Issues related to improving the energy efficiency of buildings have come to the fore in recent years. An urgent task is the choice of materials for construction, as well as the choice of a method for thermal insulation of a house, while certain requirements for thermal conductivity, flammability, environmental friendliness, weight and other parameters are imposed on the insulation.

One of the optimal options for thermal insulation of a house can be considered polyurethane foam insulation , which is applied over the entire surface in a continuous layer, which practically eliminates the formation of cold bridges.

There is a similar article on this topic - Insulation of the foundation and basement outside the house.

Spraying polyurethane foam

The method allows for insulation of structures inside and outside buildings. This method of insulation has a number of advantages that distinguish it from all others:

- PPU firmly adheres to any surface, regardless of the material. The geometry of the surface does not matter.

- No preliminary preparation of the spraying object is required. It is enough to remove dirt and dust.

- Not afraid of seasonal temperature fluctuations.

- Unaffected by precipitation.

- The lightness of the material means that there is no additional load on the object, which allows you to spray polyurethane foam everywhere without restrictions.

- This insulation option further strengthens the structure.

- The absence of seams and joints that can reduce the thermal insulation properties.

- Due to technical features, it does not require additional transportation costs.

- High environmental safety.

Spraying of polyurethane foam is carried out using special equipment. There are many varieties of such construction equipment for use on an industrial scale and for personal use.

Advantages of the material

- The material is environmentally friendly and does not contain harmful substances for the human body.

- Has a high level of water absorption.

- It has protective properties that prevent the occurrence of corrosion.

- It is resistant to mechanical damage caused by impacts, high loads, etc.

- Lifetime. Due to the fact that water is not absorbed by polymer foam, its structure is not disturbed by numerous cycles of thawing and freezing.

- No seams. Sprayed thermal insulation is applied using a special gun, so after drying a seamless layer is formed, which eliminates the occurrence of temperature bridges. If they are present, significant leaks of warm or cold air from the room occur.

- Adhesion. The sprayed product adheres well to all building materials used, only they must first be cleaned of grease, dust, poorly adhering areas of the old coating and debris.

- Expenses. Allows you to reduce space heating costs by up to 50%.

Work of specialists

This is the best way out. Companies that spray foam foam use high-power foam generators equipped with a vortex chamber, where a pressure of up to 140 atm is created. The finely dispersed mixture resulting from the chamber exits forms a quickly forming layer of insulation.

It is with the help of powerful foam generators that thermal insulation is produced from high-density polyurethane foam of 40, 60 and 80 kg/m³. Today, such material is used in production and in the construction of frame houses, where 50 mm of polyurethane foam replaces 110 mm of brick wall.

As a rule, if thermal insulation is carried out by specialists, the owners only have to prepare the surfaces for their arrival. The wall, partition or ceiling requiring insulation must be dry and clean. It is necessary to remove debris and remove patches of peeling paint. For better adhesion (sticking) of polyurethane foam, the surface temperature should be at least +10˚.

Polyurethane foam is applied quickly. After just 20-30 seconds, the insulation expands to the required volume and begins to harden.

Thickness of applied layer

To insulate the wall, it is enough to apply a thermal insulation layer 50 mm thick.

However, it will not be possible to spray over the entire surface with such precision. Therefore, professionals advise working within the range of 50-60 mm, where the minimum thickness of the thermal layer is 50 mm, the maximum is 60 mm. Foam that protrudes strongly beyond the sheathing is cut off with a knife. The data is given for a brick wall of one and a half bricks. In all other cases you need to count. To do this, you can use an online calculator (see here) or do the calculations yourself.

Insulation density

The density can be adjusted simultaneously in several ways: by changing the proportions of the components, within hundredths of a percent, by the speed and force of foam supply. Therefore, it will not be difficult for an experienced specialist to adjust the equipment to the required density. And for walls it is about 40 kg/m3.

The cost of equipment for spraying polyurethane foam with your own hands

The spread of portable installations for independent work with polyurethane foam is explained by the fact that in private homes the area for insulation can be quite small. Teams of professional workers with expensive equipment simply do not go to such sites, since it is unprofitable. In other cases, small jobs will be very expensive due to the time-consuming assembly of the installations. Disposable kits are designed for safe use by hobbyists. In areas less than 20 m2 they prove advantageous.

