13.01.2021

Projects of modern houses made of timber include the arrangement of a separate room for the boiler room. This is an important aspect of home planning that should be given special attention. Regardless of what material the house is made of - brick, concrete or wood, the room for heating equipment must comply with safety rules. However, the arrangement of a boiler room in houses made of timber has its own characteristics that must be taken into account when designing and installing a heating system.

The technology for manufacturing high-quality timber involves protecting the material from fire: wooden surfaces are necessarily treated in production with fire-fighting compounds and fire retardants, and laminated veneer lumber has an increased density and structural strength, which makes it quite fire-resistant. Therefore, it cannot be said that houses made of timber are more fire hazardous than buildings made of other materials. It is not difficult to equip a boiler room in a log house, but it is better to place it in the basement or in a special room. It is recommended to have fire extinguishing equipment in the boiler room and install smoke detectors. It is important to finish the walls in the boiler room with non-combustible materials - especially in the places where the boiler is located and around the chimney.

As a rule, all residential buildings made of timber are designed for the installation of full-fledged heating equipment while complying with building codes.

Steam heating in a log house

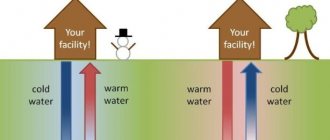

The principle of steam heating is the circulation of hot water through a closed system consisting of a boiler, expansion tank and polypropylene pipes. From the physics course we know that hot water has a lower specific gravity, due to this, it rises through the pipes. As the system passes through, it cools, becomes heavier and moves downward. To improve circulation, it is recommended to install a circulation pump into the system. As a coolant, it is better to use a special non-freezing liquid. If the heating system freezes, in various emergency situations, nothing will happen to the pipes. If you use ordinary water, it can turn into ice and damage the system.

Advantages of steam heating

- With its help, you can heat almost any home in size.

- The boiler is located in a separate room. There is no soot and dirt in the house

- Ability to adjust temperature

- The efficiency of many boilers is quite high, more economical use

- You can use solid fuel with high efficiency, such as coal

- Some boiler models can be switched to gas or you can choose an electric boiler, although it is not economical

- Possibility to choose a double-circuit boiler for heating and hot water supply

- One bookmark is enough for 16-20 hours

Flaws

- Difficult and expensive installation

- Expensive boilers, maintenance required

- Boiler room required

- Dependence on electricity. Without electricity, the circulation pump will not work.

In addition, do not forget that the heat from steam heating can negatively affect the wood from which the home is built. If the room is heated irregularly, the water in the components may freeze. If any problems arise, it is not always possible to fix them promptly

Recommendations for effective operation

During operation of a wood-burning boiler, slag accumulates in the furnace of the installation. As they accumulate, such combustion waste must be removed, because it reduces the efficiency of the unit. A decrease in efficiency by 3% is possible with the formation of a slag deposit 1 mm thick.

It is necessary to clean the walls of the boiler combustion chamber at least once a week. At the same time, the wheel gratings are cleaned. To get rid of ash and other accumulations, just move a special lever and dump the coals into the ash pan.

The installation of a circulation pump allows you to increase the energy efficiency of your heating system. The device will move water through the system faster, the liquid returns to the boiler at an increased temperature. This means that it will take less time to warm it up again. The circulation pump is usually located in the return pipe before entering the boiler.

When servicing a heating unit, it is necessary to periodically check the draft in the chimney. The channel is cleaned from soot at least once a year. To prevent the formation of condensation, special sandwich pipes are used to construct the chimney or sections of the duct located outside the room are insulated.

How to add a boiler room to a house

The addition of a boiler room to a house is quite often in demand in private construction. People purchasing dachas then gradually convert them into homes for permanent residence.

And organizing high-quality heating indoors is a very important component for creating overall comfort. Therefore, it is necessary to create a separate room to install a boiler there, which will actually contribute to part of the heating of the room

How to properly organize such suburban construction in practice. You can completely get by even with your own efforts - but it will be much more difficult than you might initially imagine. At the same time, you need to perfectly understand the technology of work, have your own professional tools, and also not forget about assistants, since such an object simply cannot be built alone.

In addition, it is worth purchasing building materials in the required quantity. It is very difficult to calculate correctly, since each individual boiler room extension to a country house is unique and has its own characteristics. Next, it must be brought to the site and unloaded.

