Flushing the heating system is a mandatory procedure for high-quality and efficient heating of the house. It is recommended to perform it annually before the hydraulic test. As a last resort, it is necessary to wash it at least once every 2-3 years - this will improve the quality of heating of the premises. We will understand how heating is flushed in order to reduce heating costs and extend the operating time of the entire system as a whole.

You can get rid of scale on pipes even in very advanced cases Source teplo.24bkd.by

Causes of pollution

The main reason is the formation of various debris in the pipeline and directly in the batteries. As a result, the radiators do not work properly and the house does not warm up well.

Often the signal to carry out work is that most of the radiators do not heat well. This is due to several reasons:

- the radiators are filled with air, and it is necessary to bleed air through the Mayevsky taps;

- the system is clogged with dirt.

Determine this so as not to do unnecessary work.

Attention! If the system has been operating for a very long time and consists of a conventional metal pipeline and cast iron batteries, then this prevention is very useful, although there have been cases where even after 10 years of operation, the pipes were not clogged with debris.

There are many reasons for pipe contamination, but they all lead to a decrease in throughput. Source strojdvor.ru

Cleaning production sequence

- During the cleaning period, the heating structure is switched off from the block line using dampers, and if they are low in saturation, auxiliary shutters are installed made of sheet iron no less than three mm thick;

- Elastic hoses (rubber hoses) are connected to the cleaning fittings using half-nuts. It is mandatory to provide reversing valves at the cold water and medium inputs;

- The work is carried out after removing the nozzle from the elevator;

Pipe testing must be carried out in compliance with the following key requirements:

- Test p must be provided at the top location (marking) of the pipelines; t water during tests should be no more than 45-46 g. air is completely eliminated through air exhaust devices in the upper segments;

- P is brought to serviceable condition and maintained after the period required for inspection of all welded and flanged connections, fittings, equipment, mechanisms, but not less than ten minutes;

- If after this time no inconsistencies are found, p is brought to the experimental level;

Frequency of cleaning the heating system

Poor heating of the batteries and extraneous sounds during their operation are the most common signals about the need to clean the pipelines. The frequency of this procedure depends on the following factors:

- temperatures during system operation;

- composition of the liquid flowing through the system;

- battery materials;

- pipeline materials.

The first cleaning is carried out immediately after the installation work on the pipeline and radiators. Further, the frequency of flushing the heating system, according to the standards, is as follows:

- for PVC products once a year before starting the boiler;

- for iron products - before and after the operation of pipes and radiators.

The choice of cleaning option depends on the materials used, as well as the overall operating period of the heating devices. Proper flushing of the heating system, regulatory documents and procedure are specified in SNiP 3.05.01-85.

Timely cleaning of pipes will preserve the integrity of individual elements of the system Source ytimg.com

Pricing

To establish an approximate price for cleaning, professionals should list the class and dimensions of the heating line, the products from which it is installed, the volume and method of connected equipment. Also, like the pricing of the heating point itself, the most accurate cost can be established only after the initial activity (testing).

When compiling the calculation and calculating a single price, the cost of depreciation of equipment, the price category of reagents and their neutralization, cleaning along with pressure testing of the heating structure and other work (including invisible ones) at appropriate prices, fuel costs and other probable expenses are taken into account.

Stages of mechanical flushing

Directly flushing the heating system in a private house or apartment is a long and labor-intensive procedure:

- The coolant is removed from the system. If this is a house, then there are no problems, but for high-rise buildings you will need access to the basement, which is often closed. Before calling a specialist, you need to take care of this in advance.

- The pipes are disconnected from the radiators. Sometimes you just can’t remove them; you need to heat the coupling with a cutter.

- When the radiator is removed, you need to visually assess its condition, since to speed up the work, mechanical cleaning may first be required.

- The battery is turned upside down and the hole at the bottom is closed. Water is poured into the device right up to the “neck” and drained using the bottom hole. The liquid should flow out, taking with it all the dirt. The process must be repeated until the water comes out clear.

Mechanical flushing is best done outdoors Source gidroguru.com

It is necessary to rotate the radiator because the coolant, moving through it, leaves scale-like growths, and by pouring the liquid in the opposite direction, the surface is cleaned more effectively. If there is a lot of dirt and this option is ineffective, it is necessary to use special acidic agents.

