the step-by-step instructions presented below you can avoid mistakes and carry out installation in the shortest possible time.

How to empty a cylinder of gas residues

You cannot start cutting a propane or methane cylinder without preparation, since even a small amount of gas, condensate or its vapor in combination with atmospheric oxygen is an explosive mixture. The slightest spark is enough for an explosion to occur. You can make the container completely safe using the method presented below.

- Open the valve and release the gas from the container.

- Using an adjustable wrench or a gas wrench, remove the tap.

- Turn the can over and drain the remaining gasoline.

- Place the container vertically and fill it with water through the top opening. In this case, all flammable components will be displaced by the liquid.

- After drying the cylinder in the open air, you can begin any plumbing work, including welding and burning old paint with a blowtorch.

Which location is suitable for installing the stove?

Even though we are looking at a mobile structure, most of the time it will be used to heat a garage, shed or workshop. To ensure that the operation of the heating device does not lead to unpleasant consequences, when choosing a location, they are guided by the current provisions of SNiP, sanitary and fire safety standards.

- The floor under the stove is constructed using non-combustible materials - fireclay bricks, cement-sand screed, asbestos fiber board or metal sheet.

- It is prohibited to install heating devices near storage areas for fuels, lubricants and other flammable materials and substances.

- When installing the stove, be sure to take into account the configuration of the chimney. The places where it passes through the roof must be protected with heat-insulating non-combustible materials.

- It is prohibited to install furnaces of this type under shelves, in places where attachments are close, etc.

- It is necessary to consider how the air flow into the room will be carried out. We should not forget that open-flame stoves consume a lot of oxygen.

- If the body of the heating device is located close to the flammable surfaces of the walls of the room, the latter are protected with heat-insulating shields.

When choosing a location for installing the stove, be sure to take into account the configuration of the chimney. Since most of the heat in direct combustion stoves is emitted into the chimney, they try to place it indoors, equipping it with a long horizontal or inclined section

It’s just important not to overdo it with its length and number of turns, since the traction force, and therefore the thermal power of the heating device, depends on this

Slow burning pyrolysis furnace “Bubafonya”

It is impossible to describe or simply list all the designs of stoves that can be made from cylinders, but it is advisable to consider in detail the “bubafonya” design. This model can be made at home with your own hands.

Safety

Before describing the design of the furnace and its manufacturing technology, let us pay attention to safety issues. We will talk about preparing the cylinder itself for processing. Despite its dense structure, the inner surface of the metal is riddled with a network of microscopic cracks. During long-term operation of the container for its intended purpose, a considerable amount of gas condensate and its sediment accumulates inside these defects. Such a substance may be explosive and is in no way beneficial to health. Before you start working with the cylinder, you need to fill it with water and let it sit for 2-3 days. It is better to perform the operation away from home. When the liquid is drained, the reasons for this recommendation will become clear - it has an extremely unpleasant and strong odor.

Video: how to safely disassemble a gas cylinder

Tools and materials for making the Bubafonya stove

To make such a heating unit with your own hands, you will need:

Table: required materials and tools

| Name | Purpose | Notes |

| Cylinder for furnace body | Manufacturing of the main product | boo |

| Steel rod with a diameter of 10 mm | Making handles for the oven lid and body | From waste |

| Angles 45x45, any profile, pipe cuttings | For support legs | From waste |

| Bulgarian | Cutting blank parts, cutting the cylinder during the manufacture of the body | |

| Steel sheet 6–10 millimeters thick | Making a pancake | |

| Steel strip 40x4 millimeters | Manufacturing of support ribs | |

| Cement, sand, gravel and fireclay bricks | Making the furnace support base | |

| Reinforcing bars | Foundation reinforcement | |

| Trowel, shovel, container for mixing the solution | Pouring the foundation | |

| Welding machine for working with ferrous metals and electrodes for it | Making welded joints when assembling the furnace | Possible to rent |

| Electric drill no less than 0.7 kW, set of metal drills | Drilling holes | |

| Measuring tool | Taking measurements and marking | |

| Locksmith's corner | Positioning of parts during assembly, quality control | |

| Kerner | Hole marking | |

| Files flat and semicircular | Removing sharp edges and burrs, adjusting dimensions | |

| Marker black | Marking production | |

| Individual protection means | Goggles, welder's mask, face shield, mittens, gloves, special shoes, rags. |

Creation options

Creating a vertical oven

Algorithm of actions:

- The cylinder is placed vertically and the neck is cut off.

