In a heating system, a very important element is the heating expansion tank. Such a device serves to accept excess coolant at the moment when it expands, thus preventing rupture of the pipeline and taps.

Heating expansion tank

The principle of operation of an expansion tank for heating is as follows: when the temperature of the coolant rises by 10 degrees, its volume increases by about 0.3%. Since the liquid is not burned, excess pressure appears that needs to be compensated. This is precisely why an expansion tank is installed.

Purpose of the tank

From a basic physics course, many remember that solids are subject to expansion when heated.

In turn, the liquid and gas increase in volume. Water cannot be compressed like gas. If water is heated in a closed container, the pressure will increase, since there is no space for expansion. As a result, the container will simply burst. These processes are observed in a closed heating circuit with a liquid container. The expansion of water by temperature is estimated by a nonlinear indicator. It indicates how many times the liquid expands per heating per degree. On the Internet you can find many visual experiments demonstrating this principle.

Experience in demonstrating thermal expansion of liquid

You can consider this experience with an example. On the left side there is a container into which one liter of water is poured. Water is filled up to the overflow hole. Temperature reading +4 degrees Celsius. The liquid at a given temperature can be considered the zero reference point. Also in the illustration you can see a vessel with divisions. It is located under the overflow hole.

On the right side of the illustration you can see the same vessel, but in a heated state. The temperature of the liquid increases. Accordingly, the density of the liquid decreases. The mass of the medium does not change. At the same time, the volume of liquid increases. When the water reaches a temperature of +90 degrees Celsius, the measuring vessel is filled. It produces a little more than 30 ml of liquid. This amount is called excess volume.

Many will say that 30 milliliters of water is not a critical volume. However, it is important to understand that if there is initially more water, then as its volume expands, there will also be more excess water. For example, if one hundred liters of water expands, then there will be an excess of 3.5 liters, and this is already significant.

An increase in the volume of the liquid medium during heating in the thermal circuit of a country house

The water in a home's heating system can heat up to 70 degrees Celsius. As temperature increases, water expands. Without including an expansion tank in the heating system, the pressure will increase significantly. Accordingly, excess water needs to go somewhere. As a rule, leaks occur from weakly protected places in the circuit. Usually the water comes out of a section of the pipeline or from a heating pipe.

To prevent undesirable consequences, a safety valve is installed. It serves to drain excess hot water. However, it will not be possible to adjust the heating operation in the house to the required level due to one factor. After the liquid cools, its volume remains the same, and since the hot water is drained, an air mass takes its place. As a result, air pockets form, and this is one of the main troubles of all heating circuits. These plugs can become an obstacle to the flow of fluid in the pipeline.

An air lock in a country house heating radiator prevents heat from being distributed throughout the radiator

Air locks can be eliminated by deflating the air mass from the batteries. Installing a safety valve will require constant addition of water to the system, which is inconvenient and not cost-effective. It takes a long time to heat the newly received water. It is much faster to heat the water that enters the boiler from the heating system pipeline.

By installing an expansion tank, you can achieve normal functioning of the heating system in your home. We are talking about a bright orange tank connected to the heating system by a tube. The vessel is designed to compensate for excess pressure in the heating system of the house.

Operational Maintenance

It must be remembered that during breaks in use, the tanks, like other components of the heating system, should be emptied and then dried. This point should not be ignored, as failure to comply will lead to corrosion and reduced service life.

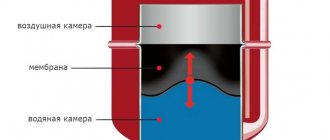

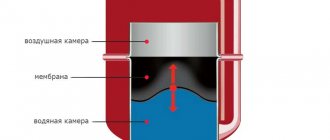

The main structural element that responds to changes in pressure from the coolant is an elastic membrane. Which is affected by a neutral gas (for example, nitrogen) or air on one side, and pressure from the coolant on the other. And the membrane takes position depending on which side has the stronger impact

When using any closed tank, owners should regularly perform a number of simple operations.

