Actterm thermal insulation is characterized by a liquid structure, but at the same time it fully realizes its main function - it reduces the intensity of heat outflow . The substance is produced using advanced technologies; today 15 formulations have been developed. Each of the options has individual properties, which allows the use of different types of materials to solve various problems: insulation, protection against condensation, etc. Akterm paint is applied to the surface in the usual way - like any other paint and varnish composition, but at the same time the properties of the structure are improved.

Experience in using liquid thermal insulation ↑

Already in the summer, when the temperature “overboard” is still acceptable, owners of private houses, as well as management companies and developers, are wondering how much they will have to spend on heating during the cold season. And the most zealous owners, of course, think first of all about the most effective insulation of the premises. Everyone understands that this must be done before the cold weather. But as for the method of insulation, the question is more complicated. And especially when it comes to internal insulation of walls and ceilings. Because everyone knows that insulating from the inside is not recommended in principle. But what to do if there is no other way? Some people have semi-detached houses like town houses, others need to insulate their garage or boathouse. What should I do?

Areas of application

Thermal insulating paints are used in various industrial areas and everyday life. In addition to its main purpose, the coating protects the surface from corrosion, does not allow moisture to enter, and reduces heat loss by up to 90 percent.

Areas of application of Akterm liquid heat insulator:

- insulation of external and internal walls of residential and industrial buildings;

- processing of external seams in panel buildings;

- insulation of wall seams of easily erected structures;

- protection of loggias, balconies, basements;

- insulation and insulation of windows;

- thermal insulation of vehicle interiors;

- insulation of floors, walls, ceilings from freezing;

- insulation of pipelines, heating mains, ventilation systems;

- processing of the external part of water transport.

What is liquid insulation for walls from the inside ↑

In recent years, a newfangled innovation has appeared on the market: liquid thermal insulation. Manufacturers offer different brands of product. There are many names. Visually, this is a fluid viscous composition; as follows from the product description, it has a ceramic base and has certain heat-insulating properties. But how effective this remedy is really is something that needs to be sorted out.

Manufacturers offer different options for liquid thermal insulation. But, as a rule, they differ only in name, but the essence is the same. Ceramic liquid thermal insulation is applied in one or several layers to a previously prepared primed surface.

Reading the praises of manufacturers and sellers about liquid ceramic thermal insulation, as experience shows, is not a very rewarding task. It’s better to start by finding reviews from real users , consumers who have been convinced of its positive (or not so positive) properties from their own experience. Therefore, our task is to find such users and ask them to leave their feedback.

So let's get started.

Remember that insulation from the inside inevitably shifts the dew point inside the wall, and hence all the ensuing consequences. Consider insulation from the inside as a last resort!

Analogs

There are many varieties of thermal paints on the construction market, differing in composition, characteristics and manufacturer.

Similar products from Akterm Beton include:

- "Bronya Universal" - suitable for treating surfaces of any material. The product is used for insulating pipelines, ventilation systems, furnaces, and work tanks. Apply a product to prevent condensation. Exceptions are surfaces where the temperature exceeds 140 degrees.

- "Bronya Nord" is a liquid insulation that can be used at sub-zero temperatures. Also suitable for application to any surface. Operates at temperature conditions of -60…+90 degrees.

When choosing a heat insulator, pay attention not only to the pricing policy, but also to the properties of the material. “Akterm Concrete” stands out among other analogues due to its ease of application and low labor costs.

Reviews about liquid insulation ↑

Marina Skvortsova:

Liquid thermal insulation in the form of so-called “insulating paint” eliminates the occurrence of condensation and mold on the walls. Is it really?

My husband and I bought a newfangled material to insulate our house. This product is called: “ TSM Ceramic Liquid Thermal Insulation ”. What can I say? In general, it is convenient and simple to use, but as for the declared effectiveness... I got the impression that it is somewhat exaggerated. And regarding flammability, the information does not quite meet the criteria. If you need details, I can tell you more about our experience.

