If there is only cold water in the house, then living in it can hardly be called comfortable. Often, to solve this problem, it is proposed to install a separate system that will heat the coolant, consuming additional electricity. But if you install a heat exchanger for hot water from heating, you can significantly save energy resources. Let's consider what types of devices are used in private homes, and how they are correctly connected to the heating system.

Plate heat exchanger Source a.allegroimg.com

What it is?

A heat exchanger is a device designed to exchange heat between two or more heat carriers not directly connected to each other.

Most often used to heat water directly from the heating system. This allows you to significantly save on heating and electricity, as it allows you to avoid spending additional energy on heating water, as is the case with an electric or gas water heater.

Theoretically, you can consider using water directly from the heating system, since its quality is not much different from water sold in supermarkets. However, in practice, it cannot be used for domestic purposes.

This is due to the following reasons:

Replacing water in heating pipes is a costly process and requires money.- The injection of new water has a negative effect on boilers and contributes to rapid wear of the system.

- Heating systems often use chemical additives to soften the water.

- The pipes in these systems themselves have a lot of deposits inside them; the standards for their use are designed for process water, and not for human consumption.

For the above reasons, it is not possible to use water directly from heating pipes for household and food purposes, and to heat water from a heating system, it is necessary to use a heat exchanger.

Heat exchanger features

Let's figure out why a heat exchanger is needed. In the device, two different media share thermal energy. Hot water in one container gives off its temperature to the cold liquid, which moves in another container. And the simplest example is a system of two steel pipes of different diameters.

Cold water moves less. A small section of this pipe is placed in another, larger diameter. The latter contains hot water. And after a short time, the temperatures of both liquids become equal.

In order for the process to proceed steadily and constantly, the water is forced to move (circulate). And giving the flows certain speeds allows you to minimize all heat losses. Moreover, only one energy source is used to heat two systems at once.

This arrangement significantly increases the autonomy of the home. And eliminating unnecessary equipment from operation allows you to be less dependent on network resources. Thereby reducing energy costs in the home.

Stainless steel heat exchanger Source s-ip.com.ua

The performance of the entire system is affected by:

- Device model (design).

- Temperature regime.

- State of the system.

The last point relates to the amount of heat loss. The surface of the pipes through which the liquid moves is responsible for this. If scale has formed on the walls, the heat transfer of the system is significantly reduced. The latter is also influenced by other factors, including simple fat deposits.

In the fight against losses, prevention of blockages and contamination comes first. The heating heat exchanger is equipped with filters that filter out foreign particles and suspension. Also, at certain intervals, the device must be completely cleaned of scale and other deposits. To do this, it is disassembled and washed using special means.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

What are the advantages of using the device?

The main advantages for which it is worth installing this device are:

- High efficiency . The heat exchanger is capable of supplying water at the optimal temperature to several places in the house at once.

- Economical. The device allows you to heat water directly from heating; there is no need to install a heater and waste additional electricity and gas.

- Small size . The device is quite compact and does not take up much space.

- Easy to install and use . The device is easy to install, does not require frequent maintenance, and is easy to clean.

Steel heat exchanger

Advantages of steel appliances:

- Increased thermal conductivity - like cast iron, steel quickly heats up and perfectly transfers heat to a cold carrier.

- Low weight - steel heat exchangers do not weigh down the overall heating system, so they can be used to provide hot water supply in large houses.

- Impact resistance – steel structures are very strong, so they are not afraid of mechanical damage.

- Resistance to thermal changes - steel can withstand sudden temperature changes within the system without consequences.

Disadvantages of steel heat exchangers:

- Susceptibility to corrosion – steel is characterized by low resistance to acidic environments, which significantly reduces the life of the heat exchanger.

- Inability to increase the power of the device by adding new sections.

- Rapid cooling - steel quickly releases temperature, which increases fuel costs.

Advice. To manufacture a high-quality and durable heat exchanger, it is recommended to use pipes made of heat-resistant steel with a diameter of at least 32 mm and a wall thickness of 5 mm or more.

How does the device work?

The way the device works is that it allows two independent systems to exchange heat with each other.

Depending on the specific type of device, the pipes are connected to each other by plates, or arranged in a special way , for example, a pipe with a heat carrier is located inside a pipe with a receiver.

