A bypass is a piece of pipe identical to a section of the main, installed in its key places. It is installed only in single-pipe circuits that ensure the flow of coolant through only one pipeline, which originates from the boiler and ends near it. At the same time, the water first leaves the heat generator in the direction of all the radiators of the house, and then, having given up its heat to them, returns to it.

The main difference between two-pipe systems and their single-circuit counterparts is the ability to separate the coolant supplied and returned to the boiler into separate flows. Therefore, for a two-pipe system there is no need to install a bypass. And in the case of one circuit, when both the supply and return are inseparable and flow in one stream, it is simply necessary.

This bypass structure is mounted on contours from one pipe, which can run in 2 planes: vertical and horizontal. This means that the bypass can be installed in different ways. Vertical contours are found in buildings with a height of 2 or more floors, horizontal contours are found in private one-story buildings and apartments.

Depending on the functions assigned to such a bypass structure, the location of its installation is selected: on a pump that drives the coolant through a pipe or on separate radiators.

Regardless of the installation location, the bypass element ensures continuity of fluid flow in the pipeline regardless of the serviceability of the main units. In a heating circuit, the bypass is a spare channel through which the liquid continues to circulate in the circuit, which means that pressure drops and surges will not occur in it.

Bypass diameter

bypass in the heating system

Depending on the installation location of the device - on the battery or pump, the required circuit diameter may vary.

A bypass of smaller or identical diameter to the main pipe is mounted on the pump. There is no fundamental difference between these options, since its main task is simply to maintain coolant circulation in emergency situations, at least by gravity, for example, when a pump operating from the network does not receive power due to temporary power outages.

In this case, it is impossible to narrow the circuit itself, and the diameter of the pipes leaving the pipeline does not play a major role. When the pump stops operating, the flow of coolant through it will completely stop, and therefore, with identical sections of its pipe to the main, the bypass element will not change the direction of water flow. And if it is necessary to flow water through the pump, it is enough to simply block the movement of the coolant using a ball valve on the main pipeline.

But when installing a bypass directly on batteries, its diameter plays a major role, since it must be optimally combined with other equipment. Firstly, compared to the pipes connecting the radiators to the main line, the bypass should be 1 size smaller in diameter. Secondly, the bends to the heating radiators themselves require an order of magnitude smaller caliber than the main pipe.

Thus, work is ensured according to the following scheme:

- The coolant flows along the circuit to the location where the radiators are installed on it.

- When encountering a branch between the direct flow into the radiator and the bypass path through the bypass, the water will flow along the route that currently has the least resistance.

- A certain amount of water will flow , overcoming resistance, without changing its original vector of movement.

If the diameters of the outlet pipes coincide with the diameter of the bypass, a sufficient amount of water will not enter the radiators and their thermal efficiency will decrease. And if the diameter of the bypass exceeds that of the pipes, the coolant flow will stop completely.

Diagram of pipe sizes in a system with a bypass on the radiator:

Reducing the diameter of the pipes relative to the main pipe provides additional acceleration of the coolant flow , which causes it to move more intensely in the radiator itself, releasing thermal energy more evenly and efficiently.

For example, in a polypropylene heating system, the diameter of the main pipeline is 32 mm, which means that pipes are needed that distribute water to radiators with a diameter of 25 mm. A 20 mm diameter loop is suitable for such a system. It will be able to ensure water flow along the optimal route with the least loss of thermal energy.

Mechanism designs

In general, the bypass design may include the following elements:

- Pipe.

- Circulation pump.

- Valves. There should be two valves. There are several types of bypass pipe valves, which will be discussed below:

- Cranes with a movable stem. When using such taps, the internal lumen of the pipe is blocked with a rubber washer. A special feature of this type of cranes is that they can be repaired without much difficulty. The disadvantage of representatives of this type is that the internal clearance of such faucets is half the nominal value, which contributes to the loss of coolant.

- Ball valves. This type of faucet closes the gap using a metal ball that has a specific clearance. When the tap is fully opened, the internal clearance is no less than the nominal one, so there is no loss of coolant. However, this type also has a drawback - if not used for a long time, the ball sticks to the seal, as a result of which the faucet handle simply does not yield to force.

- Shut-off valves. The shut-off valve is a valve on a straight line. If it is absent, then the water, driven by the pump on the bypass, enters the direct line and then back into the jumper. So it will circle around one small contour. Therefore, a valve is needed that will prevent the flow of coolant to the pump. When choosing this valve, you can also note the following two options:

- Ball valve. The characteristics of such cranes are discussed above.

