Every housewife has encountered such a problem as a decrease in pressure in the water supply system during the simultaneous operation of several points. This problem is solved using a distribution manifold. Among consumers, they are better known as water supply combs. This wiring scheme is considered the most effective and in demand these days. This engineering solution is quite complex, but has a number of advantages.

Why is a collector distribution system needed?

First you need to find out what a comb or water supply collector is. The comb is a distribution device used during the installation of heating systems, water supply and during the connection of heated floors. The design of the comb makes it possible to distribute heat flows over the entire area of the room. Let us consider in detail what role the comb plays in the plumbing system, how to select it and install it.

In houses of old construction, the main method was used during installation. Pipes were connected to the main branch one by one, because of this, residents of the old type of housing stock still suffer from uneven distribution of pressure and temperature. Traditionally, water pipes used the tee wiring method using threads or welding. The capabilities of the tee do not allow for stable pressure when operating several points at the same time; this is where the comb comes to the rescue of the water supply system.

There are no such disadvantages in wiring for far water supply using combs or collectors. The pipes are connected to the main line in parallel. Connecting a comb for cold or hot water, or even filling the pool, does not in any way affect the water supply of neighboring apartments.

The distribution comb for any water serves to equalize the pressure in the network, preventing sudden changes in pressure and water hammer. In modern houses, distribution manifolds are installed for hot and cold water supply. Using a comb-type collector, an independent water supply system is created for each apartment, moreover:

- it is possible to install a water pipe in the apartment to each point;

- guarantee of independent operation of all plumbing fixtures independently of each other.

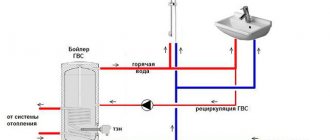

In order to achieve optimal results, it is recommended to install comb manifolds on cold and hot water supply. The outlet of each pipe must be equipped with a tap that will quickly stop the water supply to any device. This property will be a good help during a malfunction of the faucet or cistern.

Advantages of collector wiring system:

- reliable connection in the system;

- clear work;

- stable pressure;

- ensuring convenient use of household appliances connected to the water supply;

- there is a possibility for installation on a pipe with hot water;

- elimination of temperature changes;

- you can install the water supply in a hidden way;

- There is no need to completely shut down the system for repairs at individual points.

The disadvantages include, perhaps, the cost of the collector itself, as well as some components that are needed for its installation (fittings, risers, valves, etc.). Moreover, many connections make the system itself more cumbersome. But when taking into account the reliability and benefits of the design, the costs are fully worth it.

Leaders of sells

For an even clearer understanding of what a distribution comb is and how to choose the best device for yourself, you need to look at the recent sales leaders. From this information, you can find out what requirements must be met and what new functions have been added by manufacturers.

You will be presented with 2 types of distribution comb and distribution manifold, common throughout the world, which have the most modern functions:

- distribution comb for 2 pipes. Combines low price and excellent quality. The manufacturer is the famous company Rehau. The average price in Russia is 700 rubles. Serves to regulate the coolant on several circuits. You can connect to the device both ordinary cold water passing through pipes and a heated floor system, as well as other heating devices. Installation of the comb is facilitated thanks to the sliding sleeves with which it is attached to the pipes. Made of brass, this material is characterized by long service life and high strength.

- distribution manifold for 11 groups. Collectors have the same functions as combs, the only difference is in the number of connections - the collector has many more of them, connections are made in groups, for cold and hot water separately. Rehau has proven the high quality of its devices. This is evidenced by the numerous purchases by Russians of collectors and combs from their company. The Rehau Rautitan HLV distribution manifold branches out the circuits of radiator distribution systems. All devices have passed mandatory quality checks and necessary tests, including pressure testing in emergency situations. Just like the comb, the manifold of this company is made of brass, which indicates high quality and durability. The average price in Russia for the Rehau Rautitan HLV distribution manifold is 11,000 rubles. The kit includes: eurocone, ball valves, connecting nipples and built-in air valve.

