An old Russian stove is a very effective source of heat, used to heat country houses, prepare delicious dishes and baked goods. The efficiency of using the energy of burned wood is at least 60%, thanks to which the brick structure is of interest to private developers and homeowners.

This material will be useful for novice stove makers and home craftsmen who want to organize home heating with their own hands. We propose to study the structure of a classic design with a stove bench, then consider the designs and arrangements of modern versions of the Russian stove.

Construction of a traditional oven

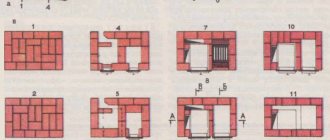

We will not describe the history of the Russian stove and its role in a village house - the topic is widely covered in fiction and technical literature. Let's get straight to the point - let's briefly analyze the traditional design shown in the figure below:

- The lower part of the structure - the guardianship - was built of stone or wood - cedar, larch. The walls of the base form a niche - a stove where firewood was dried and household utensils were stored.

- On top of the guardianship, the first arched vault and a large firebox of the furnace - the crucible - were built. Under and the second arched vault was made with a slope towards the brow - the front part of the structure.

- A roof was placed over the furnace, where the bed was located. The cavity between the second arch of the firebox and the ceiling was filled with sand to increase the heat capacity.

- In front of the mouth of the furnace, a special niche was provided - a bend, ending at the top with a hail (smoke collector) and the chimney itself. The horizontal shelf at the bottom of the opening—the shelf—has a semicircular window facing outward.

- Stoves were installed in the side walls of the brick heater - small niches for drying clothes and other things. The chimney was equipped with a valve and a view located above the heil.

Reference. The history of the evolution of the Russian classic stove is described in great detail in the popular book of the same name, author - Gennady Fedotov, published in 2003.

A real Russian stove is fundamentally different from other brick heating structures in the following ways:

- deep vaulted firebox made with a forward slope;

- the chimney is located in the front - in the center or in the corner of the building;

- An indispensable attribute is a bench located above the fuel chamber.

Now let’s look at the operating principle of the stove, shown in the diagram:

- The firewood is placed closer to the back wall of the furnace and lit. The combustion air enters through the outer window of the hearth and the mouth of the firebox, and moves above the bottom of the chamber.

- The heat generated during combustion heats the body of the furnace - the side walls, sand backfill and bench.

- Light combustion products rise to the roof of the firebox. The slope does not allow gases to immediately leave the chamber - first they give off heat to the ceiling, then they become heavier and are forced out by a new hot flow.

- Having passed under the arch of the furnace, the combustion products exit through the upper zone of the mouth, rise into the smoke collector and leave the stove through the chimney.

Note. During the combustion process, bread is not baked or food is cooked. When the oven is well heated, the coals are first raked out from the firebox, then the food is loaded into metal dishes - cast iron pots - using a grab handle. The outlet is closed by a damper.

Brick heater with access to 2 rooms of a wooden house

Despite its many advantages, a Russian stove with a stove bench is rarely built in a traditional design. Useful space in a modern interior is worth its weight in gold, and a classic heater takes up a lot of space, while poorly warming the lower zone of the room. For construction, it is better to consider projects of modernized structures, where this problem has been solved.

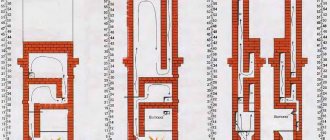

Another diagram of the furnace masonry

*

We will not dwell on this option in detail. From the previous diagram it is easy to understand what each element in the illustration represents.

Figure 5. Layout diagram of another furnace option

This model is one of the simplest. However, it is effective and efficient. Unlike more complex structures, the execution of this one can also be entrusted to even a relatively unprepared homeowner.

Figure 6. Alternative design with a bed

Improved heater options

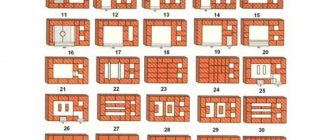

Many Russian masters were involved in the modernization of the classic stove - I. Kuznetsov, I. Podgorodnikov, A Emshanov, A. Batsulin. The essence of the changes is as follows: the details of the old design were taken as a basis - the vaulted furnace, the bend and the high above the mouth. New functional elements were added to them:

- Instead of a hearth, a hob is placed, and a small flood is arranged below. A parallel summer passage shaft is laid out, connected at the top with the main smoke collector.