Our organization, for example, most often offers its client frame construction. This choice will definitely save money and significantly speed up the construction of the foundation. In addition, the insignificant weight of the overall structure will not greatly disturb the main country house - especially at the junctions of the roof. In addition, the frame openings are filled with high-quality insulation, which in its characteristics surpasses any other material that can be used to make walls.

The external finishing of such an extension can be made of the same material as the main structure. Inside, it is best to use cement bonded particle board. This is a non-flammable material that perfectly withstands temperature changes and varying humidity.

The floors are also made insulated and covered in their purity with the same material that is used on the walls. It is necessary to provide a place where exactly the boiler will be installed - for this, it is partially necessary to perform separate reinforcement of the structure during the construction of the frame of the walls and floor.

It is best to install the door from the street - and it would be better if it was metal. You can, of course, make an entrance to the boiler room extension directly from the house - in this case, a custom-made plastic door based on a double-glazed window will do. It is best to avoid wooden products. In general, this is, of course, only a brief part of all the information - we will tell you everything else over the phone.

Fire protection for walls, ceilings and floors

The wooden walls of the building must be treated with fire retardants - compounds that protect the wood from fire. After this, you need to finish the surfaces with fire-resistant materials. This can be ceramic tiles, plasterboard or cement-bonded particle boards, which are then plastered and painted with water-based paint.

Metal panels or porcelain stoneware are installed on the floor. The flooring material is laid on the concrete surface. The wooden ceiling is protected by plasterboard, under which the electrical wiring is hidden. The gypsum board is then plastered and painted.

Popular option in Russia

The equipment is inexpensive and to install the system correctly, you only need to correctly calculate the location of the radiators.

Types of heating

Gas boilers are most common in those territories of Russia where there are no problems with gas. But compliance with safe gas handling measures should become firmly established in your life.

Solid fuel boilers operate mainly on wood and coal. Nowadays they are used less frequently, but are not without their advantages.

Heating radiators in a wooden house made of aluminum are light in weight, but less durable and do not withstand pressure changes. Biometal radiators combine the advantages of aluminum and steel. Lightweight aluminum body and coolant made of steel pipes that do not corrode and therefore have a long service life.

Local heating of a house made of timber is carried out using heat guns, convectors, fireplaces, air heaters, and stoves. The disadvantage of this type of heating is that these devices can only heat a small room.

To organize an autonomous heating system for a house made of timber, you must have a centralized boiler and pipes. This installation must be stationary and heat the room completely. Today, this is the most popular type of heating for low-rise buildings. The efficiency of this type of heating is achieved through an individual approach to the creation of heating system designs for each individual home.

Gas heaters are not used very often in local systems. These designs provide for the presence of an open hearth. In addition, gas burners absorb oxygen in large quantities.

Gas is very popular in autonomous heating systems for houses made of timber. Heating boilers in a modern wooden house are so advanced that there is practically no need to monitor their operation. The system is fully automated, the boilers are economical and heat large areas at once.

Steam heating of a private house made of timber

Advantages

- It is possible to heat the entire house, even a large area.

- The boiler is installed in a specially designated place.

- There is a temperature control function.

- High efficiency and cost-effectiveness.

- Solid fuel can be used.

- Installation of a double-circuit boiler for water heating and room heating.

- One fill of fuel is enough for a long time.

Flaws

- Complexity of installation and high cost.

- High cost of boiler equipment and its maintenance.

- You need to look for a separate room for the boiler.

- Depends on electricity (circulation pump).

Heating a house made of timber using an air system

Here the coolant is air, which enters the system after heating. This type of heating is suitable for regions with mild climates.

pros

- High efficiency.

- There is no need for additional equipment.

- You can connect the climate system.

- Ease of control.

- Condensation does not collect on the windows.

- Heats large areas.

Minuses

- Must be installed at the construction stage of the house. Pipes through which air passes are installed in recesses in the walls, under the ceiling or in false walls.

- The system requires constant maintenance, and this is difficult to do with this installation method.

Water floor heating

Any type of flooring can be laid on top of the system. If the system fails, the floor will remain warm for several days. The disadvantage of such floors is the complexity of installation; it is necessary to do engineering calculations first.

The screed is made at a level of 8 cm, which in turn steals space. The optimal water heating temperature should be 40 °C.

