All its key elements are installed through the bypass in the heating system of a modern house. This simple engineering solution facilitates the maintenance and repair of equipment connected to the main line. It also increases the efficiency and economy of heating, which is not bad at all, isn’t it?

Do you want to add a bypass to your heating system, but don’t know how to do it correctly? We will help you cope with the task - the article discusses the purpose of this element of the heating system and the key points of its installation.

Visual photos and accessible recommendations will help even a beginner cope with installing a bypass on his own. In addition, videos have been selected demonstrating the step-by-step process of assembling the bypass section.

Bypass for circulation pump

The circulation pump is the main element along with the hot water boiler if the design of the heating system requires forced circulation. Even when using the forces of gravity and natural circulation, the pump is able to improve and complement the performance of the system for the better. When installing equipment, as required by the rules, a bypass is required for the circulation pump in the heating system. Its presence is due to a number of reasons, which simply should not be ignored.

Blitz tips

- Installing a piping on the riser is unacceptable; it should be placed near the heat exchanger at a distance of at least 2/3 of the pipe length. At the same time, it is also not recommended to install the module very close to the radiator; this can lead to overheating and changes in current parameters, which will disrupt the operation of the entire system.

- Installing a valve on a valveless bypass in apartment buildings is prohibited. Despite certain conveniences for the user, this is a gross violation of SNiP, since the installation of auxiliary elements on risers can lead to a violation of the calculated flow of thermal mass and disrupt its proper circulation.

- When making a bypass module yourself, you should use high-quality components. During the welding process, the seams must be even and smooth.

- The installation of the bypass module must be carried out in such a way that in case of repair, parts that wear out quickly can be dismantled using an adjustable wrench.

Bypass in the heating system - options for proper installation. Overview of the main functions of a bypass in a heating system, what is it - we answer with details, installation of a bypass in a heating system, bypass for a circulation pump, on a heating radiator, in heating. Bypass in a heating system, what is it - the theory of its necessity and the practice of installation. Bypass in a heating system: use and installation diagrams. Bypass in a heating system - options for correct installation. Overview of the main functions What is a bypass in the heating system of an individual house

Why is it needed?

A bypass is a jumper connecting the input and output of one of the elements of the heating circuit, a bypass path through which water can flow without entering the radiator, pump or even boiler.

For a circulation pump, a bypass is needed to:

- exclude the pump from the operating circuit;

- adjust the performance of the heating circuit;

- prevent idling;

- dismantle equipment at any time for repair or maintenance.

The circulation pump allows you to install a pipeline from the boiler to the radiators along arbitrary routes, increases the flow rate of the coolant, making it independent of other system parameters, thereby increasing heat transfer and efficiency. However, it also makes the heating system dependent on electricity.

If for some reason there is no electricity, you can only rely on an uninterruptible power supply unit or switch to natural circulation mode, as far as the design allows. Only the pump itself creates resistance to the coolant current when not in operation. The bypass is precisely designed to solve this problem.

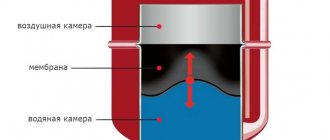

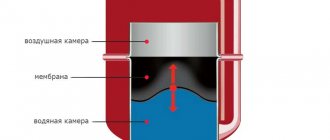

For the pump, the bypass is designed as a continuation of the main pipe from the boiler to the heating circuit with a large diameter. While the pump is connected in parallel to this section. If you allow water to flow around, then there will be no resistance. To do this, a valve or ball valve is installed on the bypass.

The second point when you cannot do without a bypass is draining the coolant and refilling the system. The pump will not allow pipes and radiators to be filled freely with liquid, creating an obstacle. The result can be the formation of an air lock, which is difficult to get rid of. A completely open current through the bypass completely eliminates the problem.

The last case of fine-tuning performance is used quite rarely. It is enough to set one of two or three pump speeds to regulate the flow rate and pressure. However, if each radiator has its own thermostat, it is very important to provide protection for the pump. If all radiators are closed, and the resistance to the coolant current in the system increases, then the bypass saves from reloading the equipment, partially closing the circuit to itself.

Features of application

Most often, bypasses are used for the following purposes:

- Maintenance of individual devices without stopping the entire system. If for some reason you need to remove equipment in the heating system or on the water supply line, for example, to repair or replace it, you should simply close the inlet and outlet valves of the working medium and then the liquid will flow through the bypass, and you can dismantle the necessary device without consequences .

Bypass in the heating system

- Improving the operation of a single-pipe heating circuit. The main disadvantage of a single-pipe system is the uneven distribution of the coolant: since the batteries here are connected in series, as it moves, the working fluid cools down and the last devices receive almost cold coolant. To avoid this, a bypass is installed in front of each radiator - thanks to it, a certain part of the media moves around the batteries and, as a result, reaches hot water even to a distant device.

Advice. In a similar way, you can regulate the heat transfer of radiators in a two-pipe system - just turn off the tap in the selected location, and the hot medium will move to those areas that really need heating.

- Maintaining the heating system without power supply. If the system uses an electric pump, then it is logical that if the power supply is turned off, it will stop working and stop the heating process. But the bypass will also save you in this situation: by turning off the pump supply valve and allowing the media to flow through the jumper, you can activate the natural circulation of the liquid and restore the system’s functionality.

How to assemble

The bypass for the circulation pump is ideally a continuation of the return pipe running from the radiators to the boiler. A pump is installed parallel to the selected section of the pipe, for which pipes are cut into. To prevent DC current from flowing through the bypass, a shut-off valve or valve is needed.