- Check valve. Its device includes a metal ball that is capable of closing the inlet under water pressure, so no human intervention is required. When the pump is turned on, under water pressure, the valve will close on its own, thereby ensuring proper operation of the system.

Application

If there is a pump in the heating circuit, it is installed directly on the bypass part. This is a common practice when an electric pump is installed in a gravity circuit - a single pipeline in which the coolant circulates by gravity.

It accelerates the speed of water flow through the pipes and thereby increases the efficiency of the entire heating system. This is due to the fact that due to the high flow rate of the coolant, it manages to pass through the entire circuit without losing most of the thermal energy.

In practice, this is expressed in the fact that the last radiator of the circuit receives not cold or barely warm water, but rather hot water, which still has a sufficient amount of thermal energy to ensure heating of the room in which it is installed.

Radiator connection options

In modern construction, several schemes for connecting heating devices are practiced. Radiator connection options: diagonal, bottom, side. The installation of each heating device circuit has its own characteristics.

Diagonal connection

Radiators in operation are the most efficient.

The coolant supply pipeline is connected to the heating device from above. The return line is connected to the radiator from below, on the opposite side. The diagonal connection allows you to warm up the heating device, which has a large thermal output (many sections). Typically, this scheme is used in large rooms. Installing radiators in a diagonal manner is complex and time-consuming. It requires the involvement of experienced, qualified craftsmen. The main advantages of this scheme:

- quick and easy installation;

- saving on expensive materials and energy resources;

- It is possible to install a bypass.

Lateral connection of radiators is used not only in apartments of multi-storey buildings, but also in cottages, townhouses, dachas, office and industrial premises.

Installation

bypass in a one-pipe system

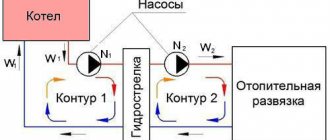

bypass on the mains pump line

There are 2 options for installing a bypass together with a pump that circulates water in a single pipeline: on a new or old circuit. There is no difference between them either during installation or during heating operation.

When installing a bypass together with a pump, the following rules must be observed:

- Firstly , on the main circuit in the middle of the bypass pipes, it is imperative to install elements blocking the pipe. This will allow the coolant to flow through the bypass with the pump, without the effect of reverse flow.

- Secondly , it is extremely important to correctly place the pump on the bypass structure: the impeller axis must be located in a horizontal position, and the cover with stamps must be directed upward. If there are inconsistencies, the cover can be twisted by unscrewing the four fasteners on the pump body. This positioning of the marks solves 2 problems: it makes it easier to access them for connection and, in the event of a leak, it reduces the likelihood of liquid getting on them.

- Thirdly , only a ball valve should be installed as a lock, and not a check valve.

Because with the valve the circuit will begin to function like this:

- A running pump accelerates the flow of water in the circuit.

- The coolant flows through the bypass into the main pipeline in opposite directions.

- According to the effective vector, it goes without restrictions, and according to the reverse vector it is delayed by a check valve.

- It automatically closes and does not allow water to circulate normally through the two pipes.

Thus, increased coolant pressure is created on the valve plate precisely after the pump, because the flow rate behind it is always faster. In theory, when the pump is turned off, the coolant no longer acts on the valve, which in this case does not close.

This allows the liquid to move by gravity through the main pipeline without getting into the bypass. But in reality, the bypass with the valve does not function as it should.

The problem is that the valve disc generates excessive resistance comparable to a whole meter of pipe. Under the conditions of the gravitational circuit, water will not be able to overcome it, and its circulation will stop completely.

Before installing a bypass in combination with a check valve, you need to know that there is actually no advantage to mounting the pump on it.

If the valve is replaced with a standard ball valve, it becomes possible to direct the vector of water flow in the circuit.

bypass with pump

In order to install a bypass with a pump in the heating circuit, you will need the following set of parts:

- welded-in line pipes with threads;

- ball valves mounted on both sides;

- corners;

- pre-filter installed in front of the pump;

- a couple of American women to dismantle the pump for maintenance and repair.

- Installation in front of the radiator. What does it matter? Installation rules: how to install.

A bypass element is installed in front of the radiator in case water stops circulating inside it for some reason, then its circulation along the bypass throughout the rest of the circuit will continue, despite the malfunction of one of the elements.

It performs the following functions:

- Ensures continuous movement of coolant along the main heating line.

- Allows you to regulate the water temperature in radiators.

In heating systems with one main circuit, water circulates in it, sequentially transferring heat to 1, 2 and subsequent radiators. Thus, as it passes through each subsequent radiator, the thermal energy of the water decreases, which means that the first heating element will heat up much better than the last.