- Hot gases from the additional firebox are directed through smoke circulations made in the lower part - the stove. Then the combustion products are discharged into a common pipe.

An example of modernization - in winter mode, gases from the furnace and furnace heat the lower part of the structure - At the end or on the sides of the furnace, vertical channels are installed, again leading to the lower zone under the firebox, then into the chimney.

- The channels from the firebox go into the attached heating panel and out through a combined pipe.

- The firebox is made from the bottom of the furnace and communicates with it through a grate installed in the hearth (bottom) of the main firebox. Gas ducts from the furnace penetrate the furnace and converge into a vertical shaft leading into the chimney.

Note. The changes made allow the stove to be heated in two ways: in Russian (the smoke comes out through the mouth and high) and in the heating and cooking mode (gases move around the channels).

Another example - there are vertical passages in the side wall that form a heating shield.

We tried to clearly describe common concepts; there are many more existing options. The purpose of the changes is to improve heat transfer and functionality of the basic design. If desired, a water circuit register or an oven is mounted inside the flues (the cabinet is placed next to the firebox).

Now we will analyze the updated options in detail using specific examples - with drawings and procedures.

Correct operation

To use the device correctly and safely, the following rules must be observed:

- Carefully monitor the condition of the chimney and clean it from ash in a timely manner.

- Before each kindling, check the quality of the draft - this will help prevent smoke from entering the room.

- If the stove has not been used for a long time, a thorough inspection is carried out for damage and cracks.

- You should not light a stove while intoxicated or very tired; it is not recommended to leave small children alone near a burning stove.

Precise construction and compliance with all operating rules will ensure high-quality operation of the stove, efficient heating of the house, and the preparation of delicious traditional dishes.

Mini-oven project with stove

The Russian heating and cooking stove “Teplushka” with an additional combustion chamber has a power of 3.5 kW. The structure is designed for heating a small house or cottage with an area of 30-40 m², as well as cooking in winter and summer. The device of a small heater is shown in the drawing.

The mini-oven can operate in 3 modes:

- Summer move. We open valves 1, 2 and 3 (see the picture), load the firewood with firewood. The gases immediately escape through the main channel into the pipe, and the stove heats up. Damper No. 3 plays the role of a hood.

- Firebox for winter. We use the lower chamber again and close valve No. 1. Then the combustion products move through the furnace and flue ducts into the oven, exit through the channel to the front side and then into the main chimney. The entire body of the furnace is heated, from bottom to top.

- Firebox in Russian. We light firewood in the furnace, open the sealed mouth door and valve No. 3, valves 1 and 2 are closed. The smoke goes into the hailo and the main chimney, only the stove bench is heated. For full heating, close the door, open damper No. 2 - the gases will flow through the lower channels of the stove.

Note. The diagram of gas movement under different operating modes is shown in the figure.

Thanks to its efficiency and relatively low cost of materials, a mini-stove can easily be called a housekeeper. One minus is the small size of the bed. The maximum height of the building is 2.1 m, in the area of the ceiling - 147 cm.

Building materials and stove fittings

To make a Russian mini-oven with your own hands, you need to buy components and materials:

- solid ceramic bricks – 670 pieces (the chimney is counted separately);

- fireclay bricks for the firebox – 25 pcs. (brand ША-8);

- fireclay block brand ШБ-94 or similar in size – 1 pc.;

- door of the main chamber mouth 25 x 28 cm, possible with fireproof glass;

- loading door 21 x 25 cm;

- ash pan door 14 x 25 cm;

- two grates measuring 300 x 250 and 220 x 325 mm;

- wooden template - circle - radius 460 mm, length - 65 cm;

- cast iron hob with 2 burners 71 x 41 cm;

- 3 valves: 13 x 25 cm - 2 pcs., 260 x 240 x 455 mm - 1 pc. (brand ZV-5);

- equal angle corner 40 x 4 mm – 3 meters;

- steel sheet 1 mm thick for a shelf in a stove;

- galvanized mesh for reinforcement, cell 3 x 3 cm - 2.1 lm;

- kaolin wool, corrugated cardboard.