Along the pump activation line the following are installed:

- ball valve;

- coarse filter;

- pump with American connections;

- ball valve.

At the edges of this assembly, elbows and pipes are installed for insertion into the main pipe. The order of the elements is indicated according to the direction of liquid flow, so the filter should be strictly in front of the pump. The diameter of the pipes is selected equal to the outlet cross-section of the pump, while for the bypass the same pipe is used as for the return itself.

Bypass assembly diagram

In the bypass section itself, only shut-off or control valves are installed: ball check valve, ball or needle valve.

A ball check valve is preferable for providing a bypass to the circulation pump. It operates on the principle of a spool valve. If the pump is turned on, the ball inside the valve, under the influence of pressure, blocks the current through the bypass. If the pump is turned off, then the direct flow of liquid from the boiler, bypassing the pump, predominates, and the valve does not prevent this.

The ball valve has two closed/open positions. It is prohibited to install it in intermediate positions, since the surface of the shut-off ball quickly wears out and becomes covered with sediment, which leads to damage to the Teflon insert. If it is necessary to fine-tune the bypass capacity, then preference is given to a needle valve, only taking into account that its flow area is significantly smaller than that of a ball valve of the same size.

It is better to use ready-made solutions. Prepared bypasses for circulation pumps are produced. They already have ball valves or valves installed in a common section of the pipe and all the piping for the pump, including a filter and fasteners. A ready-made bypass may turn out to be much more reliable in assembly and more durable in operation. The installation location of the pump is unified and is suitable for any model of suitable power and throughput. You have to choose based on the diameter of the main pipe and productivity.

Before installation, the coolant should be completely drained from the system. A circulation pump with a bypass is mounted on the cold return pipe directly next to the heating boiler. This reduces the impact of high temperatures on equipment.

It is necessary to initially determine the optimal inclusion option:

- For a plastic pipe, it is better to use American-style dismountable connections and connect a pre-assembled pump unit with a bypass. Connect the branch with the pump using tees soldered into the main pipe.

- For steel pipes, first the branch pipes for the branch with the pump are welded, and then the valve on the bypass.

When working with welding, it should be taken into account that the valves do not tolerate overheating. Especially ball ones, where the Teflon insert can become deformed. The connection point of the main pipe should be distanced from the valve using extended pipes or fittings by at least 20 cm on both sides. In this case, the shut-off valves are combined with fittings using threaded connections.

The entire structure must be oriented in such a way that the pump outlets are positioned strictly vertically or horizontally, and the working shaft is strictly horizontal. This will increase the survivability of equipment and reduce the production of parts. All valves must be freely accessible and nothing should prevent them from being closed. Allow sufficient space to allow easy removal of the pump and other components.

Battery tying

If the installation of the system is carried out independently, then you need to know all the requirements that apply to this or that element. This also applies to the bypass. It is often installed in places where radiators are mounted. But why do you need a bypass in a heating system? This issue needs to be looked at more carefully.

Radiators are tied according to a simple pattern

Why is it needed?

Previously, single-pipe heating was used in the construction and improvement of houses. This greatly simplified the work and also reduced costs. In this case, two collectors were installed in the elevator unit, which were responsible for supplying and processing the coolant. Further heating was developed according to different schemes:

- Top feed. There was a pipe running from the collector to the top floor. The coolant was supplied upward through this riser. After that, it went down, passing through all the radiators.

- Bottom feed. In this case, the coolant begins to flow into the radiator when it is raised up. This series connection of devices has some disadvantages.

In both the first and second cases, the connection is made in series. This means that if a problem occurs on some equipment, you will have to turn off the entire system. To circumvent this problem, special jumper pipes were included in the system. So, if necessary, the radiator is disconnected from the system using taps without disturbing its operation. This makes it possible to easily repair the battery.

The jumper is installed closer to the battery

This is not the only reason for using a jumper in heating. The room is heated using radiators. If there is a bypass with valves, apartment owners have the opportunity to independently adjust the coolant supply. Thus, controlling the temperature in the house is not difficult.

The dressing tube has different shapes

Bypass installation

To carry out heating installation, you must have certain knowledge and skills. This takes into account the method of pipeline assembly. For this purpose, threaded and fitting connections are used, as well as pipe soldering. Having these skills will make the job easier. It is worth considering some rules and recommendations from experts:

- There should be no valves between the rack and the bypass. Otherwise, the coolant circulation may be disrupted.

- On the vertical riser pipe, the jumper is mounted in close proximity to the battery. In this case, space must be provided for installing shut-off valves. It is mounted on both sides of the radiator.

- Do not install valves on the bypass unless necessary. If you install taps on the jumper, the circuit will become unbalanced. In an autonomous system of a private house, this in turn allows you to redirect the flow. In a multi-story building, this option is ineffective and is a violation of standards.

- The size of the pipes is important. The diameter of the insert is two sizes smaller than the section of the stand. The pipes that go to the radiators are made one size smaller. In the horizontal scheme, the size ratio is somewhat different.

Compliance with the dimensions of pipes and pipes will ensure normal operation of the system, in accordance with all the laws of hydraulics. As for installation, its features directly depend on the type of material used. If we are talking about a metal pipeline, then it is enough to simply weld the jumper and install the taps.

Installation is carried out in different ways

The use of polypropylene, as well as metal-plastic, requires the use of special fittings. You can build a bypass yourself from a pipe of the required size or purchase a ready-made part.

The pump is often installed on a jumper

Why do you need a bypass?