Why did we even think about liquid thermal insulation?

The fact is that our apartment is in a panel high-rise building on the first floor. The walls always freeze and get wet in winter. We were exhausted, in short. We studied this issue for a long time, none of the experts advises insulating walls from the inside, because no one knows how to solve the main issue: to shift the cold bridge towards the street, outward.

We discussed everything, a variety of options. At one time they wanted to insulate the walls from the outside with foam plastic together with a ventilated façade, but for an apartment building this is still not an option. And so we decided to insulate from the inside when we were told about this new technology.

We were advised of modern technology - it’s simple: liquid thermal insulation . We read about it and found where to buy it. It turned out that this is not a cheap material.

Price issue

One liter of liquid thermal insulation TSM ceramiс, based on our experience, is enough for approximately 2 square meters of surface. The average price is in the range of 400-500 rubles.

For clarity, I will show you in numbers. The floor height in our apartment is 2.70 m (can be rounded to three); the width of the walls is 3.0 m (we subtract from this area a window of 1.5 x 1.5 m (approximately). This means that the wall area is 6.85 sq.m., excluding protrusions, etc. This means that the consumption of liquid thermal insulation is approximately 7. Divide for 2 liters and we get 3.5 liters. We calculate the cost: 3.5 X 450 (if we take the average price) and we get more than 1575 rubles.

We only counted the wall itself. And you also need to paint the corners, slopes, protrusions, etc.

In short, we bought 4 liters. It was terribly interesting to experiment and understand what kind of magical thing it was.

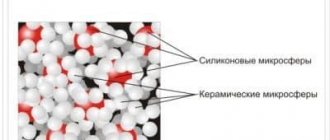

We open the jar, inside there is some kind of mixture with ceramic balls. This all needs to be mixed VERY thoroughly, otherwise, the instructions warn, nothing will work - the technology will be broken. I had to mix everything in a bucket, bringing it to a viscous, viscous consistency. And I’ll tell you, a lot of effort needs to be made... We did everything exclusively according to the instructions, we didn’t want a bummer with a “violation of technology.” Finally mixed. We don’t have a spray gun, so we decided to apply it to the cleaned surface with a brush. Doesn't apply as well as I would like. The feeling is not at all the same as when applying regular paint. There is some kind of unpleasant sticky consistency here - well, they gave up and decided to cover it with wallpaper later. What's in the bottom line? The wall actually stopped freezing from the inside. It has not frozen for three years now. It would seem good. But the slopes freeze, and ice often even forms. But the main thing that’s unpleasant is that all this is now getting wet and mold has started to appear on our thermal insulation. On the slopes, on the wall, black dots began to appear everywhere, here and there. That's it.

The next season, I painted the facade with the remains of my thermal insulation - I simply refreshed the wall from the outside and painted over some graffiti. We didn't notice any effect at all.

The so-called “ultra-thin thermal insulation for insulating walls and ceilings,” offered by the market in different variations of names, is essentially a material whose effect is based on the property of reflecting the spectrum of thermal radiation. This type of thermal insulation includes a ceramic component (as a rule, you can see small ceramic balls in it), which reflects the heat flow into the room, preventing cold from penetrating into the room - the walls become warmer to the touch and stop freezing.

Why is it worth insulating with Akterm thermal insulation?