Which include:

- periodic inspections to detect corrosion and mechanical damage - this procedure should be carried out twice a year;

- checking the pressure in the system, which is performed every six months;

- periodic inspections of the integrity of the membrane - such operations are carried out according to the manufacturer’s recommendations.

And in addition, throughout the entire operation, users will have to comply with the requirements regarding permissible temperature and pressure standards.

To repair tanks, you should use only original components, as this will ensure not only the required performance, but also safety of use.

The following article will introduce you to the rules and features of selecting an expansion tank for open-type heating systems, which owners of houses with open heating circuits should read.

Various types of containers

There are various designs of expansion tanks. They vary in size and shape. You can determine which vessel is needed by calculating its data. Also, when choosing a unit, you should take into account the type of heating system installed in the house. The form factor of the tanks is represented by a tablet, as well as a cylindrical shape.

Expansion tank in the form of a tablet

The different appearance depends on the method of use. The customer can purchase:

- Open type tank;

- Closed tank with built-in membrane.

Closed tanks without a built-in membrane are also available. However, experts recommend refraining from using this type of tank in home heating systems. Unfortunately, the design features of this product require careful refinement. The movable partition in such tanks is replaced by an air mass. Thus, air will be allowed to enter the internal heating system of the house, and the presence of air in the circuit is unacceptable. In such a tank, the water level will increase all the time until it reaches a critical point.

How to set the optimal pressure?

The heating system has pressure gauges that control the pressure in the circuit. On the expansion tank itself there is no fitting for installing a measuring device. But there is a nipple or spool for releasing and pumping air or gas. The nipple is the same as on car wheels. Therefore, you can check the pressure level and adjust it using a conventional car pump with a pressure gauge.

Even a simple automobile hand pump with a pressure gauge or an automatic compressor will be suitable for pumping air into the expansion tank.

Before releasing excess pressure or pumping air into the expansion tank of a domestic gas boiler, it is necessary to prepare the system. The car pressure gauge shows the value in MPa; the data obtained must be converted into atmospheres or bars: 1 Bar (1 atm) = 0.1 MPa.

Pressure measurement algorithm:

- Turn off the gas boiler. Wait until water stops circulating through the system.

- In the area with the hydraulic tank, close all shut-off valves and drain the coolant through the drain fitting. For boilers with a built-in tank, the return flow is shut off, as well as the water supply.

- Connect the pump to the tank nipple.

- Pump up the air to 1.5 atm. Wait a little for the remaining water to pour out, then let the air in again.

- Close the valves of the shut-off valves and use a compressor to pump up the pressure to the parameters specified in the passport or to the level - pressure in the system minus 0.2 atm. If the tank is pumped, excess air is released.

- Remove the pump from the nipple, screw on the cap and close the drain fitting. Fill the system with water.

You can check the correct air pressure adjustment when the boiler reaches operating parameters.

If the tank is inflated correctly, then the needle on the pressure gauge of the device during measurement will show a smooth increase in pressure without any jumps or jerks

If the air pressure in the expansion tank is incorrectly adjusted, the entire heating system may malfunction. If the expansion tank is over-inflated, the compensating properties will not work. Because the air will push excess heated water out of the tank, increasing the pressure in the pipes of the heating system.

And with underestimated pressure readings of the compensating tank, water will simply push through the membrane and fill the entire tank. As a result, when the coolant temperature rises, the safety valve will operate.

Sometimes in double-circuit gas boilers, fuses work even if the pressure of the built-in expansion tank is correctly adjusted. This indicates that the tank volume is too small for such a heating system. In this situation, it is recommended to install an additional hydraulic tank.

Open tank

Installed in the heating system of the house. The system is not isolated from the atmosphere, although it has a closed design. The system is not sealed. Accordingly, conditions for the occurrence of excess pressure will not arise.

Open heating system in a country house

Installation of an open tank

The expansion vessel for an open heating system is mounted at the highest point of the heating circuit. You cannot install the tank at another point, since the rule of communicating vessels will apply, as a result of which water will pour out of the tank. The location of the open tank at the top of the heating system serves as a proven method of removing air from the circuit. It is worth noting that there is air in the circuit, one way or another. It can be dissolved in water, and also be formed as a result of a chemical reaction between water and the material from which pipes and heating radiators are made. If you do not pay due attention to removing air from the system, one or more pipes may simply fail. An open tank serves to remove gas bubbles from the water in the heating system of the house. Simply put, this tank serves to remove air.

