The main element of a gas boiler is the burner. It is around it that all other elements are displayed. Many aspects of the use of the equipment depend on the design of the node. First of all, it is safety and efficiency. Therefore, many people want to make a gas burner for the boiler with their own hands, which will meet all the requirements of the owners. At first glance, this may seem like a complicated process, but in reality it is not.

Homemade gas burners

The main components in the manufacture of powerful gas burners are industrial valves. They may be new, but for a homemade device it is enough to use used ones if there is no gas leak. They are designed to work in tandem with a 50-liter propane gas cylinder, which has an angle valve and a reducer.

Burner with valve VK-74

The structure of this burner is shown in Fig. 1. The oxygen cylinder valve VK-74 is used as a basis. A fitting-handle machined on a lathe is installed at the outlet end, to the corrugated part of which the hose from the cylinder is connected. A cap with a prepared hole with a thread for the nozzle is screwed onto the part of the valve with a conical thread K3/4˝, with which it was connected to the gas cylinder. You can use a ready-made blowtorch or gas stove.

The nozzle is made from a piece of 1/4˝ steel pipe 100 mm long and welded to the cap on two pieces of ∅5 mm wire. A distance of 15 mm should be left between the cap and the nozzle to allow air to enter the combustion zone. The position of the nozzle is adjusted by bending the wire holders to achieve a central flame position.

Sequence of actions to ignite the burner:

- Open the cylinder valve;

- Place a lit match near the nozzle and slowly open the burner valve;

- Control gas ignition;

- Adjust the flame using the burner valve

A homemade gas burner of this design has one drawback associated with the location of the valve. The gas flow is directed in the opposite direction to the normal position. Stuffing box seals experience constant gas pressure (including when the valve is closed), so it is necessary to constantly monitor the tightness of the seals.

Burner converted from acetylene gas cutter

If you have an acetylene torch with a faulty oxygen supply valve, do not rush to throw it away. It is also suitable for making a burner (Fig. 2). The mixing chamber requires modifications, the contents of which must be removed to reduce weight. The oxygen barrel and valve will need to be removed. Solder the resulting hole with hard solder. Connect the hose coming from the gas cylinder reducer to a fitting with a left-hand thread M16 × 1.5.

Using a union nut, secure a homemade tip bent at 45° to the mixing chamber to make it more convenient to work with the burner. Screw a flange with a nozzle welded to it onto the thread of the tip.

One of the options for such a burner is to use a cap with an M22 × 1.5 thread. The design of the nozzle here is similar to the nozzle of the burner described above. The homemade gas burner is ready for use.

Gas mini burner

Mini gas burners are more suitable for working with small parts. The mini burner is based on a needle for inflating balls. It is necessary to make a cut in it, a little further than the middle of the needle. Some needles already have a similar hole, which significantly speeds up the work process. Next, you need to take the syringe needle and bend it about 45 degrees in the middle.

Mini gas burner design

It is best to sharpen the pointed end of a syringe needle so that it is straight. After this, it needs to be inserted into the ball needle so that one end comes out through the hole, and the other protrudes from the large needle by several mm. The resulting mini structure should be fixed using soldering. After this, droppers must be attached to the bases of the two needles. Clamps - dropper regulators need to be moved as close to the needles as possible. In the resulting burner they will act as gas and air supply regulators. They also need to be fastened together, and this is best done using a heat gun. All that remains is to connect a source of compressed gas to the finished device, the burner is ready for use. This homemade gas burner can heat objects up to 1000 degrees

You should work with it carefully, observing safety precautions

Preparation for the manufacturing process. Regulatory requirements

Consider preparation for the manufacturing process

.

Understanding the device

m of gas burner and having decided on the model, you can move on to the next preliminary stage. Make a list of the necessary materials and tools. The following list can be taken as a basis:

- fuel control valve;

- welding machine, grinder.

- steel tube 100 mm long and with walls 2 mm thick;

- steel cap, piezoelectric element, rubber for handle;

Don't forget about little things like connecting elements. For example, for a valve type VK-74 you need to stock up on a cap with a conical thread.

Now let's take a closer look at the requirements of supervisory authorities

.

A burner for a sauna stove, made on your own, must have a certificate of suitability from Rostechnadzor. When using main gas as fuel, it is necessary to obtain such a document from the gas supply organization. Moreover, a special permit is required for operation.