>

Selecting the energy carrier to use

It is very important to decide in advance what fuel the unit will run on. Taking into account the choice of boiler mainly determines how to properly install and equip the room. Mainly 4 types of energy carriers are used:

- From an economical point of view, let's use natural gas. Its use has another advantage - ideal environmental friendliness. The minimum amount of soot after combustion allows for much less frequent preventative measures to be taken to clean the chimney and boiler.

- The use of liquid fuel does not require permits from other organizations. The construction must be designed taking into account the free access of the tanker to fill fuel containers.

- The cheapest option is to use solid energy. The disadvantages include the manual method of loading fuel and the rapid clogging of the chimney.

- Electric boilers operate in waste-free mode and require virtually no cleaning. Disadvantages include high energy costs and the lengthy process of obtaining permits when connecting units with a power of more than 12 kW to a three-phase network.

Having selected the desired model, you can begin preliminary work.

Is it possible to install a gas boiler in a wooden house?

Existing SNiPs allow the installation of a gas boiler room in a private wooden house. The exception is old-style apartment buildings.

Room requirements for installing a gas boiler in a wooden house include the following:

- The boiler room is located on the ground floor or in one of the rooms. In a wooden house, it is prohibited to install a gas boiler in the basement, except in a specially equipped, separate room.

- The premises must meet the requirements described in the PPB and sanitary standards.

- It is prohibited to place heating equipment in living rooms. Installation in the kitchen-living room is not allowed; installation in the bathroom and toilet is conditionally prohibited.

- It is mandatory to have personal protective equipment and fire extinguishing equipment, as well as smoke detectors and fire alarms.

Before commissioning, the functionality of the heating system is checked, as well as the presence of all necessary safety components. The Gaznadzor inspector will make sure that the requirements regarding the installation of boiler equipment are met. A separate audit is carried out to ensure the availability of all documents necessary to put the boiler into operation. The minimum package of documents includes:

- Research results from an electrical laboratory testing the parameters of installed grounding.

- Permission from Rostechnadzor.

- Home gas supply project.

The full list of documents is approved by the local gas management department.

Conclusion

The cost of a gas boiler, its installation, operation and safe operation make the equipment the most attractive today. In fact, during installation you do everything yourself, and only when connecting to the gas main do you call a special service.

Also on our website you can find out information on how to install a chimney in the wall of a wooden house.

The video in this article will give you the opportunity to find additional information on the above topic.

How to hang a gas heating boiler in a wooden house

The technical conditions for installing a gas boiler in a frame or log house differ significantly.

In the first case, we are talking about a hollow material, therefore, special fastening bars are used for fixation. If the boiler equipment is heavy, it is recommended to install a gas boiler in a frame house on through studs that are fixed outside the building.

Mounting a boiler in a frame house significantly increases the load on the wall. There are restrictions on the weight of the equipment. If you plan to install a model with a built-in buffer tank, preference should be given to floor-mounted boilers.

Methods for attaching a boiler to a wooden wall of a log or timber house are characterized by ease of fixation. For installation, special wood bolts are used to ensure reliable fastening.

When installing attachments, you will need to comply with safety regulations and maintain minimum distances to door and window openings.

What underlay to use on a wooden wall

If the boiler room is lined with wood, fire protection is provided. The backing on a wooden wall under a gas boiler can be done in several ways:

- A layer of basalt insulation is hung on the wall, after which it is sheathed with steel sheets.

- Special basalt fireproof sheets are used. The advantage of this solution is the minimum thickness of the protective layer, while simultaneously ensuring maximum fire protection.

Installation of a mounted boiler in a wooden house without first making a protective layer is prohibited!

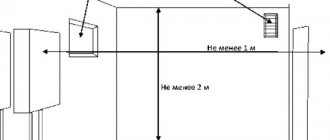

Distances from the boiler to the ceiling, windows and doors

When planning a house, the future location of the boiler room is taken into account and the exact installation location is considered, taking into account the minimum requirements regarding distances to the ceiling, window and door opening. The boiler is placed taking into account the following requirements:

- The boiler is located on a blank wall, without window or door openings.

- For optimal air flow and air exchange in the room, the boiler is installed opposite the doorway. Minimum distance 2-3 m.

- The distance to the floor is maintained within 0.8-1.8 m. In this gap, installation of the boiler is allowed. The minimum distance to the ceiling is at least 0.8 m.

- The ceilings are sheathed with non-combustible material. GVL slab is optimally suited. Further finishing with gypsum mixtures is allowed.