Types and design of water combs

The differences between plumbing combs vary as follows:

- degree of sophistication;

- material;

- number of taps (from 2 to 4);

- center-to-center distance of branches (36 - 100 mm).

For a larger number of plumbing connections, it would be better to use a combination of several distribution devices. For example, at 6 points you can install two combs with 3 outputs each.

The simplest design of a distribution comb looks like a pipe with several outlets. Their number varies from 2 to 4. Such a collector is designed directly for distributing water flows and its assembly is quite easy to do yourself.

More complex types of combs for water supply are far equipped with ball valves and control fittings required for each outlet. The taps have only two positions, on and off, and shut-off valves make it possible to change the flow intensity. Many consumers find the second option the most convenient. The most sophisticated models are equipped with mechanical or electronic sensors and can be installed on heating and hot water supply systems.

Calculation of comb throughput

The calculation of the parameters of the distribution comb includes determining its length, the cross-sectional area of its cross-section and pipes, and the number of heat supply circuits. It is better if the calculations are done by engineers using computer programs; in a simplified version, they are only suitable at the preliminary design stage.

In order to maintain hydraulic balance, the diameters of the inlet and outlet manifold combs must match, and the total throughput capacity of the nozzles must be equal to the same parameter of the collector pipe (the rule of total sections):

n=n1+n2+n3+n4,

Where:

- n is the cross-sectional area of the collector4

- n1,n2,n3,n4 - cross-sectional areas of the pipes.

The choice of comb must correspond to the maximum thermal output of the heating system. What power the factory product is designed for is written in the technical data sheet.

For example, a distribution pipe diameter of 90 mm is used for a power not exceeding 50 kW, and if the power is twice as high, the diameter will have to be increased to 110 mm. This is the only way to eliminate the risk of unbalancing the heating system.

The cross-section of the collector pipe is equal to 3 diameters of the connected pipes, the distance between the supply and return combs is 6 diameters, the distance of the pipes from each other is 3 diameters

The 3-diameter rule is also useful (see picture above). As for calculating the performance of the circulation pump, the specific water consumption in the heating system is taken as the basis.

Each pump is calculated separately - per circuit and for the entire system. The figures obtained in the calculation are rounded up. A little extra power is better than too little.

Where and how best to install the comb?

The location where the comb will be installed is best determined during the design of the plumbing system. But most often you have to install it into an existing circuit. The main criteria when determining a location are:

- accessibility for repair and installation;

- moderate or low humidity;

- load-bearing wall on which the comb can be mounted;

- additional lighting with the ability to carry out work in emergency mode.

Sometimes the comb is generally mounted in a separate room, or special manifold cabinets are installed specifically for it.

The combs are mounted on hot and cold water supply. To avoid confusion and for ease of use, manufacturers make models in different colors (red and blue).

The nuances of installing the comb:

- Installation must be carried out by a specialist. Without specialized knowledge, the average person will experience difficulties during installation.

- To secure the device to a mounting cabinet or wall, use mounting clamps.

- Installation of the unit is done without additional compaction.

- Separate collectors are installed for cold and hot water.

- In the plumbing circuit, this unit is mounted after the filter and pressure reducer.

- The distribution manifold is necessarily equipped with shut-off valves (regulating and shut-off type).

- In the case of equipping the water supply of a two-story house, there may be a need for a circulation pump.

Installation should be done only after the wiring system has been completed. Subsequently, it is recommended to consider possible system upgrades. To do this, it is recommended to leave several free connections in the comb, closing them with a plug.

How to choose a distribution manifold?

Before purchasing a collector, it is recommended to check the technical parameters of different models for the optimal choice for your plumbing system.

Nuances taken into account when choosing:

- pressure in the water supply;

- comb throughput capabilities;

- number of water intake points;

- installation on cold or hot water supply;

- installation on hot or cold water supply;

- possibility of connecting an additional point.

No less attention should be paid to the material from which the collector is made:

The preferred materials are bronze or brass copper due to the fact that they hardly accumulate sediments that can cause corrosion.

