In any heating systems used for heating individual cottages and dachas, mud deposits accumulate over time, interfering with their functioning. To bring them to a state of operation with the best efficiency, flushing the heating system in a private house is used.

Typically, many homeowners perform these procedures with their own hands without calling specialists. In this case, they should know the various options and technology for carrying out the work, and the equipment used.

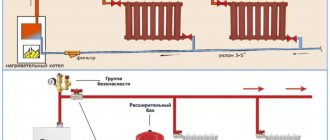

Rice. 1 Main components and diagram of a domestic heating system for a private house

Causes of blockages in domestic heating systems

Typically, ordinary distilled water or antifreeze circulates through the heating circuit, which carries dirt. The immediate appearance of mud deposits can be caused by the following reasons:

- In some heating systems of a closed or open type, replenishment and replenishment of the coolant is carried out by supplying water from the water main. Since ordinary water contains salts of various metals, when it is heated, scale forms, which reduces the efficiency of the entire system.

- The popular antifreezes used, ethylene glycol and propylene glycol, have a limited service life. When it is exceeded, the liquid decomposes with the formation of solid sedimentary fractions, leading to unpleasant consequences.

- If the operating temperature of antifreeze is exceeded in the event of emergency situations associated with equipment malfunction, the heating fluid may lose its initial physical and chemical parameters with the formation of an insoluble precipitate.

- The use of low-quality homemade antifreeze leads to the fact that they disintegrate with the formation of solid deposits.

- A large number of heating boilers contain heating elements made of steel and cast iron. Since these metals are subject to corrosive decomposition, the resulting rust leads to a decrease in the performance of the entire heating system of the house.

- Some heating circuits use galvanized or regular steel piping. The pipe material deteriorates over time, and the rust formed as a result of these processes leads to a decrease in the flow area of the channel and, accordingly, a decrease in the efficiency of the entire system.

- Sometimes colonies of bacteria form in a heating system without drained coolant or when it operates at low temperatures. Their reproduction leads to blockages and destruction of metals by waste products.

Rice. 2 Examples of the location of blockages in radiators and their type

How do you know when rinsing is necessary?

You will understand that flushing the heating systems in a private home will be necessary when you see the following signs in operation:

- the temperature regime in the house has decreased, although the boiler does not stop working stably;

- pipes become warmer slower;

- heating elements heat up unevenly;

- the pipes are hot and the radiators are cold;

- Fistulas in the pipes often began to appear, and ruptures occurred.

The appearance of at least one of these signs indicates that the heating system is clogged.

Signs that a flush is needed

The following factors may indicate the need for flushing:

- Filters are dirty. A properly assembled heating circuit must contain coarse filters in a transparent flask. In this case, intense contamination of the cartridge indicates the need to flush the heating circuit.

- A signal about the need for flushing can be the low temperature of radiators, heated floor circuits, or their prolonged heating.

- Increased electricity consumption by a heating boiler for heating premises in comparison with the previous period indicates the formation of a layer of scale on its heat exchanger.

Signs of scale on the inner surface of pipes

The main reason to think that heating radiators need to be flushed is the appearance of the following signs:

- increasing energy consumption to achieve the usual indoor temperature;

- noticeable to the touch difference in temperature of radiators and pipes suitable for them;

- uneven heating of radiators, when their upper part becomes much hotter than the lower;

- when the heating boiler is operating, extraneous noise or crackling appears;

- increased heating time for the heating system.

Details on how to flush a well with your own hands: causes of blockage, cleaning options, prices.

How to clean soot from a boiler at home: step-by-step instructions.

How to make a two-pipe heating system for a private house with your own hands.

Contamination may also appear after replacing radiators. In this case, their source becomes unnoticed debris in new batteries.

DIY washing equipment

A properly designed heating system should have a threaded pipe with a ball valve at the very bottom of the pipeline to drain the coolant. Usually, heating fluid is poured through it, screwing a flexible liner to the fitting.