The average cost of a one-time installation is from 16 to 30 thousand rubles. It contains approximately 1 m 3 of polyurethane foam. The same volume of composition purchased from a specialized company will cost more than 30 thousand rubles. The benefits of working independently are obvious.

Price for sprayed insulation

The cost is quite high. Starts from 350 rubles for 1 container. If you need to do work on the walls of the house or roof, the amount will be quite large.

Spraying systems cost around 200 rubles per 1 kg. Sold in barrels from 200 kg. The amount for one container is no less than 40,000 rubles. But this amount of spray, with a density of 20 m3, is enough for approximately 133 m2.

Calculation. Working with the foundation. For 1 m2 you will need 3.25 kg of components with a density of 45 m3. For the foundation, a density indicator from the presented figure and higher is suitable.

A density of 30 m3 or more will require 2 kg of the finished substance.

Calculation. Liquid insulation Polinor in cylinders. Protection of the walls of a house with an area of 375 m2. For 2 layers of coating, 406 pieces were required. The cost of one is from 400 rubles. The total amount is more than 150,000 rubles.

Ready-made kit for spraying polyurethane Foam Kit

A disposable system for insulating polyurethane foam, Touch*n Seal Foam Kit, manufactured in the USA, is presented in the following configuration:

- 2 cylinders, sufficient for private use, filled with polyurethane foam.

- Hose – 4 m.p.

- Spray gun - “pistol”.

- Nozzles 8 pieces - 4 each, for flat and round pressure.

Hoses are connected to the cylinders, a suitable nozzle is put on the gun, and the gun is mounted to the hose. Several disposable attachments allow you to take breaks while working. The kit is usable for a month, from the first opening. The layer hardens in 1 – 2 minutes. Excess will be removed after hardening.

Insulation of residential buildings

and buildings for industrial or commercial purposes, experts recommend equipping them only on the outside. However, installing insulation on an external wall is not always possible.

Reasons

there may be several - from a ban by city authorities to technical difficulties that arise during the installation process itself.

In such cases, the option of internal insulation

subject to choosing the right material for insulation.

Among the few disadvantages of polyurethane foam

Most often, the high cost of the material required to perform thermal insulation work, equipment and the services of relevant specialists is mentioned.

However, upon detailed analysis

each of these disadvantages turns out to be only a small problem that can be solved without much effort. Thus, the risk of destruction of the coating under the influence of ultraviolet radiation is eliminated by cladding using lining or drywall.

Acquisition costs

polyurethane foam and spraying equipment pay for themselves due to the reduction in the amount invested in paying bills and purchasing medications, as well as the absence of the need to change the insulation two or three years after installation.

The thermal insulation layer obtained thanks to sprayed polyurethane foam will last at least five decades

, and its properties (high strength, moisture resistance, non-toxic, environmentally friendly), structure and shape remain the same as immediately after installation.

As an added benefit

It is worth mentioning the significant savings in space consumed when using other types of insulation. As for the costs of specialist services, they can also be eliminated if you do the insulation yourself.

For even more savings

, you should not purchase large volume cylinders. An intentional or forced break in work exceeding 1 month leads to the need to purchase a new spraying installation. The device, which was in operation, becomes unusable.

Rating of expensive products up to 1000 rubles

Irfix (4631141152769), 890 ml

The Russian manufacturer has launched the production of high-quality and reliable sprayed polyurethane insulation. Reviews about the product are only positive. You can purchase it either in an online store, by placing an order online, or by visiting any specialized retail outlet. Sold in cylinders. The kit includes a special gun for applying the composition to the surface. The product is intended for both internal and external work. The minimum temperature of use is 5 degrees Celsius.

Drying speed is average; for complete curing you need to wait a day. Belongs to the professional class. It has excellent thermal insulation characteristics. Resistance to significant temperature changes has been revealed. It is advisable to use in summer. The composition contains chemical components, so it must be applied carefully, using protective equipment. It is afraid of severe frosts, losing its original properties. The fire resistance indicator is high. During use, the foam expands slightly.

The product is intended for thermal insulation of pipelines, buildings, any building structures and structures, regardless of the complexity of the form. It fits perfectly and lasts well for a long time on wood, concrete, brick, stone. It is advisable not to use for application on polyethylene, Teflon, polypropylene. Over the years it does not deform and does not change its original qualities. Protects paint, putty, plaster from ultraviolet radiation.