- Using a marker, make marks on the surface. Mark the locations of the firebox, chimney, vent, etc.

Markings on a gas cylinder to create a vertical oven.

- Using a cutter or grinder, cut out the intended holes.

- Next, proceed to installing the grate. It is made from cut reinforcement. The parts are welded inside the body to the intended location in a snake or in a row.

- Door hinges are welded to the cylinder body and cast iron (metal) doors are installed. Latch bolts are attached to them or a sliding mechanism is constructed.

- If the potbelly stove will be used for cooking, then a metal sheet cut to size is welded to the top of the tank. This strip will be the hob.

- Seams and joints are cleaned and checked for strength and tightness.

- The opening for installing the chimney pipe is made on the side or at the top of the cylinder. The size of the opening must be equal to the diameter of the pipe. Often the smoke exhaust is made from above through the central hole in the cylinder. When installing on the side, the elbow is first welded to the cut-out opening, and then the pipeline itself is welded. It removes combustion products through the roof or wall of the room.

About

What you will need for work: tools and materials

This model of a “long-lasting” stove can be made in just a few hours. All you need for this is a great desire and proper organization of the work process. You will also need to thoroughly understand the design of the unit and prepare everything you need in advance.

Tools you will need:

- welding machine - a small, lightweight inverter with the ability to adjust the current up to 200 A is best suited for these purposes;

- angle grinder (colloquially a grinder or “grinder”);

- cutting and grinding discs intended for metal work;

- drill press or electric drill;

- set of drills;

- medium-sized hammer;

- blowtorch;

- chisel;

- sledgehammer;

- tape measure and metal ruler;

- core (a device designed for applying marks to facilitate drilling);

- scriber for marking metal surfaces.

As for materials, there is no need to follow the list exactly. The beauty of homemade structures lies precisely in the fact that they will use any iron that can be found in the backyard or in the corners of the garage (workshop).

Any large container, for example, an unnecessary metal barrel, is suitable for making the furnace body.

So, the list of necessary materials:

- steel pipes with a diameter of 80 to 250 mm, which will be needed for the manufacture of an air supply riser and a chimney;

- a suitable metal container with a diameter of 300 to 600 mm with a wall thickness of at least 2.5 mm (you can use a used gas cylinder, a fuel barrel or a piece of pipe at least 120 cm long);

- a metal sheet with a thickness of at least 4–5 mm from which the air distribution piston will be made;

- durable metal hinges, which will be needed to secure the firebox and ash door;

- asbestos cord (it is needed to seal the loading window and other operational openings);

- corners with a flange from 50 mm, channels and profile pipes - for the manufacture of air distributor blades, support legs and other structural elements;

- a round metal pancake with a thickness of at least 5 mm and a diameter of 120–150 mm (you can take any suitable gear or sprocket from a motor vehicle);

Features of operation of a pyrolysis furnace

The main difference between pyrolysis furnaces is the ability to use a wide variety of fuels. In solid fuel stoves, it is possible to burn not only traditional flammable substances, but also rubber, plastic and other materials that are strictly not recommended for burning conventional stoves.

This feature is associated with complete decomposition of the fuel and secondary combustion of the resulting gases in a separate chamber. After this, only carbon dioxide and water vapor remain in the smoke emissions. No harmful emissions into the atmosphere occur during pyrolysis.

But when using such fuel at the ignition stage, a persistent smell of burnt rubber remains in the room. Therefore, such heating units must be installed outside residential premises.

Important nuance

There are two types of gas used in everyday life. More precisely, two compositions of the gas mixture. And the characteristics of these mixtures differ greatly:

- Main gas , which consists of methane with an indicator - a strong-smelling component that allows you to quickly detect a leak. The main difference is that the mixture is lighter than air. Therefore, in a properly made furnace, a leak in the fittings is not a problem - the gas will simply go through the direct-flow system into the pipe, onto the street.