Attention! These acids must not be used for aluminum radiators.

In general, preparations need to be made before the process.

- Inspect all structures and heating pipes;

- Identify sections of the pipeline (risers, their discharges) that should be cleaned separately, then divided into stages;

- If necessary, install shut-off fittings to close fragments of the pipeline route and remove washed out deposits from the OS;

- Calculate the costs of the sphere and water to obtain the desired result after cleaning;

- Determine the need for hydrotesting (pressure testing) of the heating pipeline;

After completing the preparation, the above work is performed until the water and air connection is clarified.

However, hydropneumatic flushing can be done with your own hands in the following order:

- The heating pipes are gradually filled with water. Important points - 1. In a structure that has 1-2 tiers, there is no need to increase the pressure. 2. If an inspection is carried out in the MKD, the injector increases the pressure to the required values;

- The configuration filled with water is kept under pressure after 30 minutes. During this moment, the debitometer can simply identify the locations of leaks. If the arrow has moved and p has dropped, it means that leakage in the structure predominates;

- After a leak is detected, the water is drained (in full or not), the leaks are eliminated, and the procedure is repeated;

Select a calculator to calculate the cost of work

- Calculation of the cost of a contract for hydraulic testing

- Calculation of the cost of chemical flushing of the heat exchanger

- Calculation of the cost of maintenance (TO) of ITP and TsTP

- Calculation of the cost of installing UUTE

- Calculation of the cost of designing a heating point

- Calculation of the cost of operating engineering systems

- Calculation of the cost of chemical flushing of central heating pipelines

- Calculation of the cost of diagnosing pipeline damage

Cleaning methods without disassembly

There are methods that can simplify the procedure. Here are several options for flushing the heating system without disassembling it:

- Dispersed cleaning . This method can be used for any materials. Cleaning can be done even with the heating running, and the liquid is drained into a cesspool or sewer in the house;

- Chemical method . In this case, alkalis and solutions are used. This is an excellent and cheap option, but is not applicable for non-ferrous metals;

- Electrohydropulse cleaning . Thanks to an electric discharge, scale is removed from the coolant without deforming the pipeline itself;

Sometimes it is very difficult to unscrew the battery, so it makes sense to choose cleaning methods without disassembly Source ytimg.com

See also: Catalog of companies that specialize in water supply, sewerage and related work

- Pneumohydropulse method . Cleaning is carried out by repeated action of impulses created by special devices;

- Hydropneumatic flushing of the heating system . Scale is removed using thin jets of water supplied under pressure through a special nozzle.

Disperse cleaning

This cleaning resembles a chemical option, but the composition does not come into contact with pipes and batteries, but acts on scale molecularly. Thus, the product almost does not reach the surface of the devices, but only affects the growths, which are crushed and then go into the sewer.

Advantages of the method:

- the high efficiency of this option in contrast to other methods of cleaning the system;

- safety for the external environment, cleaning stations and equipment;

- improvement of the hydraulic performance of the system due to the appearance of a hydrophobic film inside the pipeline, which for a long time protects the surface from the formation of growths;

- does not affect the structure of metal or plastic;

- You can clean equipment made of any material, including aluminum.

Disperse cleaning is not particularly difficult Source samstroy.com

Dry cleaning

This cleaning option involves the use of chemical or biological products.

The flushing method using biological products is more environmentally friendly and effective. It is based on the principle of introducing biological compounds into the system, after which the splitting of the growths begins. This technology does not require disconnecting the batteries or disassembling them.

An undoubted advantage of cleaning with biological agents is that it can be painlessly used in old heating systems; all cleaning products are water-based.

Attention! The required effect will be achieved in 2-3 days.

The chemical cleaning method consists in the action of the product on contamination and its removal by dissolving the growths. These drugs act on scale, which subsequently comes out of the heating pipes simultaneously with the coolant flow.

The most common means are:

- DOCKER TERMO (not for use on non-ferrous metals).

- Metalin (not suitable for aluminum).

- Master Boiler Power (can be used for any materials).

- Compositions "SP" (selected taking into account the instructions on the packaging).