The water heats up quickly without coming into direct contact with the heat source.

The device is connected to heating and water pipes. Water passes through the system and is heated by a heat source, and then arrives at the tap in a heated state.

Types of heat exchangers for hot water systems

Today there are many of them, but among all, the two most popular for everyday use are shell-and-tube and plate-type systems. It should be noted that shell and tube systems have almost disappeared from the markets due to low efficiency and large sizes.

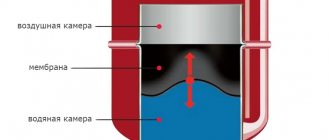

A plate-type heat exchanger for hot water supply consists of several corrugated plates located on a rigid frame. They are identical to each other in design and dimensions, however they follow each other, but according to the principle of mirror reflection, and are divided among themselves by specialized gaskets. Gaskets can be either steel or rubber.

Due to the alternation of plates in pairs, cavities appear that during operation are filled with either heating liquid or a heat carrier. It is due to this design and operating principle that the displacement of media between themselves is completely eliminated.

Through the guide channels, the liquids in the heat exchanger move towards each other, filling the even-numbered cavities, and then exit the structure, receiving or giving up some of the heat energy.

Scheme and principle of operation of a hot water supply plate heat exchanger

The more plates in number and size there are in one heat exchanger, the larger the area it can cover, and the greater its productivity and useful effect during operation will be.

For some models, there is space on the direction beam between the locking plate and the frame. It is enough to install a couple of slabs of the same type and size. In this case, the tiles installed additionally will be installed in pairs.

All plate-type heat exchangers can be divided into several categories:

- 1. Soldered, that is, non-separable and having a sealed main body.

- 2. Collapsible, that is, consisting of several individual tiles.

The main advantage and plus of working with collapsible structures is that they can be modified, modernized and improved, from removing unnecessary ones or adding new plates. As for soldered designs, they do not have such a function.

However, plate-brazed heat supply systems are more popular today, and their popularity is based on the absence of clamping elements. Thanks to this, they are distinguished by compact sizes, which do not in any way affect their usefulness and performance.

Kinds

Based on their design, devices of this class are divided into two main categories:

- tubular,

- lamellar.

For domestic needs, plate-type devices are used due to greater ease of use and efficiency, as well as easy transportation and installation. Among tubular devices in everyday life, as a rule, the shell-shaped version is used.

Lamellar

Plate type heat exchangers are a structure of plates installed parallel to each other and connected in a single housing . The heat carrier and heat receiver flow in separate pipes connected to communications on the front and rear panels of the device.

Plate heat exchangers are in turn divided into three groups:

Collapsible. In this version, rubber seals are used to ensure the tightness of the structure.

The advantages of collapsible heat exchangers are ease of installation and use.The downside is the regular need to replace rubber gaskets and sensitivity to aggressive substances.

- Soldered. The design of such devices is more durable and is made of steel. Unlike collapsible ones, they rarely require maintenance and are tolerant to any environment. The disadvantage is the large weight of the structure and the impossibility of disassembling it, resulting in more difficult transportation.

- Welded. Made from heavy metals, used only in industry.

Tubular

This type of device is used mainly in industry, and also as structural elements of air conditioners and refrigerators.

They are used less frequently for heating water, since to ensure the same efficiency as from the plastic type, such a device must be quite large in size.

The advantage of this type is its high resistance to any conditions and environments . A common design is when another narrower one is located inside one wide pipe. The heat carrier flows through the inner pipe, and the receiver flows through the outer pipe.

In turn, tubular exchangers are divided into several types:

Case-like. A large number of tubes connected in a lattice.

It is possible to connect several devices of this type to achieve greater efficiency.This type is most often used in everyday life among tubular exchangers.

- Twisted. The pipes are twisted together around a single core. It is a compact and quite effective option. A variation of this design are spiral heat exchangers, in which both channels wrap around a single partition.

- Irrigation exchangers are designed in a spiral shape. Water flows down the gutter. Mainly used in ventilation systems.

Design and operating principle of plate heat exchanger

Available programs are downloaded; several versions can be used in calculating the heat exchanger for greater confidence in the results.

The disadvantages are the lack of a water heating function.

