Pipes made from a symbiosis of metal and plastic are produced for the construction of intra-house highways. The new products made it possible to assemble a water supply and heating system yourself, without involving plumbers. Pipelines serve for a long time, are installed extremely simply and quickly, without creating problems even for inexperienced craftsmen.

By installing metal-plastic pipes yourself, you can save a lot of money, preserving the family budget for more important expenses. To install them, a home craftsman only needs to stock up on an easy-to-use tool, patience and knowledge, which we are ready to share with site visitors.

We will tell you everything about the specifics of using metal-plastic products and methods of connecting pipelines assembled from them. The article describes in detail the negative and positive aspects of their use. Here you will learn how to install trouble-free systems.

Features of metal-plastic products

Metal-plastic (metal-polymer pipes) are composite products for the production of which various types of materials are used. Such elements have an attractive appearance, good wear resistance, elasticity, and strength.

Metal-plastic pipes are distinguished by high consumer qualities (strength, flexibility, resistance to high temperatures and aggressive substances), as well as an aesthetic appearance

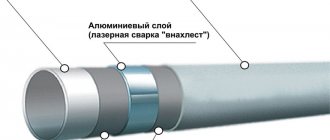

Typically, a pipe consists of five layers. A durable polymer, usually cross-linked polyethylene, is used as a supporting base. It makes the inner surface smooth, protecting it from blockages, and also contributes to the strength of the product.

An adhesive is applied to the core, on which aluminum foil that stabilizes the pipe is attached (it also prevents the ingress of oxygen). The connection is secured by butt or overlap welding.

The design of a metal-plastic pipe involves the use of five layers of different materials: two layers of polyethylene, two layers of glue, a layer of aluminum foil

The fourth layer is also applied with glue, to which the outer covering is connected - white polyethylene, which provides protection to the product and gives it an aesthetic appearance.

What is taken into account when choosing pipe diameter

Heat generator power. It is taken as a basis and determined individually for each building. What does the owner focus on when purchasing a boiler?

For the total area of all heated premises. This is exactly what the manager at the point of sale will definitely clarify if the buyer has questions about this item.

Coolant speed. If it is less than 0.25 m/sec, then there is a risk of airing the system and causing traffic jams on the highway. Exceeding the value of 1.5 is fraught with “noise” in the highway.

This is especially noticeable when the pipes are metal, and even laid in an open way. But in any case, the movement of the coolant along the route will be clearly audible.

Practice has proven that for a private building (with an autonomous heating circuit) you should focus on an indicator in the range from 0.3 to 0.7. This is the optimal value for any system.

Circuit configuration. In private houses, when installing it, as a rule (regardless of the circuit), all the “threads” are connected to the collector. Each of them is “loaded” with a certain number of radiators.

There is no point in purchasing pipes of the same diameter for all lines, given that the larger the cross-section of the workpiece, the higher the price of 1 running meter.

Pipe diameter. The outer one does not play a special role, since products made from different materials have differences in wall thickness. This parameter only indicates the ease of fastening the product. The internal diameter is about the throughput of the route. It is he who is decisive.

Pipe diameters are usually indicated in inches. For us, this is an unusual (non-metric) system, so you should know the rules for converting quantities. The ratio of inches to centimeters is ½.54 (or 25.4 mm). Pipe material – metal-plastic, steel, PP, PE.

Specifics of the structure. First of all, this relates to the effectiveness of its thermal insulation - what materials it is assembled from, what method is used, and so on.

Technical characteristics of pipes D 16-20 mm

Here are the data typical for metal-plastic pipes of common diameters (16 and 20 mm):

- The wall thickness is 2 and 2.25 millimeters, respectively; The thickness of the aluminum layer is 0.2 and 0.24 mm.

- One running meter weighs 115 and 170 grams and holds a volume of liquid equal to 1.113 and 0.201 liters.

- The thermal conductivity coefficient is 0.43 W/m K, the expansion rate of metal-plastic is 0.26x104 per 1 degree Celsius, the roughness coefficient is 0.07.

