In order for it to be safe and comfortable to live in a private house, the owner must take the trouble to install a good heating system. There are several ways to keep your home warm, but the most popular is gas heating.

Today we’ll look at this topic in more detail, let’s look at the disadvantages and advantages of gas heating, how to choose a gas boiler, and find out what heating options exist using this method.

No. 1. Features of gas heating of a country house

The operating principle of gas heating is simple: gas burns and heats water (coolant), which circulates through a closed pipeline and heating radiators, heating them and releasing heat into the room.

Advantages of using gas as fuel:

- relatively low cost;

- autonomy and the ability to turn the heating system on and off at any time and adjust the temperature at your discretion;

- water is an excellent coolant, and since the circulation system is closed, its volume in the system does not change;

- the ability to heat water for the hot water supply system (provided that a double-circuit boiler is used);

- ease of temperature control.

Flaws:

- after switching on, water heating systems do not heat the air as quickly as, for example, electric convectors or fan heaters;

- Gas heating is not suitable for dachas and country houses that are visited from time to time in winter. If the room temperature drops to negative values, the water in the system may freeze, causing the pipes to burst. Here the solution is either to use electric heating or gas convectors;

- water should contain a minimum of salts;

- The entire gas water heating system requires maintenance. It is necessary to monitor not only the operation of the boiler, but also the condition of the pipes and radiators.

Advantages

- The most basic and important advantage of using gas heating for a private home is its low cost, since gas is the most accessible and inexpensive type of fuel.

- Easy to use. Using the equipment is easy - it does not present any difficulties.

- Although relatively cheap, these boilers have high efficiency.

- Gas boilers can heat up a large room in a short time due to their efficiency.

No. 2. Heating with main and bottled gas

Gas heating can be realized through:

- main gas pipeline;

- liquefied gas in cylinders and gas holders.

If a dacha or country house is located close to a gas pipeline, then you don’t have to think long about how to organize heating - the choice is obvious. The main gas pipeline allows us to talk about complete autonomy in providing heat, makes it possible to equip a system of heated floors, but it can take a lot of time to coordinate all the necessary documentation.

Even if there is no gas pipeline in the area, it is possible to organize an inexpensive gas heating system, and for this they use liquefied gas cylinders . The costs of setting up such a system pay off within several years. Bottled gas is not capable of providing a completely autonomous heating system, but the problem can be solved by connecting several cylinders. The security of the existing system will need to be checked every one to two weeks.

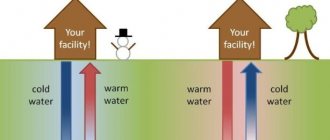

Gas tanks - large-volume containers located underground near the house - have shown themselves to be excellent From time to time, their gas reserves are replenished with special gas carriers. Despite the fact that the use of liquefied gas is not as convenient as main gas, for areas located far from gas pipelines it is a real salvation. The heating system works the same whether from the main gas or from liquefied gas. Gas tanks are installed on a concrete pad; if necessary, two tanks can be connected into one system if gas needs increase later. Gas tanks are made of steel, and when choosing, pay attention to the wall thickness (the larger the better) and volume (depending on needs).

Required documents

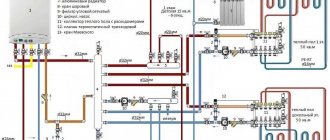

Scheme of gas heating of a private house.

Conducting gas to a dacha is a serious matter. To successfully complete the last stage - directly connecting blue fuel - you need to successfully start from the first: collect all the documents.

You must submit an application for gas supply to the dacha. As well as a document proving your identity, a certificate of ownership of a dacha, a certificate of ownership of a land plot, an agreement on the preparation of design and technical documentation, a form with information about technical conditions. You will need contracts: for the supply of gas from the main pipe, for the installation of gas equipment, for maintenance, for the supply and payment of work.

And the act of putting devices into operation.

First, contact the chairman of the board of the dacha cooperative and write him a request to supply gas to the dacha plot.

No. 3. Gas boiler for a summer house and country house

Most gas boilers are universal and can be used with any gas source. The thing is that even those devices that were initially developed to work with the main gas pipeline can be adapted to use liquefied gas. As a rule, it is enough just to change the burner or buy a new one if the kit did not have a suitable one. The remaining “alterations” will be minimal. This versatility of gas boilers is especially convenient when the area where the country house is located is just developing: at first you can use cylinders, and then connect the system to the gas pipeline - the investment will be minimal.

If you plan to use only gas cylinders , then when choosing a boiler, pay attention to those models in which the lower threshold of the operating gas pressure is minimal - this will save money during operation. In addition, the boiler must be selected with a high level of efficiency, certainly not lower than 90%.

The choice of gas boilers is huge, and it all depends on the requirements put forward. Based on functionality (number of circuits), boilers are divided into:

- single-circuit . Are used only for organizing heating;

- double- circuit They are equipped with an independent hot water supply circuit, so with their help they solve another problem - warm water in the tap. Such boilers can be of the flow-through type, if the required amount of warm water is small, or they can be equipped with a built-in boiler, which ensures full heating and hot water supply.