The average cost is 609 rubles.

sprayed polyurethane insulation Irfix (4631141152769), 890 ml

Advantages:

- ease of use;

- no odor;

- not afraid of ultraviolet rays;

- practicality;

- efficiency;

- reliability;

- versatility;

- value for money.

Flaws:

- not identified.

Tris

The products are manufactured by a domestic manufacturer. It looks like a gas-filled polymer. The structure is foamy-cellular. Can be applied to interior and exterior surfaces. Ideally attached to plastic, wood, stone, brick, glass, metal, concrete and other building materials. The frozen mixture is completely odorless, exhibits unique resistance to pathogens and fungi, and prevents mold from appearing. The top can be painted or finished.

The density is insignificant, the thermal conductivity is impressive. The cells are filled with air, which significantly increases the insulating capacity of the material. Soundproofing and heat-saving characteristics at a high level. A completely dried ball has a thermal resistance R (1.85 K/W). The polymer is sold in aerosol cans of 1000 ml. The shelf life reaches one and a half years.

The product is very popular among professional craftsmen. Often purchased for household needs. It is used for thermal insulation of industrial and residential premises. Helps to escape from the cold in severe frosts and heat in sultry summers. Suitable for application to complex geometric structures. Eliminates cold bridges. Absorbs sounds and prevents them from leaking into rooms.

It is advisable to use at an ambient temperature of 18 degrees Celsius. It is applied using a special gun with an adjustable spray head. Promotes uniform application of the layer. After 6 minutes a crust will form. Complete polymerization occurs within one hour. Package weight – 995 grams.

Purchase price – 520 rubles.

sprayed polyurethane insulation Tris

Advantages:

- ease of application;

- versatility;

- excellent adhesion;

- reliability;

- long service life;

- perfect sound insulation;

- not afraid of temperature changes;

- practicality;

- functionality.

Flaws:

- none.

PenoPlex FastFix (850 ml)

One-component polyurethane insulation. Apply by spraying onto prepared substrates. Belongs to the category of universal. Suitable for use in a variety of building structures, outbuildings, residential and industrial premises. It holds firmly on both horizontal, vertical and inclined bases, including those with a negative slope (roofs, slopes, etc.).

Often used on small objects. It can be used both independently and as additional thermal insulation. Ideal for uneven walls and surfaces with irregular geometry, where sheet material cannot be used. The main component is polyurethane. Capacity volume – 850 ml. Density indicator – 16 – 20 kg/cub.m. Withstands temperatures from 45 degrees below zero to 90 degrees above zero. Complete curing occurs within 24 hours. A dense crust appears after 15 - 20 minutes. Fire resistance class – B2. The color of the product is bright orange.

Retailers offer products at a price of 500 rubles. If you order online, you can get it a little cheaper.

sprayed polyurethane insulation PenoPlex FastFix (850 ml)

Advantages:

- practicality;

- safety;

- ease of use;

- hardens quickly;

- retains its original characteristics for a long time;

- positive reviews;

- value for money;

- excellent adhesion to any building materials;

- versatility;

- reliability.

Flaws:

- absent.

How polyurethane foam is made: basic principle

The production of polyurethane foam involves a very complex technological process. The PU foam mass is formed as a result of the reaction between a polyol and a diisocyanate or polymer isocyanate in the presence of certain catalysts and other additives. Since the polyurethane foam itself must be produced immediately before pouring or spraying, the manufacturer supplies two phases of the polyurethane foam mixture in separate containers. The phases are mixed in special installations before performing work. Here's what happens when the two phases mix:

Due to the variety of isocyanates and the huge range of polyols, polyurethanes with different properties and applications can be obtained. It can be elastic foam, rigid foam, elastomer, etc. It is impossible to find out everything about the production of polyurethane foam, since the exact formulation of the phases is kept secret by the manufacturers. Even if all the necessary components are available, an experienced chemist will have to select the necessary proportions for a long time to ensure the required properties of the mixture.

Polyurethane foam spraying technology

Before insulation is carried out by spraying polyurethane foam, you need to prepare the surface to be treated. To do this, clean it from dirt and dry it well.

It is important to remove all rust from metals and degrease them. Aluminum requires mandatory coating with a primer with a high degree of adhesion, this will help increase the adhesion of the insulation to the surface

The temperature of the environment and components plays an important role in the spraying process. To obtain a highly effective layer, the composition must be from 10 to 25 ° C

The optimal temperature for the room is above +5 °C. Work in a colder environment can only be done with a solution heated to the desired state.