In essence, a bypass is a simple jumper that allows coolant to flow freely, bypassing any equipment. If we talk specifically about the circulation pump, then such a device allows:

- exclude the device from the heat-carrying circuit;

- prevent engine idling;

- fine-tune the heating;

- repair equipment or carry out maintenance without having to turn off the heating.

The main advantages of a system with a circulation blower are the increased speed of water flow and, to some extent, ignoring the resistance of the working circuit. But at the same time, such a scheme cannot work without electricity.

Moreover, when forced to switch to natural circulation, the pump will create additional resistance to the flow of water. This can happen if it needs urgent repairs. To remove this resistance, a bypass is needed.

A bypass is also necessary in situations where it is necessary to drain or fill the system with coolant. In this case, the blower will be an obstacle to the water and may create an air lock. The bypass will ensure free flow of liquid, eliminating the problem.

Finally, when adjusting the performance, it takes on part of the load, thus protecting the pump. You don’t have to set up the system often, but additional insurance never hurts.

How to prevent insolent guests from returning?

Following simple hygiene rules will help avoid the return of annoying guests:

- take out the trash once a day or more often;

- do not leave open food on the table - it is better to transfer it to a closed container or simply cover it with a microwave hood;

- do not leave dirty dishes in the sink;

- Conduct a thorough wet cleaning of the kitchen weekly;

- Water the plants in moderation and remove fallen leaves immediately. The soil can be covered with sand or pebbles to prevent the appearance of midges;

- Clean your pet's bowl and cage regularly;

- check vegetables and fruits in the refrigerator daily for freshness, remove rotten ones;

- Wipe any drops or puddles that have formed immediately.

Hygiene is the main prevention of the appearance of midges in the apartment.

Bypass assembly

The bypass is a section of the main pipeline between the heating boiler and the working circuit. In this section of the direct current, a ball valve is installed, which, when the supercharger is turned on, blocks the movement of the coolant. A less practical solution is a shut-off valve, the normal position of which is closed when the system is running.

The pump is installed in parallel, by means of two branches, embedded in the main pipe and directed towards each other. For fastening, you should use quick-release fittings of the “American” type, which will allow you to quickly dismantle it if necessary. As the fluid moves, a coarse filter is installed in front of the supercharger, and on both sides this design is limited by shut-off valves. The diameter of the pipes must correspond to the inlet and outlet openings of the pump.

Often the best solution is to buy a ready-made bypass assembly. Manufactured for pumps of various diameters, they are already equipped with all the necessary shut-off valves and filter. All you need to do is install it in the desired area of the heating system and install the pump. The key parameter is the distance between the fittings. For the most common type of circulation pumps, it is 110 mm.

Bypass installation

First of all, you need to decide on the right place to install the circulation blower. The location should be chosen so that there is room for convenient repair and dismantling of the assembly elements. It is also necessary to consider the location of all valves and taps - they must be freely accessible.

With a two-pipe heating system, the circulation pump cuts into the return coolant circuit - this reduces the likelihood of overheating.

The bypass assembly algorithm differs depending on the material from which the pipes are made:

- If the pipes are plastic, then the pump assembly is assembled immediately, after which it is connected to the pipeline using soldered tees.

- If the pipes are metal, you should first weld the outlet pipes for the pump unit, and then install the bypass valve.

In no case should the shut-off valves be allowed to overheat due to welding - this will negatively affect its quality. For example, the Teflon insert of a ball valve may become deformed. Therefore, the welded joint must be at least 20 centimeters away from taps and valves.

The pump should be positioned so that the operating shaft assumes a strictly horizontal position. This will reduce the gravitational load on the shaft and increase the service life of the pump.

Operating principle of the bypass valve

If an unusual situation occurs, a power outage or a pump breakdown, the pressure stops and the valve automatically closes the jumper, allowing water to flow naturally. This allows the heating system to be fully automated. The disadvantage of automatic bypass is sensitivity to water contamination and small contaminants. Before installation, it is recommended to clean the water supply system of the AED to remove deposits and rust in pipes and radiators.

Before starting work, you need to decide on the material of the water supply system. For polypropylene pipes, dismountable connections are used, and first the pump block is assembled along with the bypass. The branch is connected using tees mounted in the main pipe. For the steel version, first the pipes are soldered in, then the valve on the bypass. The bypass system is installed towards the coolant and must be assembled in a certain sequence.

Assembly diagram:

- Filter;

- Check valve;

- Forced action pump.

The diameter of the bypass line passage must be equal to the return diameter. Experts recommend that all taps be equipped with dismountable fittings during installation. In this case, various situations will be eliminated during the repair.

Operating principle of the bypass valve

Before starting installation work on installing the pump, it is necessary to drain the coolant from the system. The entire structure is oriented so that the outlet pipelines are vertical or horizontal, depending on the stroke of the pipe.

How the bypass line works:

- They assemble a section of the bypass that will be located parallel to the highway;

- A section equal to the length of the bypass is cut off from the return;

- Tees are installed at the ends of the line;

- A section with shut-off valves or valve is mounted between them;

- The assembled section of the bypass is connected to the main line with pipes of equal length.

During installation, it is necessary to leave space for subsequent dismantling of the pump and other elements. It is necessary to carry out the installation correctly, making sure that the arrow on the housing coincides with the coolant current.

How to install a bypass in a heating system - installation options and rules

In modern construction, when installing heating systems, a bypass is necessarily used. This element significantly simplifies the maintenance and repair of any elements of the heating system, and also has a positive effect on the efficiency and economy of heating. This article will discuss how to properly install a bypass in a heating system.

How to choose a water pump for heating your home

A heating pump for a private home is selected according to several basic parameters:

- Productivity and pressure;

- Rotor type;

- Power consumption;

- Control type;

- Coolant temperature.