Depending on the type of draft, boilers are:

- with natural traction . Ideally suited when the house already has a chimney. Such a boiler will be cheaper, although its installation will be somewhat more complicated, and during operation it will sometimes be necessary to clean the chimney pipe;

- with forced draft , or turbocharged. In this case, combustion products are discharged through a small pipe equipped with a fan. The pipe can even be mounted into a wall, but it is better to place it away from windows and ventilation systems. Forced draft allows combustion products to leave the boiler faster, does not require the construction of a chimney, but constantly uses electricity during operation.

The type of ignition may also differ:

- manual , i.e. using a match - this is the most ancient method, often unsafe. Today such boilers are almost never produced;

- piezo ignition . Here, instead of a match, a spark is used, resulting from pressing a special button. This is a more advanced method and, according to many experts, best suited for the conditions of a country house, because electricity is not used for ignition, which can cause problems;

- Electric ignition is convenient, economical, and safe, but for areas where power outages occur, it is not an option.

According to the installation method, boilers are divided into:

- wall;

- floor

The question here is not only about personal preference, but rather about the required power. Floor-standing boilers are more powerful, efficient and durable devices, but they are also somewhat more expensive than wall-mounted ones. Wall-mounted boilers have lower power (at a maximum, they provide heating for a house with an area of 300 m2) and take up minimal space.

There are some safety requirements for the room where the boiler will be installed. The room must be at least 7.5 m2, with a ceiling height of at least 2.5 m. If the house is wooden, then it is better to insulate the room with the boiler with roofing steel, or, in extreme cases, with asbestos sheets 3 mm thick.

Short instructions

Installation diagram of a parapet type gas boiler.

Technical documents that contain characteristics of the area and a plan for supplying gas from the central pipe are drawn up and carried out by licensed organizations. Usually these are technical specialists of the gas campaign.

All installation of gas connection equipment (water heaters, boiler, meter, pipes) is done by a team of installers.

Conclude an agreement for gas supply from the central pipe and an agreement for the installation of equipment. These are completely different jobs, and they are carried out according to different estimates.

The room where you plan to install gas equipment must have ventilation, a window, lighting and a concrete floor. If you want to install the entire set in the kitchen, then you will have to drill holes in the doors and make ventilation near the gas installations.

After installation is completed, you need to conclude a contract for the maintenance of gas equipment. Call an employee from the gas control department and draw up a report on putting equipment and gas meters into operation.

Related article: Choosing bricks for load-bearing walls

Take the commissioning act and enter into an agreement with the customer service department of the gas campaign for the supply of gas and payment for it at the meter.

No. 4. What boiler power is needed?

One of the main characteristics of a boiler is its power. According to this parameter, boilers are divided into devices of low (up to 65 kW), medium (up to 1700 kW) and high power (up to 15000 kW). Low-power boilers are usually used for dachas and country houses; the rest have found application in industry.

The choice of boiler power depends on a lot of parameters:

- room size;

- climatic conditions;

- quality of home insulation;

- the need to heat water for hot water supply.

According to the simplest calculation , for every 10 m2 of heated space you will need 1 kW of boiler power. This formula gives a general idea of the requirements for heating equipment, but to obtain more accurate data it is worth considering other parameters. For houses built according to a standard design with a ceiling height of no more than 3 m, the calculation is simple. For every 10 m2 of area you will need the following boiler power:

- 0.7-0.9 kW for houses in the southern regions;

- 1-1.2 kW for the middle band;

- 1.2-1.5 kW for Moscow and Moscow region;

- 1.5-2 kW for northern regions.

The results of these calculations are valid if the boiler is used only for heating. In the case of double-circuit boilers , which also operate for hot water supply, it is worth adding another 25% of power to the result obtained. If the house uses a forced ventilation system, it is better to add 5% of the power to the obtained value.

If the house is built according to an individual project, then the calculation becomes somewhat more complicated. For this, special calculators are used, but you can approximately calculate the required power using the following scheme:

- We calculate the heat loss of the building using the formula V*Рt*k/860, where V is the volume of the room, Pt is the maximum difference between the external and internal temperatures, and k is the dissipation coefficient, depending on the thermal insulation;

- for well-insulated houses with reliable double-glazed windows k = 0.6-0.9, for buildings with an average level of thermal insulation - 1-1.9, with a low level - 2-2.9, without thermal insulation - 3-4;

- for example, there is a house with an area of 120 m2 and a ceiling height of 3.5 m, it is well insulated, but not enough (k=1), the temperature in the house must be maintained at 210C, and outside it can drop to -200C. Heat loss will be (120*3.5)*41*1 = 17.22 kW;

- The power reserve is 15-20%, so for our house we will need a boiler with a capacity of about 22 kW.