- When the material breaks transversely, the strength coefficient is 2880 N.

- The strength of the connection between the adhesive layer and the foil is 70 N/10 sq. mm, the strength coefficient of the aluminum welded layer is 57 N/sq. mm.

- Metal-plastic pipes can operate even at +95o C, briefly withstanding temperatures of +110-130o C.

- Within the temperature range from 0 to +25o C, the system operates at a pressure of up to 25 bar, and at +95o C it can withstand a pressure of 10 bar.

- The tightness and integrity of the metal-plastic pipe is broken under a load of 94 bar (at +20° C).

With proper installation and compliance with operating rules, products made of metal-polymers can last 50 years or more.

Application area

Due to the technical characteristics of metal-plastic, the material has found application in pipelines for cold and hot water supply, as well as sewage.

It is used for various heating systems:

- Underfloor heating device "warm floor".

- Connection to wall-mounted radiator radiators.

- Heating of soil in closed greenhouse complexes and greenhouses.

- Water heating device for swimming pools.

- Laying protective screens for power cables.

- Compressed air supply.

Metal-plastic products can be found in air conditioning systems and in transport routes for the movement of gaseous and liquid substances.

Areas of application of metal-plastic elements

Pipes made of metal polymers are widely used in the construction of individual houses, in industrial construction and agriculture.

The main areas of their use are:

- transportation of liquids, gaseous agents;

- laying drainage systems, water pipes, heating;

- in structures involving the transfer of compressed air;

- supplying heating components to radiators, installing heated floors;

- installation of air conditioning circuits;

- protection and shielding of wires (primarily power);

- construction of irrigation systems.

Metal-plastic is not recommended for use:

- when organizing central heating systems with the proposed construction of elevator units;

- in places with an assigned fire safety level “G”;

- with the expected supply of hot liquid in the pipeline with a working pressure >10 bar;

- in rooms where it is planned to place sources of thermal radiation with a surface temperature of over 150 degrees C.

In addition, it is undesirable to use metal-polymer pipes in safety, signal, overflow, expansion circuits and in fire-fighting water supply systems.

Metal-plastic products are widely used in private and industrial construction. This photo shows pipes used for laying heating systems

Tools needed to install a plumbing system

- Wrenches: adjustable and open-end. Used for tightening nuts in compression fittings.

- Scissors for cutting pipes. Without their use, cutting the material into the required pieces with smooth edges becomes much more difficult.

- Sanding paper is necessary to clean the cuts from small roughness.

- Calibrator. With its help, the cut is restored to its original roundness, lost during the cutting process.

- Press pliers are required for manual crimping of press fittings.

- A construction hair dryer is used to heat pipes before bending.

Three main methods of pipe routing

The wiring of metal-plastic systems can be carried out using different methods, each of which is selected based on the feasibility and possibilities of further access to the system.

Option #1: hidden

In this case, all pipes and connections are hidden deep in the wall under the finishing materials. Only fittings and bends for connecting plumbing fixtures are exposed outside.

The hidden installation method involves installing the structure in the wall, where recesses are specially prepared for pipes, after which the surface is sealed

When using this installation method, the interior design is preserved, in addition, masking communications protects them from accidental damage.

This option has several disadvantages:

- Laying channels for pipes requires a complex and labor-intensive gating process. After laying communications, the surface must be restored again.

- This method is not suitable for load-bearing walls, where gating is prohibited by regulatory documents.

- Quite a high cost associated with additional work.

This method is best used when renovating a bathroom. It is not advisable to install a hidden installation in an already decorated room, since this will require complete dismantling of the wall covering (cladding, plaster).

Option #2: open

If for some reason the pipes cannot be hidden in the wall, they can be laid along its surface. This option is more convenient for visual inspection of joints, which allows, if necessary, to quickly clean the area or replace a component.

With the open method, pipes are laid along the surface of the wall, which allows for control of connections and reduces the cost of work

Open wiring can be used in rooms that have already been renovated, since the installation will not harm the design of the walls. The advantages of this method include its ease and lower cost of work than when laying internal communications.

