Integrated approach - turnkey installation

We work honestly - contract and project

Our work is 20% cheaper than competitors

Fast delivery of heating without overpayments

We have been working since 2003, we have completed over 1000 houses

When building or renovating a residential building or premises, the question of proper installation of internal heating systems often arises. A modern heating system in a private house provides for the creation of the most favorable conditions for residents during the cold season with maximum conservation of natural resources and funds to pay for them. Therefore, it is better to entrust the installation of a heating system to professionals who have extensive experience in this field and use specialized equipment and tools.

Professional heating installation provides positive results for decades

The Teploservice-OVK company invites you to cooperate in resolving issues related to the installation of heating devices and the laying of internal communications. At the same time, the price for installing home heating will be significantly lower if you order a comprehensive package of services from us. The company's specialists are always ready to help in developing the most optimal heating system option for a private home, office, industrial or administrative building. The projects we bring to reality are a guarantee of reliable heating operation at your facility.

Estimate for 2 days. We will draw up a complete specification for the installation of the heating system and calculate the cost of the work. You will receive an estimate and consultation for FREE !

Heating project. We will provide the design of the heating system of your home with a detailed description of the dimensions and the engineering equipment used FREE OF CHARGE in case of heating installation by our company.

Engineer visit. Our specialist will visit your site on the day the order is received, or by prior agreement on the date. At the site you will receive a detailed consultation

Discounts and payment. All our clients purchase equipment from us without extra charges, cheaper than anywhere else! You can receive an additional discount depending on the volume of work and execution time. We accept payment only upon completion of work upon signing the Certificate of Completion

Types of water heating systems

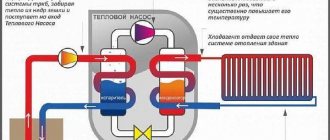

The type of heating system is determined by a combination of several factors. These include the circulation of the coolant, the method of assembling the system, the lower or upper option for laying the supply pipe, etc.

Regardless of the type of heating device, be it a traditional radiator, a baseboard convector or a “warm floor” coil, the heated water reaches them and, after cooling, leaves in the standard way for all systems.

Double-pipe and single-pipe designs

The final object of heat transfer is devices located in all heated rooms of the house. In many ways, the efficiency of heating depends on the pipeline installation scheme, so we will dwell in more detail on one- and two-pipe wiring.

The most common classification consists of two points:

- Single-pipe version - series connection of radiators. The bottom line is that the coolant entering the system sequentially flows from one device to another. On approaches to distant points, it has time to cool down significantly.

- Two-pipe version - a system with parallel connection of the supply and return pipes. Its principle is based on the fact that supply is carried out to all devices almost simultaneously. The cooled water does not flow into the next device, but is collected by the return line and moved to the boiler.

Single-pipe schemes come with both natural and forced water movement. Within their class, they are divided into two types: flow-through and with bypasses.

In flow-through circuits, the coolant, upon reaching the outermost radiator, has time to cool down greatly, so in distant rooms it is recommended to install devices with an increased number of sections.

Image gallery

Photo from

Specifics of single-pipe type

Pros and cons of a single-pipe scheme

The principle of a two-pipe heating circuit

Pros and cons of a two-pipe system

The introduction of a bypass into the system makes it possible to partially redirect the hot coolant to the following devices, due to which almost all batteries receive and give off almost equal amounts of heat. The movement of heated water is regulated either by two valves installed on the bypass and supply pipe, or by one three-way valve.

The main difference between two-pipe structures is the use of two branches: supply and return. The first serves to supply hot coolant to the radiators, the second - to drain water back to the boiler.

Single-pipe assembly requires rapid cooling of the coolant, so wiring of this type is recommended for installation in country cottages with a small area or in country houses (+)

The two-pipe wiring diagram is used in systems with both types of coolant movement. Depending on the number of processed circuits, it can be single- or double-circuit.

In the first case, the boiler is installed at the beginning of the pipeline, and the pipes are routed to the left and right of the unit along the perimeter of the heated object. In the second case, the boiler is installed in the center, and the heating circuits are positioned so that their rings are on both sides of the unit.

The 2-pipe system is more functional and reliable, allowing heat to be evenly distributed throughout all rooms. Thanks to additional taps and adjustment devices, you can control the heat supply to each individual radiator. If one element fails, the performance of the remaining devices will not be affected.

The design of a two-pipe system will ensure an almost simultaneous supply of heated water to the appliances. The cooled coolant is drained through the return pipe (+)

Variations in connecting pipes and devices

All of the listed types of water heating for arranging a country cottage are divided into subtypes:

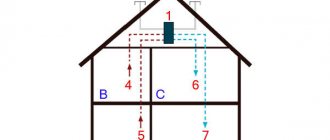

- According to the location of risers connecting heating appliances. They are divided into horizontal and vertical. It is clear that the former are used in one-story buildings, the latter in multi-story buildings. Single-pipe systems with natural movement have only supply risers.