Cleaning batteries requires special equipment Source vodakanazer.ru

The main significant disadvantage of the chemical cleaning method is the difficulty in choosing the right amount of product. The possibility of its use is also complicated by the fact that most often the main parts of the heating system are made of different materials. Chemical compounds have a special effect on both metal and plastic products.

Configuration testing

To determine the need for hydropneumatic flushing of the central heating system, you need to perform an initial examination. It can be done at home, without resorting to the service of expensive workers. Only based on the results of the research can the issue of performing the operation be resolved. In addition, following the implementation of regulatory requirements, the heating structure must be subjected to anti-corrosion treatment - this will perfectly protect the walls of the pipes for the subsequent operational period.

The main circumstances that the heating infrastructure needs this operation are evidenced by the following signs:

- If the heating boiler produces unusual noises that were not there before;

- The time it takes to warm up the configuration to the operating position is greatly increased;

- The most important circumstance is considered to be the irregular heating of heating components. For example, if the pipes are hot to the touch, and the batteries are somewhat colder, you need to urgently clean them;

- A side effect of the blockage is an increase in energy consumption when the same temperature is reached and in the same external weather;

Video description

Flushing batteries hydropneumatically is shown in detail in this video:

Hydrodynamic method

The essence of this washing is the active action of water on the growths. When the required section of the pipeline is selected, a stream of pressurized water is directed at it. The liquid comes out of a special nozzle of the required cross-section.

When deciding how to flush the heating system in a private house, consisting of cast iron elements, it is recommended to choose the hydrodynamic option. It is quite difficult to remove deposits from this metal using chemicals.

One of the main advantages of the cleaning method is environmental friendliness. This is due to the fact that only water is involved in the process, and not alkalis and acidic preparations. To achieve the required result, special equipment is used that allows you to create a pressure of more than 250 atm.

Using a special product, the layer to be removed is softened. And only then the surfaces of the system begin to be processed.

The operating principle of hydrodynamic cleaning Source tildacdn.com

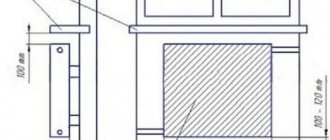

During the work, a pneumatic gun is used, which efficiently cleans radiators and a pipeline about 50 meters long. The equipment can only be used with pipe diameters of no more than 15 cm. The device is small in size and quite easy to use.

The main advantage of a pneumatic gun is that it successfully performs spot cleaning of all elements and allows you to touch the most inaccessible areas. During hydropneumatic cleaning, it is not necessary to disconnect heating devices from the system, which is also important.

What is better to fill - antifreeze or water?

The most common method is to fill the heating volume with water, but recently, especially for small house systems, antifreeze is increasingly being used, which has many advantages (except for the relatively high price, of course).

It should be taken into account that water as a coolant also requires costs - it must be prepared (remove salts and oxygen) before filling the heating volume with it, and cold water treatment systems and reagents for them cost some money.

If you use water as a coolant, keep in mind that liquid from the water supply is least suitable for this purpose. It contains calcium salts and other substances that cause deposits on pipeline elements. In addition, tap water is characterized by a large volume of dissolved oxygen. To prepare it, it is advisable to use special chemical water treatment plants.

So the decision to use a special liquid as a coolant is justified in many cases.

Briefly about the main thing

To maintain the efficiency of heating quality, a number of rules must be followed:

- Avoid using unprepared liquid as a coolant. In its simplest form, preparation involves boiling. This way the amount of salts is significantly reduced. But it is more effective to purchase specially created inhibitors that reduce the activity of corrosive processes. When choosing them, you need to make sure that the composition and material of the surfaces match.

- Know when heating systems are flushed and strictly follow the main steps.

- Coarse filters must be installed on heating lines. They are mounted in such a way that the pipe faces down. This will make it easier to clean, since all dirt is drained simultaneously with water.

- When choosing a contractor company, pay attention to companies that provide a guarantee for the activities carried out.

The heating system is cleaned by the company's professional staff within one day. Therefore, you should not neglect this service. The result will be a constant comfortable temperature in all rooms, as well as significant savings on heating.

How to calculate the volume of coolant

To select equipment for water treatment (to select the rate at which replenishment flow occurs, and therefore calculate the speed of its operation), or when using antifreeze or imported water as a coolant, you need to know the volume size of your heating system. How to calculate it?