Appearance of the finished mini-stove for a country house

Red brick laying is done using sand-clay mortar. When constructing a chimney, it is allowed to add M400 cement. Fireproof stones are placed on another solution - fireclay clay, mortar and the like.

Advice. For beginners, we recommend making solutions from ready-made building mixtures sold in stores.

Laying progress - step-by-step instructions

A reinforced concrete or rubble concrete foundation is cast under the furnace, the dimensions of which are 10 cm greater than the dimensions of the structure. Start construction when the concrete reaches 75% strength; under normal conditions, the hardening process will take about 2 weeks. This assumes an average daily air temperature of +20 °C and proper care of the monolith.

Having installed waterproofing from 2 layers of roofing material, make the first row continuous (40 bricks will be needed). How to fold the stove according to the order, read on:

- An ash chamber is formed on 2-3 tiers, a cleaning door is installed, and columns are built to support the bottom of the furnace. The 4th row continues the main walls of the stove; the ash chamber is covered with cut stones.

- Rows 5-6 form the main smoke channel and the bottom of the firebox made of refractory bricks. The grate is installed without mortar; a row of fireclay stones placed on edge is placed on top.

- On the 7th tier a loading door and a vertical summer shutter are installed. Rows 7-9 are laid according to the pattern, at the end the fireclay brick is covered with kaolin wool (marked in green). Please note: on the seventh tier the walls are reinforced with steel mesh.

- Rows 10 and 11 partially cover the flues and the lower heating chamber; a grate for the furnace and a hob are installed. The 12th tier begins to form the main firebox, and on the 13th tier the door is attached to the mouth of the furnace.

- Rows 14-17 are laid according to the diagram, corners are installed to cover the cooking opening. On the 18th tier, steel profiles are covered, and an arched vault with a radius of 46 cm is built from wedge-shaped stones.

- Tiers 19, 20 are made according to the scheme, the cavity between the vault and the walls is filled with sand or filled with thick masonry mortar. When the filler dries, 21 rows are laid - the roof.

- From 22 to 32 tiers the front part of the heater is built. On the 24th row, both smoke valves are placed, on the 25th - an iron shelf measuring 42 x 32 cm. Having laid the 29th tier, cover the stove with the same sheet.

Recommendation. Create a gap between the ceramic and refractory masonry using regular packing cardboard. Subsequently, the paper will burn out, but the gap will remain. Horizontal seams between red and fireclay bricks are not filled with mortar, only with kaolin wool.

To understand the construction down to the smallest detail, we suggest watching a video with a detailed demonstration of the masonry of each row and explanations from the master:

Making the foundation

To build a Russian brick stove with a stove bench, you should prepare the foundation. The weight of the structure will be quite large, so a massive base with a carefully calibrated horizontal surface will be required. It is better to do this at the stage of building a house, when the general foundation is laid.

The base for the stove is made in the form of a monolithic concrete slab, but not connected to the foundation of the house. A hole up to 30 cm deep is dug in the selected area; its contours should be larger than the dimensions of the base of the future furnace. A layer of sifted sand is poured onto the bottom of the prepared pit and formwork is placed.

The height of the formwork above the ground level is 10-15 cm. Then the formwork is filled with concrete mortar, after drying the surface is covered with a layer of coating waterproofing. Between the base for the furnace and the general foundation there should be a 1 cm expansion joint, which is covered with sand.

Foundation diagram

The Russian stove with a stove bench begins to be installed only after the concrete has completely dried. The brick should also be prepared before work; just soak it in a bucket or trough of water.

