Natural gas is the most convenient and affordable type of fuel for operating heating boilers in private houses. The pipeline system for supplying gaseous fuel to the burner, simple ignition, parameter control and shutdown make the operation of gas heating systems simple and not requiring special training. The ability to immediately stop combustion in emergency situations provides an increased level of safety during operation of the installed equipment.

At the same time, there are special requirements for installing a gas boiler in a private house. Their implementation is mandatory for all types of equipment in order to ensure a minimum degree of risk when burning explosive fuel in residential buildings and individual structures.

Requirements for premises and air exchange

An important advantage of a private house, in contrast to city apartments, is the ability to allocate non-residential premises for the installation of heating equipment. The current regulatory documents provide a number of requirements for the size and arrangement of such rooms. The main ones:

- a total area of 4 m2 or more must ensure that the boiler can be placed at a distance of 350 mm from the outer wall;

- ceiling height of at least 2.5 meters;

- the floor level in the furnace room is not lower than the zero level of the building;

- the width of the entrance door is from 800 mm, and the door should open outward;

- the mandatory presence of a glazed window, the area of which is determined depending on the thermal performance of the gas boiler;

- the lighting standard is set to 0.03 l/m2;

- The minimum cross-sectional area of the air channel for supply natural ventilation is 8 cm2 for each kW of heating unit power.

When organizing the air supply, it is necessary to take into account the amount used for gas combustion and also add three times the air exchange for the volume of the room.

All walls and internal partitions must be built of non-combustible fireproof materials with a fire resistance rating of at least 45 minutes. The layout of the room and the arrangement of ventilation ducts should not contribute to the spread of flame in a fire.

The volume of free space not occupied by installed equipment is standardized depending on the power of the installed boilers:

- for heating units up to 30 kW - less than 7.5 m3;

- 60 kW – 13.5 m3;

- more than 60 kW – 15 m3.

Installation of a gas boiler in a private house with a total thermal output of more than 200 kW is prohibited. In this case, the power of one unit should not exceed 100 kW.

Boiler room preparation

First, work is carried out to improve the furnace room, radiators are attached, water supply and heated floors are installed. Before fixing the main unit, electricity and sewer pipes are installed. Heating is installed after laying a solid floor based on cement screed. The walls, floor and ceiling are finished with fireproof materials.

Installation of high-quality heating devices involves the installation of auxiliary equipment. It is necessary to use the boiler diagram to provide for all the nuances of the arrangement. The locations of the mounting holes are marked on the wall and floor, and all missing elements are installed. The heating boiler is installed last.

Correctly connected boiler in the living room

Flue gas removal

Channels and pipes designed to remove gas combustion products must ensure normal combustion in the boiler furnace. Due to this:

- the cross-section of the smoke exhaust duct should not be less than the dimensions of the boiler connecting pipe;

- it is allowed to reduce the cross-sectional area of the chimney if the design of the heating unit provides for the forced removal of combustion products and air supply;

- channels can be located inside capital walls and partitions of appropriate thickness or be attached to them;

- the material for the manufacture of chimneys must be fireproof and not subject to active corrosion;

- the design of the chimney must include a special hatch for cleaning the channel from soot and a device for draining the resulting condensate;

- the height of the chimney is higher than the ridge of the roof or a line at an angle of 15° when moving away from it.

All butt connections of elements are made airtight and exclude not only the release of combustion products into the premises, but also the possibility of air leaks and a decrease in draft.

Self-installation

To correctly connect all the connecting elements, you need to place the boiler in the prepared place. This could be fireproof slabs, a concrete base, or even a small podium. If a durable wooden podium is mounted, then it is covered with a metal sheet, which at the final stage should protrude beyond the body by at least 28 cm.

Reliable connection of a wall-mounted boiler depends on the correct installation of the unit, so the horizontal level is carefully checked with a building level. If the floor-standing boiler was installed incorrectly, the position is corrected using movable legs, or fragments of a steel sheet can be placed under the body.

Preparatory activities

Preparation for installing a gas boiler in a private house begins with studying regulatory requirements, rules for installing a gas boiler in a private house, design solutions for the arrangement of auxiliary equipment, technical characteristics and internal structure of the boiler unit.

To obtain permission to connect a heating boiler to a gas pipeline and supply gas to a residential building, the owner of the building must submit an application to the local gas service, where the request will be reviewed by specialists within a month.

After this, the applicant is given technical conditions for connection or a reasoned refusal until the existing comments are completely eliminated. Installing a gas boiler without obtaining and fulfilling technical conditions is considered illegal and may entail liability for the owner of the house, the level of which is determined by the consequences of the crime.

