- Functions of devices used for piping a gas boiler

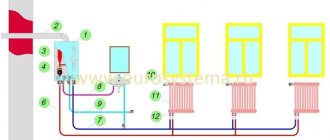

Two-pipe heating scheme for a house with a hydraulic arrow and collectors, designed for the ground floor and 1st floor

How does an open heating system work?

There is no need to install a pump to start the system. The coolants are constantly in a closed system, so there are no losses. Installation of the heating system is so simple that it does not require special skills.

Open heating system

What are the main parts of the system?

- Gas or solid fuel boiler. The consumer can choose the best option that meets the desired requirements;

- Heating radiators. You can make your choice in favor of either cast iron or steel;

- Expansion tank made of steel;

- Pipes.

How does an open heating system work?

The first step is to heat the water in the boiler. Hot water then flows under pressure into the pipes and reaches the low pressure zone. After the hot water makes a complete whirlpool and gives off heat, it returns to the starting point - the boiler. Due to the fact that water expands under the influence of high temperatures, an expansion tank is required in the system. It acts as a compensator for excess water volume. The tank is an object that is not sealed hermetically. To make it easier to start the heating system, it is necessary to install a mortise tap. With its help, air is removed from the system. The operating principle of an open heating system is divided into two stages:

- "Innings". The water is heated, flows through pipes into radiators and heats the room;

- "Treatment". The cooled water from the radiators is returned through the pipes to the boiler.

Features of the arrangement of an open heating system:

Be sure to place the expansion tank above the level of other heating system devices;

Choose water rather than antifreeze as the coolant; Since water can evaporate when heated, it is important to monitor its level in the boiler and replenish reserves in a timely manner.

Stages of gas heating installation

Selecting and installing a heating system is a multi-stage process. It includes:

- system design - calculating heat losses, choosing a circuit, wiring;

- preparation of equipment - the actual selection of radiators, pipes, boiler, as well as preparation for installation: For example, if autonomous gas equipment needs to be placed in the house, then you will need to build an extension;

- installation of a heating system - installation of radiators and pipes;

- installation and connection of a gas boiler;

- checking and configuring the system.

The last stage involves registering a gas meter and an operating permit from the gas company.

Drafting

The starting point for the project is heat loss calculations. Ideally, this is done using special equipment - thermal imagers. But you can do without them. On average, a house loses 10–15% of heat through the walls, up to 15% through the basement, and up to 30% through the roof. This depends on the level of insulation, the material of walls and roofs, and the design of the building.

On average, it takes 1 kW to heat 10 m² of housing with a ceiling height of no more than 2.5 m. That is, to heat a building with an area of 250 m², a boiler with a capacity of at least 25 kW will be required. It will consume 2.5*24=2.5 m³ of gas per day. This will amount to 1800 cubic meters per month. m. Taking into account the weather in the region, the result is multiplied by the corresponding number of cold months.

Calculate approximately, only to establish some maximum limits. They serve as the basis of the project along with the features of the building.

Design includes:

- dividing the house into zones and determining the required temperature conditions in each of them;

- calculation of the heating network by zones or rooms;

- calculation of the number of sections for heating the zone;

- selection of heating type - wiring, installation diagram;

- calculation of boiler power, equipment and materials.

Valera

The voice of the construction guru

Ask a Question

Power largely depends on the material of the heat exchanger in the boiler itself and the material of the radiators. Bimetallic successfully transfers heat to the room at a water temperature of +35°C. The cast iron battery begins to heat up at a coolant temperature of at least +50°C.

Equipment preparation

Radiators, pipes, and boiler are selected based on the requirements of the project.

- Pipes – for heating, metal-plastic ones are considered the best option. They can withstand high heat, are durable and have a lower coefficient of thermal expansion. This makes installation much easier. It is also possible to take polyethylene ones.

- Radiator - They produce a variety of options. Aluminum batteries heat up very quickly even at low coolant temperatures, are resistant to corrosion and are beautiful. However, the material is soft and cannot withstand water hammer. Cast iron, on the contrary, is resistant to pressure changes and gives off heat for a long time, but it is very heavy and takes a long time to heat up. Bimetallic radiators heat up quickly, retain heat for quite a long time, but are more expensive and not as durable.

- Boiler – its main characteristic is power. You need to buy a boiler with a power reserve of 15%, no less. It is worth considering that if the house is large, and even three-story, you should not install a double-circuit one. Even with high power it will be ineffective.

The rest of the equipment - taps, regulators, fittings - is selected according to the material of the pipes and batteries.

Installation and connection of equipment

Only specialists install gas equipment and connect it to the main line. But some of the related work can be done with your own hands.

- First of all, a room is equipped : at least part of it is finished with fireproof materials, and ventilation is equipped.

- Install the boiler , connect the circulation pump and manifold, if required. Connect the device to the chimney.

- Install all necessary control sensors and regulators .

- Laying pipes . Heating pipes can only be mounted on the wall using brackets. They must be placed at a slope of 5 mm per linear meter.

- Radiators are installed - also on brackets.

- The heating system is filled with water and its operation is checked.

Then the gas boiler . An employee sets up the system, seals the device and the meter.