Let's look at how to choose water pumps for heating a private home.

Performance and pressure

Correctly made calculations will help you choose the unit that best suits your needs, which means it will help you save your family budget.

The performance of an electric water pump refers to its ability to move a certain amount of water per minute. The following formula is used for calculation – G=W/(∆t*C). Here C is the thermal capacity of the coolant, expressed in Wh/(kg*°C), ∆t is the temperature difference in the return and supply pipes, W is the required heating power for your home.

The recommended temperature difference when using radiators is 20 degrees. Since water is usually used as a coolant, its heat capacity is 1.16 W*h/(kg*°C). Thermal power is calculated for each household individually and expressed in kilowatts. Plug these values into the formula and get the results.

The pressure is calculated in accordance with the pressure loss in the system and is expressed in meters. Losses are calculated as follows - losses in pipes are considered (150 Pa/m), as well as in other elements (boiler, water purification filters, radiators). All this is added up and multiplied by a factor of 1.3 (provides a small margin of 30% for losses in fittings, bends, etc.). There is 9807 Pa in one meter, therefore, we divide the value obtained by summation by 9807 and obtain the required pressure.

Rotor type

Home heating uses wet rotor water pumps. They are characterized by a simple design, minimal noise levels and no need for maintenance. They are also characterized by small dimensions. Lubrication and cooling in them is carried out using a coolant.

As for dry-type water pumps, they are not used in home heating. They are bulky, have a high noise level, and require cooling and periodic lubrication. They also require periodic replacement of seals. But they have a large throughput capacity - for this reason they are used in heating systems of multi-storey buildings and large industrial, administrative and utility buildings.

Power consumption

The most modern water pumps with energy consumption class “A” have the lowest power consumption. Their disadvantage is their high cost, but it is better to invest once to get reasonable energy savings. In addition, expensive electric pumps have lower noise levels and a longer service life.

Control type

Through a special application you can get information about the operation of the device wherever you are.

Typically, the rotation speed, productivity and pressure are adjusted using a three-position switch. More advanced pumps are equipped with electronic control systems. They control the parameters of heating systems and allow you to save energy. The most advanced models are controlled wirelessly, directly from a smartphone.

Coolant temperature

Water pumps for heating a private home differ in their operating temperature range. Some models can withstand heating up to +130-140 degrees, these are the ones that should be preferred - they can cope with any thermal loads.

As practice shows, operation at the maximum temperature is possible only for a very short time, so having a solid reserve will be a plus.

Other characteristics

When choosing a water pump for heating, you need to pay attention to the maximum operating pressure for the selected model, installation length (130 or 180 mm), type of connection (flange or coupling), and the presence of an automatic air vent. Also pay attention to the brand - under no circumstances buy cheap models from little-known developers. The water pump is not a part you should skimp on

The water pump is not a part you should skimp on.

Bypass device

A bypass is a bypass part of the pipeline that ensures the coolant moves along a path that bypasses a certain section of the pipeline. One edge of the circuit is connected to the supply pipe, and the second to the return pipe. Various elements of the heating system, such as pumps, are usually installed on the bypass.

At the connection point between the bypass and the inlet pipe of the device that needs to be bypassed, a shut-off valve is installed. Its presence makes it possible to direct the flow of liquid parallel to the device itself and regulate the intensity of the coolant supply. A valve is also installed on the return pipe, which allows you to exclude a section of the pipeline from the system without the need to stop it.

Quick installation tips

Among the common options is when the heating circulation pump is installed on a bypass. It is easier to dismantle such a system when the need arises, when the device is temporarily disconnected from the network. The work will require the purchase of the following tools:

- Sealant.

- Tow or linen thread.

- Pliers.

- Assembly is carried out using open-end and adjustable-type wrenches.

Adapters with bends and taps are prepared separately, “American nuts” become part of the original kits

The diameter of the product and reliable material are the most important characteristics that are worth paying attention to

Actions are performed in the following order:

- Assembling the crane assembly. One is assigned to a straight pipe, the other two are located at the edges of the pump. Precise welding of a fragment with a tap requires preliminary measurement of the “return” section.

- Assemble the pump loop. For now, the nuts are only screwed on, and their tightening is postponed to one of the finishing stages of the work.

- Try on the bypass loop. Separate markings are for places where welding to the pipe takes place.

- Welding. It is better to trust it only to specialists with sufficient qualifications.

- Assemble the lower assembly on the return line.

- Connection of the pump to the power supply.

An arrow is always drawn on the body. It is needed to indicate where the coolant is moving. Preservation of the specified side is ensured when turning the units.

The pump is powered from conventional 220-volt networks. It is advised to opt for a conventional connection with a separate power supply line. A phase with zero and protection is required. A three-pin socket with a plug helps organize the connection of elements with each other. If there is a connected power wire, the relevance of the solution increases. Correct installation of the heating pump with your own hands is completed.

Types of bypasses for heating

When installing a bypass, shut-off valves are installed not only on the pipes of the connected device, but also on the bypass itself. The type of fittings used allows us to classify several types of bypasses, each of which is suitable for certain operating conditions.

The following types of bypasses exist:

- Unregulated;

- With manual control;

- Automatic.

The characteristics of devices with different types of shut-off valves have significant differences, so before installing a bypass in the heating system, you need to carefully consider each type.