The design of an individual furnace is developed taking into account all the technical requirements and rules set out in the conditions. The heat losses of the building are calculated and the boiler power is determined taking into account the consumption of hot water for household needs.

The finished project must be approved by the special supervision service of the gas supply organization. To do this, together with it the following is sent to the regulatory authority:

- technical passport of the boiler;

- manufacturer's instructions for installation and operation of the heating unit;

- a copy of the certificate for its compliance with current regulatory documents.

The next stage of work is to complete the equipment and necessary materials. Here you should pay attention to the compliance of the connecting fittings in size and thread pitch with the mating connections of the boiler, pumps, tanks and other equipment provided for by the design solutions.

It is necessary to understand that the furnace equipment is part of the heating system and should not be considered as a separate isolated section of the house.

Dual-circuit

In order to correctly install a powerful gas factory boiler with two circuits in a classic private country house, you need to take into account several nuances. With the traditional connection scheme of a double-circuit unit, one heat exchanger heats the coolant fluid inside the system, and the second provides consumers with hot water. These resemble an autonomous high-tech boiler room.

Compact gas boiler

Installation of boilers in individual houses

The method of placing a heating boiler in a residential building depends on its design and can be floor- or wall-mounted. It should be noted that floor-standing models in most cases exceed the thermal power of wall-mounted heat sources.

In addition, a freer coolant circulation pattern in such devices allows them to be installed for operation in autonomous heating systems with natural circulation.

Installation of floor-standing boilers in a separate combustion chamber

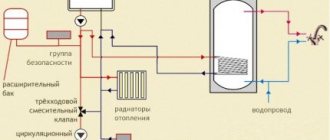

If it is necessary to install a heat source with a power of more than 32 kW, gas boilers with floor installation are chosen, since the thermal performance of serial mounted models does not exceed the specified value. The developed standard furnace schemes for private houses provide for the presence of:

- expansion tank;

- domestic hot water heater;

- capacitive or speed separator;

- distribution comb;

- at least two circulation pumps.

In addition, it is necessary to install emergency discharge lines and safety valves that are activated when the pressure in the pipelines increases.

Boiler installation work begins with the preparation of brick or concrete foundations not only for it, but also for all tanks, which, after filling with water, will become quite heavy. After this, distribution combs and pumping blocks with shut-off valves should be assembled and secured to the wall according to the design diagram.

Boiler piping

Place the tanks and boiler on the bases and, if there are mounting holes, secure the position using anchor bolts. Now you can begin work on the installation of the chimney and installation of pipelines.

One of the circulation pumps is installed on the return line between the boiler and the separator. The second is on the supply line after mixing the coolant flows in the separation column. A safety relief valve must be installed on the heated water outlet line from the boiler, which will protect the installed equipment when pressure increases.

Return.

Emergency discharge pipelines must not be connected to household plastic sewers, which may be damaged when boiling water is drained. The material must be metal. At the connection to the water supply, a heating system make-up regulator is installed, which in a simple version is a bypass valve that regulates the pressure after itself.

The length of the horizontal section of the chimney at the outlet should not be more than two diameters of the factory pipe. After this, the chimney must be moved to a vertical or inclined position at an angle of at least 30°. If the temperature of the exhaust flue gases exceeds 85° according to the unit’s passport data, metal chimneys must be closed with thermal insulation.

The connection of a gas boiler in a private house to the gas pipeline, purging of the fuel line and a test run of gas are carried out by employees of the gas supply organization. These works may be carried out by the installation organization, but only in the presence of a representative of the controlling office.

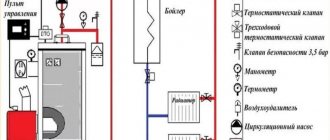

Installation of wall-mounted boilers

Unlike floor-mounted structures, wall-mounted models do not require such complex piping and installation of auxiliary equipment. A circulation pump, expansion tank, heat exchanger for heating domestic hot water and a safety valve are already installed inside the body of the unit, which in design is a compact mini-furnace.

However, the power of such boilers usually does not exceed 32 kW, which can ensure the operation of a heating system in a residential building up to 300 m2. Moreover, if we take into account the consumption of hot water in double-circuit devices, then the heated area must be reduced by 25-40%. But for small buildings, wall-mounted gas boilers are the most optimal solution to the issue of organizing stable heating operation.

Boiler installation location

There are two types of mounted gas boilers on the market, which differ in the way they supply combustion air and remove flue gases. They are called boilers with atmospheric and closed combustion chambers. In the second case, the design of the unit provides for an axial fan-exhaust fan and a double coaxial chimney. The piping of both types is structurally no different.