- A mixture of propane and butane is what is “packed” into cylinders at gas filling stations. This blend is better known as liquefied domestic gas. An important difference is that it weighs more than atmospheric air. As a result, in the event of a leak, it becomes very dangerous, since it can accumulate in the room or firebox of a stove converted to gas.

Hence the rule! You should not make your own stoves with gas burners designed for bottled gas.

And even the presence of a gas tank does not help - the same propane-butane mixture is filled into it.

Accordingly, if there is a gas main near the house, you can make a project, a permit and bring the pipe into the house. And instead of a boiler with a system of pipes, batteries or water circuit registers, install a furnace in which to burn gas.

But if only a bottled gas supply option is available, then there is no place for homemade products. We need to go a little different way.

Tips and tricks

Experienced craftsmen advise making a potbelly stove from a gas cylinder, taking into account the following nuances:

The chimney should not take the shortest route. In this case, the heat will leave along with the combustion products. The optimal type of chimney is a broken pipe.

The chimney is made in a broken shape so that heat does not escape from the stove along with the smoke. Curved pipe prevents heat energy from escaping

It’s just important that the pipe is not made of aluminum!

- Any type of fuel can be used as fuel - coal, wood. If necessary, you can burn household waste and carpentry waste in a potbelly stove.

- You can increase heat transfer and make a potbelly stove with high efficiency by increasing the length of the chimney. Parts with straight sections or downward slopes should be avoided.

- If you attach an additional one to the main body cylinder (in the form of a vertical pipe), then you can use the heat twice as much. Such a potbelly stove of two cylinders creates good draft; combustion products and smoke will not enter the room/garage/utility room. In addition, the heat transfer of the heating device will increase.

Video: demonstration of a potbelly stove made from a gas cylinder

- To prevent a potbelly stove made from a gas cylinder from cooling down quickly, a mesh is welded to the chimney pipe and round river stones are placed there. The installation will work on the principle of a sauna stove. The stones distribute heat evenly and do not cool down for a long time. However, with such a potbelly stove, it will not be possible to quickly heat the room.

- A potbelly stove with a water jacket is another way to increase the efficiency of the stove. An expansion tank is welded around the cylinder and connected to the radiators. The volume of the tank should be 10% of the total displacement.

A potbelly stove made from a gas cylinder can be used both indoors and outdoors. On a horizontal installation with a hob, you can cook food and heat the kettle.

A potbelly stove made from a gas cylinder is a budget option for an efficient heating device that anyone can make. To do this, you need to have materials and tools on hand, as well as have basic skills in working with welding and a grinder.

We increase the efficiency of the furnace

A potbelly stove can heat a room in literally a matter of minutes.

Moreover, you can throw whatever comes to hand into the firebox: since it does not have an extensive network of chimneys, and the smoke in it comes out “directly,” you don’t have to worry about them getting clogged. But if a conventional heating stove installed in premises for permanent residence has an extensive network of chimneys that retain heat, in a potbelly stove it goes directly into the pipe, so its efficiency is not very high. That is why it is too “gluttonous” and requires a lot of fuel.

To reduce fuel consumption, you can use the following tips from experienced stove-makers:• firebox door and vent

in such an oven must be as airtight as possible;

otherwise, the air supply to the potbelly stove will increase, and the fuel will burn out too quickly;• to regulate the release of warm smoke in the chimney, it is advisable to provide a damper

;• next to the stove, you can provide

side metal screens

at a distance of 5-6 cm from the stove, in this in this case, it will heat the room not only through heat radiation, but also through convection (circulation of warm air); • a potbelly stove, “clad” in a metal casing, will help retain heat much longer;

Potbelly stove in casing

Round furnace with afterburner and casing with heat gun

• to retain heat in the room, elbows should be built up in the pipe; however, soot will be retained in them, so it is advisable to create a collapsible structure; • the pipe can also be given a stepped shape: arrange the elbows in stages, making a 30° turn with each step; in this case, each of the elbows must be securely attached to the wall with rods;

Stove with chimney elbows

• chimney capacity

should be less than the productivity of the furnace itself, in which case hot gases will not go into the pipe immediately;

its diameter should be only 2.7 times larger than the volume of the firebox, for example, with a firebox volume of 40 liters, the diameter should be 110 mm; • you can increase the efficiency of the stove by blowing the chimney with a fan