For supply, use any plastic containers, hoses and an electric water pump. Typically, inexpensive vibration pumps are used as pumping equipment. In their absence, you can use pumping stations or surface circulation electric pumps, their downhole submersible analogues.

Many specialists use special pressure testing machines to fill the heating fluid circuit. There are a number of other options for supplying liquid to the pipeline using hand pumps.

Sometimes situations arise when the passage channel of the heating circuit is completely clogged. In this case, they call specialists who carry out cleaning using special equipment - compressors, pneumatic guns, high-pressure units.

Rice. 3 Pumping units with tanks for professional hydrochemical washing

Related article:

What should be the pressure in the heating system, how to increase or decrease it . On our website there is a separate article describing the pressure standards in the heating system in a private house and in a city apartment, as well as how to increase or decrease it. Read it, it might be interesting and relevant.

Powders

G63

The powder removes scale from the heating system. The finished solution is compatible with cast iron, metal, and aluminum surfaces. When saturated with scale, the solution turns brown. The product is used in a concentration of 25–100 g/l of water. Washing is carried out at a temperature of 30...40 °C.

Price: from 61$/2 kg.

Descaling powder - G63

pros

- with corrosion inhibitor;

- contains a scale saturation indicator;

- suitable for steel;

- The line includes an acidity neutralizer;

- contour processing in 45 minutes.

Minuses

high price.

SteelTEX ZINC

The drug is compatible with most metals used in heating systems, enameled surfaces and zinc. Before pouring the finished solution into the system, mix it with water until a concentration of 7–15% is achieved; more powder is added during the washing process. The composition includes an indicator of residual acidity. It is recommended to use it with a neutralizer of the same line, which will enhance protection against metal oxidation.

Price: from 4557 rub./5 kg.

SteelTEX ZINC

pros

- the solution can be poured into the sewer;

- compatible with most metal surfaces;

- anti-corrosion protection.

Minuses

No.

SteelTEX ZINC

Flushing the heating system in a private home - options

When choosing a system cleaning option, first of all pay attention to the type of contamination. If cleaning the house is done with chemical reagents, the materials used to make the pipeline and radiators are important.

Hot water

Typically, this method is used to clean the heating circuit when replacing antifreeze that has expired - ethylene glycol, propylene glycol, glycerin.

In this case, the liquid is drained, the filters are washed, and then water is pumped into the circuit under a working pressure of 1 - 1.5 bar. Next, turn on the boiler to the operating or maximum heating temperature, and force the water to move along the circuit using an electric circulation pump.

After some time, the water is drained, after which the circuit is filled with non-freezing liquid.

Rice. 4 Types of flushing fluids

Chemical reagents

One of the most widely used methods for flushing the heating system in a private home is the use of chemicals. Usually they are an acid or alkali dissolved in ordinary water.

It is worth noting that the main sources of pollution are metal corrosion products. Since acids work best with rust, they are used much more often for flushing heating systems than aggressive alkalis. The recommended content of the most commonly used hydrochloric or sulfuric acids in washing solutions is from 3 to 10%.

Price issue

From a financial point of view, the least burdensome way to clean your heating system is to do all the work yourself. In this case, the total costs will not exceed several hundred rubles. You will have to purchase consumables and tools:

- brush,

- brush,

- sealing tape or linen.

If you order cleaning from a specialized company, the cost of the work will depend on the technology chosen.

As a rule, comprehensive cleaning will cost from 6,000-8,000 rubles.

Washing one heating battery - from 800 rubles. This cost will include both the work itself and the solution of organizational issues: how to flush the heat exchanger at home, what technology will be used, etc.

How to prevent contamination of your home heating system

To avoid frequent contamination, blockages of household heating systems and associated cleanings, it is useful to pay attention to the following expert advice:

- The main enemy of steel radiator, bimetallic (they have a steel pipe manifold inside) heat exchangers and heating elements of boilers is oxygen dissolved in water. Pipelines made of any metals do not allow it to pass through, but popular polypropylene is not a barrier for it. Therefore, it is unacceptable to use polypropylene or fiberglass-reinforced heating pipes in the system with any type of steel components. The pipeline must be made of metal-plastic or polypropylene reinforced with aluminum. Cross-linked or heat-resistant polyethylene used in heated floors must have an oxygen-impermeable EVOH shell (copolymer of ethylene and vinyl alcohol).