System testing and technology verification

Pressure testing is carried out after connecting the gas boiler. The algorithm is as follows.

- Fill the system with water slowly to reduce the amount of air in the radiators as much as possible. As soon as the pressure gauge reaches the desired value, the water supply is stopped.

- There is an air vent in the battery connection. If the valve is automatic, air release is performed without human intervention. If there is a Mayevsky tap, you need to manually bleed air from each battery until a stream of water appears.

- Turn on the boiler - set the switch to zero, turn on the gas supply. Follow the instructions, since the activation procedure is different in different models.

- Before starting, you need to bleed the air in the circulation pump . To do this, remove the panel on the device, unscrew the central bolt and turn it in the direction of the arrow. Then pull the air vent cap and release the air. The latter interferes with the rotation of the blades.

During work, you need to monitor the pressure gauge: the pressure must be within normal limits.

Schemes for water heating in a private house

To heat cottages, heating systems with water as a coolant are installed, consisting of:

- water heating boiler (single-circuit or double-circuit);

- pipelines and fittings (metal or polypropylene);

- bypasses that allow you to disconnect individual heaters from the network;

- batteries (cast iron, aluminum, steel and bimetallic);

- expansion tank.

Gas heating units are equipped with a specific safety system, including a solenoid valve and a thermocouple. The devices are connected to each other by wires. If the heating unit is functioning normally, the thermocouple junction is heated by the igniter. At this time, current flows freely through the winding of the solenoid valve, which ensures the open position of the valve. When the thermocouple cools down, the gas access is blocked by an electromagnetic valve.

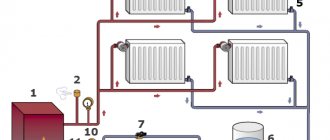

According to the battery connection diagram, they are single-pipe and double-pipe. In the first case, water is supplied and discharged from the radiator using one pipe. In the second, the heating device is connected to two separate pipelines (supply and return).

Heating pipes to the radiators can be connected in a bottom, top, side or diagonal pattern

Heating circuits, based on the principle of water movement in pipes, are available with forced and natural circulation. When installing the second option, the coolant circulates in the system due to convection and gravity. And the forced scheme involves the installation of a circulation pump.

To ensure normal operation of a system with two or more circuits connected to the manifold, it provides for the installation of a hydraulic arrow. The hydraulic arrow eliminates pressure drops and the possibility of water hammer.

The expansion tank can be open or closed (divided inside into two parts by a sealed membrane). For gravity heating systems, an open option will be sufficient. A closed tank is designed for forced circulation circuits.

When using an open expansion tank, the water is saturated with air, so that this does not become a problem, the system should be supplemented with an air removal circuit

For small cottages, the natural principle of water movement will be sufficient. However, if a residential building has two or three floors, then you cannot do without a pump. The length of the circulation circuit in the first scheme is limited to 30 meters. The boiler will not be able to “push” water over a greater distance.

With natural circulation of the coolant in the gas heating circuit of a private house, there is no pump. If the boiler is chosen to be non-volatile, then the entire heating system is independent of the power supply. There are simply no elements that consume electricity.

On the one hand, it is more stable in operation, but on the other, the quality of heating in it is lower (the water reaches the radiators farthest from the water heater when it is very cold). The latter especially applies to pipelines and batteries made of steel or cast iron. These materials have high hydraulic resistance, which reduces the coolant current.

In addition to using standard radiators in a country house, you can organize gas heating using “warm floors” (+)

It is also possible to organize a combined heating system. In it, the circulation pump is connected to the main line through a bypass. If it is necessary to quickly warm up the air in the rooms, it is turned on to accelerate the water circulation. In other cases, it is cut off from the main pipe by shut-off valves, while the system continues to function in a natural (gravitational) mode.

Water heating

Undoubtedly, when asked what types of heating there are, it is water heating that first comes to mind. Water heating has the following advantages:

- Not very high surface temperature of various devices and pipes;

- Provides the same temperature in all rooms;

- Fuel is saved;

- Increased service life;

- Quiet operation;

- Easy to maintain and repair.

The main component of a water heating system is the boiler. Such a device is necessary to heat water. Water is the coolant in this type of heating. It circulates through closed pipes, and then the heat is transferred to various heating components, and from them the entire room is heated.

Components of water heating

The simplest option is natural circulation. This circulation is achieved due to the fact that different pressures are observed in the circuit. However, such circulation can also be of a forced nature. For such circulation, water heating options must be equipped with one or more pumps.

After the coolant passes through the entire heating circuit, it is completely cooled and returned back to the boiler. Here it heats up again and thus allows the heating devices to produce heat again.

Classification of water heating systems

Water heating type may vary according to criteria such as:

- water circulation method;

- location of distribution lines;

- structural features of risers and the diagram according to which all heating devices are connected.

In a pump heating system, heating of the coolant can also take place thanks to a hot water boiler room, or thermal water that comes from a thermal power plant. In a heating system, water can even be heated by steam.

Water heating with circulation pump

The disadvantage of direct-flow connection is the dependence of the thermal regime on the “impersonal” temperature of the coolant in the external-type supply heat water.