Option #3: combined

In this case, the pipes are laid along the surface of the unfinished walls, after which they are covered with boxes or false panels. This is a rather complex method, since it requires the perfect fit of decorative elements into the interior, which can also be used as drywall, tiles and other materials.

How to bend a metal-plastic pipe

Often when installing metal-plastic pipes, it becomes necessary to bend the pipe. This can be done by hand or using a spring. It’s easier and faster to work with a spring, but you have to buy one (it’s inexpensive). The spring is inserted inside the pipe and bent in the required direction. The pipe follows the bend, the spring is removed. It is easy to bend metal-plastic pipes with a spring - no great effort is required, the actions are easily controlled, and it is possible to correct the result.

What’s good about this method is that you won’t be able to squeeze the walls, which happens when you apply excessive force manually. It is also impossible to make a sharper bend (with a radius less than the minimum) and compress the walls at the bend, narrowing the flow section.

Spring for bending metal-plastic pipes

You need to bend MP pipes by hand gradually. Take it with your hands on both sides of the bend (at the same distance from the center of the future arc), with your thumbs supporting the pipe from below. In this position, begin to lower the edges down, while at the same time pressing upward with your thumbs.

Manual bending of metal-plastic pipes

With this method, sometimes the pipe loses its geometry due to excessive efforts. This negatively affects its throughput. Such areas cannot be installed in water supply or heating. To avoid such situations, the bend area is heated. This can only be done with a hair dryer. Open fire must not be used. Heated plastic is easy to bend. At the same time, it does not compress (the main thing is not to overdo it).

Methods for bending MP pipes

Another way to avoid deformation is to pour sand inside. It will not allow the walls to shrink.

Wiring diagrams for bathrooms and bathrooms

For plumbing work carried out in bathrooms and toilets, three layouts of metal-plastic pipes can be used. For private houses, the most rational option is to use a collector.

Efficient collector system

A reliable and practical option that involves connecting each object to a central pipe through a supply pair. This allows the faucet to regulate or turn off the water supply to each specific plumbing fixture.

With parallel wiring, each plumbing fixture is equipped with its own water line and its own shut-off valve. All branches come out of one device - the collector

All control devices are located in a compact manifold, which is placed in a space specially designated for them (cabinet).

Supply pipes with a minimum of connections do not require special control, which allows for hidden installation. The disadvantage of this option is the rather high cost, since for each connection you will need to purchase a special shut-off valve. Since such a system is quite complex, work must be done carefully and carefully.

In collector water distribution, control devices and shut-off devices are installed on the pipe supplying water to the collector

An important advantage: if a separate item (washing machine, faucet) fails, there is no need to completely disconnect the bathroom from the water supply - just turn off the necessary shut-off valve.

Serial connection system

This option involves connecting each plumbing item to the main pipe using a separate tee. It is more suitable for bathrooms with a minimum number of objects (washing machine, common faucet).

Sequential wiring, shown schematically in the figure, is recommended for use in rooms with a small number of objects that are alternately connected to pipes using tees

A sequential scheme can be implemented after finishing work has been completed in the room, using an open laying system. The assembly process is quite simple: the pipe is laid from one object to another, and at the same time the supply element is removed from the tee.

This option requires minimal financial costs. It should be taken into account that if there are a large number of liquid intake points, the pressure may not be enough, and the system will function with difficulty or even fail completely.

Wiring system with pass-through sockets

The connection of plumbing fixtures is similar to the serial one, but instead of tees, sockets are used. This scheme is usually used only in individual houses, since it requires laying long pipes, as well as installing an additional pump that will help provide the required water pressure.

When performing connecting work with metal-plastic pipes, several important nuances should be taken into account:

- When developing a design, it is desirable to provide a minimum of connections.

- It is important to use pipe and couplings made from the same material.

- It is better to use thermal insulation for the pipeline to prevent condensation from settling.