You might be interested

Stoves and heating systems Gas heaters for a dacha with a cylinder: which one to choose and calculation of the required power to heat the room Having a dacha or outside the city is the longed-for dream of many residents of modern... Evgeniy Afanasyev 36516 1

Stoves and heating systems How to choose a stove for a cauldron - rating of the best models of 2022 The taste of real pilaf probably does not leave anyone indifferent. And that’s why... Evgeny Afanasyev 959 0

Furnaces and heating systems Which metal-plastic pipes to choose for heating: types of pipes and which ones are better to choose Without any exaggeration, it can be said that the appearance of metal-plastic pipes in its... Evgeniy Afanasyev 2372 0

Stoves and heating systems Rating of heat pumps for heating a home: recommendations for choosing Against the backdrop of a constant rise in energy prices, more and more homeowners are turning their... Evgeniy Afanasyev 558 0

Stoves and heating systems Leningrad heating system: diagram and what critical mistakes should be avoided during installation When building any country house, the owner, one way or another, must face... Evgeniy Afanasyev 165250 0

Unregulated bypass

The device of unregulated bypasses is a simple pipe that does not have any equipment. The pipe is constantly in an open state, and the liquid moves through it arbitrarily, that is, there is no opportunity to influence the intensity of the water flow. Unregulated bypass pipes are most often used to connect heating appliances.

When designing a heating system, it is necessary to take into account the fact that water always moves primarily through those areas where the hydraulic resistance is minimal. In the case of a bypass, this means that the internal diameter of its vertical section must be smaller than the internal cross-section of the main pipeline. If this requirement is not met, the coolant will simply gravitate towards the bypass.

When designing horizontal heating distribution, other rules apply that must be taken into account before making a bypass into the heating system. The heated coolant has a reduced specific gravity and always tries to move upward. In order for the system to operate normally taking into account this rule, the diameter of the lower part of the bypass must match the diameter of the main line, and the cross-section of the pipe leading to the radiator must be smaller.

How to calculate the air pressure in the hydraulic tank?

If the device is installed in a basement, then you can easily calculate the minimum required pressure. To do this, take the height in meters from the top to the bottom point of the system. Let's take a height of 7 meters as an example. You need to add 6 to it, divide by 10. The result is 1.3 atmospheres. This is how we obtained the minimum air pressure in the system located in a two-story house.

If the pressure in the system is less than this value, water simply will not flow to the second floor. The manufacturer sets the air pressure to 1.5 atm. But sometimes it happens that in the device this value may be different.

For this reason, after purchase, it is necessary to check the pressure inside the hydraulic tank using a regular pressure gauge. It attaches to the nipple. When the need arises to increase pressure, you can use a car pump. If a hydraulic accumulator is used together with pumping equipment, then the lower limit for turning on the pump should be equal to the pressure level in it.

Bypasses with manual adjustment

Bypasses that are adjusted manually (manual bypasses) are equipped with ball valves. The use of ball valves is determined by the fact that they do not change the pipeline capacity at all when switching, since the hydraulic resistance in the system does not change. This quality makes the ball valve an optimal option for bypass.

Shut-off valves of this type allow you to regulate the volume of liquid that passes through the bypass section. When the tap is closed, the coolant moves in full along the main line. The operation of ball valves has one important nuance - they need to be turned regularly, even if there is no need to adjust the system. This is due to the fact that if left stagnant for a long time, the taps may become tightly stuck and will have to be replaced.

Manual bypasses in heating systems can be used in several ways. Most often they are used to connect batteries to a single-pipe main, as well as for piping circulation pumps.

Price and recommendations

If we analyze the prices for bypass and components, we can summarize that they are not that high and completely depend on the region of your residence. So, in Moscow you can buy it for 5,000 rubles, and in Yekaterinburg for only 3,000 rubles. These amounts are simply meager compared to those that you will save on heating when using this pipe and taps.

How to choose a suitable bypass?

Just follow our advice and you definitely won’t go wrong:

- Buy only certified products.

- Demand to show the seller a hygiene certificate.

- Upon visual inspection, the bypass you choose should be smooth, without any dents, chips or signs of corrosion.

- If the product has threaded connections, check that they are easy to screw on and off.

- Welding seams must be solid, without pores.

- After purchasing a product, always keep the receipt and warranty card until the period indicated on it expires.

Automatic bypasses

Bypasses with automatic adjustment are usually installed in the piping of a pump installed in a system with natural coolant circulation. Such heating systems can operate independently, but thanks to the pump, the speed of fluid movement along the circuit increases, which reduces heat losses and increases heating efficiency.

The presence of an automatic bypass in the pump piping allows the system to independently regulate its operation, i.e. no human intervention required. When the pump is running, the coolant passes through it, and the bypass is closed at this time. When the pump stops, the bypass opens and the liquid moves in it, while the stationary pump impeller cuts off the coolant flow.

Automatic bypasses are divided into two types:

The design of the first type of device contains a check ball valve. The hydraulic resistance of the valve is minimal, so the liquid easily moves on its own. When the pump is turned on, the coolant begins to move faster, is transported into the main line and diverges in two directions.

Further movement of the liquid occurs without any obstacles, and the reverse flow is blocked by the valve. The operating principle of the valve itself is extremely simple - the hydraulic pressure on the outlet side exceeds the inlet pressure, so the ball is pressed closely against the seat of the structure and does not allow the fluid to move.

Valve bypasses are quite convenient and simple, but they are very demanding on the quality of the water with which the heating system is filled. If the water contains various impurities, such as rust or scale, the valve very quickly becomes dirty and becomes unusable, as a result of which it has to be replaced.

Injection bypasses are devices similar in principle to a hydraulic elevator. A pumping unit is installed in the main line, which is connected to the main circuit using pipes of smaller diameter. With this scheme, both pipes are inserted into the main pipeline.