Connection to the water supply system

Work on connecting a gas boiler to a water supply is similar to connecting to a heating circuit. The only difference is that pipes and taps of a different diameter are used. And here you will also need a filter to purify the water. Remember, any debris that gets into the boiler can cause irreparable damage, so you shouldn’t skimp.

The main rule is that a connection error will be costly. The minimum is the creation of an emergency situation, the maximum is an explosion. The connection to the gas pipe must be made very carefully. Before starting, check everything again; caution in such a matter is the key to safety. Of course, you can connect to the gas pipeline yourself. But we strongly recommend turning to specialists. It won’t cost that much, but you will definitely be sure that everything is done in accordance with the standards and there will be no leaks. The first start-up of the boiler is also recommended to be carried out under the supervision of a specialist. The first launch can bring many surprises and reveal problems that you cannot correct on your own.

Features and Benefits

Heating systems differ in the configuration of the expansion tank - a special container that compensates for the thermal expansion of the coolant. An open tank is installed in a gravity system - the liquid moves through the pipes without installing a circulation pump for heating. The coolant moves due to the natural circulation of the medium, which changes density when heated and under the influence of gravity.

A feature of a closed system is the use of a closed expansion tank, which is a sealed container equipped with an elastic membrane inside. This ensures efficient operation under pressure and eliminates contact of liquid with air.

Internal structure of closed expansion tanks

With forced circulation

A closed-type heating system in a private house may include a circulation pump that forces the coolant to actively move, maximally warming up all heating devices or the heated floor circuit.

A closed heating system with forced circulation has a number of advantages

:

Heating of a liquid under pressure occurs faster; the risk of airing of the pipeline and radiators is reduced; evaporation of the coolant (which is especially important when using antifreeze) and the penetration of oxygen into the liquid, which provokes corrosion of the metal elements of the system, are prevented; due to the installation of the membrane tank below next to the boiler, and not at the top point of the circuit, as in open systems, installation and maintenance are simplified; the movement of liquid under low pressure simplifies the calculation and installation of the pipeline - unlike a gravity system, in this option there are no strict requirements for the angle of inclination of the pipes and pipes of smaller diameter can be used; there is no need to use large-diameter pipes and install them in an open manner in order to have access to any part of the system to eliminate air pockets.

Example with an induction boiler

The heating system of a private house with a circulation pump and a membrane expansion tank provides better heating of the premises compared to gravity. But it has one significant drawback - energy dependence. The operation of the pump requires electricity, so this option is not suitable for buildings in remote areas with insufficient power supply or its complete absence.

With natural circulation

The gravity heating system is energy independent, and this is its advantage. Typically this is a heating system with a solid fuel boiler or stove; liquid fuel units are less commonly used.

Heating without a pump is suitable for a home with a relatively small area; it is important to correctly calculate the diameter of the pipes for each part of the system and design their installation scheme, observing the optimal angle of inclination of the pipeline sections. It is necessary to reduce the risk of airing and ensure efficient movement of coolant

A circulation pump can be added to a closed heating system with natural circulation at any time, increasing its efficiency. This is the best option for areas where there are problems with power supply. In this case, if there is a temporary lack of electricity, the house will not be left without heat - a closed-type system in a private house will work like a gravitational one.

Natural circulation

The use of electricity for heating

The use of electricity is one of the ways to create heating for a private house without gas with the installation of a water circuit. Of course, this is an expensive type of heating. In principle, the following electric heating systems for a private home using electricity are possible:

- use of an electric boiler for water heating;

- placement of electric convectors in the premises of the house;

- use of infrared heaters;

- creation of warm floors.

Electric convector

An electric convector is the simplest device for heating air in a living space. The heating device by installing electric convectors impresses with its ease of installation, safety, protection against overheating and environmental friendliness. Infrared heaters are no less convenient for use, and sometimes a combined option of using electric heaters is chosen.

Such devices can be easily combined into one system and ensure its operation in automatic mode. If prices for electric convectors for heating a private home are quite affordable, then the constant increase in electricity tariffs reduces the demand for these convenient heating systems.

Infrared heated floors

One of the most popular options for a country house is infrared heated floors. They are produced in the form of a film, the thickness of which is about 3 mm. Installation of this floor is simple and affordable. The film is laid under any floor covering. Often the film is installed on walls and even on the ceiling. “Heated floors” are most often placed on the ceiling in two-story cottages or in houses with an attic. A large heating area speeds up the heating of the entire room and saves up to 40% of energy.

Electric boiler

Electric boilers are quite a worthy replacement for gas boilers. With their help, it is easy to create home heating alternative to gas heating. Only the price of electricity significantly limits the demand for these convenient and safe devices.

Every 100 m2 requires a power of 10 kW. If you need to install a powerful boiler, you will have to coordinate its installation with Energonadzor. The electrical wiring in the house, as a rule, does not meet the requirements, so an additional line is made from the entrance to the boiler.

According to the principle of operation, boilers that use electricity to heat the coolant are divided into:

- electric boiler with installed heating elements;

- electrode electric boiler;

- induction electric boiler.