Spraying of polyurethane foam, reviews of which are almost always positive, is carried out under pressure above 100 atmospheres. Approximately two seconds after spraying, a foaming reaction occurs, followed by hardening of the composition. The resulting layer provides excellent thermal and waterproofing.

Thermal insulation of a house using polyurethane foam

The technology of insulating a house with polyurethane foam is valued for its efficiency and speed, meeting safety standards, and excellent insulating properties.

It is suitable for any external and internal structures, including loaded ones, the only limitation of application is the high price. Reviews from building owners are mostly positive; many are thinking about purchasing equipment.

Among the noted advantages are high adhesion, the absence of cold bridges, the ability to process complex and hard-to-reach areas, strength and resistance to moisture and fungus.

Features of polyurethane foam

The technology is relevant for any building surfaces, including metal. Moreover, it successfully protects the latter from corrosion by forming a film directly on the area in contact with the pipe or fittings.

Cured foam is completely impenetrable to external influences and is only afraid of mechanical damage and UV rays. There are two varieties: with an open and closed cell structure; in the cold climate of the Russian Federation, the second, more expensive and dense, is more often used for construction purposes.

This type of polyurethane foam belongs to the class of materials that are difficult to ignite and prevents the spread of flame.

Density is a controlled indicator, on which the cost of spraying polyurethane foam directly depends.

Changing the chemical composition and equipment settings allows you to vary this characteristic from 15 to 80 kg/m3 (it can be higher - up to 300, but according to reviews this is not necessary), which is important when insulating structures with varying degrees of load.

There is a clear relationship between the volume of foam formed and the ambient temperature (with the same insulation thickness, 17% more components are consumed); in the cold season, additional heating is required.

PPU with a closed structure has vapor permeability close to zero, this limits its use in internal insulation schemes. In any case, it is not recommended to completely cover both the floor and walls with it in unventilated rooms. As an option, a composition with a density below 12 kg/m3 with open cells and appropriate vapor and waterproofing is used.

Technology and basic circuits

Work on insulating polyurethane foam begins with choosing its density, taking into account the load-bearing capabilities of the structures and the thickness of the future layer according to the climatic conditions of the region. When doing it yourself, it is recommended to adhere to the following scheme of actions (using the example of a facade):

- Surface preparation: applied to stable, clean and dry structures, heated if necessary. Evenness does not play a special role, but there should be no peeling pieces of the old coating.

- Installation of sheathing (recommended). Theoretically, a frame is not needed, but installing guides helps control the level and facilitates the finishing process. The height of the sheathing is selected taking into account the future thickness of the insulation.

- Application of polyurethane foam: in a thin layer (no more than 5 mm) in the direction from bottom to top. If necessary, the process is repeated.

- Upon completion of the polymerization process, excess foam is cut off along the guides and external finishing is carried out. To plaster polyurethane foam, a chain-link mesh must be placed (similar to polystyrene foam, secured to the sheathing or material). The easiest way is to cover the facade with siding, clapboard, or, if you have an unlimited budget, to cover it with brick.

This guide is also suitable for roofs or floors on joists; experienced operators use up raw materials without leaving a trace, even without lathing.

It is allowed to use polyurethane foam in systems with heating elements (both pipes and cables); it is believed that such insulation reduces space heating costs.

When insulating pipelines, containers or metal walls, the preparatory stage includes the removal of old flaking paint and rust. A mandatory step in any scheme is sealing and hiding from ultraviolet radiation.

Mid-price segment products

Penosil Premium Insulation Foam (890 ml)

The product is very popular among builders. It has excellent soundproofing and thermal insulation characteristics. Quickly and efficiently eliminates cold bridges. Prevents the appearance of condensation on cooled surfaces. It is applied easily and simply; you do not need to have any special knowledge or skills in this matter. The thickness of the applied layer can be adjusted. Product reviews are only positive. You can purchase it either at a specialized retail outlet or place an order online in an online store.

Before you start working with the cylinder, you need to bring it to a temperature of at least 20 degrees. For heating, you can use a container with warm water. The surface requires pre-treatment. It is cleaned of ice, dirt, dust, and grease stains. The dry base must be moistened with water for optimal results. The can must be shaken well (at least one minute). The spray nozzle is inserted into the nozzle of the gun. Afterwards the container is shaken well. Working position – bottom up.