- According to the location of the supply and return pipes. They come with top or bottom wiring. The first provide for routing the supply at the highest points of the system, due to which the coolant enters the devices from above. According to the second situation, the return and supply lines are laid below the radiators.

Gravity systems with bottom wiring are used extremely rarely due to difficulties with air removal in long-distance devices. Bottom wiring is better combined with pump circulation, each device of which is still equipped with an air vent.

Vertical heating systems are constructed with upper and lower wiring. It is clear from the diagram that they are used for furnishing houses with two or more floors

Heating with overhead wiring is installed in cottages without basements, but with an attic. Occasionally, in the absence of an attic, the supply is laid along the line where the ceiling meets the walls, which negatively affects the interior picture. Bottom wiring is suitable for houses with a flat roofless roof, but with a basement.

In systems with horizontal wiring there are no or a minimal number of vertical risers

Pipeline assembly method

Classification according to the method of pipeline construction divides heating systems into tee, manifold and combined.

Tee circuits can easily be considered a classic of the genre. They involve assembling pipelines and connecting devices to them using tees used in the nodes connecting pipes to risers, radiators to pipes, etc. In principle this is a sequential circuit.

Image gallery

Photo from

Tee assembly diagram

Perimeter version of the structure

Collectron type heating assembly

Combined device version

The collector or otherwise radial design increases the possibilities of water heating of the cottage. This is a kind of modified system with separate pipeline branches (beams) extended to each device and with a distribution element in the center.

The distribution unit - the manifold is equipped with many outlets, thanks to which you can control the heat transfer of each device separately and turn it off for repairs. If desired and financially possible, each outlet can be equipped with its own pumping device.

The main advantage of the collector is the ability to control and regulate heating processes in individual rooms of the entire building from one “control point”

Manifold wiring is arranged mainly for horizontal circuits with a lower supply pipe. When installing in 2- and 3-story buildings, it is recommended to install a distribution manifold on each floor - this way you can regulate the air temperature in any corner of the building.

The control unit for cottages with several floors consists of two interconnected units: a supply manifold and an analogue for the return. The first is responsible for the delivery of hot coolant to the devices, the second stimulates the removal of cooled liquid.

You can connect not only a radiator structure to the collector-distribution device, but also a “warm floor”, hot water supply, as well as a plinth (panel) system (+)

Manifold wiring is arranged on the basis of one- and two-pipe heating systems and is used in combination with a perimeter (tee).

Features of baseboard heating

Radiators or batteries in the traditional sense are not the only heating devices for creating a comfortable microclimate in individual rooms. Not so long ago, “warm baseboards” appeared - heating elements, in their shape and location reminiscent of construction analogues of the same name.

The design of a baseboard heater is simple: inside there are elements reminiscent of radiators with copper tubes, outside there is a durable solid metal box that gives off heat well

The operating principle of the device located around the perimeter helps maintain the set temperature constantly. First, the tubes inside the housing are heated, then the box, from which warm air rises, increasing the temperature of the walls.

Thus, the air in the room is heated directly from the baseboards and from all the walls along which they are located.

A rational step is to use warm skirting boards in places that directly border on cold air from the street: on terraces, verandas and balconies

Advantages of baseboard heating:

- creating a comfortable microclimate that excludes active air circulation;

- the possibility of insulating risk zones at the junctions of floors and walls, where mold often appears;

- simple installation that can be performed without the involvement of specialists;

- selection of modules by type (single- and double-row) and power (for example, 310 W and 510 W);

- various designs that do not require camouflage;

- affordable price.

The disadvantages include special location conditions: furniture cannot be placed along horizontal elements, as this will harm the heat transfer process. Each circuit included in the system should not be longer than 15 meters, so for a large room it is necessary to install 2 or 3 circuits (combined heating is an option).

For baseboards, the same coolant is used as for radiators - water or antifreeze in an amount of approximately 330-350 g/m. Normal temperature is from +45ºС to +80ºС, in some versions heating up to +110ºС is allowed

In addition to water baseboards, electric ones are used, but their maintenance is too expensive for a private home.

Equipment for the "Warm Floor" system

An effective and inexpensive design called underfloor heating, which heats the room from the floor side, has long proven itself only from the best side. It is actively used in city apartments to create a comfortable atmosphere in bathrooms, toilets, bedrooms, kitchens and loggias.

Diagram of a heated floor: a flexible tube of small diameter through which heated coolant circulates is part of an adjustable heating system

The pipeline must have high thermal conductivity, strength, elasticity, and minimal resistance, so metal-plastic or cross-linked polyethylene is used for its manufacture. The protective and stabilizing coating is a cement screed.