An open expansion tank for the heat-carrying fluid on the supply pipe of the heating system

It is also possible to install an expansion tank on the return path of water movement in the heating system. However, even in this case, it must be installed at the highest point of the highway section. It is necessary to install a vertical pipe directed to the tank installation point. The tank will not remove gas from the system if it is mounted on the return path of the heating system. Because of this, during the installation of the entire heating system, valves are installed on the heating radiators. They are also mounted at the very top of the supply pipeline.

About malfunctions and tank repairs

During operation of the machine, the following breakdowns of the expansion tank may occur;

- contamination or failure of the bypass valve of the plug;

- rupture of the tank body;

The tank wall ruptures when the internal pressure is too high

- Antifreeze leaking from under the cap.

The leakage of the lid is characterized by the appearance of multi-colored streaks on the body

Most car enthusiasts, when a valve or body breaks down, simply replace the part with a new one. This is justified by the lack of time for repairs and the low cost of these spare parts. Although, if desired, the burst plastic of the tank can be soldered, and the lid can be disassembled and cleaned.

Leaks from under the cork occur when the seal is not tight or due to the design features of the container. For example, on VAZ 2110 cars, a stream from the upper small fitting connected to the radiator hits directly into the neck, causing a leak. The solution is to install a more advanced tank from Priora.

Types of tanks

The design features of an open vessel are quite simple; it has a certain volume. A cap with a loose structure is placed on top of the tank. It protects the water from foreign objects getting into it. Since the tank is not sealed, the pressure level in it is identical to atmospheric pressure. The vessel can also be equipped with a number of pipes depending on its design.

Open type expansion tanks

The customer can choose the volume of the open tank. No action is required to use them. The product is made of stainless steel, which prevents the formation of rust. It is also possible to manufacture a custom-made tank according to individual client conditions. In manufacturing, galvanized or stainless steel sheets are used.

At the moment, several possible open layout expansion tank schemes have been successfully tested and are operating. The most elementary design is a vessel with a pipe embedded in the lower part. The pipe is used to connect to the heating system of the home.

A simple diagram of an open tank for coolant expansion

This scheme eliminates the circulation of water through the vessel. Using this container, the water in the heating system is located up to the middle division in the tank. If the volume of water in the heating system changes, it will also change in the expansion tank.

It is necessary to constantly monitor the liquid level in the expansion vessel. Since water is constantly evaporating, it is necessary to maintain its level in the heating circuit by adding water to the tank. If you do not replenish the water supply, air will take its place, and this is unacceptable in a home heating system.

You can estimate the amount of liquid in the tank using a pipe connected to a transparent hose.

Expansion tank with transparent hose to control water level

Often, an open-type expansion tank is placed in the attic. This is a good solution, because the vessel is not conspicuous. When located in the attic, you can simply go into this room and inspect the container. There is no need to stand on a ladder and check the tank in an awkward position.

You should also pay attention to another way to control the expansion tank.

Reservoir with a pipe for overflow and control of the minimum liquid level

First, two pipes are installed in the tank. Using one of them, you can determine the maximum filling of the container. It is cut into the upper part of the tank, and it acts as an overflow. A hose is placed on the nozzle. An overflow is also installed, excess water from which goes into the ground.

The lower pipe is designed to connect to a pipe that goes to one of the living rooms. A ball valve is inserted into this pipe where it is convenient for the client. Using this pipe you can determine the minimum water level in the tank. If water does not come out of the tap, then the liquid needs to be added. A sufficient water level can be seen by how water flows out of the upper pipe.

Features of choice

It may seem to you that the expansion tank has a simple design and you can choose it only based on volume. But there are a few more points to consider:

- The membrane material must be resistant to reagents and additives used in coolants;

- The inside of the tank must be covered with high-quality paint or other coating.