Sellers ask 492 rubles for the goods.

sprayed polyurethane insulation Penosil Premium Insulation Foam (890 ml)

Advantages:

- ideal sound and heat insulation properties;

- application speed;

- drying speed;

- independent choice of the thickness of the applied ball;

- excellent adhesion characteristics;

- reliability;

- safety;

- durability;

- functionality;

- Suitable for all building materials.

Flaws:

- not identified.

Profflex (T-Flex)

The product is manufactured by a Russian company. For spraying you need a professional gun. Package volume – 890 ml, weight – 940 grams. The insulation belongs to the single-component category. Universal type. Polyurethane spray - aerosol. Suitable for thermal insulation of various building structures, economic and domestic facilities. Ideally fits on any surface, including those with a negative slope and vertical type. Purchased for processing small areas. It can be used as an independent or auxiliary coating. It will perfectly cover hard-to-reach places where it is technically impossible to use sheet material.

Purchased for interior and exterior decoration. It has a fine-cell structure. It is applied with a ball 2.5 cm thick. It has the best insulating characteristics. One cylinder is enough to treat an area of 2 sq.m. It is advisable to apply at least two balls; the next layer is laid after the previous one has completely cured. It is used at air temperatures from 10 degrees below zero to 40 degrees above zero. Withstands temperature changes from -45 degrees to +90 degrees, without loss of original properties. Completely hardens in 12 hours. Upon completion of polymerization, it does not pose a threat to human health, is completely harmless, and does not release toxic compounds into space.

Retail outlets offer goods at a price of 400 rubles.

sprayed polyurethane insulation Profflex (T-Flex)

Advantages:

- minimum time for complete drying;

- complete safety after polymerization;

- absence of toxic components in the composition;

- perfect adhesion;

- ease of use;

- efficiency;

- long service life;

- positive reviews;

- value for money.

Flaws:

- not identified.

Titan Professional Thermospray (870 ml)

Excellent professional polyurethane thermal insulation from a Polish manufacturer. Produced by Selena. Thermal conductivity is low. Can be used at a minimum temperature of 5 degrees Celsius. One-component composition, completely ready for use. Self-adhesive insulating composition based on polyurethane. It has a high level of adhesion to a variety of surfaces. Holds firmly on brick, concrete, metal, wood, polystyrene foam. Bottle volume – 870 ml.

An ideal option for insulating balconies and increasing the level of sound insulation of premises for both residential and industrial purposes. It is easy to insulate an air duct or pipes and protect structures from damage by fungus and corrosion. Very easy to apply. Even a novice master can cope with the task. The surface is covered with a continuous sealed ball. In this case, no seams are formed. There is no need to use additional equipment. The components cannot be mixed.

The substance is sold in cylinders with a special spray nozzle. Excellent for spraying large substrates, non-standard areas, and hard-to-reach places. Seals cracks well. A five-centimeter layer is sufficient for thermal insulation.

Purchase price – 460 rubles.

sprayed polyurethane insulation Titan Professional Thermospray (870 ml)

Advantages:

- versatility;

- practicality;

- helps isolate hard-to-reach areas;

- economy;

- efficiency;

- quality of the material used;

- long service life;

- ease of application;

- safety;

- reliability;

- value for money.

Flaws:

- none.

Characteristics of polyurethane foam

PPU is popular not only because applying polyurethane foam with your own hands is a fairly simple process. This material has excellent characteristics:

- thermal conductivity coefficient 0.019-0.028 W/m*K;

- vapor permeability tends to zero;

- density 30-60 kg/m. cube;

- does not burn - according to GOST 12.1.044 it is classified as low-flammable materials;

- does not absorb moisture - the percentage of closed cells is from 85 to 95.

This also applies to the insulation of frame walls with expanded clay. In addition, it is quite heavy.

It has good adhesion (adhesion) to all materials. Thanks to its almost complete waterproofness, polyurethane foam protects metals from corrosion. In the characteristics of polyurethane foam there is also such a thing as start time. This is the number of seconds it takes for foaming to occur. The start time for different types of work is slightly different. For horizontal surfaces, the foaming time should be about 5-10 seconds. For ceiling insulation, this period is reduced to 3 seconds.