In the case when a one-stage connection scheme is selected. However, plate-brazed heat supply systems are more popular today, and their popularity is based on the absence of clamping elements. Let's look at a few examples of circuits.

That is, during installation after cleaning, everything will fall into place without much effort. Before installing a plate heat exchanger, it is important to take into account that, when performing a do-it-yourself calculation for a plate heat exchanger for a boiler, the incoming temperature should not exceed 55 degrees. Producing a high flow rate, high-speed units slightly underheat the exiting liquid; this drawback was discovered by specialists during operation. One of the options for two-stage connection of heat exchangers. In this case, primary heating comes from the heating return pipeline.

Here it is brought to the desired temperature and sent to the consumer. Air conditioners, heaters, plastic heat exchangers, accordingly, require more complex maintenance with the help of computer and service support. The temperature is controlled using a sensor and a control valve installed on the return line, which can also be installed on the supply side.

You can also turn to a specialist for help, who will carry out the calculations with his own hands, without puzzling the client. Having the same power, it is three times smaller in size than a shell-and-tube one, and at the same time is capable of providing a large flow rate of the heated medium, for example, water for domestic hot water needs. These outlets can be in the form of a flange, welded pipe, or threaded connection.

Operating principle of a plate heat exchanger.

Shell-and-tube Shell-and-tube heat exchanger for hot water from heating is simpler in design, but less efficient, which is why, to ensure the required temperature, it must have a substantial size. The thickness of the plate depends on the maximum operating pressure. The experience and skills of our specialists allow us to perform both simple calculations and complex installations with start-up pads. The disadvantage of this scheme is the greatly increased load on the heating system and inefficient heating of water in the second circuit with a larger temperature difference. To do this, you will need the help of specialized personnel of a particular company.

A temperature difference of at least 10 degrees is also important. The value for the sink is multiplied by the number of devices in the house that can be used in parallel, and added to the value for the bathtub or shower, depending on what is being used. Disadvantage: high cost due to the connection of two heat exchangers for preparing hot water. The temperature is brought to normal by reheating, but from the coolant that is supplied. SYSTHERM Heat exchangers in hot water supply Today, organizing processes for providing water is one of the main conditions for creating a comfortable life for citizens. Heat exchanger (register) for a bathhouse - which one to choose and how to connect it to heat water?

How to calculate a model for a specific building?

When selecting a specific device model, the following parameters must be taken into account:

- number of residents in the room;

- the volume of water required by one resident per day, the standard consumption rate is 120 liters per person per day;

- degree of heating of the coolant - in centralized heating systems the standard is heating equal to 60 degrees;

- whether the device will work around the clock, or whether it is planned to be turned off periodically;

- water temperature in pipes in winter;

- number of appliances consuming hot water;

- permissible percentage of water loss.

The performance of the device must be calculated for the winter season, when the most active use of hot water is implied. For accurate calculations and selection of equipment, you can contact supplier companies.

Using plate-type heat exchangers to provide domestic hot water

This method is good because the return water heat is usefully used, and also because the circuit is compact.

In the new heat exchanger, this is achieved by increasing the number of plates of the same area.

The diagram shows a plate heat exchanger for heating of the simplest design with pipes located on opposite sides of the unit. It is no longer completely cold that is supplied for heating, but warm.

In systems with natural circulation, this type of installation is ineffective. In ITP Dependent heating connection with automatic regulation of heat consumption.

It is also important that no one can guarantee that these calculations will be percent correct. It is advisable to install the same filter at the cold water inlet - the equipment will operate longer. As a result, the cost of hot water per liter will be much lower. The plates of a plate heat exchanger are arranged one after the other, rotated by degrees.

Their structure is more complex, the cost is higher, but they are able to extract maximum heat and have high efficiency. The assembly diagram of a plate heat exchanger is not complicated; the upper and lower guides are fixed to a tripod and a fixed plate. Connection diagrams for PHE Connection diagrams for plate heat exchangers Here you can find out what types of connection diagrams exist for plate heat exchangers to communication networks. Due to its small dimensions and weight, installation of the heat exchanger is quite simple, although powerful units require a foundation.

Let's talk in more detail about the most affordable, reliable and effective. The power depends on the total heat exchange area, the temperature difference in both circuits between the input and output, and even on the number of plates. With this scheme, water preparation occurs in two steps. The piping of the second stage is identical to the parallel connection, except that instead of cold water, already heated water from the first stage is connected.