All of the above devices have common features that distinguish them from gas and solid fuel boilers. These features, which can be advantages when using boilers for heating country houses:

- high level of security;

- noiselessness;

- simple adjustment of housing temperature, possibility of automation;

- there are no problems with fuel, its transportation and storage;

- do not harm the environment;

- easy to install;

- can be floor-mounted, wall-mounted, three-phase and single-phase.

Electrode boiler

An electrode boiler is the most economical electric boiler for heating a private home, having a small size. Compared to heating element boilers, savings reach 40%. They are characterized by the absence of scale and rapid heating of water.

New heating element

The heating element heats the water in the circuit using tubular heating elements. Its main function is to generate heat. The heating circuit is practically no different from the circuits used for gas or solid fuel boilers. In this case, the correct location of the heating radiators in a private house relative to the windows is necessary. If there are several windows, then radiators are installed under each window.

There are rules and regulations for installing heating batteries:

- the distance between the wall and the battery is at least 2 cm;

- between the window sill and the radiator 8 - 10 cm;

- between the floor and the bottom of the battery 10 - 12 cm;

- In all cases, it is desirable to install a heat shield.

Induction boiler

An induction boiler can be represented as an electromagnetic inductor, or transformer, which has a primary and secondary winding. The secondary winding is the housing, in which the so-called Foucault eddy currents are induced. Since the boiler body is a short-circuited loop, significant currents are induced in it, heating the boiler body, and therefore the coolant. Induction boilers are more economical than heating element boilers and are quite suitable as alternative types of heating for a private home or cottage.

Features of solid fuel boilers

Gas supply and centralized electricity supply are still not available everywhere in Russia. Gas is cheap only in capital cities, and even there it is becoming more expensive. Electricity is expensive everywhere.

Communication networks leave much to be desired: power outages and sudden voltage changes are commonplace outside the city. It is not always possible to connect to the main gas, and purchasing liquefied gas in cylinders is an energy-intensive business.

Heating with a solid fuel boiler has several advantages:

- you can choose the type of fuel that is cheapest in your area - firewood, peat, coal, wood waste, etc.;

- solid fuel boilers are the cheapest in the category. Long-burning models are more expensive, but their thermal efficiency is higher;

- a large assortment. Automation and auxiliary strapping elements can be purchased separately if necessary;

- Unlike gas units, the installation of a solid fuel boiler does not require permission from the local administration.

Now about the cons:

- fire hazard. But both gas and diesel models have this drawback. And in case of problems with wiring - even electrical ones;

- the need to monitor the amount of wood/coal in the firebox. A solid fuel boiler cannot be simply “turned on and forgotten”. It is less often necessary to add fuel to pellet and long-burning boilers, but in this regard they are not very autonomous;

- The combustion process of solid fuel is difficult to control (for other units it is enough to turn off the gas valve or turn off the electricity). The inertia of solid fuel boilers is high, and so is the entire system.

Solid fuel boiler design

https://youtube.com/watch?v=MY-xodMMyDI

Heating scheme

The circulation of water through pipes and radiators occurs due to the upward movement of the heated liquid, as well as from the operation of the circulation pump.

Additional items:

- Shut-off valves (the more taps there are, the easier it will be to maintain and repair heating elements).

- Air vents (oxygen, which gradually accumulates in pipes, is destructive to metals; it must be vented periodically).

- Thermostat (needed to keep the temperature in the rooms at the same level, saves fuel).

Installation of a floor-standing gas boiler in an existing heating system

An expansion tank is a mandatory attribute of any system. It can be closed or open. The closed one is paired with a circulation pump. An open tank is placed as high as possible, for example, in the attic of a house.

Pipe routing

- Single-pipe.

- Two-pipe.

Single-pipe. A pipe extends from the boiler to which radiators are connected in series. The further away the radiator is from the heater, the colder it is. This scheme is the simplest and requires few materials. But it is only suitable for small houses where the coolant will not have time to cool down. In addition, the system cannot be adjusted.

Two-pipe system - all radiators are connected to the supply pipe in parallel. Each one receives the first, hot water. After passing through the battery, the water flows into the return pipe and returns to the boiler. The system is a little more expensive, but all rooms are heated evenly. Suitable for multi-room houses.

Single-circuit or double-circuit boiler - it does not matter when choosing the type of wiring.

Connecting radiators

There are three options for connecting heating radiators:

- Unilateral.

- Lower.

- Diagonal.

They differ not only in location, but also in efficiency.

Let's look at each of these options in more detail:

- One-sided option. The supply and return pipes are located on one side of the radiator. The method saves materials, but is not very effective if the radiator consists of a large number of sections (the coolant simply cools down while it reaches the last section).

- Bottom option. Outdated and ineffective (radiators give off 15–30% less heat than they could). The liquid flows where it is easier - along the bottom of the heating devices, and the upper part remains unused.

- Diagonal option. The most correct. The water enters at the top of one side of the radiator, and, having passed through the entire battery, comes out at the bottom on the other side. This installation is required for long heating appliances. With such a scheme, you can expect that the radiators will give out the passport indicators.

All radiators are universal and have 4 possible connection points. This means that the connection method depends only on your desire.