Advantages of heated floors:

- effective on any type of flooring (laminate, linoleum, carpet, ceramic tile);

- noticeable heat savings - from 30% to 50%;

- inexpensive cost and installation;

- possibility of DIY installation;

- use in combined heating systems (along with radiators and convectors).

Autonomous water heating does not depend on the supply of electrical energy, as it is powered by a gas (or other) boiler.

Option of a combined heating system (warm floor + panel radiators) with an extensive temperature control and regulation system using sensors and thermostats

The disadvantages of water heated floors include imperfect adjustment and the impossibility of installation in the city with centralized heating, but this does not apply to local country systems. If installation rules are violated, an emergency situation and flooding may occur, so you should carefully consider both the choice of equipment and installation.

PROFESSIONAL SOLUTION TO THE PROBLEM

Our company provides a wide range of services for the installation of heating systems at home, cottage, apartment or office at competitive prices. We offer our clients professional installation of the following elements:

- gas, solid fuel, electric and diesel boilers;

- heating radiators;

- heated floor;

- boilers of various capacities.

Heating installation is carried out by our craftsmen in stages, which ensures reliable and safe operation of heating equipment and laid communications for a long time. During installation, strict compliance with all regulations of the facility and the requirements of project documentation is necessary.

Liquid fuel boilers

In terms of the cost of heating equipment and its installation, heating with waste oil or diesel fuel will cost approximately the same as with natural gas. Their efficiency indicators are also similar, although the processing, for obvious reasons, is somewhat inferior. Another thing is that this type of heating can easily be called the dirtiest. Any visit to the boiler room will end with at least the smell of diesel fuel or dirty hands. And the annual cleaning of the unit is a whole event, after which you will be smeared with soot up to your waist.

Using diesel fuel for heating is not the most profitable solution; the price of fuel can hit your pocket hard. Used oil has also risen in price, unless you have some cheap source. This means that it makes sense to install a diesel boiler when there are no other energy sources or, in the future, a main gas supply. The unit easily switches from diesel fuel to gas, but the exhaust furnace will not be able to burn methane.

WE ARE THE OFFICIAL INSTALLATION SERVICE

Laying methods

This procedure can be carried out in several ways:

- closed;

- open.

It is worth noting that the closed method is not only characterized by increased labor intensity, but also makes it possible to save space in the room. This is very relevant when it comes to small bathrooms.

At the same time, we can immediately note the main disadvantages of the closed method:

- inability to conduct a preventive inspection of pipes to examine their condition;

- the need to break down walls in order to carry out repairs in the event of a leak and, as a result, the need for further repairs.

As for the open method, its only drawback is the reduction of free space in the room, as well as changes in its appearance.

But the advantages include:

- low labor intensity of installation, which has a positive effect on the speed of its implementation;

- the ability to see a leak in time and eliminate it;

- ease of repairs on any site;

- the ability to improve the system while using it.

WHAT IS INCLUDED IN THE WORK

Complete installation of a home heating system involves searching for the most successful configuration of heating communications, including the boiler, in order to make the most efficient use of thermal power and reduce heat loss.

Equipment installation includes the following activities:

- selection and installation of a heating boiler and corresponding radiators;

- installation of a security system - if the boiler does not have a built-in one;

- installation of an expansion tank;

- laying main pipelines, including risers;

- installation of shut-off valves;

- if necessary, connect a voltage stabilizer;

- checking all components of the installed system for leaks;

- starting and adjusting heating equipment.

Hidden pipe routing and floor insulation

If we take aesthetics into account, then the heating pipes hidden in the floor are very useful. Please remember that you must have access to the installation connections at any time. What if there is a breakthrough somewhere.

This is why the floor must be done carefully. In cases where there is absolutely no need to insulate the floor, and the rough covering itself is laid on the joists, then heating pipes can be routed between the joists. Access to the pipes must be precisely at the points of their connections, which may subsequently, if installed poorly, leak.

If you need to insulate the floor and would like to hide the heating pipes, then the best option would be an additional foam concrete screed. To do this you need to take some actions:

- We lay all heating pipes carefully.

- We fill the floor with additional foam concrete screed. Where the pipe connections go, we make a small inspection well. We wait until the screed has completely hardened.

- Once the screed has hardened, you can lay a subfloor of plywood, in which holes are cut at the places where the heating installation connections are made.

- We lay a finishing flooring on top, for example, marmoleum, in which it is also necessary to cut out hatches so that there is access to the heating installation connections.

If you are hospitable and often have company over in the evenings, then it is advisable to lay the subfloor from tongue-and-groove plywood. It will be much stronger, but at the same time a little more expensive than ordinary plywood sheets.