Their structure is more complex, the cost is higher, but they are able to extract maximum heat and have high efficiency. In accordance with the rules, in addition to the working pump, a reserve pump of the same power is installed in parallel. The experience and skills of our specialists allow us to perform both simple calculations and complex installations with start-up pads. Then the plates are made from titanium, nickel and various alloys, and the gaskets are made from fluorine rubber, asbestos and other materials. It should be noted that shell and tube systems have almost disappeared from the markets due to low efficiency and large sizes. Plate heat exchanger operating principle

Technical selection criteria

When choosing a heat exchanger, it is necessary, first of all, to pay attention to such parameters as the design and power of the device, as well as its cost. When using a device with a water tank, the choice of a tank of suitable volume plays an important role.

Design

To heat water from the heating system, devices of various designs are used, differing from each other in heating speed and efficiency:

With a coil .

In this design, the function of the heating element is performed by a coil filled with water. The complex shape of the element significantly accelerates heating. The coil can be installed at the bottom of the tank, or vertically for more uniform heating.- With two coils . Two coils provide even greater efficiency and heating speed.

- For heat pump . It differs in the way it is connected to the heating system; it can also be equipped with a coil.

- Device with electric heater . An additional heater speeds up the heating process. This option is the golden mean between a conventional heat exchanger and an electric water heater.

Volume of the tank

An important factor that must be taken into account when choosing is the size of the tank:

- For small spaces, a tank of one hundred liters is suitable . This is a compact and economical option, the easiest to transport. It is worth remembering that a small volume of water retains heat for a much shorter time, so it will have to be heated more often.

- For most private homes, a tank with a volume of 200 liters is suitable . This is enough for several plumbing fixtures, and the temperature will remain for quite a long time.

- For large houses, a tank with a volume of 500 liters is suitable . Such tanks are also used in production. For most premises, such a large volume will be an unnecessary and uneconomical solution, since such a tank will require much greater energy consumption.

Device classification

Heat exchangers for hot water supply are made of either steel or cast iron. The latter method is more traditional, since not so long ago stainless steel was considered a scarce material. And the use of ordinary metal was unprofitable. Therefore, the system was very quickly damaged by corrosion.

Heat exchanger made of cast iron Source pechiexpert.ru

But even the abundance of modern materials did not exclude the production of cast iron models. After all, their casting is characterized by high speed and extreme simplicity. And today, both conventional cast iron structures and more complex models made of modern steel are equally popular.

Cast iron

A heat exchanger made of this metal has very good performance. And they buy it more for reasons of economy, since its cost is much lower than that of its stainless counterparts. But when purchasing a cast iron structure, you need to be prepared that it has serious disadvantages.

The surface is highly fragile. And any serious blow simply splits it. Cracks can also appear due to thermal exposure. If cold water pressure is applied to a well-heated structure, the walls will most likely not withstand it.

Such damage can no longer be repaired. But otherwise the material is capable of long-term use if treated with care. And it does not require preventive intervention as often as its stainless steel counterparts.

Heat exchanger cassette Source termotactic.ru

Household models and their prices

Currently, there are a large number of heat exchange devices on the market, differing from each other in type of design, heating rate, tank volume and cost.

Lamellar

Here are some popular models:

R-012-10-19 PROMTECHSERVICE .

The plates of this model are made of steel. Between the plates there are thermal pads that effectively transfer heat from the carrier to the receiver.The strength of the structure is ensured by the corrugated surface. Approximate cost of the device: 14,000 rubles.

- KAORI Z. Soldered version model. The flows are directed diagonally. The plates have a large heat transfer area. Durable and reliable model. Cost from 32,000 rubles.

- Innovita DHW . Budget solution, installed on a gas boiler or heating network. The model is intended for use with Innovita boilers. Cost from 8000 rubles.

Shell and tube

Below are popular models of shell-type heat exchangers:

- TNG-1.6-M8/20G-2-2-I . A popular model, often used in industry and at home. It has tube sheets and a vertical heat compensator. Price – from 9000 rubles.