- It is necessary to provide free access to metering devices, filters, and detachable connections.

Compliance with the rules will allow you to create a reliable system that can last for many years.

General description of couplings for crimping

A press fitting connection is one of the most reliable methods of joining metal-plastic pipes. As a result of this installation, the pipeline turns out to be one-piece, but very reliable. If after assembly you need to change its circuit, you will have to redo a lot from scratch, but leaks are practically excluded.

The reliability of the press connection is ensured by crimping the pipe around the fitting fitting with a special stainless steel sleeve. If the pipe needs to be replaced, the pressed section will need to be cut out

Press fittings are a permanent type of connection, obtained in this case by compressing a metal sleeve around an o-ring. In this case, as a result of the crimping performed, the ring is irreversibly deformed. It cannot be removed and then reused. The geometry of the pipe itself also changes slightly.

For metal-plastic pipes, fittings for crimping are made from:

- brass;

- of stainless steel.

The first option is more preferable. It is more reliable and durable in conditions of high humidity.

Unscrupulous manufacturers often use aluminum and other soft metals to make the fittings in question. They can be easily identified by weight. Brass is obviously heavier in the hands than these fakes. It is strictly not recommended to use such products for crimping metal-plastic pipes. By definition, they are not able to tightly compress the fitting and pipe plastic.

Fittings for press connections and metal-plastic pipes for installation of intra-house pipeline systems should be taken from the same manufacturer, otherwise you can forget about the absolute reliability of the joint

Each manufacturer of metal-plastic pipes recommends purchasing its own set of press fittings. And for good reason. Pipe products and fittings from different manufacturers can vary in diameter by literally a millimeter. Quite a bit, but this is enough to reduce the reliability of the connection. It’s better not to save money here, risking a break and leakage.

There is no single standard for the outlines and exact dimensions of fittings. Each manufacturer independently selects these parameters for their products. Some sellers offer universal press fittings, but this is a banal advertising ploy. The use of such connecting parts is inevitable and will result in leaks in the near future after installation.

Layout of sewer pipes

The work of installing sewer metal-plastic pipes has its own characteristics.

Sewer distribution made of metal-plastic has a number of features. In this case, it is important to use pipes of larger diameter, and also take measures to organize the slope of the pipeline

In this case, to ensure smooth drainage of wastewater and prevent blockages, it is important to comply with the following requirements:

- Maintain a slope (0.02-0.03 of the entire length of the structure) towards the drain manifold.

- It is prohibited to install bends at an angle of 90 degrees when installing structures.

- The need to install special tees with removable covers (revisions) in areas before turns that are prone to blockages.

- When installing the system in a hidden way, it is important to leave viewing windows opposite the revision.

- When assembling a system, it is important to leave a reserve intended for thermal expansion of the product.

For sewer installation, it is necessary to use pipes whose diameter ensures easy passage of wastewater.

For toilets, it is recommended to use products with a diameter of at least 100 mm; for bathtubs and sinks, 50-75 mm is sufficient.

Non-standard connections: with metal pipes, transition to a different diameter

When replacing plumbing or heating, it is often necessary to combine metal and metal-plastic. Most often this happens at the outlet from the riser. In this case, the metal pipe is cut at a certain distance - 3-5 cm, and a thread is cut on it. Next, a fitting with a union nut (collet) or internal thread is screwed onto the thread. Further installation of metal-plastic pipes proceeds according to conventional technology.

Some types of fittings that can be used when switching from metal to metal-plastic

The fitting is selected according to the diameter of the metal pipe, and the thread on the adapter must be internal - the external thread is cut on the pipe. This connection requires sealing. Wrap with flax and coat with packaging paste or simply use fum tape.

The connection of two pipes of different diameters occurs in exactly the same way. All you need is an appropriate adapter fitting with nuts/nipples of the appropriate diameter.

Rules for installation of metal-polymer structures

When laying metal-plastic systems, it is important to be guided by the following provisions:

- When laying hidden pipelines from this material, it is important to provide removable shields (hatches) that are free of sharp protrusions. They provide access to compression fittings.