MAIN INSTALLATION STEPS

To ensure that the installation of an internal heating system leads to the proper use of heat resources, the company’s specialists adhere to the following sequence of stages in the production processes:

- selection of the most effective equipment for a specific room volume;

- preliminary calculation of the order of installation of heating components;

- installation of boiler installations and communications;

- assembly of all elements into a single system;

- commissioning works;

- testing of installed nodes.

Installing a heating system and putting it into operation is a labor-intensive process that requires compliance with all technical rules, so it is better to entrust this procedure to professionals.

Boiler installation instructions

Strict requirements are put forward only for the installation of gas-powered heaters. But we recommend following these rules when installing any heat generators:

- Equipment with a power of up to 60 kW can be placed in a kitchen with ceilings of 2.5 m (minimum). More powerful units are moved to a technical room - internal, attached or free-standing.

- The requirement for furnace ventilation is threefold air exchange, that is, the amount of supply and exhaust air is equal to three volumes of the room in 1 hour. The kitchen window is equipped with a window.

- When placing a floor-standing boiler, observe the minimum technological passages - 1.25 m in front, 60 cm on the side, 250 mm in the back from the nearest building structure, as shown in the photo.

- The distances from the wall-mounted heat generator to the walls or cabinets are 20 cm on the side, 45 cm on the top, 300 mm on the bottom. Before hanging, a protective sheet of roofing steel is laid on the wooden wall.

- The height of the chimney is 5 m, calculated from the grate or gas burner, not from the ground. The head of the pipe should not fall into the wind support zone of the roof.

- The maximum number of turns of the chimney is 3, the distance from the chimney to combustible structures is 0.5 m.

The heat generator piping depends on the fuel consumed. High efficiency boilers - gas, diesel - are connected to the system directly through shut-off valves. Floor-standing versions are additionally equipped with an external expansion tank and pump.

Typical wiring diagram for a double-circuit wall-mounted heat generator

Solid fuel units must be protected from cold return flow and condensation; accordingly, a small boiler circuit with a three-way mixing valve is provided

Please note: the pump is always installed inside the circuit, on the supply or return line - it makes no difference. Detailed wiring diagrams are shown in the instructions for connecting TT boilers

Watch this video on YouTube

OUR PRICES

| Visit of the master | For free |

| Drawing up specifications and selection of equipment | For free |

| Radiator installation | from 2500 |

| Pipeline laying | from 100 |

| Boiler installation | from 9900 |

| Installation of heated floors | from 350 |

| Installation of distribution manifold | from 2100 |

| Installation of the pump group | from 2500 |

For any advice on installation of a heating system or selection of equipment, as well as any technical questions, please contact us. We will draw up a technical thermal calculation and equipment specification for your home with minimal costs for heating and water supply.

The customer service works around the clock 24 hours a day!

Stop heating the street!

Whether the radiators will be changed during the heating reconstruction process or not, but since they will still have to be removed for some time, it is highly advisable to cut off the outflow of heat to the outside. To do this, you need to cover the wall behind the batteries with heat-insulating mats aluminized on both sides. How such a bedding works in terms of heat can be read in the article on floor insulation; here it is enough to note that in a block Khrushchev house with radiators in niches, double heat shields behind the radiators are equivalent to covering the walls with 20 mm plywood.

In an alternative option for insulating the wall behind the radiator, heat-insulating material (1) and aluminum foil (2) are used separately.

Installing the shielding mat is simple: we cut holes in it for the hooks of the battery suspension, apply thin “sausages” of construction silicone or mounting adhesive using an “envelope” to the side adjacent to the wall, put it on the hooks and press it to the wall.

An indispensable condition: the mat must be organic, made of synthetic or natural fibers. The use of open mineral wool mats in residential premises is unacceptable - it is harmful to health.

OUR WORK:

- Heating installation

- Home heating installation

- Installation of heating systems

- Installation of a home heating system

- Heating recommendations

- Apartment heating

- Heating installation in Moscow

- Heating installation in Kaluga

- Heating installation in St. Petersburg

- Heating flushing

Choosing equipment for heating a private house

In places where there are interruptions in the supply of the main type of fuel, it is recommended to install universal heating boilers.

There is a huge range of boilers on the market. There are even hybrid boilers that can operate, for example, on both gas and wood. So, the choice depends purely on your preferences and needs. Of course, boilers with a full range of automation and hybrids will be more expensive. The former will more than pay for themselves with their high efficiency, and the latter – with their versatility.

It is impossible to recommend a specific model, since different devices have different power. Choose the device that is most suitable for your conditions, but try to select the boiler so that its operation is not costly. If you use wood, it is better to choose a wood-burning model. If gas is supplied, then use the gas model.