- Shell and tube heater TTAI . The design consists of two tubes with thin walls of different diameters, one nested inside the other. Thin walls promote more efficient heat transfer. The device is compact and easy to maintain. Price – from 7500 rubles.

- Bowman 190 kW . Premium device. Titanium tubes with anti-corrosion coating are suitable for interaction with chlorinated and sea water. Can work for both heating and cooling. Price from 120,000 rubles.

Heat exchanger material

You should carefully select a secondary heat exchanger for a gas boiler so that it can operate without failures for a long time.

If the DHW tap is closed, the coolant enters the primary heating circuit. The principle of operation of the secondary heat exchanger is as follows: when the hot water tap is opened, the three-way valve redirects the coolant flow from the primary to the secondary circuit; cold water begins to flow and mix with the heated liquid, and then warm water comes out of the tap.

The secondary heat exchanger is made of :

- copper;

- structural steel.

A copper heat exchanger has the following advantages:

- long service life;

- excellent thermal conductivity;

- low susceptibility to corrosion.

The disadvantage is its expensive price.

…

Steel heat exchangers are more common because they have the following advantages:

- sufficient thermal conductivity;

- cheap cost.

The downside is the susceptibility of the steel product to corrosion processes.

However, in this case, you should pay attention to the quality of the material. Reputable manufacturers of gas boilers make heat exchangers from high-quality structural steel with anti-corrosion coating. Such circuits can last quite a long time without breakdowns. Note! The secondary heat exchanger is more susceptible to clogging with salt deposits due to the low heating temperature of 30-60°C. To avoid frequent blockages and extend the service life of the circuit, it is necessary to install a filter at the cold water inlet.

Step-by-step instructions on how to make it yourself

You can construct a device for exchanging heat from the heating network to water with your own hands.

Tools and materials

To construct a plate heat exchanger with your own hands, you will need:

- welding machine;

- Bulgarian;

- stainless steel sheets - two corrugated, one flat. Thickness 4 mm;

- electrodes.

Manufacturing process

The entire manufacturing process of the device is divided into several stages:

- It is necessary to cut corrugated steel plates. You will need 31 plates measuring 300 by 300 mm.

- A strip 18 meters long and 10 mm wide is cut from a flat sheet. The tape must be cut into pieces 300 mm long each.

- Squares of corrugated material are welded to each other with a ten-millimeter strip from different sides, adjacent sections must be perpendicular. You will get 15 sections facing one way and 15 the other in the form of a cube.

- A flat stainless steel manifold must be welded to the parts where water will flow.

- A hole is drilled in each collector, and the connecting part of the pipe is welded to it.

- The structure is mounted with the open side facing the gas system.

Examples of calculations and standard prices

Important! Please note that these calculations were made for specific objects with their thermophysical properties and calculated temperatures!

The prices presented on the website are indicative only!

Accurate and detailed information is determined after a thermal engineering calculation, during which the following will be determined: frame size, materials of plates and seals, their quantity, thickness, layout.

| Heat exchanger | An object | Price |

| Plate heat exchanger Ridan NN№14A-21-TMTL40 (DN 50 mm) | Object: 5-storey residential building Temperature graphs: Hor. side: 70/40 °C Cold. side: 5/60 °С Number of apartments: 80 Number of people: 140 | RUB 118,867 including VAT Discounts are possible for this product! |

| Plate heat exchanger Ridan NN№14A-17-TKTM62 (DN 50 mm) | Object: Kindergarten Temperature graphs: Mountains. side: 75/50 °C Cold. side: 5/60 °С Number of people: 280 | RUB 103,536 including VAT Discounts are possible for this product! |

Connection diagrams

The heat exchanger can be connected to heating and water supply systems using three different schemes: parallel, two-stage mixed and two-stage sequential.

Parallel

The most simple to implement and economical scheme . A prerequisite is the installation of a temperature regulator. The disadvantages are not the most economical consumption of carrier heat, as well as the need for an enlarged pipeline.

Two-stage mixed

Also requires a temperature controller. Significantly more economical than a parallel circuit in terms of heat consumption. However, the design itself is more expensive, since it requires two heat exchangers at once. Equipment must be selected very precisely in accordance with specific conditions.

Two-stage sequential

With this connection, the incoming flow is divided into two, one passes through the regulator, and the second through the heater. The heat carrier is consumed more efficiently compared to the mixed one. The load on the network is also distributed more efficiently.