Coaxial chimney.

The location for installing the boiler is chosen depending on its design. Models with an atmospheric firebox should be mounted as close as possible to the vertical smoke channel running inside the wall. Units with a closed firebox can only be installed on an external wall or on a partition adjacent to it in order to be able to lead the coaxial pipe to the street.

Brief installation instructions

Manufacturers include an installation or marking sheet in each package, on which the contours of the boiler are drawn, markings of all connections and installation points for fasteners. Its presence greatly simplifies the work. The installation procedure is as follows:

- attach a sheet of fire-resistant material with a thickness of at least 3 mm to the wall surface;

- a mounting sheet must be glued to the surface of the sheet;

- Drill holes in the mounting marks and install anchor hanging hooks on which the heating unit will be hung;

- hang the boiler on the wall;

- check the gap between the boiler and the wall, if necessary, remove the device and tighten or unscrew the fasteners;

- Based on the markings on the installation sheet, connect the gas boiler to the heating and hot water supply system;

- install a flue on the outlet pipe and bring it to the smoke duct or take it outside;

- connect the boiler to the electrical network through a voltage stabilizer or uninterruptible power supply device;

- invite gas service workers and, in their presence, connect the unit to the gas pipeline.

Normal operation of heating attachments can only be ensured if there is a stable power supply. Even short-term failures will lead to the boiler stopping and possible damage to the electronic control unit. Therefore, the presence of protection is mandatory.

Wall mounted

To correctly connect a gas heating boiler to a water heating system in a private two-story house, you need to study the relevant literature. It is worth considering that due to a lack of oxygen, the supplied fuel will not burn completely. In this case, there is a risk of accumulation of toxic substances that do not support breathing and are dangerous to humans.

If the boiler is equipped with a closed type of combustion chamber, then a coaxial chimney is supplied with it. This is a small double tube, in which the outer part is responsible for taking in oxygen, and the inner part removes combustion products. The fan runs on electricity, so there must be an electrical outlet near the unit.

Rules for operation and maintenance of a gas boiler

Heating equipment must operate at positive air temperatures and normal humidity. At least twice a year, it is necessary to check the cleanliness and functionality of the ventilation system and chimneys. The main activities during boiler operation must include:

- annual cleaning of all installed filters;

- monitoring the technical serviceability of the control unit;

- inspection of the heat exchanger for the presence of soot;

- checking the tightness of joints and connections of the gas pipeline by soaping;

- cleaning the burner from carbon deposits and dust.

All failed parts should be replaced with new ones, rather than attempting to restore them. A conscientious attitude to the implementation of all necessary technical measures will increase the service life of the equipment and ensure your safety.

Preparation of devices

To install and subsequently start up such heating devices, the following tools and materials are required:

- American type detachable connections, ball valves. These elements are used to connect pipes with cold and hot water.

- Self-tapping screws, brackets, dowels.

- Pipes for the heating circuit and chimney.

- Filter with a deep cleaning system on a magnetic basis. This extends the service life of the boiler, since particles of debris and dirt will not enter the internal compartment of the system.

- Three-core cable, sockets, 2A automatic switch.

- Hacksaw, screwdrivers, set of keys, drill, file.

The classic connection diagram for a gas boiler allows even a beginner to install all the necessary equipment.

If plastic, copper or metal-plastic pipes are installed, the list of parts and tools may change.

Connecting all pipes

Launch

Boiler installation

Before the first start-up, gas technicians check the entire system for leaks, the visually normal condition of the device and the correct connection of communications. The heating system is then filled with water. A special system replenishment unit is already built into modern gas appliances, so the procedure does not require additional effort.

Stop filling when the pressure gauge reads 2 atmospheres. Then the accumulated air is released from the main components, circulation pump and radiators. As soon as air stops coming out of the system and water starts flowing, the equipment is ready to start at full power.

Connecting the system

The current standards are designed to control the quality of the system. Experts recommend installing a special coarse filter to ensure guaranteed protection of the boiler from scale and debris. The connection of all parts for heating a private house must be carried out strictly according to the rules with mandatory sealing of all joints. To seal the threads of parts, you can use tow and paint.

If a novice master has not yet figured out how to connect a floor-standing gas boiler to a water main, then he needs to take into account that all actions correspond to standard manipulations with a regular pipeline. Shut-off valves are installed.

It is best to use universal “American” ones with detachable connections for work, since in this case the technician will have the opportunity to quickly replace a broken piece of equipment.