Chimney

One of the prerequisites: the boiler outlet pipe must exactly match the diameter of the chimney. Other subtleties:

- The chimney from the boiler to the head should not have more than three bends.

- There should be no connections where the pipe passes through the wall or roof.

- The pipe must be insulated in places where it passes through an unheated room.

To check whether the length of the chimney you are planning will be sufficient, perform a simple calculation. Find the volume of the chimney and the volume of the boiler. The boiler must completely “fit” into the chimney. The area S of a round pipe is determined by the formula πR2. To find out the volume, multiply the resulting number by the total length of the pipe.

Conclusion. Having studied all the intricacies and carefully thought through everything, you can proceed to installation work. Remember that connecting the boiler to the gas mains should only be carried out by gas service specialists. They are also conducting a test run of the system.

Heating circuit connection

For most models, the connection diagrams are made by analogy. At the bottom of the boiler there is a pipe through which gas is connected. Next to it are tubes for connecting cold and hot water.

Near the ends of the gas boiler you can see more pipes: they are needed to turn on the heating system. The main thing is not to confuse the return water supply and the water supply directly to the radiators. All connections must be made in accordance with regulatory requirements. Don't forget to use sealants - these are special materials for sealing connections. Both time-tested tow and modern thread sealants are suitable.

In order for the boiler to serve for a long time, you need to take care in advance to ensure that no debris gets into it. Since this is practically impossible with our water quality, do not forget to install a coarse filter in the return water pipe. Thus, you will significantly extend the service life and minimize the risk of malfunctions.

Types of single-circuit heating

There are several classifications of single-circuit heating systems depending on various parameters. Initially, the main types of systems should be identified:

- open;

- closed.

Since water has a fairly high coefficient of expansion when heated (0.3% due to an increase in temperature every 10 degrees), it is necessary to compensate for the increasing volume of coolant so that the pipes are not damaged and an accident is avoided. Compensation is usually carried out through an expansion tank into which a polymer membrane is inserted. This membrane is elastic and, under the influence of increasing water volume, fills the tank completely.

The use of such membrane tanks is typical for closed, fully automated systems. Boilers for such systems operate on gas, pellets, and fuel oil. They are safe because when the pressure increases, the system automatically turns off.

Previously, predominantly single-circuit open-type systems were used, which were also called natural circulation heating systems. In such devices, a pipe is installed through which excess pressure and vapor are released into the atmosphere if intensive operation of the boiler causes a significant expansion of the coolant.

Heating installations for a private cottage are also divided into systems with:

- natural circulation;

- forced circulation.

Forced circulation is carried out by including special pumps and other engineering devices for pumping water into the system. This option is considered more modern, does not require the use of pipes, fittings of a larger diameter, and therefore additional labor costs, and is more suitable for multi-storey cottages where it is necessary to supply coolant to the upper floors. The use of pumps is difficult if there are problems with a constant, powerful power supply.

Spider system

The so-called “Spider” system refers to single-circuit natural circulation installations. Today, this principle of constructing a connection between the boiler and the lines leading to the radiator is considered outdated and is used mainly in settlements remote from regional centers, where problems with energy supply may arise. In appearance, the system really resembles a spider (the boiler is installed in the attic, with lines running from it), which is why it received this name among the common people. The installation is carried out with your own hands.

Leningradka system

The most reliable systems, which is also a variant of natural circulation, include Leningradka. "Leningradka" is the optimal price-quality ratio, taking into account the ease of project implementation and efficiency. The classic “Leningradka” is a complex of series-connected radiators along the perimeter of the premises with a single pipeline; the heating source is a boiler. This option is often installed in small two-story cottages using a circulation pump.

Approximate calculation of gas consumption

To provide 1 kW of thermal energy, 0.1 m3 of gas per hour is required. In order to heat a room of 200 m2, you will need a boiler with a capacity of 20 kW. The full power mode of such a boiler consumes: 20 × 0.1 = 2 m3/hour.

So, we divide the heating season into two conditional stages: 3 very cold months and 3 cold ones. For ease of calculation, let’s round the number of days of each period to 100. So for 100 days the boiler will operate at full capacity and the same at half its capacity or even a quarter. The average daily gas consumption for the first period will be: 20×0.1×24=48 m3, and in the second period 24 m3

Often the actual consumption is less than what is stated, since in recent years the winters are not as severe as before and do not require the full power of the boiler. The most profitable heating option is to connect to a natural gas pipeline. But remember that we use gas for both cooking and heating water, so the resulting figure must be adjusted depending on the case and the needs of the residents.

Selection and types of gas boilers

You should know that boilers have several classifications. Each type has its own right to exist and will provide good gas heating for a private home.

Single-circuit and double-circuit boilers

Single-circuit boilers are intended exclusively for heating and do not perform any other functions. Purchased if you do not need to heat hot water directly from a gas boiler.

Such boilers work directly on the heating system. They can also be used to heat an indirect heating boiler, which in turn is used to provide the house with hot water

Double-circuit gas boilers are ideal for both heating rooms and heating water. It should be noted that double-circuit boilers are not always effective for heating water. Usually only enough for one active point. If, for example, you go to the shower and someone decides to wash the dishes, then you will already take a cold shower. You should take this into account when purchasing.