- this will turn the stove into a kind of smoke cannon ;• to reduce air circulation,

firewood in the stove

should be stacked as tightly as possible;

if it is heated with coal, you need to stir up the resulting ash as little as possible; • to regulate the air flow, the door to the ash pit can be made adjustable by providing it with vertically located slots and a latch

.

which will cover these gaps; • to increase the heating area, it can be ribbed, that is, strips of metal

to the stove; • if you place a couple of

buckets or a metal box with sand

.

then they will accumulate heat and store it even after the stove goes out; sand backfill or a heat accumulator made of stones

can also be sewn inside the metal body of the furnace;

Scheme of a potbelly stove with sand backfill, the stove is made of a pipe with a diameter of 500 mm, its length is 650 mm

• oven lined with 1-2 layers of brick

. will retain heat much longer;

• the volume of the furnace also matters: the larger the area of its walls

.

the more heat they will release into the room;• bricks or metal sheet

. on which the stove is installed will help not only protect the room from fire, but also retain heat.

Related video: Do-it-yourself potbelly stove stove

8f772c3fed439782b7a382d3001fa981.jpe 6e162aebc95ce3c564df48f7a0fbfc69.jpe

Vertical stove made from a gas cylinder

Take a regular unnecessary gas cylinder

When making this model, the cylinder is installed in its usual position, the neck is completely freed, then markings are made using a tape measure and a marker.

Possible marking option for a vertical potbelly stove

Next, using a grinder (or using a gas or plasma cutter), holes are cut for the firebox and vent.

Cutting openings for doors

The next step is to install a grate between the combustion chamber and the ash pan. Since this element of the required shape and size is difficult to find, it is made from reinforcement. It is cut into pieces of the required size and welded to a pre-marked place.

The grate can be made from reinforcement

- Next, the doors are installed—cut pieces of metal are perfect for making them. They are installed on hinges welded to the cylinder body.

- It is necessary to install latches or latches on the doors - they must securely hold the doors during combustion.

- At the top of the cylinder, if desired, you can arrange a small cooking surface. It is always useful for making coffee or tea or frying eggs. This panel is made of metal sheet.

A surface like this just begs for a hot water tank.

- The photo shows a version of the preparatory base not just for a hob, but for installing a container on top for heating water, made like a samovar. The pipe coming out of the firebox will pass through a container of water, heating it.

- All seams used to weld any parts of the stove must be sealed.

- The chimney pipe can be installed in the top of the stove or in the side wall. The chimney is discharged from the room through the wall of the building or the roof.

This arrangement of the gas cylinder helps to save space, as the stove turns out to be compact and neat. It is especially suitable for a garage or a small room in the country.

Horizontal potbelly stove

Horizontal potbelly stove from a cylinder

- Another version of a stove made from a cylinder, which is placed horizontally, also has its advantage - you can install a large hob on it, which will be able to not only warm tea, but also cook lunch.

- In order for the structure of the potbelly stove to stand steadily, a reliable stand is welded for it from a corner, and after completion of the work, the finished stove is secured to it using spot welding.

- Work on the cylinder also begins with markings, after which a square hole is cut for installing the door and a round one for installing a chimney pipe. You may have to work with a round hole if you don't have a cutter. The “grinder” is not an assistant here, so first, drill holes around the circumference, then work with a chisel and hammer, and then final finishing with a file.

- Holes are drilled in the bottom of the future furnace, which will play the role of a grate, and under it a box is welded from a sheet of metal into which the ash will be poured.

In the role of a grate - rows of drilled holes

- The same chamber will be a blower, so an adjustable door is installed on it so that the air flow can be reduced or increased to establish the desired draft.

You can make the door yourself...

- You can make the door for this stove yourself by scalding a part cut out of a cylinder, or you can install a ready-made cast iron part that already has a frame. The second option will be easier to install, and it is already equipped with a latch to securely close the firebox.

...or buy ready-made ones in the store

- After installing the door, the potbelly stove is fixed on the stand or legs of the required height are welded to it.

- Then a pipe is welded onto which the chimney pipe will be installed. It can also be discharged through a wall or roof.