Equipment for applying polyurethane foam

Installations for spraying polyurethane foam come in high and low pressure. The main elements are a compressor and a spray gun, in which the PPU components are mixed. In low pressure equipment, mixing occurs at 5-10 atmospheres, and in high pressure equipment - at 100 atmospheres or more.

Different pressure affects the mixing method:

- at low pressure the components are mixed by swirling;

- at high pressure, mixing occurs through the diffusion of components.

And the leader in this niche is Rocklight stone wool insulation, made from basalt.

Low pressure units are smaller, cheaper, and easier to operate. In them you can set mixing proportions (1:1 or 1:2) and smoothly adjust productivity directly during operation. High-pressure units allow you to create a more even layer of thermal insulation; you can work at a distance of up to 125 meters from tanks with mixed components. The productivity of such equipment is significantly greater (up to 500 square meters in 8 hours). These are professional installations, which is why they are quite expensive.

Minuses

When deciding to use polyurethane foam in cylinders for thermal insulation of your home, you must also take into account its disadvantages:

- Low resistance to sunlight. It is recommended to paint, plaster or panel the finished surface, thereby protecting it from the damaging effects of ultraviolet radiation.

- The need for special protection. You need to work with the material wearing waterproof gloves and a respirator.

- Expensive. Such insulation is an order of magnitude more expensive than conventional roll or slab materials.

- Ability to smolder. Although polyurethane foam is a fireproof material, it is better to avoid direct exposure to open flames. During smoldering, the substance emits carbon monoxide, which is dangerous to humans.

- Low mechanical stability. The frozen layer must be protected from impacts and sharp tools. Almost all popular insulation materials have a similar disadvantage.

DIY polyurethane foam spraying

All work must be carried out in good weather. High humidity outdoors and indoors at this time can slightly damage the polyurethane foam. Do-it-yourself spraying needs to be done in several layers. This is one of the main principles of work.

Insulation with polyurethane foam by spraying begins with complex surfaces: chimneys, ventilation hatches and pipelines. At the same stage, you need to close all the joints that go out. It is advisable to apply the first layer with a thickness of approximately 14 mm. After it hardens, you can begin further work.

The second and third layers are applied to each other with a short time interval. It is optimal to carry out all work in one day. If this is not possible, then, starting each subsequent layer, you need to carefully prepare the surface. With proper planning of working hours, insulation of a medium-sized private house can be completed in 2-3 days.

The most effective sound and heat insulation is considered to be a structure consisting of three layers.

PENA-mini B2 Russia vs PPU Foam Kit USA cylinders

We planned for our PPU household device, like the American one, to work on the “Touch and Seal” principle, i.e. "Touch and isolate." But it was not possible to copy the Yankees 1 to 1.

In fact, there are three differences. One is negative and two are positive. Read on and decide for yourself what is better to buy for thermal insulation of polyurethane foam with your own hands: American or Russian cylinders.

PENA-mini B2 is inferior to the American Foam Kit in that imported cylinders do not require a source of compressed air. Containers with components A and B are already under pressure. Therefore, to get started, just connect the sprayer, open the valves on the cylinders and spray. The “Touch and Seal” principle in the truest sense of the word.

Our device requires compressed air, i.e. small household compressor. It is needed to create excess pressure in the cylinders. Americans pump gas into cylinders with polyol and isocyanate and seal them somewhere in Florida or California. And to a Russian in Samara or Barnaul who decided to insulate a balcony, garage, etc. with PPU with his own hands. no compressor needed. That's a plus.

If suddenly there are not enough components in the cylinders, then you need to go to a gas station. The closest ones to Samara are located in Florida, Georgia and South Carolina. California or Arizona will be more convenient from Barnaul. Or, without leaving Russia, you can always buy another new Foam Kit kit.

FOAM-mini B2 is superior to imported Foam Kit in that our installation is REUSABLE. PENA-mini B2 cylinders are filled with PU foam immediately before work, on the balcony of a house in Samara or a garage in Barnaul.

From one canister we pour component A into the first cylinder, from the second - component B into the second. And now, to get to work, you need to create excess pressure in the cylinders. This function is performed by the compressor.

Yes, a domestic product requires a source of compressed air, but the components can be added to the cylinders and used repeatedly. American cylinders are disposable.

FOAM mini is also better because it is cheaper. Domestic cylinders and components for refilling them are cheaper than imported Foam Kits.

American cylinders are expensive and can only be used once, i.e.: sprayed and thrown. Therefore, the motto Touch and Seal in relation to Russia can be clarified: Touch, Seal and Threw.