_

Organization

— refers to legal entities under the legislation of the Russian Federation (except for banks), including organizations whose main activities are financed from the budget.

Certificate

- a written certificate certifying something. (MDS 12-9.2001)

Exploitation

— the stage of an object’s life cycle at which its quality (working state) is implemented, maintained and restored. (GOST R 51617-2000)

The following requirements apply to installing an atmospheric model in a bathhouse:

- compliance with fire safety measures;

- the top of the pipe is equipped with a spark arrester;

- the pipe is insulated from the ceiling and roof.

- good adjustable traction;

- availability of proper ventilation;

- minimum bath volume 12 m3;

_

Ventilation

- exchange of air in rooms to remove excess heat, moisture, harmful and other substances in order to ensure acceptable meteorological conditions and air purity in the serviced or working area with an average lack of supply of 400 hours / year - for round-the-clock work and 300 hours / year - for single-shift work during the daytime. (SNiP 2.04.05-91)

Roof

- the top element of the covering that protects the building from the penetration of atmospheric precipitation. (SNiP II-26-76); - the top element of the covering that protects the building from precipitation. (VSN 35-77)

Cylinders can be placed in a special metal cabinet separate from the bathhouse. Gas tanks are located in an underground container at a distance of more than 5 meters from the bathhouse. The connecting pipes must be checked by a specialist for leaks. They are made of steel, copper and other non-combustible materials.

It is better not to install a homemade burner without permission from the authorized bodies, as practice shows. It's too risky in terms of security.

Having received permission to operate and all instructions, you should ensure measures to comply with the normal operating mode of the homemade sauna

. If necessary, clean the chimney and strengthen the insulation. It is necessary to periodically check the joints of the burner and the pipeline for leaks.

Keep a special log to track the dynamics of changes in the condition of the equipment. When heating a bathhouse using a homemade nozzle, follow the usual fire safety rules. Write down in it the dates and operations performed to service the elements of the gas unit.

_

Fire safety rules

- a set of provisions establishing pores. compliance with fire safety requirements and standards during the construction and operation of the facility. (GOST 12.1.033-81)

Rule

- a provision describing the actions intended to be performed.

(SNiP 10-01-94) The following article will introduce you to the intricacies of making a gas burner from an ordinary blowtorch, which is worth reading for skilled home craftsmen.

What is a jet (nozzle)

Almost all gas stoves are equipped in such a way that they can operate on both natural gas and propane (from a replaceable cylinder). It should be taken into account that when switching to liquefied gas, it is necessary not only to replace the nozzles, but also to install a reducer, which is responsible for equalizing the pressure of the incoming fuel.

The reducer stabilizes the pressure of bottled gas, ensuring normal operation of the stove. It automatically maintains the pressure parameters necessary for the operation of the equipment and prevents backflow of the medium

A nozzle (nozzle) is a bolt with a hole in the head for supplying gas to the burner. After entering the burner, the gas is mixed with air, and the gas-air mixture is ignited.

The nozzle ensures that gas enters the burner in the required volume and at the appropriate pressure. Its size determines the volume of gas required for the normal combustion process

Depending on the fuel used, nozzles are of two types: for supplying blue fuel from the main pipeline and for supplying gas from a gas holder or cylinder.

Jets (nozzles) for natural gas in comparison with jets for liquefied fuel are characterized by:

- Shortened bolt body;

- Fewer threads;

- Increased hole diameter.

If the stove is not operating correctly, it is best to replace not just one jet, but the entire set at once, and when switching to bottled gas, this is generally a necessity.

Why and why is it necessary to change the jet?

Jets for different types of gas vary significantly, so when changing the type of gas-air mixture, replacing the nozzles is simply necessary

If you pay attention to the diameter of the hole, it becomes obvious that they are not the same. In this case, the diameter of the hole depends not only on the type of gas used, but also on the size of the burner itself

Some time after replacement, negative factors may appear indicating that the stove is not working properly. Don’t rush to change the jet right away; you may be able to limit yourself to cleaning it

Each of the gas stove burners differs in power and size, so for stable operation it is equipped with a separate nozzle.