- The protective coating on the inside of the container should not react with the coolant;

- The membrane must be resistant to high temperatures;

- The maximum permissible pressure in the tank must correspond to the characteristics of your heating system;

- All connections and seams must be resistant to high pressure and water hammer.

Required capacity volume

There are no specific rules for how much liquid should be in an open type expansion tank. You can calculate the volume of increased liquid if you know the necessary parameters:

- Parameter of liquid expansion with increasing temperature;

- The volume of the entire heating network in the home;

- Heating system temperature.

The temperature expansion parameter of a liquid at different pressure levels and different temperatures can be seen in the table below:

Coefficient of thermal expansion of water at different pressures and temperatures

We can consider the situation using a simple example.

When water in a volume of one hundred liters increased by three and a half liters at a temperature of +90 degrees Celsius, the percentage increase in liquid occurred by 3.5%. It seems that a 5 liter capacity will be enough, but this is misleading. Calculation data shows that the expansion tank must be at least ¼ full. Thus, no air mass entered the heating system. It is also necessary to take into account the volume that will compensate for the expanding water mass, as well as the empty space above the overflow pipe. Qualified craftsmen install such a container, the volume of which will be 10% of the total water mass in the heating system of the house.

Models of the Zilmet OEM-Pro series

This expansion tank for the heating system usually receives positive reviews. Many buyers praise it for its durable body. The device also uses a good fuse. Only one membrane is used at the tank. If you trust the experts, it wears off slowly. It is recommended to install the model behind the radiator grille.

It is also worth noting that the modification is not afraid of high temperatures. A maximum of 10 liters of coolant is allowed. The air chamber is used with a small volume. The outlet valve in the device is designed for heavy loads. The maximum pressure indicator is at least 2 Pa. It is recommended to connect the thermostat behind the counter above the mixer. The modification is great for gas boilers. The price for it fluctuates around 1,700 rubles.

Closed type expansion tank

This type of tank is in steady demand among end consumers due to its small size. It can be installed anywhere in the heating system. If you study the design of heating systems, such vessels are mounted on the return line, near the pump. Placing the expansion tank in this way will be the most correct decision.

Location of the tank in a closed version

Unlike open tanks, a closed tank is a sealed container. That is why the pressure in the heating system can only increase to a certain point. In this regard, it is necessary to install a number of additional units that will ensure the normal functioning of the entire heating system.

These devices include:

- Safety valve. It is programmed to trigger when the pressure indicator approaches critical;

- An automatic device capable of independently releasing air that appears in it from the heating system;

- Pressure gauge. It is a device for monitoring pressure levels.

Safety group for a closed heating network

All of the above devices are required to be installed in a closed heating system. Only in this case is the circuit allowed to operate with all the required safety standards.

Components and their purpose

Composition of a closed heating system

In general, a closed heating system consists of a certain set of elements:

- Boiler with safety group. There are two options here. The first is that the safety group is built into the boiler (gas wall-mounted boilers, pellet boilers and some solid fuel gas generators). The second is that there is no safety group in the boiler, then it is installed at the outlet in the supply pipeline.

- Pipes, radiators, water heated floors, convectors.

- Circulation pump. Ensures the movement of coolant. It is installed mainly on the return pipeline (the temperature is lower here and there are fewer possibilities of overheating).

- Expansion tank. Compensates for changes in coolant volume, maintaining stable pressure.

Now in more detail about each element.

Features of operation of a closed container

The hermetically sealed container consists of two internal cavities. The cavities are delimited by a pliable partition. One of the cavities is intended for liquid circulating in the heating system. The second cavity is allocated for air, which is under the required pressure.

The external design of closed containers looks like a red cylinder. This is the standard form of tank design. They can be located not only vertically, but also horizontally. The tank body is stamped in production and has a prefabricated design. To prevent corrosion, the inside of the tank is treated with anti-corrosive.

Approximate design of most banks for expansion of coolant

The color for a closed expansion tank for installation in a heating system is always red. Thus, it is impossible to confuse it with a container that is installed in the water supply system. This equipment is called a hydraulic accumulator. They are made blue, although structurally they are no different from heating system tanks. It is important to understand that these tanks should not be misused as they are designed, tested and designed to operate at a specific temperature only. In addition, the partitions are made of rubber. It is also important to know that the pressure level in the water supply tank is different from the pressure in the heating tank. The plumbing and heating system operate at different pressure levels.