Russian "teplushka" with a couch 127 x 166 cm

The design and principle of operation of this stove are similar to the previous heat source. The difference is in size, power and some design features. There are also 3 modes available here - winter, summer and Russian fire. The heat output is 4.5 kW, the heated area is 45-50 m².

In winter mode, firewood can be burned on the grate of the furnace or in the firebox - the gases will still flow through the lower passages and warm up the entire stove

The size of the stove in plan is 1270 x 1660 mm plus 10 cm for the projection of the foundation. The height of the front part is 210 cm, the height of the bed is 147 cm. Set of materials for construction:

- refractory bricks ША-8 – 26 pcs.;

- red solid brick – 995 pcs. (the chimney is not included in the specified quantity);

- fireclay block type ШБ-94 – 1 pc.;

- main door installed at the mouth - 41 x 25 cm;

- ash pan door 14 x 25 cm, firebox door – 21 x 25 cm;

- 2 grates with dimensions 240 x 415 and 220 x 325 mm;

- stove 71 x 41 cm (2 burners);

- chimney damper type ZV-5, size 260 x 240 x 455 mm;

- 2 valves 130 x 250 mm;

- sheet steel 2 mm thick;

- galvanized reinforcing mesh – 1.5 lm (mesh 30 x 30, wire 1 mm in diameter);

- template for forming an arch, radius – 322.5, length – 645 mm;

- circled under the arch of the main firebox with a radius of 60 and a length of 77 cm;

- corrugated packaging cardboard, kaolin wool.

This is what a large “Teplushka” with a power of 4.5 kW looks like.

Preparatory work - installation of a reliable foundation. Keep in mind that after pouring the foundation, the formwork can be removed after 3-4 days (during the warm period), and the stove can be built only after 2 weeks. The base area is covered with waterproofing - roofing felt folded in half.

How to properly lay out a full-size “Teplushka”:

- Row No. 1 is continuous, consisting of 65 ceramic bricks. On the second tier, we begin to form the walls of the furnace and support columns, and install the door of the ash chamber. We install 8 stones on a poke without mortar and cut them to the height of the 3rd row. We do not connect it with the rest of the masonry - these will be cleaning hatches.

- We place the third tier according to the diagram, on the 4th we cover the ash pan. On the 5th row, we begin to build the walls of the firebox from refractory, insert a grate 415 x 240 mm.

- Rows 6 and 7 continue to be laid according to the pattern, fireclay stones are placed on the edge. After the formation of the 7th tier, we install the firebox door and the summer valve installed vertically. Rows 8-9 are built according to the order.

- On the 10th tier we cover the floodplain and cover the upper ends of the refractory bricks with kaolin wool. The front part of the chamber must be covered with fireclay block ШБ-94 or similar. We begin to reinforce the walls of the furnace with galvanized wire mesh, then we arrange a re-covering of red bricks (row 11).

- On the finished 11th tier we insert the stove and grate bars of the main chamber - the furnace. We make level No. 12 according to the order and install a large door. Then we lay out the 13th tier and arch using a circle.

- We build rows 14-17 according to the drawings, raising the outer walls of the furnace, the smoke channel and the front partition of the furnace. Next we lay an arched vault R = 60 cm made of wedge bricks. We continue to build tiers 18 and 19 according to the diagrams.

- In the twentieth row we block the front arch and raise the outer walls higher. We fill the void above the vault with a solution of clay and sand. After drying, we build tier 21 - the plane of the bed.

- Tiers 22-32 make up the front section of the stove, where the chimney is combined with the side flue. We line up the rows according to the diagrams, on the 24th level we install 2 valves, on the 29th level we place a sheet of metal covering the stove.

The expert will give step-by-step instructions for building a Russian multifunctional stove in his video:

Russian style stove dimensions

Before constructing a furnace structure, the site for the construction of a heating structure is always first selected. A Russian-style stove can be located in the corner of the room or along one of its walls. The dimensions of the heating structure depend on the size of the room. These parameters are also affected by the reliability of the foundation.