- We find or make a specification for the heating system of your home (you need to know all the elements, their quantity and the diameter of the pipes);

- The volume of water in the boiler itself (G), in the radiator section (P) and in the expansion tank (O) is found in passports or catalogs;

- In order to calculate the volume that liquid occupies in pipes, we use special reference books that indicate the volume of water in one linear meter (D) depending on the diameter;

- We find the volume using the formula O+G+(P*c)+(D*z) . where c is the number of radiator sections, z is the number of linear meters of pipe;

- Although water or antifreeze is an incompressible liquid, the calculation still has some error, so we add 10-15% of the reserve.

The essence and types of crimping

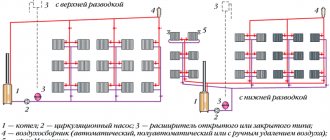

Nowadays heating is most often carried out by a “water circuit” system. At the same time, heated water circulates through the works, imparting its thermal energy to the premises. Leaks are unacceptable; the pipeline must be completely sealed for normal operation. Pressure testing specifically creates a larger volume in the pipe than normal.

When this is done using air, it is called pneumatic pressing.

When using water, then hydropressing. The latter method is considered safer and therefore more popular. For this reason, an example of hydropressing is provided as a form.

When testing, it is recommended not to exceed the pressure inside the pipe more than 15 MPa. If we are talking about raising pressure with water, then there are limitations. The maximum possible pressure should not exceed the normal operating pressure by more than 30%.

In multi-storey buildings they resort to pneumatic pressure testing if the pipes are very old and there is a risk of flooding. But then there is a level of risk and all residents must be notified of the tests being carried out.

The work process is simple, but multi-stage. The algorithm looks like this:

- The necessary materials and equipment are being prepared.

- Draining the liquid that was previously in the heating system.

- Uploading a new one.

- Create the highest possible test pressure.

- Taking control measurements after 10 minutes.

- Flushing, adjusting the heating system to normal pressure levels inside.

- Documentation of work performed, generation of reports and acts.

But this is how the list of procedures looks only if there are no “thin spots” in the heating system and, accordingly, the tightness in it is not broken. If the pressure drops quickly and does not hold, then the system needs repair work. In such a situation, the specialist performs the necessary actions (replacing the pipe, sealing connections, cleaning, etc.), and then begins crimping from the very beginning. Only a heating system that has passed the test is allowed into the heating season.

Important nuance! Pressure testing should be carried out after cleaning and flushing the pipes. Otherwise, salt and other deposits inside them can mask possible external damage and breakthroughs.

If there are deposits of about 1 cm on the inner surface, then this reduces the overall heat transfer and efficiency by 15 percent or more of the overall indicators. To document the cleaning, a special report is also drawn up.

Hydraulic test parameters

When checking the quality of a pipeline, it is necessary to determine the indicators of the following work parameters:

- Pressure.

- Temperatures.

- Holding time.

The lower limit of the test pressure is calculated using the following formula: Ph = KhP

. The upper limit should not exceed the sum of the total membrane and bending stresses, which will reach 1.7 Th. The formula is deciphered as follows:

- P – design pressure, the parameters of which are provided by the manufacturer, or operating pressure if tests are carried out after installation;

- Th – rated voltage that is allowed at test temperature Th;

- T – permissible stress at design temperature T;

- Kh is a conditional coefficient that takes different values for different objects. When checking pipelines, it is equal to 1.25.

The water temperature should not fall below 5˚C and not rise above 40˚C. The only exceptions are those cases when the temperature of the hydraulic component is indicated in the technical conditions of the object under study. Be that as it may, the air temperature during the test should not fall below the same 5˚C.

The holding time must be specified in the design documentation for the facility. It should not be less than 5 minutes. If exact parameters are not provided, then the holding time is calculated based on the thickness of the pipeline walls. For example, with a thickness of up to 50 mm, a pressure test lasts at least 10 minutes, with a thickness over 100 mm - at least 30 minutes.

Testing of fire hydrants and water supply lines

A hydrant is equipment responsible for quickly eliminating fire ignitions, so it must always be in working condition. The main task of fire hydrants is to provide the optimal amount of water to fight a fire at its initial stage.