Hydraulic accumulators and a tank for expanding coolant fluid

The expansion heating tank is designed with a ready-made threaded pipe. The equipment necessary for the correct operation of the heating system at home is connected to the pipe.

Another device on the tank is the nipple. It is used to regulate the air pressure in the chamber. As a result, it is always possible to adjust the pressure to the optimal level inside the closed tank. This indicator should be 0.2 bar less than the pressure created by the inflated medium in the heating circuit of the house. Can be seen with an example. The cold heating circuit maintains a pressure of 2 bar. Accordingly, the pressure in the expansion tank should be 1.8 bar. It is important to periodically monitor the pressure reading in the expansion vessel. The same value must be monitored in the heating system network itself. It is necessary to check the indicator before turning on the system

Operation of a tank with a membrane under varying pressure

The main and important part of a closed expansion tank is the membrane. Since the membrane is movable, the volume of the two compartments inside the tank will constantly change when the system is running.

Before turning on the heating system, an increased pressure of 1-1.5 atmospheres is created in the air part of the expansion tank. It puts pressure on the pliable septum, and it begins to move in its lower part. At the same time, in the water compartment the volume is set to the minimum value. After the heating system is filled with liquid, the pressure in the heating circuit reaches the operating level. In turn, the compartment with water increases in volume due to the pressure on the membrane, which changes its shape already in the upper part.

As the heating boiler operates, the temperature of the water in the heating system increases. Consequently, there is an increase in the volume of liquid in the heating system of the home. Excess fluid pressure is directed to the water part of the expansion tank, since this is the only place where this pressure can be accommodated. The gas pressure increases due to the fact that one part of the tank increases and another part decreases at the same time.

Operation of the elastic partition in the tank

Over time, the temperature of the water in the heating system decreases. At the same time, the volume of water changes downwards. In the part of the tank where the liquid is located, its quantity decreases. This happens because the pressure in a closed tank is established by the movement of an elastic membrane under the action of the air mass in the upper part of the tank. A flexible partition is installed in such a way as to balance the heating system of the home. That is why any malfunctions in the system are excluded. In case of a critical situation, the safety valve is turned on. It is considered an important component of security sensors. In some cases, the expansion tank is already sold from the factory with this valve.

Tank work. Actuation of the valve on the container during expansion of the heat-carrying liquid

Manufacturers and prices

Currently, the problem of buying an expansion tank for heating lies only in the correct selection of the type and volume of the device, as well as the financial capabilities of the buyer.

The market offers a wide selection of instrument models from both domestic and foreign manufacturers. However, it should be noted that if the purchase price for such devices as a closed-type expansion tank for heating is much lower than that of its main competitors, then it is better to refuse such a purchase. The low cost indicates the unreliability of the manufacturer and the low quality of the materials used in its manufacture. Often these are products from China. As with all other goods, the price for a high-quality expansion tank for heating will not have a significant difference of about two to three times. Conscientious manufacturers use approximately the same materials, and the difference in price of models with similar parameters of about 10-15% is determined only by the location of production and the pricing policy of sellers. Domestic manufacturers have proven themselves well in this market segment. By installing modern technological lines in their production, they achieved the production of products whose parameters are not inferior to the best global brands at a lower cost. It should be borne in mind that it is important not only to buy an expansion tank for closed-type heating, it also requires its correct installation. Having the necessary skills and following the instructions, you can install it yourself

If the master still has any doubts about his knowledge, then it is best to turn to professionals to guarantee stable operation of the heating network and eliminate possible malfunctions

Having the necessary skills and following the instructions, you can install it yourself. If the technician still has any doubts about his knowledge, then it is best to turn to professionals to guarantee stable operation of the heating network and eliminate possible malfunctions.

Instructions for calculating the volume of a closed container

In order to choose the right expansion vessel for your home heating system, it is important to calculate the volume of the closed expansion vessel.