How to make a collector with your own hands?

Although from the economic side this is not entirely justified, if you have the necessary tools and a lot of patience, you can make a polypropylene comb with your own hands. To do this you will need:

- hacksaw and soldering iron for polypropylene;

- pieces of polypropylene pipe Rehau with a diameter of 25 and 32 mm;

- tees 32x25x32;

- plugs for 32nd diameter;

- couplings with internal threads 32:1 inch and 25:34;

- couplings with external threads 25:34;

- sealant;

- Ball Valves;

- air extractor.

You don't have to use an air extractor. But you must leave space at both ends to connect additional devices to the water supply collector in the future. During welding work, it is very important to visually check the quality of the seams to prevent completely welded elements.

At the stage of installing a water supply or heating system using modern technologies, one cannot do without a distribution manifold. This device allows you to redirect fluid flows.

Thanks to the distribution manifold, you can easily turn off or limit the capacity of each heating or water supply circuit in a private house or apartment. This, in turn, allows you to significantly save money on heating those rooms in which maintaining a high temperature is not required.

This device also allows you to more evenly distribute the fluid pressure between consumers, which is almost impossible to do with a series connection.

How to save money on a mixing unit

Many master plumbers consider it an integral part of the underfloor heating manifold, although these are 2 different elements that perform separate functions. The task of the comb is to distribute the coolant along the circuits, and the mixing unit is to limit its temperature to 35-45 °C, maximum 55 °C. The collector connection diagram shown below works according to the following algorithm:

- While the system is warming up, the two-way valve on the supply side is completely open and allows maximum water through.

- When the temperature rises to the calculated value (usually 45 °C), the remote sensor acts on the thermal head, and it begins to block the flow through the valve, pressing on the rod.

- After the valve mechanism is completely closed, the coolant, stimulated to move by the pump, circulates only in a closed floor heating network.

- The gradual cooling of the water is detected by a temperature sensor, causing the thermal head to release the rod, the valve opens and a portion of hot water enters the system, while some of the cold water goes back. The heating cycle repeats.

Note. If the manifold thermostats are controlled by servos, a bypass and bypass valve is added to the mixing assembly. The goal is to organize circulation in a small circle when the servos, for some reason, suddenly block all the circuits.

Good news for those who are very limited in funds, but want to heat themselves with warm floors: installing a two- or three-way valve with a pump is not always necessary. There are two ways to reduce the cost of the system by avoiding the purchase of a mixer:

- power the heating circuits directly from the gas boiler through the manifold;

- install RTL thermal heads on the manifold valves.

The manifold assembly, assembled from brass tees, provides for regulation by automatically limiting the reverse flow with RTL heads.

Let us immediately note that the first option contradicts all the canons and cannot be considered correct, although it is used quite successfully. The bottom line is this: high-tech wall-mounted gas boilers can maintain the temperature of the supplied water at 40-50 °C, which is acceptable for heated floors. But there are 3 negative points:

- In spring and autumn, when there is minimal frost outside, the boiler will not be able to lower the coolant temperature below 35 ° C, causing the rooms to become stuffy and hot due to heating of the entire floor surface.

- In the minimum combustion mode, the parts of the heating unit are covered with soot twice as quickly.

- Due to the same mode, the efficiency of the heat generator is reduced by 5-10%.

Advice. To avoid discomfort from the heat during transitional periods, you need to install traditional heating radiators in the rooms of a private house, and connect underfloor heating when it gets very cold.

Thermostatic heads of the RTL type operate on the principle of a two-way valve, only they are located on each circuit and are not equipped with remote sensors. A thermoelement that responds to changes in water temperature is located inside the head and blocks the flow along the circuit when it has heated up above 45-55 ° C (depending on the adjustment). In this case, the comb is connected directly to a heat source running on any type of fuel - wood, diesel or pellets.