The NST company offers a reusable device PENA-mini B2 for insulating polyurethane foam with your own hands and raw materials for self-refilling.

Types of polyurethane foam and areas of application

- Open cell (elastic), with a density of 10-20 kg/m³;

- Closed cell (hard), with a density of 20-30 kg/m³ and higher, up to 80 kg/m³.

Polyurethane foam will perfectly protect the room from heat loss and also cope with its waterproofing.

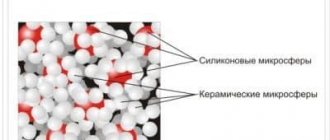

In elastic polyurethane foam, up to 90% of the cells are open. Its low density gives it a certain stretchability. In hard polyurethane foam, up to 98% of the cells are closed. This and its high density make it an unusually strong insulating material.

Different types are used in different fields. If we are talking about spraying on a material that can change its size - for example, metal structures that contract and expand with temperature changes - then elastic polyurethane foam is used. It is indispensable for waterproofing, for protecting the connection between the wall and the roof, for spraying on wooden and metal surfaces that come into contact with cold air from the outside of the building.

Closed cell (rigid) polyurethane foam is used for internal insulation and outdoor work. It is usually sprayed on surfaces made of concrete, cement and brick. Closed cell polyurethane foam is also used when they want to give the structure frame additional rigidity. Its high strength allows you to significantly strengthen unstable elements. Both types of polyurethane foam have many advantages, but very few disadvantages.

Review of manufacturers

In order for the insulation of the house to go without problems, and for the polyurethane foam to be of high quality, you need to purchase it from well-known manufacturers. There are several most popular companies:

- SYNTHESIA ESPANOLA SA produces different types of polyurethane foam, the materials are of high quality and ease of use;

- Ecotermix produces various thermal insulation systems, sprayed types of polyurethane foam;

- Demilec produces environmentally friendly thermal insulation based on polyurethane foam;

- Bayer is the world's leading chemicals manufacturer.

What is polyurethane foam?

Few people know, but polyurethane foam (PPU), which is in demand today, was manufactured back in the last century. It was first used as thermal insulation in 1957. Since then, it has not only not lost its relevance, but has also begun to be used in other areas far from construction. It is polyurethane foam that is one of the fillers in upholstered furniture, children's toys, etc. What is polyurethane foam?

At its core, polyurethane foam is one of the types of plastics. The uniqueness of the material lies in the fact that the main percentage of the substance is gas bubbles. According to studies that have been repeatedly carried out with the finished product, modified plastic in the finished product is only 10-15%. The rest of the space is occupied by gas bubbles. As a result, the material acquires special thermal insulation and performance characteristics.

. Namely:

- A 3 cm layer of polyurethane foam is identical in thermal conductivity to 7 cm, 16 cm mineral wool, 38 cm foam block and 1 m 70 cm brick wall.

- The material can be prepared directly at the construction site or purchased ready-made mixture in cylinders.

- Tests have shown that polyurethane foam retains its performance characteristics over a range of - 150° to + 220°.

- Has high adhesion to any surface

. Using polyurethane foam you can even insulate a metal structure. - After drying, the surface can be plastered or used as a base for laying ceramic tiles.

You need to know that there are several methods of insulation using polyurethane foam. You can purchase sheet material, prepare a two-component composition yourself, or use a ready-made mixture sold in containers resembling polyurethane foam.

Sprayed insulation in cylinders

It differs from a conventional sprayer - the finished substance is already in a convenient form. You just need to put on a special device (a pistol), and you can perform the necessary actions. The aerosol sprayer should be shaken periodically during application.

Analogue of construction foam. Quite a lot of it is consumed - on average, 1 spray bottle is needed for 2 m2.

Helpful Tips:

- the substance should be sprayed at a distance of 30 cm;

- It is worth adjusting the pressing force when working with sprayed thermal insulation in cylinders - it will be more economical;

- For the ceiling, a special corner attachment will be useful. It is more convenient to use;

- in winter, care must be taken to maintain heat in the container. You can wrap it in woolen cloth. Additionally, wrap the polyurethane foam in the balloons with cellophane;

- There is successful practical experience in using “heat islands” in winter - a movable shelter is built in which the temperature is maintained using heaters.

A protective suit will also be required. All other stages of working with it are exactly the same as with spraying systems.