How to properly make a chimney

To ensure maximum stability in the operation of a stove structure made from a cylinder, it is imperative to arrange high-quality draft.

To achieve this goal, the cut of the stove chimney pipe must be installed at a certain height. This is slightly higher than the edge of the mounted grate. When connecting a gas chimney to the side, it is necessary to ensure that the length of the strictly horizontal section is approximately 400 mm. At the very bottom of the vertically located part, it is worth organizing high-quality removal of accumulated moisture, as the drawings show.

- At the same time, it is recommended to use certain measures regarding the removal of incoming heat from the chimney part. There are two methods for carrying out this process:

- A horizontal section is being installed at a slight inclination of 35 degrees. Immediately after this, the channel turns upward and leads out. A completed or purchased heat exchanger of a special samovar category is installed on the chimney element; The pipe, which leaves the furnace at a special angle and then passes through the rooms, will be able to transfer warm air. Thanks to this, overall efficiency indicators become higher, while at the same time fuel consumption is seriously reduced.

A heating system based on water fuel will provide the opportunity to install about 2 or 3 radiators in a country house or garage and provide them with heat. Such a device is characterized by simplicity in the manufacturing process, that is, a special water jacket is made in the chimney section, which has two high-quality pipes.

The circulation process present in the water circuit, which is mounted on the body of the stove chimney from a cylinder, will have to be adjusted in a forced manner. A household circulation pump is ideal for this purpose.

Method of connecting gas cylinders to a heating boiler

The gas pressure is reduced using a reducer.

The containers are connected using a special reducer that converts the gas from a standard form to a gaseous one. When connecting a stove or stove, you can use a single gearbox for all containers or a separate gearbox for each. The first option will be less expensive. Several containers are connected to one boiler at once to increase the time between refills; a ramp is used for this purpose.

The wall thickness of gas pipes cannot be less than 2 mm. In areas where they pass through the walls, the pipes are foamed after being placed in separate cases. The boiler is connected to the gas pipeline using a flexible connection. For the gearbox, you can use a sleeve made of rubber fabric or a durite hose.

Gas cylinders must be installed at a distance of at least 2 meters from the boiler in a separate room or in a special gas cabinet with insulation.

Features of heating devices from a gas cylinder, their pros and cons

A stove built from a propane or methane tank will always be more productive and economical than a rectangular metal one. This is due to the cylindrical shape of the cylinder and the configuration of the firebox.

A stove built from a gas cylinder can be used not only to heat a room, but also as a hob

Its spherical surface and height-to-diameter ratio promote pyrolysis combustion of solid fuel, and this is the key to thermal efficiency. Other advantages of gas storage vessels as the basis for a homemade stove are also known:

- For the manufacture of cylinders, high-quality steels with additions of alloying elements are used. They perfectly resist corrosion and have high heat-resistant properties - the metal will not burn out even after many years of use;

- the rigidity and strength of the heat generator are ensured by the mechanical strength of the gas vessel itself;

- the cost of a new household gas cylinder is less than 2 thousand rubles, and the old one will be obtained free of charge;

- converting a tank for propane-butane or methane into a full-fledged heat generator will require a minimum of effort and time;

- optimal shape and size;

- variety of designs;

- a cylindrical vessel is well suited for the manufacture of pyrolysis heat generators;

- the optimal surface area of the oven allows you to quickly warm up the room both due to convection and radiation.

The disadvantages of a stove made from a gas cylinder include:

- high surface temperature;

- increased requirements for device placement and compliance with safety precautions;

- the difficulty of adjusting the heating temperature due to the high inertia of the solid fuel combustion process;

- low heat storage capacity of the heating unit;

- painting gas cylinders with ordinary enamel, which burns out when heated, releasing caustic substances into the room that are unsafe for health.

Almost all negative aspects are eliminated by modernizing furnaces. Thus, to regulate the air supply to the combustion zone, thermostatic draft regulators are used, and to retain heat, the stoves are covered in brickwork or equipped with a water jacket.

Thermostatic draft regulator allows you to change the degree of opening of the blower depending on the thermal conditions of the furnace

Precautions and operating instructions

During heating, the stove becomes very hot.