- It is important to lay systems through building structures using sleeves whose internal diameter is 0.5-1 cm larger than that of the pipe. The gap that forms between the elements must be filled with soft, non-flammable material that allows the pipe to move in the longitudinal direction.

- When laying metal-plastic plumbing or heating systems, it is important to avoid damage to the surface of the elements, including scratches or cuts. To unpack the bay, it is better to avoid sharp objects and mark the structure with a pencil or marker.

- Installation of the structure can be carried out using a support or suspension, which are usually present in the range of manufacturers of metal-polymer pipes. They help to attach products to the wall, while metal parts are installed with spacers made of soft material.

All stages of operations must be carried out carefully and carefully, since metal-plastic elements are sensitive to ultraviolet radiation and mechanical damage. External installation of such structures is appropriate only in places where there are no such factors.

Installation of crimp (press or push) fittings on MP pipes

Installation of metal-plastic pipes using compression fittings requires special pliers. There are manual ones and there are electric ones. Any are equipped with a set of linings for different diameters. Manual ones, of course, are cheaper. You don’t have to buy this equipment—you’ll only need it once. It is much more profitable to rent.

Press fitting for MP pipes

The press fitting consists of two parts - the body itself and the compression sleeve. Before connecting metal-plastic pipes, the cut is prepared. It is the same as when using compression fittings, but the chamfer is removed only from the inside. The following is the procedure:

- A sleeve is placed on the pipe.

- A gasket is installed on the fitting to prevent electrochemical corrosion.

- The tube is put on the fitting until it stops. There is a hole on the fitting body in which the edge of the pipe should be visible.

- Take pliers in which suitable pads (of the required diameter) are installed. The pliers are installed close to the edge of the fitting, connecting the handles of the press together and crimping the part. As a result, two concave stripes should be clearly visible on the sleeve. Their depth should be the same. After crimping, the fittings can rotate around the pipe.

That's all, the installation of metal-plastic pipes using a press fitting is completed. Such a joint can withstand pressures of up to 10 atm, which is sufficient for most systems. Not suitable only for heating systems of houses with several storeys. more than 16. Their system pressure may be higher.

Tools and materials for laying pipes

Laying metal-polymer systems requires a minimum of devices and materials, but it is better to choose high-quality devices and pipes.

Pipeline installation accessories

To create a structure made of metal-plastic, a very modest set of tools is enough: a pipe cutter, a simple pipe bender, press pliers, a sliding and spanner wrench.

To install a metal-plastic system with your own hands, you need a minimum of tools, which can be purchased in a set or separately from a construction supermarket.

To separate measured sections of pipe from the coil, it is advisable to stock up on a pipe cutter designed for cutting metal-plastic pipes. Since metal-plastic is a fairly malleable material, it can be cut with a hacksaw or even a sharp knife.

However, ideal perpendicularity of the lines, without which it is difficult to obtain a tight connection, can only be achieved by using a special cutter.

Different types of wrenches are important for installing and assembling threaded connections on pipeline fittings. If absolutely necessary, you can get by with one spanner, but for comfortable work it is better to use two spanners and one adjustable wrench.

A gauge is an important tool for creating an accurate and tight connection between a pipe and a fitting: it allows you to center the cut plane and chamfer the inside of the product.

The pipe bender allows you to change the configuration of the element, so you can save on corner fittings. It is especially important to have this tool if the design involves a large number of angular mates.

Before starting work, we advise you to familiarize yourself with the rules and specifics of crimping metal-plastic pipes.

What materials will be needed?

To lay the pipeline, it is important to stock up on the following components:

- pipes (coils, measured sections);

- various fitting options (bends, tees, corners), with the help of which individual sections of pipes are transformed into a single system;

- fastening elements - dismountable clamps and clips, with the help of which metal-plastic structures are fixed to supporting surfaces, most often on the wall.

It is important to select all the necessary materials and tools in advance so that you can carry out all the work smoothly.