When the pump starts, part of the liquid enters the nozzle and is passed through the apparatus, accelerating many times in the process. The outlet pipe, which is slightly narrowed and visually resembles a nozzle, which ensures efficient pumping of liquid, also works to increase speed.

A vacuum is created behind the outlet pipe, due to which the coolant begins to be sucked out of the bypass. The flow, moving under pressure, pulls all the liquid with it, and it continues to move along the main highway with noticeable acceleration. This effect allows you to completely prevent the possibility of reverse flow of liquid.

The technology described above only works when the pump is turned on. If the pumping equipment is turned off, then the coolant in full passes through the bypass under the influence of gravitational forces.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but on the supply or return pipeline it doesn’t matter. Modern units are made from materials that can withstand temperatures up to 100-115°C. There are few heating systems that work with a hotter coolant, so considerations of a more “comfortable” temperature are untenable, but if you feel safer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system; it makes absolutely no difference whether there is a pump in the supply or return branch. What matters is the correct installation, in terms of strapping, and the correct orientation of the rotor in space

Nothing else matters

There is one important point regarding the installation location. If the heating system has two separate branches - on the right and left wings of the house or on the first and second floor - it makes sense to install a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule remains on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal conditions in each part of the house independently of the other, and also in two-story houses to save on heating. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of movement of the coolant is set much lower, and this allows you to burn less fuel, without compromising the comfort of living.

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.

Bypass purpose

The main function of any bypass is the ability to keep the heating system in working order even if one of its elements breaks down or there is a power outage. Devices connected via bypass can be disconnected from the system without any problems - to do this, you just need to turn off both taps, and the coolant will flow around the circuit.

Thanks to the bypass, heating can continue to operate in any case, and damaged elements can be repaired, spending any amount of time. The reliability and ease of maintenance of the heating system with a bypass increases many times over.

In autonomous heating circuits, the bypass is used to solve the following problems:

- Connecting heating devices to single-pipe wiring;

- Pumping equipment piping;

- Connecting the water heated floor distribution manifold;

- Formation of a small circulation circuit when using solid fuel heating equipment.

The bypass installation method may vary depending on its purpose in a particular heating system.

What is the principle of bypass?

Indeed, for a Russian-speaking person this name sounds very unusual. But it is precisely the meaning of this term that clearly speaks of the purpose of the element.

If you try to translate the word “bypass” literally from English, then dictionaries give a lot of different definitions, which, however, come down to one fundamental concept - the nouns “detour”, “detour”, “detour”, verbs “bypass”, “bypass” , “choose a different direction” and the like. This means that it is reasonable to assume that what is meant is some kind of device that allows for alternative rather than direct movement.

This is how it really is. In plumbing systems, a bypass is a section of pipe installed in such a way that a path is opened for liquid (coolant in the case of heating, or water in the case of water pipes) not only through any device, but also bypassing it. This "shorted" flow can become uncontrollable when the bypass is kept constantly open and the fluid flow obeys only the laws of hydraulics. Often, control devices are placed on the bypass - from simple valves to automatic devices that change the cross-section of the passage depending on changes in external conditions.

Perhaps the simplest and most common example of a bypass is a jumper pipe between the connections to the heating radiator

Since we are talking only about heating systems, the bypass can be installed:

- In radiator piping, which is more typical for single-pipe heating systems.

- In the piping of the circulation pump - in autonomous systems.

- In mixing units of water heated floor systems.

- To create a “small circulation circuit” in boiler piping (typical for units operating on solid fuel).

Bypass for radiator

In single-pipe heating systems, batteries are best connected using a bypass. For two-pipe circuits and manifold distributions, bypasses are not needed, since all heating devices are connected in parallel, and each of them receives coolant at the same temperature. If one of the batteries fails, it can always be removed without turning off the heating system (of course, if there are shut-off valves).

In systems with single-pipe wiring, the batteries are connected in series, so the coolant in each subsequent device cools down. The result is obvious - distant devices receive much less heat, and there can be no talk of any uniform distribution of thermal energy.

Bypasses can solve the problem. The supply and return circuits are connected by a jumper, which ensures independent flow movement. The hot coolant enters directly into the radiator, while the other part of it passes further and at the outlet is mixed with cooled water from one radiator. This scheme allows you to deliver much more heat to subsequent heating devices.

The effect of bypass on heat transfer

The use of the element in heating networks allows one to obtain excellent results in terms of thermal energy savings. In this case, the production of a bypass can be carried out directly by a foreman at the work site, or it can be a factory model with standard characteristics.

It is a piece of pipe that is installed into the network using tees. Install it approximately one-third of the distance from the riser to the radiator. It cannot be placed further because the coolant will not flow into the radiator; placing it too close may cause the bypass to overheat and the circulation will be disrupted again. Therefore, one third is the most optimal ratio.

After this engineering element, needle valves are placed in front of the radiator, thus making it possible to fine-tune the thermal output of radiators for each individual element, without consequences for steel heating devices. An unobvious advantage of the installation is the ability, if necessary, to carry out scheduled and unscheduled repairs and maintenance of a radiator that suddenly fails, without shutting down the entire system.

The location of the product can be either vertical or horizontal. It can be used in both single-pipe and two-pipe heating systems

It is important to remember that the diameter of the pipe in the bypass must always be smaller than the diameter of the pipes through which coolant is supplied to the radiator; this will, due to natural resistance, prevent disruption of coolant circulation

Connecting the pump via bypass

It is advisable to connect the circulation pump via bypass only in those systems that were originally designed for natural circulation, i.e. they must have an accelerating manifold, pipe slopes must be observed and their diameters must be correctly selected. The pump in such systems is not intended to ensure their operation, but to increase efficiency.