The disadvantage of the scheme is the impossibility of full automation . Despite all the advantages, in practice the scheme is rarely used due to the strong influence of the heating and plumbing systems on each other and the possibility of overheating of the heating network.

Option for hot water supply in a small house with autonomous heating

Boiler room in the cottage

Let's start with a small private house with autonomous heating from a boiler installed in it. The following heating and hot water supply schemes are possible for it.

The first is the simplest, but incorrect option

It would seem that hot heating is the easiest thing to do in it. We cut into the heating system and take some of the water from it. But this cannot be done for several reasons.

- Water contains salts that cause scale deposits on heating system elements. This interferes with normal heat transfer.

Even if we do not use a water treatment (softening) device in the system, the salts that entered the pipes and boiler during the initial refueling have already been deposited on the walls. New ones, with the exception of a small amount that enters during replenishment, have nowhere to appear. If there is a constant selection, then the water will be constantly renewed, and the scale will grow quickly.

- If (which is extremely rare in private homes) a water treatment system was installed, its productivity will not be enough to provide not only replenishment, but also a hot water supply system. Installations with the required bandwidth are more expensive.

In addition, softened water does not taste good. In addition, add the price of constantly consumed reagents (and some may be harmful to health).

- The water in the heating system can be contaminated by rust washed away from pipes, radiators and the boiler. For hot water supply, either polymer or galvanized pipes are used, and their length is shorter.

- With the constant selection of network water, it may be lost from the system and boil, and then explode the boiler. Even the automatic replenishment system does not save you from this.

How to properly install hot water supply systems in this case

As a rule, the heating and hot water supply scheme in this case is built according to one of several possible options.

Install a separate gas or electric boiler

Boilers are commonly referred to as devices for heating water (water heaters). If the boiler is gas or electric, it is actually a boiler (in English boiler - boiler) designed to heat water in a hot water supply system (we will talk about other varieties below). Then in the house we will have two separate hot water heating systems not connected to each other.

The advantages of this system.

- Wiring is a little easier.

- To prepare hot water, you do not need to fire up the boiler.

Minuses:

- the price of the system is higher than that of other options presented below;

- More space is required to accommodate equipment.

This approach is justified if a solid fuel boiler is installed and you do not want to light it, for example, in the summer. Although the cost of heating with electricity is higher, when using small amounts of water (to wash dishes), for the sake of convenience, you can spend extra money.

Double-circuit boiler

Instead of a conventional boiler, a double-circuit boiler is installed. In addition to heat exchangers for heating network water, it also contains heat exchangers for hot water supply. Their coating is designed to work with drinking water and does not impair its quality.

A water supply must be connected to the input of the second circuit, and ready hot water is taken from its output. As a rule, such industrial boilers have systems for monitoring and regulating water temperature. If we are talking about devices that burn gas or liquid fuel, then the controller for heating and hot water supply systems built into the boiler automatically lights the burner when water consumption is recorded.

This approach also has both pros and cons. The advantages include:

- no need to purchase and install additional equipment, space is saved;

- the pipeline layout is simplified.

There are also disadvantages:

- a double-circuit boiler is more expensive than a conventional boiler of the same power;

- The hot water supply circuit of the boiler, although designed for running water, is still covered with scale and requires periodic cleaning.

Install a flow-through heat exchanger

Diagram of a heating and hot water system with a flow-through heat exchanger

The most justified option. In this case, a flow-through heat exchanger is inserted into the heating system; it is also called a boiler. It is a system of tubes through which water circulates, in a casing washed by another stream of water.

- That is, heating coolant circulates through one circuit, and tap water circulates through the other, which heats up.

- Such a heat exchanger is also periodically cleaned, but due to the simplicity of the design, this is easier to do than descaling in a conventional boiler. In addition, since heating is carried out not by a high-temperature flame, but by network water, deposits form slowly.

- There are two versions of such boilers with a straight block of internal pipes and with a bundle of them curled into a spiral. The first is larger, but cheaper and easier to clean, the second is more expensive, but more compact.

- If necessary, several sections of the boiler are connected to each other by “U” jumpers, increasing the power.

Flow-through heat exchangers are connected in two ways.