This article will introduce you to the range of metal-plastic products for pipeline assembly.

Installation of metal-plastic pipes using compression fittings

Compression fittings consist of several parts. The base is a cast body with threads. There is also a ferrule that secures the piece of pipe to the fitting and a union nut that clamps the connection. An important part is the O-ring, which ensures tightness.

This installation method is good because it does not require any special equipment. The second advantage is that the connection is detachable and, if necessary, the fitting can be replaced. If it fails or there is a need to change the pipeline configuration. And it's very convenient.

But there is also a drawback: from time to time, a leak occurs on the threads. It can be fixed simply by tightening it half a turn. But because of this, all connections must be accessible and cannot be bricked up. Also annoying is the need to check whether it leaked or not. Not everyone likes it.

This is what compression fittings look like

The range of fittings is wide: angles, tees, crosses, adapters (from one diameter to another). And all this with different angles, in different diameters.

Installation of metal-plastic pipes on compression fittings begins with removing the union nut and ferrule ring and checking for the presence of a rubber seal. After this, the assembly actually begins:

- The nut and ring are put on the pipe.

- The section is pulled onto the fitting until it stops. The stop is indicated by a special small protrusion-shoulder.

- The ring is also stretched until it stops on the fitting.

Before tightening the nut - The union nut is tightened. First, by hand, the connection of the metal-plastic tubes is tightened using two keys. One holds the fitting body, the second turns the union nut.

That's all, the installation process of the compression (screw, threaded) fitting is completed. There is only one caveat: if you fill the system with antifreeze, change the gaskets immediately. The ones that come with the kit will leak with anti-freeze very quickly. Use paronite or teflon ones. Only they can ensure tightness. In general, for systems with antifreeze it is better to use press fittings. They definitely don't leak (if crimped correctly).

Pipe line marking

Before starting work, it is important to think about how the pipes will be placed.

When developing a scheme, it is advisable to:

- Draw pipeline lines directly on the walls of the room where it is planned to be laid, which helps visualize the structure.

- As a starting point, use the connection point of the pipe to the tap or radiator, which must already be installed before installation begins.

- Minimize the number of tees and crosses that affect pressure stability, and also minimize the number of other fittings.

- For corner laying of metal-plastic pipes, you can use a pipe bender or corner fittings.

- All connecting elements should be provided with free access, since threaded fasteners need periodic tightening to avoid leaks.

The installation of connecting elements must be carried out after completion of calculations and marking of the structure.

How to attach to walls

When the pipeline is laid open, it must be fixed to the walls in some way. Usually special plastic clips are used for this. They are single - for laying one pipeline thread. Typically used for plumbing installations. There are dual ones - most often they are installed for heating - supply and return in two-pipe systems run in parallel.

Clips for mounting metal-plastic pipes on the wall

These clips are installed every meter (as often as possible). A hole is drilled in the wall for each, and a dowel of the required type is inserted (selected depending on the type of material from which the walls are made). A large load is not expected, but plumbing and heating look much more attractive if everything is laid out evenly, as if on a ruler.

Conclusions and useful video on the topic

In the video below, plumbers will tell you how to correctly and quickly install structures made of metal-plastic pipes:

Using the right methods and quality components allows you to create durable metal-plastic systems that will last for a long time without leaks, repairs or unnecessary material waste.

You can talk about how you installed and connected metal-plastic pipes in the block below. Please comment on the information we provide. Ask questions, share useful information and thematic photographs.

Example of water supply system layout

First, we draw a water supply layout plan. This can be done on a piece of paper, marking the necessary fittings. Please note that installation of taps requires installation of a fitting with a thread at the end. Taps are needed on taps to household appliances and plumbing fixtures, to heating radiators. This makes it possible to turn off devices without shutting down the entire system. The type of thread and its size are selected depending on the type of tap used.