Wall and floor boilers

Wall-mounted boilers are safe and automated, but often operate only on one type of gas - natural. (There are models in which you can change the burner and they will also work on liquefied gas). They can be installed in kitchens, since it is smaller in size compared to floor-mounted ones.

The power of wall-mounted boilers is often limited to 35-40 kW. Therefore, if you want to install gas heating in a large house, you will have to either install two wall-mounted boilers in cascade mode, or install a floor-standing boiler.

Floor-standing boilers are capable of heating large rooms, as they have greater power. They are universal in terms of fuel consumption: natural, liquefied, and main gas are suitable. They can be energy-dependent and independent. Often a cast iron heat exchanger is used. Due to their design, they have an efficiency lower than that of a wall-mounted one, but at the same time a longer service life.

Which gas supply to choose: centralized or autonomous?

Autonomous gas heating involves using gas as fuel. Without burning it, it will not be possible to heat the house. In this case, main gas or liquefied gas can be used. If the settlement is located far from the gas main, then an excellent option would be to install a gas tank for storing liquefied gas.

The gas pipeline supplies only natural gas, which consists of methane. The liquefied variety is a mixture of propane and butane, which is placed in cylinders or gas holders for storage and transportation. Moreover, the pressure in such containers reaches 15-18 atm.

If there is no gas supply to the AGV, heating is installed using liquefied gas. At the same time, it is unprofitable to use fuel in cylinders with a capacity of 50 liters, because the containers will have to be changed every three days. It is much more profitable to equip a gas tank that holds 20 m³ of gas. When choosing the dimensions of the container, not only the heating of the house with gas is taken into account, but also the fuel consumption for the gas stove and fireplace.

If we take into account the cost of connection, the gas pipeline is much more profitable, but this scheme can only be implemented in gasified settlements. However, at a significant distance from the main line, installing a gas tank will be cheaper.

Other features of using gas tanks:

- no need to worry about gas pressure in the pipe;

- easy operation;

- you must remember to refuel;

- From time to time you will have to call specialists for safety checks;

- installation of the system takes place in 3 days;

- When choosing a boiler, give preference to universal varieties that operate on liquefied and natural gas, or those that use only LPG (liquefied carbohydrate gases).

Convection and condensation gas boilers

Gas convection boilers are standard type devices that use only fuel combustion energy. Such units have a simple design and relatively inexpensive cost. The main problem of a convection device is the formation of condensate consisting of water and acids on the heat exchanger. The way to combat dew is to maintain a high temperature in the heat exchanger, and for this, the temperature of the coolant in the return must be at least 60 degrees. For heating devices with boilers of this type, it is allowed to use wall-mounted radiators, registers and convectors. The heated floor system and in-floor appliances cannot be combined with a convection unit, since they will not warm your feet, but burn them.

Condensing units do not always fully utilize their energy, which is produced during the combustion process. They convert the energy of condensation of water vapor into heat

For a condensing boiler, it is important that the heat exchanger has a low temperature, as well as the return. Typically, the gas heat supply scheme in a private house with a heating unit of this type is as follows: radiators are placed under the windows and a heated floor system is installed, for which the return of the heating radiators is used, where the coolant gives off the last heat.

When heating a private house using gas equipment, the following boilers are used:

- with natural circulation

- they take air from the room into an open burner and remove combustion products, directing them to general ventilation. To install them, a separate room with an area of at least 4 “squares” with a wide door and window is required; - with forced circulation

. In this case, in order to maintain combustion, air is taken from the street, and combustion products are also discharged there through a separate air duct. The boiler can be installed even in a residential area.

Alternative methods of heating a private house

Gas is not the only heat source that can heat your home. There are several other options for keeping the room warm. But are they so beneficial compared to the gas system?

Methods of alternative heating of a private house:

- Electricity. The most common and accessible source of energy, however, it is almost the most expensive. It may simply not be enough to heat a private home, since not every electrical network will be able to transfer the amount of energy required for heating. Problems cannot be ruled out in winter. Not the most economical and practical option.

- Diesel. Diesel fuel has a high price. It tolerates a very unpleasant aroma, which cannot be removed by anything, either at home or on the street. And if you take diesel fuel of insufficiently high quality, the heating system may break down. Not the best option.

- Solid fuels. Coal and wood. They must be supplied to the heating system two to four times a day. Every day it is necessary to remove ash from the heating system. Naturally, heating a house will require a considerable amount of fuel of this kind per year. This requires large amounts of money. You should have a separate warehouse for them; in addition, they are dangerous, as they can emit carbon monoxide. In this regard, gas installations are more economical and safer.

- Pellets. These are special granules that are made from peat and wood waste. Its disadvantages are similar to the negative sides of coal and firewood: you need a room to store a large number of pellets, they do not smell very good and they often need to be loaded into the heating system. The difference is that they are cheaper than all the types of fuel listed above, except gas. And they need to be loaded less often than firewood or coal: no more than once a week. Not a bad option.

Obviously, gas heating wins in many respects: efficiency, ease of operation, minimal heat loss, low cost of the fuel itself. Therefore, if you decide to install a good heating system, then opt for a system with gas heating of the coolant.