Important condition. For normal operation of heated floors controlled by RTL thermal heads, the length of each circuit should not exceed 60 m. More details about the design of such heating and the correct collector assembly diagrams are described in a separate instruction and in the next video:

A Question of Choice

A high-quality distributor is capable of operating at high fluid pressure, has trouble-free shut-off valves, and a high degree of environmental safety when distributing water.

Before purchasing a collector, it is necessary to determine the number of water consumers to which an individual pipeline will be connected. Then you need to purchase a collector, the number of outlets of which is equal to the number of water consumers.

If the supply pipe is made of polypropylene, then the distributor should also be installed from this material. In the case where the supply pipe is metal, it is better to use a distributor made of copper alloy or stainless steel.

When choosing a distribution manifold, it is necessary to take into account such a design feature of these devices as the possibility of replacing the tap of each outlet. Otherwise, if one of them fails, the collector will need to be completely replaced.

Example of installing a comb in a bathroom

Selecting a location

First of all, the water distributor must be installed in such a way as to maximize the length of each pipeline to the consumer. If this rule is neglected, then over longer sections the fluid pressure will differ significantly.

If the water supply is installed in a multi-storey building, then the collector is installed on each floor.

There are two ways to install a water comb:

- In the wall of the building.

- In the distribution cabinet.

The first installation option is used when the usable area of the room is limited, or the open installation of pipes and distribution boxes will significantly change the design of the room. In this case, a niche is built in the wall, which is closed with a valve, and if necessary, it will be possible to gain access to the control of the device.

If it is possible to install the distribution device in a utility room, then in this case a special box is installed, inside which the comb and all the pipes leading to this device are fixed.

If the water supply is installed in a multi-storey building, then the collector is installed on each floor

Installation of distribution manifold

When installing the distribution manifold inside the wall, a recess is made into which the comb and inlet and outlet pipes are placed. If it is possible to install the comb in a utility room, then this is the most suitable place to install this device.

The distributor installation process is very simple and is carried out in the following sequence:

- supply from the riser is turned off.

- The supply pipe is connected to the central inlet of the collector.

- If the device is not equipped with taps , then a ball valve is connected to each output of the distributor.

- is connected to each tap .

- If the number of taps exceeds the number of water supply circuits , then the extra outlets should be closed with plugs.

- After connecting all the pipes , the collector is fixed to the plane of the wall or box with clamps.

Price

General Fittings Cold Water Manifold - The manifold is designed for use in a cold water system only. The material from which the device is made – nickel-plated brass – does not interact chemically with impurities in water, thereby allowing the device to be used for at least 10 years.

The comb is equipped with valves that are located on the main distributor pipe. The number of pins of this device is 4 pcs., but if necessary, a block of an unlimited number of pins can be assembled from separate sections.

The price of the comb is 1400 rubles.

Distribution manifold DM, Gidruss is a universal device that can be used for distribution of water supply and heating systems. The material from which the distributor is made is structural steel, capable of withstanding coolant temperatures up to + 120 degrees. The pressure in the water supply system when installing this device should be no more than 6 bar.

Number of comb leads – 4 pcs. Fastening to a horizontal plane is carried out using special brackets that securely fix the distributor, completely preventing its movement during operation.

Blitz tips

- Despite the fact that polypropylene distributors are inferior in all respects to brass and steel combs, they cope with their task perfectly.

When installing a distribution comb in a water supply system , water consumption metering devices and filters, as well as an emergency valve that will shut off the incoming water pipe, must be installed in front of the comb. - If the distributor is installed in a private house in which water is supplied from an individual source , then the system must be equipped with coarse and fine water filters, otherwise the rubber seals used in such a system will quickly fail, including the shut-off valves of the distribution combs.

- Despite the fact that polypropylene distributors are inferior in all respects to brass and steel combs , they do their job perfectly, are easy to install and can be used not only in cold water supply systems, but also successfully for distributing heating system circuits.