For systems that were designed for forced circulation at the design stage, a bypass is simply irrelevant. Such systems operate only due to the pump, so when it is turned off, the circulation of the coolant simply stops. Bypass in this case will not solve the problem.

When connecting the pump via a bypass line, it becomes possible for counterflow in the bypass. In addition, a closed circulation loop is formed between the pump and the bypass itself. In order for such a circuit to function normally, the bypass device must be equipped with a ball valve or check valve.

When the pump is running, the device blocks the flow of liquid through the bypass pipe. The valve does this work automatically, but the tap has to be adjusted manually. When the pump stops, the bypass opens, which allows coolants from different circuits to mix. A similar scheme is not applicable in the case of injection bypasses - they completely eliminate the possibility of reverse coolant flow.

Is an additional pump needed for a Navien double-circuit boiler?

After installing a double-circuit condensing boiler, many users consider installing an additional pump in the heating system of a country house.

The need to use an additional pumping device is explained by the uneven heating of the living spaces of a two-story house with sufficient power of the boiler equipment. Advice! If the temperature differences of the coolant in the supply and return pipelines exceed 20 degrees, it is necessary to switch the circulation pump to a higher speed or get rid of air pockets.

Installing another pump is necessary in the following cases:

- When installing heating in a private house with an additional circuit, or in cases where the length of the pipes is more than 80 meters.

- For uniform supply of coolant through the heating system.

There is no need to install an additional pump if the heating is balanced using special valves. Therefore, before purchasing pumping equipment, bleed the air from the heating radiators and add water, check the circuit for leaks using a manual pressure test pump. If after such procedures the autonomous heating of a private house works normally, then another pump will not be needed.

Why do you need a hydraulic arrow?

If several pumps are installed in the heating system of a summer house or cottage, a hydraulic separator or hydraulic arrow must be included in the circuit. This device can be used together with a single-circuit diesel boiler or solid fuel unit. In the latter case, the device regulates the supply of coolant in different phases (fuel ignition, combustion phase and attenuation). Installing a hydraulic arrow allows you to balance the operation of the heating system. The main tasks of the hydraulic separator are:

- Automatic removal of accumulated air;

- Catching dirt from coolant flows.

Important! The hydraulic arrow in heating allows you to balance the operation of the system, protects it from airing, and prevents the accumulation of dirt in the pipelines. Such a device must be installed without fail if there are several booster units

Installation nuances

When installing turnkey heating, a master plumber installs a circulation pump with a wet rotor. Such a device does not create much noise; its rotor rotates without lubrication. Coolant is used here as a coolant and lubricant. When installing pumping equipment, you need to take into account the following nuances:

- The shaft of the pressure-injecting device is positioned horizontally relative to the floor plane.

- Carry out installation in such a way that the direction of water coincides with the arrow on the device body.

- Install the device with the terminal box facing up, which will prevent water from entering the electronics.

Important! Experts recommend installing the pump on the return pipeline of the heating system of a single-story or multi-story residential building. Despite the fact that such equipment is designed to operate in hot water with temperatures up to 110 degrees, warmer liquid in the return pipeline will only extend its service life. Installation of the unit is carried out only after draining the water from the system

If there is a power outage, the pump will not be able to pump the coolant, so it is connected through a bypass, and a mesh filter is installed in front of the inlet pipe to prevent scale and debris from getting onto the impeller. In addition, shut-off valves are provided at the input and output of the device for possible replacement and repair of the device.

Installation of the unit is carried out only after draining the water from the system. If there is a power outage, the pump will not be able to pump the coolant, so it is connected through a bypass, and a mesh filter is installed in front of the inlet pipe to prevent scale and debris from getting onto the impeller. In addition, shut-off valves are provided at the input and output of the device for possible replacement and repair of the device.

As we can see, installing a circulation pump requires certain skills, so the installation of this equipment must be carried out by a professional. To order a service, you can leave a request on the website or call the number

For heated floors

When installing a heated floor, it is imperative to install a mixing unit, in which a bypass pipeline is always built in. The bypass in this case will be used to ensure the normal operation of the heated floor, and without this element the heating will not be able to function.

It's all about the operating temperature, which must be maintained in heated floors. The coolant in the supply circuit can heat up to 80 degrees, but in a heated floor its temperature should not exceed 45 degrees. The liquid is brought to the required temperature in a mixing unit, which passes only the required volume of hot water. The entire remaining flow is directed to the bypass, where it is connected to the coolant from the return circuit, and returns to the boiler.

For systems with solid fuel boiler

When used in combination with solid fuel heating equipment, the bypass allows the formation of a small circulation circuit. To do this, the bypass pipe is installed in the supply, where there is a coolant heated to the limit, and is connected to a three-way valve located on the opposite side of the structure.

Thanks to the valve, hot water from the bypass and cold water coming from the return circuit are mixed. As a result, a coolant whose temperature exceeds 50 degrees is returned to the boiler for the subsequent heating cycle.

The need to return warm liquid to the boiler is determined by the fact that otherwise condensation will appear on the metal walls of the combustion chamber, which will provoke corrosion and cause damage to the unit. If you supplement the system with a bypass, then these problems can be easily avoided.

Advantages of using liquid nails for gluing materials

Convenient packaging and a unique composition have provided liquid nails with many advantages, which is why they are in high demand. These formulations are ideal for both home and professional use.

Liquid nails allow you to get a very strong connection.