There are many insulation materials, but why should you choose Akterm thermal insulation? Because it has the following advantages:

- Helps save space. Applying it in a thin layer provides sufficient protection from the cold;

- significantly reduces heating costs;

- eliminates freezing of walls;

- prevents the formation of condensation;

- used in hard-to-reach places (for example, on pipes);

- has anti-corrosion properties;

With its numerous advantages, Akterm thermal insulation has gained a leading position in the market. It allows you to get the maximum effect of insulation and protection from moisture at a minimum price. In addition, installation time is significantly reduced. The process of applying Akterm thermal insulation to concrete surfaces can be viewed in more detail in the video:

Liquid insulation for heating pipes ↑

I know that this material is used as thermal insulation for pipelines. And it seemed to me that this was a good idea. I even decided to use it for this purpose - to paint the pipeline for thermal insulation as an alternative to isover with mesh - in this case I liked it from the point of view of less labor intensity. Yes, and more economical. Painting pipes with such a mixture is still much easier and more profitable than bothering with isover and mesh. But when they applied it in a small space, they noticed that it had changed color, and a suspicion arose whether it was on fire, despite the manufacturer’s assurances. We checked - of course it was on, of course.

Based on our experience, we concluded: you should not use this material, unless, of course, you want to throw money away.

Rules of application

The liquid suspension is applied in a thin layer of 0.5-1 millimeter to any surface. After drying, the material acts as a thermal barrier. The operating air temperature should be within +7...+45 degrees with a relative humidity of 65 percent.

See also

Features of metal primers for rust and rating of the best brands

When treating a small surface area, the suspension is applied using a spatula or paint brush. At industrial facilities, liquid heat insulation is applied using a special installation using the spray method. When working with equipment, use an appropriate nozzle made of carbide material.

How it works?

Liquid thermal insulation Asstratek, after application according to instructions and polymerization, is a system of hollow microscopic bodies assembled into a thin carpet - a kind of air “bubbles” in a durable ceramic shell. Like any porous material, thermal paint prevents heat transfer from the painted surface. Insulation also partially reflects thermal energy in the infrared spectrum, returning it towards the radiation source.

Despite its hydrophobicity, the polymer coating is vapor-permeable, which allows it to be freely used in residential areas and for insulating “breathable” surfaces.

Types of thermal insulation in the Asstratek line:

- Universal is a water-soluble composition with wide application. For most work on thermal insulation of housing or industrial facilities, it will be enough to buy universal thermal insulation. In terms of cost, this is the most inexpensive paint in the presented range.

- Universal BC (all-season) based on organic solvents is frost-resistant. During transportation and during use, it does not change its characteristics even in frosts down to -30 ° C. It also has excellent weather resistance and is immune to sunlight.

- The facade is a water-soluble composition of high viscosity, due to which liquid insulation for walls does not spread over vertical surfaces.

- Decor-acoustic - textured thermal insulation that can improve acoustic characteristics. It has found wide application in the interior decoration of studios, concert halls, museums and other specialized premises.

- Metal – with an increased level of anti-corrosion protection of metal surfaces.

| Station wagon BC | Station wagon | Facade | Acoustic decor | Metal | |

| Packing, l | 20 | 3; 10; 20 | |||

| Price, rub/l | 495 | 415 | 430 | 445 | 445 |

Instructions for applying thermal insulation:

1. Prepare the surface as for painting - remove dust, rust, remove delamination, repair cracks and chips.

2. Prime the base with any composition suitable for the purpose. If the metal surface being treated has a temperature above +80 °C, the same Asstratek insulation should be used as a primer, diluted by 20-25% with water to reduce consumption.

3. After stirring the suspension until smooth, spread it in a layer no thicker than 0.5 mm and leave for a day until it dries. Exceeding the specified thickness will lead to swelling and the frozen liquid thermal insulation will crack.

4. Repeat the application process at the required time intervals until an insulation layer is obtained that corresponds to the thermal engineering calculations. As a rule, 5-10 layers may be required for effective thermal insulation, so insulation will take about a week.

If it is necessary to paint with a paint brush, layers should be applied up to 0.2 mm thick, giving each layer sufficient time to dry to touch. After 2-3 passes with a brush, the first technological layer of 0.5 mm should form.

The instructions for using insulation do not allow applying paint to lime surfaces, as well as to substrates heated above +120 °C at the time of painting. For Decor-Acoustic and Facade coatings, the limit is +60 °C.