Laying the external pipeline

The external pipeline, from the connection point to the entrance to the house, can be either above-ground, metal (pipe on racks and on clamps along the wall), or underground, both metal and polymer (PE pipe laid in a trench). If an underground pipe enters a house in the basement, you will need a so-called “base inlet” - a permanent connection between a steel and polyethylene pipe. Such connections are sold ready-made, and the price is quite reasonable; it is convenient that they come with a case (sleeve) for wiring.

kam711 FORUMHOUSE Member

I'm going to go the route of installing a gas consumption network with my own hands. I think it will be useful to many.

Option 1

- A ready-made base input is purchased (preferably in an office where there is welding).

- 50 m of PE pipes are welded onto it immediately (right in the office) and directly introduced into the house.

- The trench is being dug, the sand is all done, the pipe is being laid.

- All wiring in the house is done with MP compipe gas, up to the meter with threaded connections using anaerobic sealant.

- Representatives of the GRO are invited to view the creativity.

Option 2

- All the same, but without a trench and a PE pipe.

When wiring underground, the line must be tested for leaks (air under pressure) before backfilling. The outlet of the pipe from the ground is covered with a protective steel sleeve, and the cavity is filled with sand or filled with elastic material.

According to standards, an overhead pipeline can be made not only of steel, but also of copper.

AlexeyV888 Member FORUMHOUSE

I have four meters of pipe to the fence, not much money. The GRO will lead to an overhead connection. Why should I bother with the subway? My goal is that the GRO will not find anything to get to the bottom of. I foresee acceptance through an independent examination and court, and with the subway they have significantly added opportunities. Simplicity, clarity, and minimum requirements are important to me. The copper connection on the press fittings is just right. Regarding steel and polyethylene requirements, a lot of different tests can be carried out. For press fittings, a certificate and mechanical tests are sufficient. Well, this is how I see it, after reading all the SPs and GOSTs on this topic five times. There are examples of such execution.

Heating system installation

Installation of the heating system of a country house is carried out in several stages:

- project development, obtaining permits from the relevant authorities;

- purchase of materials, equipment and preparation of tools;

- insertion into a gas pipeline that runs along the street and through which gas is supplied to residential buildings;

- preparing a place for a gas boiler, laying out pipes;

Installation of gas equipment

boiler installation; filling the system with coolant; diagnostics.

The main criterion by which the amount of materials is calculated and the model of heating equipment is selected is the area of the house. The larger it is, the more powerful the device will be needed. For a small house, a small-sized boiler is suitable, which can be installed in the bathroom or kitchen. For a cottage or two-story mansion, it is better to choose a large, powerful device.

A heating system in a private home installed in accordance with all the rules will function for a long period. Before starting installation work, you should familiarize yourself with the heating diagram and the rules for installing heating equipment.

Requirements for gasification at home

Gasification of the private sector is carried out in accordance with the standards established by law.

You can get permission to crash into the highway or connect if all the conditions are met:

- you are the owner of the house and plot;

- There is a room in your house that meets the established requirements for installing a boiler.

There are also certain requirements for the room where a boiler with a power of up to 60 kW will be installed:

- this is a non-residential room, this can often

be a kitchen or a specially designed room - the boiler can be installed on any floor, the basement is not excluded

- The volume of the room must be equal to or greater than 15 cubic meters. meters. Permissible deviation – 20 cm in one direction or the other

- ceiling height can be at least 2 m 50 cm

- It is necessary to have a window with a window

- at least three times the volume of the hood.

If all the above conditions are met, we begin collecting documents for gasification.

You will need:

- a copy of the technical passport for the house, issued by BTI

- documentation for all gas equipment you purchased.

Next you need to visit the following authorities:

- First on the list would be a visit to the local architectural and planning office. They are in charge of the gasification of private houses. You must obtain written permission from this organization.

- The next visit will be a visit to the fire service or housing and communal services. Next comes a call to the home of an inspector who will inspect the chimney. After which, if all requirements are met, i.e. the presence and operability of the chimney, the inspector issues the owner a corresponding certificate.

- Next on the list will be a visit to the local Gorgaz or the Oblgaz branch and obtaining technical conditions for supplying gas to the house. At this authority you need to write an application using the form provided. It will require an indication of the approximate gas volume consumption per hour. Such an application is considered for 2 weeks. After this, the owner will receive technical specifications.

After reading the documents, it will be useful to know what types of gas pipelines exist, their advantages and disadvantages.

According to how the gas pipeline will be located relative to the ground, underground and above-ground are distinguished; their difference is in the method of entering into the building not only internal gas supply networks and risers, but also all gas-consuming devices.

Air heating

These types of heating of various premises are considered one of the oldest. For the first time such a system was used before our era. Today, such a heating system has become widespread - both in public buildings and industrial premises.

Air heating of a private house

Heated air is also popular for heating buildings. When recirculated, such air can be supplied to a room, where the process of mixing with indoor air occurs and, thus, the air is cooled to room temperature and heated again.