In order to calculate the exact volume of a closed expansion tank, a special formula is derived: V = (Vс * k) / D

Explanation of the formula:

Vc – volume of liquid in the heating circuit;

k – Value indicating the measure of expansion of a liquid as its temperature increases;

D – The value that determines the effective operation of the tank.

If the liquid is antifreeze, then the amount of its expansion is affected by temperature, as well as the amount of glycol contained in the antifreeze. The necessary data can be taken from the relevant reference books.

Below is a table indicating the amount of expansion of antifreeze as its temperature increases:

Expansion coefficient of antifreeze as its temperature increases

There is also a special calculation formula that gives an indicator of the efficiency of the expansion tank: D = (Рм – Рн) / (Рм +1)

It is necessary to decipher the values used in this formula.

- Pm is the highest pressure value in the heating system of a house. As a rule, this value does not exceed three atmospheres. In most cases, the pressure reading is identical to the same reading in an emergency situation when the valve is activated.

Pn - An indicator of the pressure that is created in advance in a half container of water. This can be determined by taking into account the height of the system. Every 500 centimeters is equivalent to half the atmosphere.

Professionals in heating systems recommend installing an expansion tank, guided by formulas for calculating its volume. The resulting value should be equivalent to 1/10 of the total amount of liquid in the home heating system.

For those who find it difficult to obtain accurate calculations on their own using formulas, the website contains a calculator for online calculations. Qualified workers strongly recommend double-checking the received data using calculators on several Internet portals. You should insert the necessary numbers into the free fields, and the system will automatically make the calculations. Then you need to check the resulting numbers one by one on several more sites.

An example of an online calculator for calculating the volume of a tank

Using an automatic calculation system, you can obtain the volume of a container for an expanding liquid. The owner of the house indicates the approximate amount of liquid in the heating circuit, based on the power characteristics of the boiler. According to experts, no matter what result in terms of liquid volume is obtained, it is necessary to purchase a 12-liter closed-type expansion tank for installation.

Installation

The expansion tank can be installed in any part of the heating system, but it is preferable to install it in front of the forced circulation pump. Installation can be performed with either top or bottom connections.

It is recommended to use the top supply, since this scheme prevents air bubbles from accumulating inside the tank.

If during the work it turns out that the designer made a mistake and the accepted volume of the tank is not enough to compensate for the thermal expansion of the liquid, instead of replacing the expansion tank with a larger one, a second tank of smaller dimensions is installed.

If a heating boiler with a built-in expander is installed in the system, installation of a separate tank may not be necessary. Also, when considering various installation options, it should be remembered that in order to reduce heat loss, it is better to choose the mount in which the supply line will have the shortest length.

Nuances of installing an expansion tank

Installers install a closed expansion tank, observing a number of nuances. It is necessary to install the tank so that the threaded pipe is at the bottom of the tank. Located at the bottom, the pipe will effectively remove accumulated gases from the heating circuit of the house.

The correct type of installation is one in which the expansion tank is mounted on the return line of the heating system. It is important that the distance to the boiler is minimal. In this case, the tank must be installed in front of the pump. Thus, its operation will be correct.

Conventional layout of a closed tank

The return line is equipped with a tee. The type of pipes matters when installing a container. Pipeline fittings are installed in the area between the tee and the tank. This way, you don’t have to drain the water from the system when performing scheduled work. The fittings are strengthened so that it is convenient for the home owner. A small piece of pipe is needed, as well as a ball valve. The pipe can be straight or bent. The so-called “American” is also installed to obtain a detachable connection. This will make it easier to remove or service the expansion tank. At the final stage, the pipeline fittings are opened, and all mounted joints and jumpers are checked.

Conventional location of a closed tank

Results

Initially, it is necessary to determine the volume of the tank for expansion, and only after that decide what type to purchase, open or closed. Installation of the entire system must be carried out by qualified specialists. Self-connection is not allowed. During the work, the installation team will make sure that all components and assemblies of the system are installed in accordance with safety requirements and correct installation. In addition, the home owner will be provided with a guarantee on materials and work performed. Therefore, if problems arise, the homeowner can seek help from the place where he ordered the project.