For information: Usually the water coming from the boiler or water heater is called supply, and the water going for heating is called return. On diagrams and drawings they are usually designated T1 and T2 (supply and return) for heating systems and, respectively, T3 and T4 for hot water supply.

- Direct-flow, when two flows of coolant and hot water supply move in the pipes in the same direction. In this case, you can use a less powerful device (install fewer sections), but the hot water will only heat up to the return temperature of the heating system.

- Oncoming, flows are moving towards each other. A more powerful boiler is needed, but the water heats up almost to the supply temperature from the boiler.

The disadvantages include the fact that an open hot water supply and heating system, which does not have pumps, does not work well with flow-through heat exchangers. Coolant circulation is ensured only by convection, and for high-quality heating, boilers with a large exchange surface are needed - and therefore large-sized.

Additional components and elements of the heating system with hot water supply

In order for hot water supply and heating systems to work better, most often, in addition to the direct devices for heating water, pipes and selected devices (taps, mixers), a number of additional parts and assemblies are installed. We'll tell you about them and their installation locations.

Shut-off valves

Valve

Ball valve

Gate valve

Taps and mixers in places where water is collected at sinks, bathtubs, toilets, etc. are, of course, installed by default. But it is better to additionally install several taps on the pipelines themselves.

Then, for example, you can safely replace the gasket or axle box in the kitchen faucet, without leaving the whole house without water.

Thermostat

Thermostat temperature sensor

Thermostat control unit

Valves with actuator

In double-circuit boilers and autonomous boilers, its role is most often taken over by the control system of the water heating unit. When installing separate instantaneous boilers, this device is mounted separately. It is designed to regulate water temperature.

- Of course, the simplest heating system and hot water supply system can do without it. After all, we don’t need stable 50 degrees regulated by the standard; the temperature of the water in the mixer can be adjusted simply by adding more cold.

- But if we want this, then why not. In central heating and hot water supply systems, a regulator is installed for a number of other reasons. More on this below.

- The thermostat is a sensor installed at the hot water outlet, a shut-off valve (faucet, valve, etc.) with an electric drive installed at the coolant supply (actuator), and a control unit that sets the required temperature.

If the water is heated above a predetermined level, the actuator reduces the flow of coolant through the boiler and the temperature decreases. When cooling, the supply, on the contrary, increases.

Circulation pumps

One of the pump models that can operate in DHW

Everyone is familiar with the situation when cold water flows from the tap immediately, and then hot water. This indicates that the hot water supply system is assembled according to a dead-end circuit; water flows to the tap through only one pipe under the pressure created by the water supply.

- To avoid this, especially if there is a long distance from the boiler or boiler to the extreme dismountable device, it is better to arrange circulation. That is, two pipes are installed: supply and return, and circulation is forced to be created by a pump.

- Of course, these are additional costs, but this is the only way to ensure comfortable use of hot water supply.

- It is worth looping the system and installing heating and hot water supply pumps for one more reason - to ensure normal operation of the boiler or boiler thermostats.

- Let's take another situation known to everyone: you are standing in the shower and, working with the mixer, you can’t set a comfortable water temperature. It goes either cold or hot.

- The whole point is that the system is dead-end and the thermostat cannot understand your actions - more precisely, it understands, but with a delay. That is, now you have cold water, you give more pressure to the hot water.

- The boiler thermostat, seeing an increase in flow, turns on the burner. But it will take several minutes for the hot water to travel the distance from the boiler room to the shower room. Perhaps you have increased the flow greatly, and the water will become scalding for you.

You can additionally watch the video in this article about the features of hot water supply systems with recirculation in a private house:

Check valves

Design of a simple check valve model

This is a type of fittings that allows water to flow in only one direction. It is necessary to install such a valve in front of the boiler if you have a circulation pump installed. It creates pressure greater than in the water supply network, and naturally your hot water will press on the cold water and return to the water supply.

It is advisable to install two more valves:

- In front of the suction part (inlet) of the circulation pump. If for some reason the water disappears from the water supply, it will come out of the pump housing. By running it “dry” (which almost any instruction prohibits), you can tear the impeller off the shaft.

Without resistance to the blades of water, it can spin up to high speed. In addition, in modern pumps with a “wet” rotor, water is needed both to lubricate the shaft and cool the electric motor.