The diameter of the outlet of each nozzle is calculated for a certain volume of gas supplied from the main line or gas tank

The more powerful the burner, the greater the volume of gas it requires to operate, therefore the diameter of the nozzle is required to be larger.

Choosing a nozzle for bottled gas

As already mentioned, the propane nozzle has a shortened body and a smaller outlet diameter. It is not recommended to try to reduce the hole yourself, since even fractions of millimeters are important here. By eye you can only improve the operation of the stove, but not achieve its ideal operation.

It is important to understand that standard jets simply do not exist. They are designed for each specific model

Modern kitchen stoves are equipped with a set of jets designed to operate on propane. Some models are even produced specifically for bottled gas.

A set of nozzles for a specific model can be purchased at a specialized gas equipment store or directly from a representative of the official supplier

Trouble-shooting

Having a boiler at home brings many advantages, but it also has a number of disadvantages, and the user does not always know what to do correctly. Boiler faults are common to many types

It is important to promptly determine the cause of these faults before calling emergency services. List of the most common and most likely faults

First of all, if the boiler does not start, you need to check the circuit components:

- network voltage;

- faulty boiler fan switch or motor;

- damaged boiler cables;

- false triggering contacts of automation or commissioning equipment;

- availability of water, whether the gas boiler is powered to the minimum required level specified by the equipment manufacturer.

If the boiler failure is not caused by any of these problems, the following procedure:

Pay attention to the noises made by the boiler, because they are often the first witnesses of destruction. They can also be due to hot water trapped inside the firebox or due to the presence of air in the heating system due to clogged air ducts. Pipe rupture

It usually occurs due to problems with a jammed boiler feed valve, various scale-forming deposits in the boiler, or a malfunction of the condensate drainage systems. Failures due to exceeding the pressure and temperature readings, their corresponding sensors can trigger, for example, due to a broken thermometer or, conversely, which is especially dangerous as a result of real overheating of the boiler. The heating circuits are not working, possibly due to poor quality of feed water and scale formation in the boiler pipes. A problem occurs with the burner (flame breaks, gas accumulation causes detonation and explosion).

For some of these problems, mainly pressure or temperature, the boiler monitor displays an error message, then the system shuts down and automatically restarts. If the problem persists after restarting, it is best to call a professional to troubleshoot the problem. It should be noted, however, that most of these failures can be avoided.

The best prevention is to have your boiler inspected, maintained and cleaned annually, usually by a professional. This will prevent the pipes from clogging and bursting. Prevention is better than restoration, and a simple annual inspection will protect the equipment and the health of users from possible emergency situations.

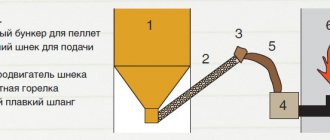

Design of a homemade gas burner

- metal case;

- gearbox;

- nozzle;

- fuel supply regulator;

- head;

- a unit for securing a gas cylinder.

The metal case includes a special glass, with the help of which the mechanism eliminates the possibility of blowing out the flame. This also includes a metal or other handle that does not exceed 100 centimeters. A wooden holder and a gas hose are installed on top of the handle. Using a reducer and a tube with a valve, the gas supply level and its length are adjusted accordingly. The nozzle is used to ignite the fuel, in this case the latter is propane.

Gasoline burner made from a telescopic antenna

Sometimes, when making homemade products, there is a need to heat up, or even melt, some part or material. Many models of burners can be purchased in stores, but what homemaker would not try to make the tool he needs with his own hands. The author of this homemade product decided to make a gasoline burner from scrap materials. Tools and materials indoor TV antenna; baby juice jar with lid; aquarium compressor (external) with hose; drill ; drill; file; soldering iron; nail 120; ball needle; head-key 4.5.