If all requirements are met, a gas boiler room in a wooden house will be highly safe. After the inspection, the Gaznadzor inspector will issue all the necessary documents and fill out a certificate of commissioning of heating equipment.

Calculation of power and temperature of a warm water floor

Main characteristics

Important elements of the house that need to be taken into account when choosing such heating are:

- Floor material. As a rule, the floor is made of boards, plywood or OSB, which are laid over the foundation beams. Such a base is quite movable, which eliminates the possibility of installing a water-based underfloor heating system, because it must be mounted with a screed.

- Insulation of walls and windows. Basically, such surfaces are made of logs or beams, which have a high level of thermal insulation. The coldest place is considered to be the opening, both window and door. That is why heating of a wooden house should be centralized in such places.

Article on the topic: Is it possible to have a wooden house covered with siding?

It is also important to note that a large amount of heat is also lost through the roofing areas, so the surface of the floor and attic should also be carefully insulated.

Moreover, a material such as wood has good flexibility, which allows the entire system of pipes and air vents to be installed without much interference.

Installation of a boiler room in a private house - some requirements

To heat a country house you need a boiler room. The arrangement of such a room requires an absolutely competent approach. It is this device that creates the coziness and comfort of your home, as well as its safety.

Therefore, you should approach it with special attention

You cannot save on some materials, and especially equipment. It is better to entrust the installation of the boiler and some additional equipment to professionals. They will do their job competently and efficiently, with all acceptable standards.

The most important thing for this process is the interior decoration of the room. It should be so fire resistant that it can withstand an open flame for approximately 25 minutes. There are also some specific nuances that must be foreseen in advance, regardless of where your boiler room will be located.

Boiler room requirements:

- Calculate the boiler power, taking into account the area of the room;

- It is best to purchase equipment in advance;

- Select a door of the required size, which must be fireproof;

- All dimensions of the boiler room must comply with special standards;

- Give preference to finishing material – tiles.

Before starting construction of a hotel boiler room, a plan is made, which must be agreed upon with the gas service. Then, of course, this object must be added to the technological plan of the entire site.

Air heating of a house made of timber

In this case, air itself is used as a coolant. After heating, it is supplied to the heated room through special air ducts. Such systems are widespread in Western European countries with a temperate continental climate and mild winters.

The heated air is generated here in an air heater. The operating principle of a heat source is based on the combustion of fuel in the form of liquid or gas in a special chamber. Cold air flows, using a special fan, enter the exchanger where they are heated. Additionally, before heating, they can be cleaned of dust and enriched with oxygen. Next, the heated air enters the room through special air ducts.

Advantages of the air system

- High efficiency;

- Lack of additional components, in the form of pipes, hoses, for transferring coolant

- Possibility of connecting additional climate control equipment, with which you can maintain an optimal microclimate;

- Easy control and switching to different temperatures;

- No condensation on windows;

- Great for heating large areas.

Flaws

The negative aspects of such heating include:

The need for installation during building construction

Therefore, when designing, you should immediately take this into account, since air ducts are installed in special niches in the walls, mounted under a suspended ceiling or in false walls. In addition, this heating method must be constantly maintained, and making changes to an existing wiring is quite difficult.

Stove heating in a wooden house

Since ancient times, people have used stoves to heat their homes. This heating method is designed to heat the room in which the heat source itself is located. The undoubted advantage of stoves is that they can use different types of fuel, which is why they have been popular in many countries of the world for many centuries.

However, many are mistaken in thinking that with just one stove they can heat the entire building. This principle applies only to small buildings. It is necessary to take into account the power of the stove and correlate it with the heated area. Therefore, such heating is suitable only for one-story houses and small buildings with an attic.

Let's look at the disadvantages of stoves

- Low efficiency, not economical

- You have to constantly add fuel

- Do not use high-calorie coal

- With periodic (non-constant) heating throughout the day, the temperature can change dramatically;

- Stove installations and fireplaces take up a significant area that could be used for other useful purposes;

- Constant presence of contamination due to the fuel used;

- Increased risk of fire

For large buildings, the stove can be used as a backup heating source. The best solution for such buildings is steam heating.

Tools and materials for building an extension

The construction of an extension to a house for equipping a boiler room requires the use of tools for engineering, general construction and facing work; they are not scarce and technically complex and, as a rule, are present in every household:

- shovels and crowbar for excavation work;

- concrete mixer, containers for transferring mortar for pouring the foundation;

- carpentry tools for performing formwork work;

- mason's set: rulers, angles, plumb lines, trowel, trowel and spatula for masonry work;

- grinder, drill, hammer, pliers for installing a reinforced belt and fastening the formwork for the foundation;

- chainsaw for roofing.