- Tap water entering the heating boiler feed system must be cleaned of metal salts - when the coolant is heated, they form a deposit in the form of scale. To do this, it is advisable to install a filter with ion exchange resins in the path of the recharge flow.

- Any thermal carrier loses its chemical activity over time due to a decrease in the oxygen concentration in its environment. Therefore, replacing it too frequently is not recommended. For example, ordinary water does not lose its properties and can circulate in the circuit for an indefinitely long period of time, being cleaned using self-washing filters with polypropylene cartridges.

Rice. 12 Selection table for some brands of washing reagents

The simplest and most effective way to independently flush individual heating systems is to use commercially produced chemical solutions. The cleaning procedure can be carried out both with individual elements (radiators, boilers) and with a closed heating circuit if the materials of all components match.

Causes of pollution

Corrosion is considered to be a common cause of clogging of iron lines. It accumulates in the middle of the system and does not allow fluid to circulate freely. As a result, interruptions occur in the operation of heating systems.

Plastic pipes do not rust, but scale can still form on the walls, which also interferes with the constant operation of the heating system.

Also, the appearance of contaminants is influenced to a certain extent by the quality of water, which contains various impurities.

Therefore, it is necessary to distinguish the following types of blockages:

Heat exchanger flushing frequency

If the system does not have a filter, the heat exchanger needs to be cleaned every 2 years

The frequency of cleaning heat exchangers is specified in the operating instructions supplied with the product. Most manufacturers recommend doing this every 2 years. However, if water saturated with lime is used, a thick layer of plaque can boil in just one heating season, even if the boiler has a stainless steel circuit. When a filtration system is installed in the harness, the procedure can be carried out at intervals of 4-5 years. Water needs to be changed annually, as it changes its structure and acquires properties that are aggressive towards metal.

It is best to calculate the required frequency of cleaning the heat exchanger experimentally. After the end of the heating season, you need to disassemble the boiler, remove the circuit and assess its condition. The plaque will tell you how long it will take for its thickness to reach a critical state.

How to clean heating pipes

Cleaning heating pipes and radiators is carried out in several ways:

- chemicals;

- dispersion agents;

- water under pressure;

- pneumonic impulses.

Chemical and dispersion cleaning agents are liquids for heating pipes with different characteristics. Chemicals corrode everything, even the walls of the circuit, so a leak often appears after flushing. Dispersive agents for flushing heating pipes only act on the contamination itself. At the same time, polymer products tolerate chemical cleaning quite well, some of them can even transport acid. Heating pipes are cleaned using special pumps into which liquid is poured.

After completing the work, the liquid for flushing heating pipes cannot be immediately poured into the sewer; a neutralizing agent must first be added to it.

You will also need special equipment to flush heating pipes with water under pressure. The idea is to remove plaque with a jet of water. A more interesting method of pulse cleaning. A gun is connected to the compressor, which creates pulses at a certain frequency. They, like small explosions, separate the scale from the walls layer by layer. First, pulses are created, then the circuit is flushed. The procedure is repeated several times until the water is clean, or approximately clean.

Consequences of clogging

Regardless of the source of the blockage in the heating pipe, the outcome is almost always the same:

- after a certain point the pipes become clogged;

- the movement of water in the pipes decreases and later even the water pump will not be able to pump water through this system.

The situation is much worse with thermosyphon heating, where there is no such pump. As a rule, once clogged, heat is not allowed to pass through and the pipes remain cold. And this is only part of the problem. In addition, the boiler itself begins to heat up very much, which can lead to its breakdown.