In air heating systems, the air is heated by air heaters. The primary heater for such components is hot steam or water. In order to warm the air in the room, you can use other heating devices or any heat sources.

Local air heating

When asked what kind of heating there is, local heating is often equated only to industrial premises. Local heating devices are used for rooms that are used only during certain periods, in rooms of an auxiliary nature, in rooms that communicate with external air flows.

The main devices of the local heating system are a fan and a heating device. For air heating, devices and devices such as air heating devices, heat fans or heat guns can be used. Such devices operate on the principle of air recirculation.

Heat gun

Central air heating

Central air heating is done in rooms of any type, if the building has a central ventilation system. These types of heating systems can be organized according to three different schemes: with direct-flow recirculation, with partial or complete recirculation. Full air recirculation can be used mainly during non-working hours for standby types of heating, or to heat the room before the start of the working day.

Central air heating

However, heating according to such a scheme can take place if it does not contradict any fire safety rules or basic hygiene requirements. For such a heating scheme, a supply ventilation system should be used, but the air will be taken not from the street, but from those rooms that are heated. The central air heating system uses such structural types of heating devices as: radiators, fans, filters, air ducts and other devices.

Air curtains

Cold air can come in in large quantities from the street if the entrance doors in the house are opened too often. If you do not do anything to limit the amount of cold air that enters the room, or do not heat it, then it can negatively affect the temperature regime, which should correspond to the norm. To prevent this problem, you can create an air curtain in the open doorway.

Limiting the amount of cold air entering from outside the building takes place thanks to design changes in the entrance to the room.

Electric air curtains

Compact air-thermal curtains have become increasingly popular lately. The most effective curtains are considered to be “shielding” type curtains. Such curtains create a jet air barrier that will protect the open doorway from the penetration of cold air currents. As a comparison of heating types shows, such a curtain can reduce heat loss by almost half.

Without using gas or electricity

Today, there are several alternative options for heating a room that do not require electricity or gas supply. Such heating from pipes without batteries will save money. Heating system options can be as follows:

- stoves and fireplaces. They heat the room using the energy of burning wood or coal. If you decide and choose this option, you will need to build a stove or purchase ready-made communications, which you only need to install correctly. At the same time, as a result, the family receives an environmentally friendly and economical method of heating, and if the stove is equipped with a frying surface, then it will cope with cooking food;

- an autonomous heating system from a personal source of electricity, which can be obtained in two ways:

- with the help of sunlight. Here you will have to spend money on special solar collectors that can convert solar energy into thermal energy and thus work as a heater. Naturally, you will have to invest in the purchase of equipment, but the expenses will be one-time, and the receipt of electricity will be constant;

- using the power and energy of the wind. To do this, you will have to build a special apparatus, which consists of a turntable, a generator and a battery. If you can’t assemble it yourself, you can purchase a ready-made structure that converts wind power into electricity.

Video 2. Heating without gas and wood. New!

Without pipes and boilers

An autonomous heating system is often equipped with a boiler to which pipe-radiator communications are connected, which make it possible to heat several rooms at once. However, properly selected heating without pipes and batteries, which operates from a single heat source, can work just as effectively. Most often this is:

- a stove made of brick or metal, which will be an ideal option for supplying heat to one room or two adjacent rooms;

- a fireplace, which was used in ancient times to heat castles;

- electric heater, reflex or oil-based;

- air conditioners, etc.

Remember that for a country house built according to the old “five-wall” principle, one stove, which is located in the middle of the house, is quite enough for high-quality heating. Even today, in such structures, heating is carried out without pipes, radiators and boilers.

Heating without fuel

It consists of pipes that are filled with freon, as well as throttle, compressor and heat exchange chambers. The device operates like a refrigerator and is based on simple physical laws.

The pipes are located deep underground or in a lake at a decent depth so that the ambient temperature does not rise above 8 0C even on the hottest day.

Already at 3 0C, freon boils and rises through them into the compressor, where it can be compressed and thus heats up to 80 0C.

In this form, it is sent back to the highway underground, repeating the cycle in a circle.

Warmth without heating

Even without a heating system, without pipes, radiators and boilers, it is possible to warm up the room.

There are several methods that are used both together and separately. These include:

- maximum insulation of your home. To preserve the particles of heat that come after cooking, breathing of residents, etc. It is enough to insulate the walls, add warm floor coverings to the interior, heavy curtains on the windows so that they block the access of cold air and do not allow heat to leave the room, etc. Even if the heating system works as it should, such nuances will allow you to save energy resources and not consume more heat than necessary;

- insulation of home wardrobe. Wear a warm sweater and slippers. While watching TV, cover yourself with a warm blanket or use a warm cape, a heating pad in bed and warm drinks (tea, milk);

- psychological heating. We change the design of the room, its color scheme to a warmer one (peach, yellow), add knitted decorative elements and wooden accessories. Use scented candles and photographs of warm countries in the interior. Thus, there is an impact in two directions: on the eyes and touch. This way you can deceive the body and make it feel warm.

In any case, you can find an opportunity and a suitable method to warm your home. Heating without pipes and boilers can be an effective solution to this problem even in severe frosts. Using the above methods, you will be able to warm your home even in the most unusual situations.