In order not to freeze in your home in winter, you will have to heat it using various types of fuel. Since conventional stoves are considered a relic of the past, houses are heated using gas or another type of fuel, but using a more advanced heating scheme. Installation of such heating equipment requires a separate room. Such a room is called a furnace room, boiler room, but most often a boiler room. There are certain requirements for this kind of premises, since any type of fuel is considered dangerous. Therefore, it is necessary to ensure the safest possible operation of the boiler room.

Regulations

To install boiler equipment in a private home, you must rely on a number of rules. Until mid-2003, some standards were in force, and from mid-2003 other standards began to apply (SNiP 42-01-2002), so this document should be followed.

A boiler room in a private house must meet a lot of requirements

It is advisable to familiarize yourself with these standards, although specialized organizations are involved in design documentation. After reading the documents, you can decide in advance what equipment can be installed and what cannot be installed in a private home. In this case, you can also decide what preparatory work will have to be done so that the equipment can be installed without delaying the entire process. If any difficulties arise, you must contact the design department for help, since they know exactly all the intricacies of installing this type of equipment, depending on the specific plan of the residential building.

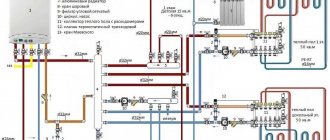

Scheme with hydraulic arrow

The water arrow in the boiler room circuits of the house prevents the occurrence of thermal shock. The essence of its action is to separate and link several circuits.

Carrying out one-time operation of heating, hot water supply, heated floors involves an unstable load and variability of the thermo-hydraulic properties (temperature, pressure drops) of the networks. The heat supply source does not tolerate instability well, so a hydraulic arrow is installed between it and the consumer branches.

The main function of the device is to set the coolant in the desired direction automatically in order to avoid thermal shock.

Installing a gas boiler in a private house: installation rules

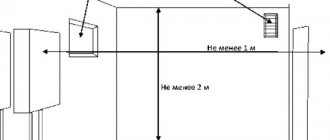

Option for installing a wall-mounted gas boiler - at least 10 cm to the wall.

To choose a place to install a gas boiler, you need to take into account the power of the boiler.

So:

- If the boiler power is no more than 60 kW, then it is permissible to install it in the kitchen, but subject to certain rules.

- If its power exceeds 60 kW, but does not exceed 150 kW, then the boiler must be placed in a separate room, regardless of what floor it is on.

- When the boiler power ranges from 150 kW to 350 kW, it is installed in a separate room located on the first or ground floor, in an extension or in a separate building.

Naturally, this does not mean at all that boilers with a power of less than 60 kW are not allowed to be located in a separate room. Sometimes it is even necessary, since all life support elements are located in one place that is quite convenient for maintenance. Despite this, you will have to take into account the size of this room. The dimensions of the room, depending on the power of the boilers, must meet the following parameters:

- Boilers with a power of up to 30 kW are installed in rooms with a volume of at least 7.5 cubic meters.

- For boilers with a power from 30 to 60 kW, the volume of the room should not be less than 13.5 cubic meters.

- Boilers with a power of 60 to 200 kW must operate in rooms with a volume of at least 15 cubic meters.

It should be noted that this does not mean the area of the room, but its volume. If the boiler is planned to be installed in the kitchen, then there are completely different requirements - the volume of the kitchen is at least 15 cubic meters, and the ceilings should be located at a height of 2 and a half meters.

There are also general requirements for the premises in which heating equipment is planned to be located.

So:

- Regardless of the nature of the boiler room, it must have electric lighting. The area of the windows should be 1 m. cubic not less than 0.03 m. square glazing. Again, not the area of windows with frames, but purely the area of glass. In this case, the windows must open outward.

- The window should have a window or transom.

- Ventilation is provided, as well as disposal of combustion products through the installation of a chimney. Low-power boilers (up to 30 kW) can be equipped with a chimney that passes through the wall.

- It is also necessary to provide for the availability of water and sewerage.

Recent regulatory documents are characterized by the presence of one more general rule. If the boiler power is over 60 kW and there is a hot water circuit, it will be necessary to install a gas level sensor that turns off the gas supply automatically if the level of harmful gases in the room is exceeded.

If there is a boiler and a heating boiler, when determining the size of the boiler room, their power is summed up

Requirements may differ significantly depending on the type of boiler room and the equipment installed in it.

✅ Boiler room in a private house of 180 sq.m. And a warm water floor. // Sasha Bagot

Boiler room location

First, let's look at the definitions. A boiler room means a technical room with a whole range of special equipment, which is designed to organize hot water supply in the house. In parallel, the same complex is responsible for heating. That is why, taking into account its multifunctionality, it is more appropriate to call the room a boiler room, although both names are common in everyday life. There are three variations in the location of the boiler room.

- The first is inside the house: in the basement or basement, or in a remote room on the first floor.