A valve installed in front of the pump will prevent water from leaving the housing. In this case, the pump must be mounted at the bottom, below all water points.

Attention. As a rule, the entrance to the toilet cistern on the first floor is the lowest. Don't forget about this.

- At the entrance to the house there is a water supply, and in several other places on the cold water networks in the house. The thing is that some faucets can transfer hot water into the cold line. The valve will help to avoid unnecessary consumption of water and energy for heating it.

Advice. The fact that one of your faucets is faulty is indicated by the appearance of warm or hot water in the cold taps. Find the problem and fix it.

Pressure gauges

Pressure gauge

These are devices for monitoring pressure. You can do without them, but then it will be more difficult to find faults. It is advisable to install them at the cold water inlet before and after the water heater (boiler) and pump.

Then we can immediately find the following faults:

- No cold water supply, pressure will be low.

- Clogged boiler or water heater, large pressure difference before and after.

- Failure of the pump, on the contrary, lack of pressure drop.

It is desirable that the scales of pressure gauges (measurement limit) intended for heating and hot water supply should be such that the operating pressures are in the second third.

Thermometer

Technical thermometer

In principle, you don’t have to install it, but it makes it easier to control the water temperature. It is mounted after the circulation pump, and if it is not there, then at the outlet of the water heater (boiler). If you have a thermostat with a display, then, as a rule, you can control the water temperature using it, based on measurements from its sensor.

Pipeline layout

There are no special requirements for the installation of hot water pipelines in a small house. They are laid in any way, usually parallel to the cold water supply.

If you need to supply hot water to the second or third floor, risers are made. It is not necessary to observe slopes, since water is supplied under the pressure of a water supply system or a circulation pump.

Thermal insulation of pipes will avoid losses

But it is important to take into account that after installation the heating and hot water supply system must be thermally insulated so that there is no waste of energy. Any insulating materials can be used.

How to use?

There are two main options for using a heat exchanger to heat water:

- The first option is to heat running water. The disadvantages of this method are limited water consumption, difficulty maintaining heat, and lack of water reserves. Pros: the system is compact.

- Heating in the container. The heat exchanger is immersed in the tank and filled with water. The design allows you to maintain the temperature for a long time, while there is always a supply of water. The disadvantage of this method is that the large dimensions of the tank require a lot of space.

Everything you need to know about hot water is presented in this section of the site.

Principle of operation

Heat exchangers for preparing DHW water operate on a non-contact principle. Their design may be different, but the principle of operation is the same - they work on the principle of heat transfer. There is a heated coolant (in this case from the heating system), which is supplied to the pipes/channels of the heat exchanger. The hot coolant gives off some of the heat to the tubes through which it flows. Other parallel channels carry water that needs to be heated. In contact with the walls heated by the coolant, it heats up. This is exactly how a heat exchanger for hot water from heating works.

Schematic diagram of using a heat exchanger for preparing hot water from heating

For heating to be effective, the heat exchanger must be made of a material with high thermal conductivity. Usually these are metals - copper, stainless steel. Copper is an expensive metal, but has excellent thermal conductivity. Stainless steel conducts heat less well, but due to its strength, the walls can be very thin, which makes such heat exchangers also effective.

Selection of a tank for a DHW heat exchanger. What is important to consider?

It is recommended to choose tanks with protective heat-insulating coatings around them - the more efficient it is, the less heat is lost into the environment and the fewer energy losses occur. Buying a double shell tank will definitely solve this problem.

It is worth adding that the design of the casing and the heat exchanger itself is identical in both vertical and horizontal orientation, so the choice between a vertical and horizontal heat exchanger is limited only by deciding the best spatial configuration of the entire container in the place where it should be installed.

It is also important to pay attention to the manufacturer of the heat exchanger, because this parameter indirectly affects the quality of the equipment and all its components. DHW heat exchangers are not cheap and replacing them always causes a lot of hassle; in addition, a malfunction of the device will lead to large electricity bills. That's why you should buy an exchanger from well-known manufacturers for your home.

Did you find this article helpful? Please share it on social networks: Don't forget to bookmark the Nedvio website. We talk about construction, renovation, and country real estate in an interesting, useful and understandable way.