Nowadays, they often begin to build a stove in an already built house. This is not quite the right option. After all, it is more convenient to thoroughly think through the heating structure at the design stage of a residential building. However, even in this case, craftsmen will always build an effective stove. It can have the following design:

- Mini Russian stove, the width and length of which are 1240 mm and 1780 mm, respectively. This option is suitable for construction in a country house, under a canopy or even in a summer kitchen.

Miniature Russian stove design Source blogspot.com

- A medium-sized heating structure, also called a home stove. Its dimensions are 2130*1470 mm. This option is suitable for heating a house up to 40 m².

- Full-size heating structure with dimensions 3250*2250 mm. Such a stove is capable of heating a large one-and-a-half-story residential building.

On a note! The dimensions indicated above are unusual even for some stove makers. However, experienced specialists know well that previously the length was measured in arshins. Therefore, if you use not millimeters, but the ancient system of measures, then it turns out that a Russian home stove, the dimensions of which are now 2130 * 1470 mm, previously had dimensions of 3 * 2 arshins.

The above dimensions of a Russian-style stove are only recommended dimensions. When constructing such a heating structure, it is more important to maintain proportions when laying the vault, hearth, furnace and chimney. In the latter case, you need to lay out a channel of a suitable cross-section to ensure effective traction.

One of the stove size options Source ps.494444.ru

Construction Technology Tips

The construction of a Russian heating stove is a serious matter. It will be very difficult for a homeowner without experience in the stove business, so we recommend stocking up on time and patience. We published detailed instructions for preparing the mortar and laying it in an article about building a fireplace; we advise beginners to familiarize themselves with the specified material.

Here we will give general recommendations regarding the Russian home stove:

- Even the mini version of the heater weighs over 2 tons. The foundation slab must be supported on a stable soil horizon; the depth can be determined by the occurrence of the existing foundation of the dwelling.

- In the finished building, the “sole” must be arranged separately from the foundation of the house, retreating at least 10 cm. At the stage of construction of the cottage, the foundations, on the contrary, are combined - a common formwork is set up and concrete is poured.

- You need quality bricks and mortar, not a gully clay mixture. The correct geometry of the stones will make your work much easier - uneven bricks will have to be filed down.

- Soak the red brick in the bucket for 2-3 minutes, as shown in the photo. Do not immerse the refractory in water, just rinse it to remove dust.

- It is allowed to lay the furnace and firebox from ceramic bricks, as our ancestors did. But remember: such cameras are afraid of accidental overheating; the material begins to crumble and crumble.

- A bed built on a loose base is also afraid of temperature fluctuations. This is why it is recommended to fill the void above the vault with clay mortar. If you fill the cavity with sand, small cracks may appear on the roof. No sooner had the stove been built than repairs needed to be done.

- The refractory masonry is not tied to the ceramic; cardboard is inserted to provide a gap between the two walls. Horizontal seams are laid with kaolin non-combustible wool.

- The pipe does not have to be made of brick all the way to the top. Lighten the structure - after cutting, install a sandwich - a chimney that goes out onto the roof, as shown in the photo.

Reference. Often, stove makers strengthen the arch and walls with an iron frame welded from corners.

Finally, a few words about how to properly heat a new stove. After drying the stove for 2-3 days (in summer), first build a small fire on the top damper. When the pipe warms up, start heating the furnace little by little, then the lower chamber. Increase the amount of firewood slowly, do not rush. The task is to uniformly heat the furnace body for final drying.

Preparation of clay solution

To build and paint a Russian stove at your dacha with your own hands, you will need 3.5 m3 of mortar. To do this, take a certain amount of components and dilute them with water.

You can use an iron barrel as a container. Soak the clay in water and leave it for a couple of days. Next, add sand, and thoroughly mix the entire solution with your feet (after putting on rubber boots) until the mixture is homogeneous. Since the width of masonry joints is no more than 3 mm for fireclay bricks, all large pebbles must be removed from the mortar.