- The second is in a special extension: the boiler room is built close to the house, mainly from the bathroom side.

For the boiler room you need to allocate a separate room

- The third is in a separate building: the heating system is installed in a separate building, which is connected to the main house via communications.

Advice. The recommended option for locating the boiler room is in a separate building: due to the remoteness of technical equipment from living rooms, households are provided with maximum safety and comfort.

Boiler room in a private house in a separate room

A separate room is required when the boiler power is more than 60 kW, but does not exceed 200 kW, and this room must be equipped with a fire-resistant partition with a fire resistance level of about 45 minutes. Brick, cinder block and lightweight concrete fall under similar characteristics, not to mention heavy concrete.

It is not the area of the boiler room that is standardized, but its volume; the minimum ceiling height is also set

It should be recalled what requirements apply to such premises:

- The volume of the room is at least 15 cubic meters.

- The ceiling height is at least 2.5 meters with a power of up to 30 kW and from 2.2 meters with a lower boiler power.

- The presence of a window with a transom, as well as a glazing area of at least 0.03 square meters per cubic meter. volume meter.

- Ventilation should exchange air three times within an hour.

If the boiler room is located on the ground floor or in the basement, the requirements are more stringent, and for every one kilowatt of power you will have to add 0.2 cubic meters, taking into account the mandatory 15 cubic meters. The walls must also be made of materials that do not allow gas and steam to pass through. If you plan to install equipment with a power of 150 to 350 kW, you will have to provide the boiler room with a separate exit to the street. It is acceptable for the exit to be connected to a corridor that leads to the street.

As a rule, premises for arranging a boiler room in a residential building are selected with a focus on ease of maintenance, so they significantly exceed all requirements.

Attached boiler rooms: requirements

The previous requirements, plus some new ones, apply to such premises.

The extension is made of non-combustible building material

So:

- A room is built on a solid section of the wall so that the distance to the nearest windows and doors is at least 1 meter.

- For construction, non-combustible material is used, in the form of brick, cinder block or concrete.

- The walls of the extension are not connected to the walls of the residential building. In other words, the extension will have to be provided with a separate foundation, as well as four walls.

What nuance still needs to be paid attention to? If the boiler room is attached to an already built house, but there is no suitable room and the ceiling height does not allow the installation of boiler equipment, then the organization will help solve this problem by requiring an increase in the glazing area. If the house is just being built, then you will have to meet all the standards, otherwise the project will not be approved in any case. The requirements for attached boiler rooms are extremely stringent, so you will have to maintain all the characteristics.

Application of finishing materials

A few simple tips will help you avoid problems when operating your equipment:

- Thermal insulation components are used for gluing the perimeter of walls. To ensure the presence of air gaps, bars are installed. PVC panels are subsequently attached to these elements.

- Many developers prefer to leave the cement floor. But laying porcelain tiles helps maintain cleanliness.

- Arrangement of continuous operation of a double-circuit boiler requires the presence of a hot water outlet to the house and a cold water supply to the equipment.

Compliance with all rules and requirements contributes to the serviceability of any unit and ensures the safe residence of the owners.

You can ask your question to our author:

Installing a gas boiler in the kitchen: room requirements

In the kitchen it is permissible to place gas boilers with a power of up to 30 kW and which are equipped with a combustion chamber of any design, with the boiler located both on the floor and on the wall.

The requirements for installing a gas boiler in the kitchen mostly relate to volume and ventilation

The following requirements apply to the premises:

- Ceiling height is within 2.5 meters.

- The volume of the room is not less than 15 cubic meters.

- Effective ventilation system.

- Availability of fresh ventilation.

When hanging boilers on walls, the latter must be constructed of fire-resistant materials. The distance to the side walls should be at least 0.1 meters. In the absence of such walls, installation of boilers is allowed, provided that there is a non-flammable gap of 5 cm between the flammable walls and the boiler itself. This could be a layer of plaster or a non-flammable screen made of fire-resistant material.

The screen can be made of sheet steel; the dimensions of the sheet should be 0.7 meters larger in height and 0.1 meters larger on all other sides, compared to the dimensions of the boiler itself. Between the sheet steel and the combustible base, a layer of fire-resistant material, about 3 cm thick, is laid. This may be asbestos or other fire-resistant material.

Start of installation work

First of all, you should install a grounding loop, which is required by the rules of regulatory documentation. The most popular and simplest method is the use of 4 metal pipes. They are evenly located along the entire perimeter of the structure. To connect the pipes to each other, they are tied with corners and then welded. The connection to the house is carried out with 12 mm rods.

It is prohibited to attach load-bearing walls of a building to existing ones. The extension to the house is made with separate independent structural elements. During the construction process, the installation of an input sleeve is provided if the use of gas is planned for fuel. Any pipe stump with dimensions of 100x100 mm is secured in the wall with expanded clay concrete.