Purpose of a plumbing comb

A plumbing comb (collector) is a device for draining water from a common riser to consumer appliances. The comb is installed to equalize the pressure in the water pipes and uniformly distribute water from the riser (pipeline) to the existing plumbing fixtures in the house (faucets, toilet, washing machine, shower cabin and sink), each of which is connected to a separate outlet.

The device itself is a large diameter pipe with several outlets. The presence of a comb allows you to successfully supply water to all appliances in the house and, if necessary, block access to water for one of the plumbing fixtures (locally), without the need to turn off the entire water supply (all equipment operates independently of each other without loss of water pressure).

- Installation of a crest on ready-made communications

– 2000 rubles - Installation of the comb price per output

- 300 rubles - Repair of the comb with repair of supply pipes

- 3,500 rubles. - Dismantling the comb

– 150 rubles.

Installing a comb in the water supply system

When installing a comb (collector) yourself, you need special tools, as well as knowledge of the water supply system. You should come up with a diagram of the distribution pipes in advance, select the type of pipes used, and calculate the length of each fragment (as well as the type of connections). When choosing pipes connecting to the comb, polypropylene pipes are most preferable (they are the easiest to install into the system, which is an undoubted advantage when installing a collector system yourself).

Installation of a plumbing comb

The collector wiring diagram must take into account that each unit of equipment located in the room is separately connected through a comb. A tap should be installed at each branch from the central system: this system will eliminate the need to shut off the water supply to the entire system in the event of failure of one of the lines diverging from the comb. To be able to completely shut off the water supply system, a tap should also be installed at the base of the collector.

Comb installation

The comb is installed according to the following scheme:

- Polypropylene pipes are cut and soldered, as well as their fragments are connected using fittings (the ends of the segments are heated and quickly inserted into the fittings).

- The shut-off of collector and shut-off valves is checked and the water supply is subsequently started.

- Each wiring is checked separately. In the absence of leaks and problems with water supply, we can state the successful completion of installation work

In most cases, the comb is installed separately for hot and cold water. All combs are designed taking into account the upcoming installation: mounting clamps are provided for mounting on an installation cabinet or wall, and the possibility of connecting central heating heat meters is allowed. All devices have high hydraulic characteristics, are resistant to corrosion and allow installation work to be carried out without the use of additional sealing measures.

If you do not have the necessary knowledge and experience in plumbing work, you can turn to experienced professionals. Competent specialists will select equipment taking into account the type of existing pipes, quickly and efficiently perform all necessary installation work and test the system for faults.

“>

Advantages of installing a collector device

Distributing water to each consumer according to the classical scheme using tees is cheaper than collecting water pipes. However, the use of combs has a number of advantages.

Distribution devices allow you to regulate the pressure in each branch. If you install a water supply system according to the classical scheme, then a decrease in pressure often occurs in an open mixer, for example, above a bathtub. This situation can occur when someone in the house uses the toilet, washes dishes in the kitchen sink, or turns on the washing machine.

The pressure difference will cause a change in water temperature. This leads to discomfort while taking a bath. A person can even get burned due to the increase in water temperature. A water collector for plumbing helps to avoid situations. It prevents pressure drops in the home system.

The use of a comb collector reduces the likelihood of a sharp change in water temperature in an open tap. Source 299999.ru

Combs with valve mechanisms on the branches to regulate the water supply in each branch allow you to repair faulty plumbing fixtures. In this case, there is no need to shut off the entire water supply system.

The use of comb collectors also allows you to reduce the number of joints in the water supply. Thanks to this wiring scheme, the likelihood of leaks in the house is reduced. After all, a single pipeline can be laid from the collector to each water collection point.

In addition, combs allow you to quickly install additional plumbing if necessary. In this case, there is no need to redo the existing system.

However, the collector distribution of water supply pipes is characterized by high consumption of materials. Its implementation requires almost 8 or even 10 times more pipelines than for installing a water supply system according to the classical scheme. To reduce the cost of creating such a system, it is recommended to use pipes made of metal-plastic or polypropylene.

If there are collectors, separate water pipes are supplied to all plumbing fixtures. Source kotel02.ru