Installing a bypass in heating allows you to mix the hot coolant that comes directly from the main line with less energy loss with the one that enters the radiators and loses it, which allows you to partially compensate for these losses right on the go, without waiting for it to return directly to the heat generator.

Bypass device:

Installation rules:

- Vertical installation involves connecting the radiator to the riser using a pair of pipes. The bypass closes them together and is mounted in front of the battery.

- There is no need to install any locks between the main pipeline and the bypass element

- In a horizontal single-pipe system, the bypass is fixed in a horizontal plane directly in front of the battery. And to ensure circulation, it is necessary to select its optimal diameter in relation to the main line and pipes.

How is underfloor heating used in the system?

In a residential building, heated floors are connected to a boiler, which supplies hot water and heating. In this case, the water temperature for all structures will be equal. To ensure that the water in the heated floor structure is not so hot, special mixing units are used. To prevent a strong pressure surge, a bypass with a valve is installed in the unit. In this case, a three-way mixer is used to regulate the amount of chilled water. The water is mixed in the unit and moved to the water floor collector using a pump.

Scheme of operation of a heated floor design

Installation diagrams for water heated floors in a private house. Before starting work, you should study possible installation and connection schemes. A special publication on our portal will help you.

Blitz tips

- Installing a bypass is desirable in conditions of insufficient natural circulation of fluid in the heating circuit.

- When constructing a bypass yourself , it is not necessary to select each of its elements separately; it is better to purchase a ready-made assembly from a specialized store, which will save time and guarantee against inconsistencies between elements during the assembly process.

- To automatically regulate the temperature in your home, you can use a thermostat with a built-in ball valve.

- Horizontal installation of the device is preferable due to the lower likelihood of air accumulation in it.

- When installing the device, additional support points and clamps should be provided in advance to prevent it from moving under the influence of gravity or other factors.

- In case of poor water quality with a large number of impurities and suspended matter, to increase service life, you should choose special pumps with filters, which are recommended to be periodically removed and cleaned.

Choosing a location for installing heating devices

Radiators are installed under windows. This is a long established rule. The largest heat losses occur from windows in a room. The length of the radiator should be 0.7-0.9 times the length of the window sill. If it is necessary to install several heating devices in a room, but there is only one window, it is advisable to mount them on load-bearing walls.

The distance between the floor and the radiator must be no less than 100 mm. Ignoring this rule leads to a decrease in the efficiency of the heating device. It will also be difficult to clean, repair, or replace individual parts of the radiator. The distance between the heating device and the wall must be at least 50 mm. So the radiators will not heat the wall, but will give off their heat to increase the temperature of the internal air. It is prohibited to change the connection diagram of heating devices on your own in apartments and country houses. Repair of heating systems must be carried out in advance with the locality management services.

What is a battery jumper and what is it for?

First of all, in order to determine why a bypass is needed on a heating radiator, it is worth saying that it is not installed on all heating systems.

The fact is that such devices are not installed in an apartment building equipped with a two-pipe heating system. The coolant in a two-pipe system enters the battery from the hot water supply pipe, and is discharged directly into the return pipe, so if it is necessary to turn off the battery on one of the floors, nothing bad will happen to the system, the taps will simply be turned off at one point, and the coolant will continue to circulate in system. It's another matter when the building is equipped with a single-pipe heating system. Here the issue is more difficult to solve - the coolant flows through the pipes to the highest point, where the distribution is made through the risers. The riser pipe is connected to the battery, the coolant, passing through the radiator registers at the outlet, enters another section of the pipe, which descends to the floor below. Then the scheme is repeated, and so on until the basement. Everything would seem simple - fewer pipes, easier for the coolant to move through the system. But, as we know, there are no perfect systems; this, at first glance, simple scheme also has flaws. First of all, this is the cooling rate of the coolant - it turns out with each battery, it becomes colder and colder. The second point is that if one battery breaks down, you will have to shut off the entire riser, because by turning off the valve for supplying and draining water from the radiator, the entire chain is interrupted and the riser stops working. A way out of this situation was found - a jumper on the heating battery. Simple and rational.

Meaning of the term

The word “bypass” is a borrowing and was originally translated from English as “bypass”. This term is used in close connection with hydrodynamics, namely with the passage of a liquid substance through pipes.

That is, the heating bypass is a kind of additional path for the flow of current, while it bypasses the main line. Moreover, this device is found, in addition to the heating system, in all similar systems that use pipes for transportation. For example, this is a gas pipeline, an oil pipeline, a water pipeline, and so on.