An example of a water supply system using metal-plastic pipes

Also, transition fittings are needed before and after the meter (water or heating depends on the type of system). Having drawn a detailed plan, put down dimensions on all areas. Using this drawing, you calculate how much and what you need. Fittings can be purchased strictly according to the list, and it is advisable to take pipes with some reserve. Firstly, you could make a mistake when measuring, and secondly, in the absence of experience, you can spoil some piece - cut off less than required or crimp incorrectly, etc.

Agree on the possibility of an exchange

When purchasing everything you need, agree with the seller that you can exchange/return some fittings if necessary. Even professionals often make mistakes with them, and even more so those who decide to do the wiring of a plumbing or heating system from metal-plastic with their own hands. No one will take the rest of the pipe back from you, but fittings will easily be taken back. But to be sure, keep the receipt.

Sometimes it is more convenient to use collectors. They allow you to connect several consumers in parallel. There are collectors for plumbing and for heating (when installing heated floors)

When and how to start work

When you get home, lay out the fittings and proceed: installation of metal-plastic pipes in the summer can be done immediately, in the winter you need to wait some time (12 hours) until all the elements warm up to room temperature. It is advisable to cut one piece of pipe of the required length at a time. It's a little longer, but you definitely won't get confused. Further actions depending on the selected type of fittings.

Heating installation with metal-plastic pipes is done only with press fittings

After completing the installation of metal-plastic pipes, the pipeline is checked. If it is a water supply, just open the tap at the inlet. This must be done gradually and smoothly. The system will immediately begin to fill with water. If nothing leaks anywhere, you did everything right. If any connections are leaking, they must either be redone if press fittings were used, or tightened if the assembly was based on crimp connectors.

If a heating system was assembled from metal-plastic pipes, before starting it must be pressurized - tested with high pressure by pumping cold water into the system. If the test was successful, you can do a test run of the heating.

Which type of docking is better?

Each of the previously described methods for joining pipeline elements has its own advantages. The compression connection is removable; if individual sections wear out, they can be replaced without problems. Disadvantage - periodic maintenance is required, checking the tightness of joints.

Push fittings are the easiest to install. Their installation does not require special skills or complex devices.

When installing press fittings, we obtain a one-piece joint that does not require constant inspection. Such a node can be walled into a wall. Used on straight sections of pipeline.

It should be noted that the joining method depends on the material from which they are made and the operating conditions of the pipeline.

Saving Tips

The cheapest way to install a metal-plastic pipeline is to solder it using heating devices. The fittings used in this case are made of polypropylene and have a low price.

All other fittings include elements made of copper, brass, and corrosion-resistant steel in their design, which significantly increases their cost. Push fittings are considered the most expensive.

Sources

- https://TrubaMaster.ru/vodoprovodnye/soedinenie-metalloplastikovyh-trub-fitingami.html

- https://kachestvolife.club/o-chistote/santehnika/tehnologiya-montazha-metalloplastikovyh-trub-svoimi-rukami

- https://truby-moskva.ru/kak-montirovat-metalloplastikovye-truby.html

- https://InfoTruby.ru/soedinenie/metalloplastikovyh-trub

- https://homeli.ru/stroitelstvo-doma/inzhenernye-sistemy/kanalizatsiya/metalloplastikovye-truby

- https://trubarik.ru/metalloplastic/soedinenie-metalloplastikovyh-trub-fitingami

- https://santehnika.guru/truby/montazh-metalloplastikovyh-trub.html

- https://aqua-rmnt.com/uchebnik/truby/montazh-metalloplastikovyx-trub.html

- https://InfoTruby.ru/soedinenie/5-sposobov-soedineniya-metalloplastikovyh-trub

[collapse]

Service

Even metal-plastic pipes have their own service life. It is believed that it is 50 years. This statement may be true, but over 50 years you will need to carry out maintenance of the water supply system at least several times. You can do this yourself without disturbing utility workers.

Even if the installation is carried out according to all the rules, leaks may form at the fitting connections over time. There may be several reasons for this:

- Rubber sealing rings are quickly destroyed, especially by hot water, so they often need to be replaced. In this case, the fitting is unscrewed and the ring is changed. It is better to put a silicone seal.