Advantages of liquid nails:

- high strength of connections;

- excellent adhesive properties allow you to glue tiles, baseboards, mirrors and other materials to liquid nails;

- simple system of use;

- the connection is of high quality not only when gluing smooth surfaces, but also in cases where the materials do not fit tightly;

- thanks to liquid nails, installation on curved surfaces does not cause difficulties;

- the adhesive, unlike conventional fasteners, does not damage the treated surface or violate its integrity;

- the composition is not afraid of corrosion and sets instantly;

- installation work takes place without unnecessary noise and dirt;

- the adhesive composition is non-toxic (with the exception of questionable low-cost products);

- efficiency and fire resistance;

- absence of sharp and unpleasant odors (most formulations smell neutral).

On a note! Neoprene nails have increased frost resistance and moisture resistance. For aqueous formulations these figures are much lower.

Bypass installation

Including a bypass in different types of systems has its own nuances, so before making a bypass for heating, you need to understand these points.

For example, when connecting radiators via bypass, the following rules must be observed:

- The internal cross-section of the bypass should be one step smaller than the diameter of the main pipe;

- The bypass must be installed at a minimum distance from the radiator;

- When used in apartment buildings, the bypass cannot be equipped with a tap.

Installation of a heating system bypass can be carried out both when installing a new system, and when repairing an existing structure. In the latter case, before work you need to prepare a set of pipes of suitable diameter, two tees and shut-off valves.

The inlet pipe of the structure is equipped with one of the following devices:

- Ball valve, which has minimal hydraulic resistance and completely allows coolant flow;

- A valve that allows you to manually adjust the intensity of liquid flow;

- A combination of a ball valve and an automatic thermostat - this combination can adjust the operation of the system automatically.

The outlet pipe is always equipped with a ball or shut-off valve. To connect individual elements, welding or threading can be used. Regardless of the type of connection, it must be airtight. Before putting the system into operation, you need to check it for leaks.

A bypass with a pump in the heating system is installed taking into account the following points:

- The bypass on which the pump is planned to be installed is usually part of the main line. The internal diameter of the bypass must be large enough to ensure normal natural circulation in the system. The pump is mounted on a separate pipe, the internal cross-section of which may be smaller than the diameter of the main pipeline.

- To simplify your work, it is best to buy a pre-assembled pump unit with the necessary parameters. It is very simple to install such a structure, since all the elements are already correctly assembled and the connections are quite reliable.

- When installing it yourself, the pump must be positioned so that the impeller axis is horizontal. The surface with the terminals to which power is supplied should be directed upward - firstly, this will simplify access to the contacts, and secondly, it will eliminate the possibility of liquid getting on the contacts if the system’s seal is broken.

- The area with a bypass must be equipped with a check valve or ball valve, which prevents the flow of coolant in the opposite direction - this optimizes the operation of the system. Of course, before installing the bypass, you need to purchase all the components.

Before installing a bypass with a check valve for the circulation pump, you need to think carefully about the design of the future system and take into account all possible nuances.

Mechanism design

One of the most popular schemes for the heating system of an individual house is a scheme where the central water supply line is preserved, and the circulation pump is installed in a parallel pipe.

Before making a bypass into the heating system, you should consider: the design of this device depends on its area of application:

- a product consisting of a jumper and 2 ball valves are installed near the radiator;

- such a device includes several parts: a circulation pump, a filter, two taps, as well as an additional tap for the main circuit;

- You can also install a pump to automatically regulate the room temperature, replace the ball valves with thermostats that, if necessary, shut off the flow of coolant into the pump if a certain temperature is reached in the room.

The shut-off valves are a ball valve, as well as a check valve, the need for which in the heat supply system is justified. A check valve can be used to replace a faucet. When the circulation pump is turned on, the valve is closed. If the power goes out, the check valve will open automatically, allowing the system to switch to natural circulation.

Therefore, it is important to choose the right bypass design and shut-off valves. When there is no valve, the pump is turned on through a small system circuit formed by a pipeline and a bypass. The check valve device requires a ball to block the lumen of the pipe and a plate with a spring

Installing such a valve in a heating system is due to its advantages, because it operates without human presence. When the circulation pump is turned on, the water pressure closes the valve

The check valve device requires a ball to block the lumen of the pipe and a plate with a spring. Installing such a valve in a heating system is due to its advantages, because it operates without human presence. When the circulation pump is turned on, the water pressure closes the valve.

However, the valve is still inferior to the valve in terms of operational reliability, since the coolant contains abrasive impurities.

Experts recommend using only high-quality valves from trusted manufacturers, since if the ball valve leaks, repairs will not help.

Device installation

Installing a bypass in the heating system does not cause any particular difficulties; it can be done with your own hands

It is only important to adhere to a few requirements:

- select a bypass cross-section that will be smaller by a size than the diameter of the supply and return, so that, if necessary, the water flow will bypass the battery;

- the device should be mounted closest to the heating device and furthest from the riser;

- it is necessary to place the control valve between the radiator and bypass inlets;

- instead of ball valves, you can use thermostats, thanks to which the process of removing the coolant can be automated;

- when using a home-made product, before installing a bypass in the heating system, you need to carry out welding work;

- When installing the device, it must be mounted near the boiler so as to prevent the pump from overheating.

Bypass - such a seemingly simple detail, is important to ensure that the heating operation in an individual home is as useful as possible. It allows you not only to simplify radiator repair when necessary, but also to save heating costs by 10%. If the selection and installation of the device is carried out correctly and all requirements are taken into account, then the operation of the heating equipment will not cause unnecessary trouble for the owners

If the selection and installation of the device is carried out correctly and all requirements are taken into account, then the operation of the heating equipment will not cause unnecessary trouble for the owners.