List of tools

To make work easier when laying a Russian stove with your own hands, you need to prepare working and measuring tools in advance. The working tool set should consist of:

- bayonet shovel;

- containers for preparing masonry mixture. It should be wide enough and have low sides;

- a shovel and two metal sieves with mesh sizes of 2x2 and 1x1 mm. This tool is used to sow clay and sand;

- trowel - a special trowel, which is used to take the mortar and distribute it among the masonry elements, and also remove excess mixture that protrudes beyond the seam;

- hammer - pickaxe. They can be used to divide a whole brick into several parts and trim the resulting surfaces;

- jointing, which helps to seal masonry joints and give them the desired shape;

- scraping - a rubber plate with a handle. It cleans the internal surfaces of the masonry from excess mixture and seals the seams in hard-to-reach places;

- saws - grinders. It can be cut more accurately and bricks can be adjusted for laying curved structural elements;

- rules - for leveling the upper plane of the foundation.

Control of vertical and horizontal masonry joints and geometric parameters of the entire furnace structure is carried out using:

- bubble level;

- plumb line;

- square;

- roulettes.

Date: September 25, 2022

Trial fire

After drying is complete, perform a test fire in the following sequence:

- the combustion chamber is loaded as much as possible with dry wood, laying it in dense rows and set on fire. At this moment, the valve should be fully open, and the wellhead valve, on the contrary, should be tightly closed;

- after the first batch of firewood has burned out, the next portion of wood is loaded, but only 2/3 of the furnace is already filled;

- The intensity of fuel combustion is regulated using a valve;

- Complete closing of the valve is possible after all the firewood has burned out and the formed coals have gone out.

The next fire can be started only after the stove has completely cooled down.

Final works

You have built an excellent and multifunctional fireplace for your home with a stove bench on your own. Not only is it pleasant to admire, but the fireplace can heat a room and retain heat for a long time even after the combustion process has ended. The credit for this goes entirely to the material. Brick has a high heat capacity and is able to accumulate heat.

The very presence of a stove in the house requires the design of the room to be designed accordingly. A brick stove without finishing looks good against the background of wooden or wood-trimmed structures. In this case, it is necessary to comply with all fire safety rules. When lifting the chimney through the ceiling, you will have to install a heat-protective belt. This will save not only from a possible fire, but also from deformation of the ceiling material.

Modern styles of room decoration will require the same from the fireplace. Here you can use different materials to suit the owner’s taste. The exception is those that are unstable to elevated temperatures. But if one of the main functions of the stove is heating, which is most likely, then it is better not to cover the brick, but to give it the opportunity to fully transfer heat to the room.

By removing the remaining mortar from the surface of the bricks and treating the seam gaps, you can achieve an excellent appearance of the masonry, which once again proves the importance of observing dressing during the construction stage

Design Features

The Russian stove has come a long way, changing and improving over the centuries.

A huge contribution to the development was made by I. S. Podgorodnikov, who developed the “Housekeeper” and “Teplushka” series, on the basis of which all Russian stoves are now made. The design was further improved by I.V. Kuznetsov, who separated the firebox and cooking chamber, sealed the pre-furnace and thereby increased the safety of the structure and efficiency. Modernized versions are now in use. The design of a Russian stove with a fireplace is very popular in private houses made in classic and country style.

The main elements of a standard Russian stove:

- Pipe.

- Valve.

- Door.

- View.

- Hilo.

- Six with a window.

- Sub-bake.

- Mouth.

- Podina.

- Backfill.

- Crucible.

- Arch.

- Ochelok.

To make a Russian stove with a fireplace, an additional fire chamber is installed on the side inside the brickwork (it can be open or closed). They also make special channels through which heated air passes, convective pipes and panels, an ash box, and a sealed combustion door with fire-resistant glass.

General form

As a result of such an improved design, the house becomes warm, as if a classic Russian stove was operating. But the device turns out to be clean (the emission of combustion products into the living space is reduced), the level of safety and ease of use increases.

Traditionally, a bench (roof) is installed on the top of the stove behind the chimney. The stove bench warms up due to heat transfer from the “ceiling” of the furnace. The base is usually coated with clay, and wood is laid on top - then the place turns out to be warm, but not scalding.