- Fitting. The adapter itself may also burst. In this case, simply replace it with a new one.

- Pipe. Perhaps during installation the cut was made unevenly and the sharp ends led to leakage. In this case, the product is cut again, flared and installed in place. If the pipe itself suddenly bursts, it is not repaired, but replaced entirely.

If you are not sure that you can install the pipes yourself, it is better to contact a qualified plumber. After all, if leakage from pipes ruins the repairs you just made, it is unlikely to give you pleasure. Although, as practice shows, most people successfully cope with the independent installation of metal-plastic pipes.

DIY installation features

Self-installation of an individual heating system has its own characteristics and nuances. Most questions arise regarding the issues of giving the desired shape to the pipe line and the choice of connection methods.

How to bend a pipe

The most optimal way to bend a pipe is to use a special device - a pipe bender. If this is not available, an alternative method of bending is used by heating with a construction hairdryer. It should be remembered that, unlike steel, metal-plastic is a more fragile material and therefore the bending radius is equal to seven times the diameter of the pipes being connected. If the bending angle is smaller, it is best to install an elbow fitting.

Connection methods

With an open installation method, experienced plumbers recommend connecting individual sections of the thermal distribution with compression fittings. If pipes are laid in a hidden way, for example, in a floor structure, press fittings or crimp couplings are used.

Detachable connections are installed only with open heating pipelines.

Species diversity

In addition to functionality, when choosing fixing elements for a pipeline, the installation method and external data are considered. The option of using products once or several times is also taken into account. Let's take a closer look at what can be used to attach polypropylene, metal-plastic or metal pipes to the wall.

bracket

Functional fasteners are relevant for laying utility lines along walls, floors and ceilings. The clamp is used for working with water pipes with heated coolant. That is, installation is carried out using a floating method.

The design looks like this:

- Console. Made from metal or polymers. It has a curved shape with a base for attaching plastic and metal pipes to the wall. May consist of one or two parts. This is a supporting part that allows you to secure the pipeline at a small distance from the base.

Bracket for manifold channels Source shopify.com

- Accessories. A bolt with washers and a nut to close the ring in a given position. There may also be additional suspensions and clamps, rubber seals.

The individual components are fastened together without welding. This way you can adjust the diameter of the bracket. Installation of fasteners can be done using self-tapping screws, dowel-nails, anchor bolts or a welding machine.

Clip

For the manufacture of fasteners, polystyrene with fibrous inclusions made of polyester is most often used. Less common are plastic products with similar performance characteristics. This takes into account the preservation of quality under changes in temperature conditions. This explains the main application - fixing hot and cold water supply channels.

The shape of the clips is similar to a bowl with a widened base and narrowed edges. This is necessary for fastening polypropylene pipes by snapping. The range includes single and double products for separate and parallel fixation of water channels. The second type can be extended using special connectors or mounting protrusions (a protrusion and groove are provided in the side of the base).

Pair clip Source leroymerlin.ru

According to their design, clamps are divided into two types:

- solid cast with a dowel (easy to use, but cost a little more than analogues);

- simple or collapsible in the shape of a bowl without additional elements.

Clamps are used for pulling pipelines made of metal-plastic and polymer alloys (rigid, flexible and corrugated channels). The outer diameter of the channel is limited to 5(16) to 50 mm. This is enough for the private sector.

The main advantages of such fasteners are simple installation, reusable use and the ability to fit into the interior. The disadvantages include two points. Application limited to lightweight polymer pipelines. Fragility, ductility and low mechanical strength can lead to breakage or deformation of the “bowl” walls. This mount requires complete replacement, as it cannot be restored.

Installation includes three steps. Before fixing the pipe to the wall, markings are applied to the base. Next, the clip is fixed on the working surface using a self-tapping screw or dowel-nail. The final step is to insert the pipe by pressing the channel into the clip with slight pressure.

Clips with dowel for mineral base Source stroykaydoma.ru