Wall material is purchased according to design specifications by type and quantity with a margin of 10-15%. If these are foam blocks, then you will also need a dry adhesive mixture.

It is better to purchase material from a stone manufacturer with quality certificates, and not from an unknown seller. Also, you should not take very cheap blocks, which may indicate poor quality of wall products. For work, well-dried material is used, the masonry process is carried out in a warm and dry period of time.

Requirements for gas boiler houses

We list the basic requirements for boiler rooms when installing gas boilers:

- The dimensions of the room for the boiler room are at least 2.5 meters in height and at least 15 m3 in volume.

- Only heating units with a power of up to 150 kW are allowed to be installed in a boiler room located within the building. If a boiler with a power of more than 150 kW is selected, then the rules for boiler room equipment regulate the construction of a separate standing structure or extension. But such an extension can only adjoin and have common external walls with non-residential premises (with a garage, workshops, bathrooms, storage room or dressing room).

- If you install a boiler model that runs not on gas from the main pipeline, but from a liquefied gas cylinder, it is unacceptable to store gas cylinders in boiler rooms. The cylinders can only be stored separately, and a pipeline is laid to supply gas to the boiler.

- An extension for the boiler room, in the case of a common external wall with non-residential premises of the building, can be equipped with two entrance doors, for convenience - both to the street and to the building. But the requirements for the internal door to the building must meet fire safety standards (heat-resistant materials and a high degree of fire resistance).

- A separate boiler room or extension should be built from fire-resistant materials. The structures must have fire safety characteristics - fire resistance of at least 45 minutes, and the impossibility of igniting internal surfaces in the event of fires from the boiler.

- Equipment with a gas boiler (and any solid fuel boiler as well) requires a solid separate foundation; as an option, concrete floors reinforced with mesh are installed.

- In the boiler room, it is necessary to have a water supply and sewerage system, since the heating system must be provided with make-up, and draining the water is periodically necessary. Insulation of the premises and provision of thermal insulation and/or heating of water and sewer pipes are also required.

- Requirements for illumination of the boiler room - the organization of natural lighting, as well as electric lighting, is mandatory. The minimum illumination values are 0.03 m2 of translucent glazing per cubic meter of boiler room volume. The smallest boiler room (15 m3) requires a window glazing area of 0.45 m2.

- The requirements for ventilation and air conditioning are standard; the air exchange rate for boiler rooms is standardized = 3 (a complete change of air in the volume of the room three times per hour). Natural ventilation is provided by a window built into the window frame and an air vent in the lower level of the entrance doors. As an option, a window with a mesh is made in the door for ventilation. The area of both the gap and the ventilation window must be at least 0.025 m2.

It is possible to place a gas boiler in a kitchen room, which will require meeting the special requirements of building regulations. As a rule, the most compact models of gas units are installed in kitchens.

To install gas boilers in the kitchen, the standards require:

- Only heating units with a power of up to 30 kW are allowed to be installed in kitchens.

- The unit is installed or hung on brackets on the outer wall of the house. The material of the wall structure is allowed only to group NG (non-combustible); cladding with heat-resistant panels is allowed.

- The dimensions of the premises for boiler rooms are minimum 2.30 meters in height and 15 m3 in volume.

- Lighting requirements - the minimum area of translucent glazing should be 1/3 of the floor area.

- A mandatory device for forced ventilation with mechanical drive is also required for used models of boiler units with closed burners, and when installing chimneys of a coaxial design.

Mounting the chimney of a wall-mounted boiler

The rules for installing a chimney directly depend on the model of the boiler. Atmospheric units with an open firebox operate on natural draft, and structures with a closed combustion device are connected to a coaxial type chimney, in which simultaneous forced air intake and removal of flue gases occurs using a blower fan. The height of the chimney head outlet depends on the distance of the boiler smoke pipe and the location of the ridge or parapet:

- If it is no more than 1.5 m, then the pipe is installed with an elevation of 0.5 m above the parapet/ridge point.

- If the distance is in the range of 1.5-3 m, then its highest point should not be below the parapets.

- If the gap is more than 3 m, the pipe is mounted so that its upper level is located no lower than the line at an angle of 10 degrees from the ridge to the horizon.