Next, you should arrange a sewer drain. It is intended for the process of emptying the system during preventive and repair measures. A pit (hole) is made on the floor surface to a depth of 0.5 meters.

To ensure the supply of fresh air through the hood, a hole of appropriate size is made. With natural air supply from the street, the window area parameters must meet the following requirements - for 1 kW of power at least 8 sq. cm, and when connecting from adjacent rooms - 30 sq. cm per unit power. A ban on installing forced ventilation applies to gas boiler houses, which must be insulated.

The interior space is equipped with lighting with the following characteristics - for 1 cubic meter. m of volume accounts for at least 0.03 sq. m glass.

Free-standing combustion chambers: requirements

A separate boiler room can be like this.

A separate room for arranging a boiler room will be required if the boiler power is more than 200 kW. Such buildings must have the following parameters:

- The construction is made entirely of non-combustible materials.

- The volume of the room is at least 15 cubic meters with the addition of 0.2 cubic meters per kilowatt of power.

- The ceiling location is not lower than 2.5 meters from the floor level.

- The glazing area is not less than 0.03 square meters per cubic meter of volume.

- The window is equipped with a window or transom.

- The boiler is mounted on a separate foundation, the height of which is no more than 15 cm compared to the height of the floor.

- If the boiler weighs no more than 200 kilograms, then it can be installed directly on the floor if it is concrete.

- The heating system must include an emergency gas shut-off sensor.

- Doors should not be reinforced; they should be loosely secured.

- Availability of an effective ventilation system.

Permission to put heating equipment into operation will be issued only if all requirements are met.

Choosing doors to the boiler room

If the boiler room is located inside a residential building, then the doors to this room must be made of fire-resistant material that can withstand fire for 15 minutes. As a rule, these conditions correspond to doors made of metal, and they can be either factory-made or home-made.

If the furnace room is equipped with doors facing the street, then they should be loosely secured. This will allow, in the event of a gas explosion, to protect the boiler room from destruction by the blast wave, which will soften its blow after the doors with the frame are pushed out onto the street. The advantage of such doors is that gas can freely exit the boiler room.

In projects you can find an additional condition, which refers to the presence of a grille at the bottom of the door that covers the through hole. This hole will allow fresh air to flow freely into the boiler room.

Ventilation arrangement in the boiler room

Ventilation in the boiler room should be so effective that it can provide three times the air exchange in one hour. To determine the performance of ventilation equipment for a specific room, you need to take the volume of this room and multiply by three, and then add a 30 percent margin.

For example, if you take a boiler room with dimensions of 3.5x3.5x2.5 meters, you will get a volume equal to 30.625 cubic meters. If this result is multiplied by 3, the volume will be 91.875 cubic meters. If we add a 30 percent reserve to this result, we get a volume equal to 119.4375 cubic meters. In other words, ventilation should renew about 120 cubic meters of air in the room every hour.

For ventilation to really work effectively, it is necessary to install supply ventilation with a grille in the wall, closer to the floor. The exhaust pipe can also be run through the roof or through the wall closer to the ceiling. The outlet of the ventilation pipe must be located at the same level as the outlet of the chimney.

Installation of solid and liquid fuel boilers: requirements

Liquid fuel boilers usually operate noisily.

Basically, the rules for arranging premises are the same regardless of what type of fuel they operate on. Despite this fact, there are a number of separate requirements in terms of arranging a chimney, as well as arranging a place for storing fuel. As a rule, the requirements are mentioned in the passport, and they boil down to the following:

- The working thickness of the chimney should not be less than the dimensions of the outlet pipe, and over its entire length.

- The chimney design should have the smallest number of bends, and it should be straight.

- At the bottom of the wall it is necessary to equip a hole for fresh air ventilation, at the rate of 8 cm square per kilowatt of power.

- Combustion products can be discharged either through the roof or through the wall.

- Below the chimney level, a special cleaning hole should be located to facilitate the inspection and maintenance process.

- The chimney is mounted from non-flammable and gas-tight material.

- The boiler should be installed on a non-combustible base, especially if the floors in the room are wooden. First, asbestos is laid on the floor, then sheet metal, and only then the boiler.

- If the boiler is coal-fired, then additional requirements are imposed on it, since coal dust is considered explosive.

You should also pay attention to the fact that the chimney can be exhausted both through the roof and through the wall using a non-combustible passage unit.

Here we should mention boilers running on liquid fuel. Their functioning is associated with a number of disadvantages that must be taken into account. Firstly, they make a lot of noise, and secondly, they give off a specific smell of flammable material. Naturally, such a boiler can hardly be installed in the kitchen, and in residential premises (as well as in non-residential ones, but within the house), it simply does not make any sense. For such boilers it is necessary to provide separate rooms. That is why such boilers are practically not used for heating residential buildings (private buildings).