Design and principle of operation

A piece of pipe of this type is called a bypass, which serves to redirect the coolant around any point, this could be:

- Radiator.

- Pump.

- Branching.

- Heated towel rail.

Often, the segment is attached by soldering or welding with one end to the pipe, which enters the main line, and the other is cut into the outlet circuit. It is necessary to install a ball valve on the bypass, a valve or a valve at the discretion of the home owner. Thanks to such practical elements, the flow of liquid can be completely blocked or the flow into a certain device can be regulated.

Initially, such bypass pipes were used to carry out repair work without stopping the functioning of the boiler and the entire heating system as a whole. But over time, the element began to be considered mandatory for equipping single-pipe mains, and it was given the name bypass.

At the personal discretion of the homeowner or customer, a bypass device is installed in a two-pipe system; professionals consider these manipulations optional.

The battery does not heat in a private house

The reason why batteries in a private home do not heat up may be a number of factors. We can only consider the question in general. There are different reasons and they are not always obvious. Sometimes such a small thing as a faulty faucet or a clogged chimney can become a stumbling block. Despite this, there are no hopeless situations, the main thing is to determine the reason why the battery in a private house does not heat, the rest is a matter of technology.

Insufficient boiler power

If the radiators in a private house do not heat well, then one of the reasons may lie in the heating boiler. In your home, you can say with almost 100% probability that the heating circuit is autonomous. So the boiler is standing. It could be:

Why do batteries heat poorly in a private home? The reason may be an incorrectly selected boiler power. That is, it does not have enough resources to heat the required amount of liquid. The first sign that the power has been selected incorrectly is the constant operation of the heating device, without shutdowns.

Although in this case the heat exchangers will heat up at least a little. And if the water in them is completely cold, it means that the boiler is broken or cannot turn on. Modern units have a minimum pressure requirement in the system. If this requirement is not met, it will not turn on. In addition, there is an automation and security system.

Let's take, for example, a gas boiler. It contains a sensor that monitors that all gases go into the chimney. It is possible that the chimney or some smoke outlet pipe is clogged. In any case, the sensor will send a command to the control unit and it will not allow the boiler to turn on.

Problems with the batteries themselves

The batteries in a private house do not heat up, what should I do? If no problems are found with the boiler and it is working correctly, then the reason why the batteries are cold should be looked for in the circuit itself. Possible options:

- airing;

- pollution;

- insufficient pressure;

- incorrect pipe routing;

- Incorrect connection of heat exchangers.

If the batteries are cold, then you need to check all the above factors. We have already written in more detail about what to do if the batteries do not heat up. The specificity of a private house is that all characteristics can be controlled independently.

Then make sure there is no dirt in the pipes and heat exchangers. How to do it? You will have to drain water from cold radiators in a private house. What to do is known, you need to unscrew one end (bottom) of the battery and substitute a larger vessel. If black water flows, then there is nothing to think about - this is pollution. It is necessary to rinse the circuit to clean water. Sometimes thick liquid flows out of radiators along with water. This is dirt collected in copious amounts.

What other reasons could there be for cold radiators in a private home? If the problem is not air or pollution, then circulation is broken. This may be due to low blood pressure. In general, in an autonomous circuit the coolant pressure does not exceed two atmospheres. If you have new batteries, then look at their data sheet. In modern heat exchangers, the operating pressure requirements are higher than in Soviet models

Pay attention to this

Disruption of coolant circulation

We will separately consider the disruption of coolant circulation due to improper pipe routing and piping of heat exchangers, as a result of which the batteries are cold. In your home, you are free to choose the method of pipe routing. It could be:

- two-pipe heating system;

- single-pipe heating system.

It so happened that many people previously preferred a single-pipe heating system, also known as “Leningradka”. It was believed that it was simpler and cheaper, but in reality this is not the case. In addition, in this scheme it is very difficult to regulate the temperature of the heat exchangers as they move away from the boiler room. The farther from the boiler, the more sections there should be. Therefore, it is not uncommon that the last battery in a private house does not heat. The coolant flows through one pipe. In such a scheme there is no return.

It turns out that water enters the heat exchanger, cools there and is again drawn into the general flow. Accordingly, after each radiator the overall flow becomes colder. The difference increases with distance from the heating element. As a result, the water may reach the extreme heat exchanger almost cold.

In a two-pipe system, errors may be made in the piping:

- incorrectly installed shut-off valves;

- incorrect connection of the heat exchanger (there are three types: side, bottom, diagonal);

- The diameter of the bends is incorrectly selected.