Some owners carry out annual cleaning of blockages in such a system by changing the water. In other words, the old unclean, rusty water is drained and filled with new water. And this is reasonable, because when the old water is drained, a small amount of chips and rust leaves it. But there is also the opposite side. For rust to occur, iron and oxygen are required. If the pipe is metal, then there is always iron in it, but oxygen is contained in the water. As a rule, when you do not change the fluid in the heating system for a long time, the oxygen content in it decreases significantly, which means that the rusting process stops. With a constant change of water, on the contrary, it is activated. To summarize, we can say one thing - this method helps to get rid of a small amount of rust, but, on the other hand, we only accelerate the new process of its formation.

What causes pollution?

The main source of clogging that slows down the operation of heating units is the coolant. In the role of which tap water is used. When filling pipelines, small grains of sand and deposits enter with water and eventually settle on the walls of the radiators.

The second reason is scale. It occurs in the heat exchanger through contact of water with the hot walls of the boiler. Over time, the resulting layer covers the inner surface of the heating equipment, which subsequently negatively affects the output of thermal energy. If you do not periodically flush the system, scale can clog the channels of pipelines and radiators. Such consequences will lead to serious repairs and large financial costs.

Another main reason for low efficiency is the formation of rust on the walls of metal pipes. This occurs due to the high content of oxygen and salts in the water.

Instead of an epilogue

Currently, purchasing a cleaner for the heating system does not present any difficulty - you can find it in any hardware store. The main thing is to choose the right type so that it can come into contact with the material of the pipeline being processed without negative consequences. You should also carefully study the instructions for use to determine the need to use protective gloves and other equipment. Regarding sources of purchase: experts advise purchasing the cleaner at retail if you need to do a small amount of work. In other cases, it is better to buy products through online platforms, then it will be possible to save on large volumes of packaging.

Chemical flushing of a gas boiler

When chemically flushing a boiler, plaque and scale are removed from contaminated surfaces of boiler equipment and heat exchanger fragments, thanks to treatment with various chemical compounds and reagents. Most often, acid is used for washing boilers, which effectively removes carbonate scale, which is formed when magnesium and calcium salts and ferric iron combine and settle on the surface of the heat exchanger. Chemical washing is a standard, simple procedure that you can do yourself at some intervals. This flushing usually does not require disassembly of the structure.

Chemical cleaning of a gas boiler.

To carry out chemical flushing, you will need a chemical reagent and special equipment called a booster for flushing the heat exchanger. A booster is a device that consists of a tank for a cleaning agent, a pump and a heating element. During the procedure for flushing a gas boiler using a booster, a warm solution is first prepared and introduced into the heat exchange system (for acid flushing).

Thanks to the device, the cleaning reagent circulates and the waste liquid is removed. The acid chemical wash booster can be used on any type of gas boiler and is capable of effectively cleaning any type of boiler equipment. The main difference between a booster and installations that clean steam systems is that the booster does not need to use a heating element, since the cleaning liquid can be heated by the heat exchanger itself.

However, this is unsafe and not as effective, so it is recommended to use boosters that have heating elements, which allows you to use a solution of the same temperature and act on different parts of the heat exchanger with the same efficiency.

Gas boiler system diagram.

Acid washing is used to remove carbonate scale or ferric scale. The main reagents that are included in these solutions are sulfuric or hydrochloric acids; phosphoric or nitric acids are less commonly used. The reagent is selected depending on the type of contamination and the abundance of scale; the materials from which the heat exchanger and boiler are made are also taken into account.

Do-it-yourself flushing of a double-circuit gas boiler is carried out in two stages. At the first stage, an active reagent that has acidic properties is used. Using a reversible pump, it is necessary to create a powerful flow of solution, eroding the layer of deposits that would be affected by the acid.

The procedure takes from 2.5 to 6 hours, depending on how dirty the surfaces of the gas boiler are. When deposits and scale have dissolved, it is necessary to remove the active solution and fill the heat exchanger with a solution that neutralizes the acid residue. If the heat exchanger is made of cast iron, then due to the likelihood of the opposite effect, it is better not to flush the boiler with your own hands.