Safe use of a potbelly stove

It is advisable to make a reflector, in addition, it will improve the distribution of hot air flows. To increase heat transfer, you can line the stove with stones or bricks. I recommend installing it on a foundation. Can be made from bricks and mortar. Flammable materials must be kept at a safe distance. The stove produces almost no ash, so you will have to clean it very rarely, using a scoop with a short handle. Over time, the metal of the case may burn out. It will have to be replaced with a new one.

Pyrolysis ovens can only be heated with wood (chips, sawdust). Liquid fuel will not provide a long burning effect. In addition, toxic substances are released into the air and pollute the atmosphere. Before lighting, remove the lid and remove the piston. Firewood is laid on top, then wood chips and paper are placed. Ignite through a pipe supplying air. Open the damper and throw lit paper or a rag inside (matches go out due to strong draft). When the wood burns well, close the air supply. The combustion process goes from top to bottom.

Video: how a DIY potbelly stove works

The task is simple - make a stove with your own hands. Determination in achieving goals and a little creative ingenuity. Follow the technology, show perseverance and the fruit of your labor will serve for many years, creating a warm atmosphere.

Self-assembly

Let's see how to make a potbelly stove from a gas cylinder. Our step-by-step instructions will tell you about all the stages of this simple process. First, you need to decide on the design - the gas cylinder in the design of the potbelly stove can be located vertically or horizontally. Here it all depends on the availability of free space, but the horizontal arrangement is still more convenient in terms of loading firewood of increased length (and ensuring long-term burning).

Regardless of how the body is located, the stove itself will consist of three parts:

- The main body - it is also the combustion chamber and a container for ash (the ash pan will be located in the lower part);

- Doors - through one, firewood is loaded, and through the second, coals and ash are removed;

- Chimney - combustion products are removed through it.

There will also be a grate inside.

A homemade long-burning stove made from a gas cylinder is a unit of increased volume. Therefore, you have to find the largest cylinder. If the volume is too small, you will have to constantly add more and more firewood.

All dimensions and indicators are given as an example. Depending on your needs, you can make the desired changes based on this drawing.

You can make a potbelly stove from a gas cylinder without a drawing - we will use the illustration given as an example. The ash pan door will have dimensions of 20x10 cm, the loading door will have dimensions of 30x20 cm. To cut these holes, use an angle grinder (grinder). Cut carefully, as the cut pieces of metal will serve as doors.

Next, carefully cut off the upper part where the faucet is located - this is where the chimney of our potbelly stove will come out. We weld a pipe with a diameter of 70-90 mm and a height of 10 cm here, after which we proceed to welding the grate. The grill itself can be made from pieces of metal or reinforcement. After that, we attach it inside the gas cylinder using welding.

Since you will be working in a confined space inside a gas cylinder, be sure to take safety precautions.

The next stage is preparing the legs. The easiest way for them is to choose a piece of thick reinforcement. We cut the reinforcement into pieces of suitable length and weld it to the bottom of our potbelly stove. Now we proceed to installing the doors - simple metal hinges are used for this. Try to weld the doors as carefully as possible to minimize the gaps between them and the body. If necessary, weld pieces of metal around the perimeter for maximum sealing.

Do not forget to weld metal locks to the doors of the potbelly stove from a gas cylinder - they will not be difficult to make yourself from sheet iron.

Refilling containers with gas

All cylinders are filled to 85% to prevent an explosion.

A gas stove for a building or bathhouse requires timely filling of containers with fuel. Tanks are not filled to more than 85% of the total volume, since gas can expand and break through the walls of the cylinders if they are filled in the cold and immediately brought into a warm room. Gas supplies can be replenished at gas stations or at independent points. Before selecting and pumping a substance, the container is placed on a scale in order to turn off the gas supply in time and prevent an increase in pressure.

Even if refueling is carried out according to the rules, the risk of overflow remains. Small cylinders of 5 liters fill up to 2 kg, large cylinders of 12 liters up to 6 kg. This amount will be enough to heat a house or bathhouse. The pumping occurs at high speed; if the critical level is exceeded, the excess must be pumped out immediately. It is better to refill cylinders in places where there are electronic scales with a cut-off device, which increases the level of safety.