Of course, you don’t have to bother yourself with calculations and take a boiler with a power many times higher than required, because automatic systems can regulate gas flow. But not everything is as simple as it might seem. Firstly, a much more powerful boiler than necessary will cost more, its efficiency will decrease, malfunctions may occur in the operation of the equipment, components will quickly wear out, so it is better to take a boiler that at least approximately meets the requirements of a particular country house or cottage.

If the source of gas is a gas cylinder, then the calculations and setup of the system are approached with special responsibility. Practice suggests that heating and hot water supply to an insulated house with an area of about 130 m2 will require 3-4 cylinders per week, and this is provided that outside temperatures drop to -230C, and in the house they are maintained at +230C.

Condensing boilers help save money and increase productivity , which, in addition to the heat of combustion of fuel, also use the heat of combustion products and water vapor. In conventional boilers, this heat is released outside. The efficiency of such boilers often exceeds 100%. If the performance of one boiler is not enough, then you can connect several boilers “in cascade”.

To save gas, you should also insulate the room, equip the heating system with automation and gas leak detection sensors.

Gas tank installation

The installation of a gas tank itself is not difficult; its connection itself will cause more complications. That is why it is important to entrust the work to professionals. But in general, you can try to understand the system on your own. However, you can definitely do the installation of the tank yourself.

Step 1. First of all, you need to dig a pit suitable for the size of the gas holder. Before installing the gas pipeline, it is important to lay a warning tape that has an indelible inscription indicating the presence of gas.

First you need to dig a pit

Step 2. Next, you need to arrange a gravel bed by pouring gravel onto the bottom of the pit. It is also important to take care of creating a concrete base - it can be poured, or you can simply lay a concrete slab on the bottom of the pit.

Preparing the pit bottom

Laying a concrete slab

Step 3. After this, it is enough to lower the gas tank itself to the bottom of the pit and be sure to secure it with metal pins and cables.

The gas tank itself is lowered

It is important to secure the tank well

Step 4. Next you need to make a trench from the gas tank to the house. Pipes will be laid in it to supply fuel to the residential building.

Digging a trench

Step 5. You need to lay a gas pipe in the trench and bring it to the house.

Pipe laying

Prices for multilayer pipes for gas

Multilayer gas pipe

Step 6. One of the important stages is the installation of the gas supply system. Here it is better not to act on your own, but to call a specialist.

It is better to entrust the installation of the gas supply system to a specialist

Gas supply system being installed

Step 7. After installing all elements of the system, you need the technician to check its tightness using a special solution.

Checking the tightness of connections

Step 8. Then you need to connect all the devices and test the system for functionality.

System testing

Step 9. Only after this can the pit with the gas holder be filled with soil. It is recommended to fill it with sand.

A pit with a gas holder is filled in

No. 5. Gas heating schemes for a country house

A gas heating system with a boiler works quite simply: the coolant is heated, receiving heat from the combustion of gas, circulates through pipes and radiators and returns to the boiler when it has cooled down. Coolant circulation through the system can be:

- forced;

- natural.

Natural circulation is carried out through the use of an expansion tank, which is mounted at the highest point of the house, and is ensured by the difference in the density of hot and cold water: heated water with a lower density is displaced upward by colder water. Having risen to the highest point of the heating system, the heated water flows by gravity into all radiators and heating pipes, and when it returns to the boiler, it already has a lower density. The cycle repeats. To ensure natural circulation, it is important that the boiler is lower than the radiators, and the greater the difference in level, the better. Horizontal sections of pipes are made at an angle to ensure a higher flow rate of hot water to the radiator and cold water to the boiler. In addition, it is better to take polypropylene pipes with a deliberately oversized diameter, and the fewer bends and turns, the better.

Forced circulation is carried out using a pump, and some modern boilers already have it built-in. Installing a pump will solve a lot of problems and install the boiler in any convenient place, neglecting the slope of the pipes, but will result in higher electricity bills. Nothing prevents you from enjoying the benefits of both systems: you can use the pump when there is electricity, but when there are interruptions, you can rely on natural circulation.

No. 6. Pipe layout diagram

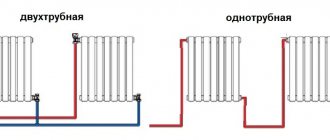

The heating system can be implemented in one of the following options:

- single-pipe scheme. It requires a minimum amount of materials and is relatively easy to install, so it is often used for heating a country house, and can even be organized independently. Minus The problem is that different rooms are heated unevenly, so a single-pipe scheme is suitable only for not very large country houses. The coolant from the boiler enters the first radiator, then flows into the second, third, etc., gradually cooling and returning back to the boiler;

- two-pipe scheme is more advanced and provides for the supply of warm water to the radiator through one pipe and its removal through another pipe from each battery separately. This wiring allows all radiators to heat up evenly, and the temperature of each can be adjusted separately using special shut-off valves. TO shortcomings This includes more complex installation and higher costs.