First, the author disassembles the antenna. Having cut off the antenna on both sides, he pulls out the tubes and gets 3 tubes of different lengths and diameters. A through hole with a diameter of 4 mm is drilled in the middle of the largest tube. To make a faucet, the author cuts a 15mm piece from the average diameter of the tube. Drill a 3mm hole at a distance of 5mm from the edge. Places a piece of tube on the nail, close to the head. Marks on the nail where the hole in the tube is located. Marks the cut line 4mm below the tube. Drills a hole with a diameter of 2 mm in the nail. Cuts the nail along the previously marked line. Inserts the faucet into the hole drilled in the large tube. Aligning the holes in both tubes, solders them. To prevent the nail from popping out, a stopper is used. Cutting off a 4mm piece from the middle tube, puts it on a nail inserted into the faucet. Solders the edge of the nail and the cut piece. It is necessary for the nail to turn in the tap. Next, in order not to break it, the author inserts a piece of wire into the thinnest tube and bends it around the can, forming a semicircle of 70-80 degrees. Makes a nozzle. Cuts off the head of a ball needle. Solders the needle at an angle to the semicircular tube. This is done so that the nozzle can then be inserted into a large tube. Mark the hole on the tube with the tap where the nozzle will be inserted, taking into account that the end of the nozzle should stick out from the tube by a couple of millimeters, and the opposite end of the nozzle tube. The excess can be cut off. Having made a hole (not through) inserts the nozzle. If necessary, the edge of the tube can be trimmed. Cuts the edge of the tube into 6 parts and bends them inward. Inserts the opposite end and solders both sides of the tube. Next he makes the burner head. Cutting off 5mm from the key head, expands the hole with a 5mm drill and places it on the nozzle. Makes a container for fuel. Drill two 4mm holes into the lids of the jars - their holes are opposite each other. Inserts a middle tube into one of them so that it does not reach the bottom of the jar by 1 cm. Stepping back 2 cm from the lid, cuts it off. After sawing off another 2.5 cm from the tube, insert it into the second hole in the lid. Solders the tubes to the lid. The tube from the compressor is connected to the long tube of the container, and the burner is connected to the short one. He pours gasoline into the container and, following safety precautions, lights the burner. You can watch the video in more detail. Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Equipment setup

Floor-standing gas boilers with an atmospheric burner can be configured independently. Pressurized systems are regulated by an automatic control unit and do not require additional configuration.

Scheme of actions for setting up single-stage equipment:

- Install the device on the boiler.

- Connect to the gas pipe.

- Check for absolute tightness.

- Remove the burner housing.

- Using a pressure gauge, measure the gas pressure at the inlet.

- Connect to electricity. Make sure that the jumpers and phases are connected correctly.

- Place a gas analyzer in the chimney pipe.

- Start the device.

- Using a pressure gauge, take pressure readings at the outlet of the burner block. Pressure readings must correspond to the parameters indicated in the data sheet.

- Adjust the air flow using the air damper.

- The gas analyzer readings must also comply with all gas equipment installation standards.

Setting up gas equipment should be carried out by specialists. The simplest open-type boilers can be configured independently if you have certain skills and knowledge of the design of the burner unit. The efficiency of the boiler, its level of efficiency, and fuel consumption depend on the quality of the burner. It is possible to superficially determine that the equipment is malfunctioning by the changed burner flame.

A heating system where the main element is a gas stove is a common type of heating for private households and cottages. There are many things in favor of natural gas as a heat source: high efficiency, environmental friendliness, and the ability to make the heating process fully automated. The fuel itself is also the most inexpensive at present, unless, of course, you take into account wind energy and solar radiation. But these methods have not yet found wide demand due to the unaffordable price of the equipment.

The quality of gas heating depends on how efficiently the gas burner for the stove works.

Service Features

Servicing a gas burner involves only one operation - cleaning it.

This should be done annually. Users are not recommended to carry out this procedure on their own, since it requires disassembling the boiler and, accordingly, its correct assembly. Typically, service centers clean burners.

Accumulated dirt is removed by blowing with compressed air. Setting its pressure should be approached with caution: some of the modern burners can be damaged by a pressure of 8 - 10 atm.

To reduce the need for cleaning the burner, a filter should be installed on the gas supply pipe. This can only be done by a specialist from the gas industry, where you need to apply.

Did you know that a modest voltage of 12 volts can also serve as a heat source? Assemble a 12 Volt heater with your own hands and check it yourself - instructions are included in the article.

Why you need an inverter for a heating boiler and how to connect it, you will find out by reading this information.

Purpose and principle of operation

It does NOT matter in which country the tandoor was used, but all these ovens worked on the same principle. Firewood was placed in the lower part of the oven, the ceramic walls retained even heat for a long time, and many different dishes could be cooked inside the oven

When the firewood turns into coal, it is partially removed, and the rolled out dough is placed on the walls of the oven, which after a very short time turns into a fragrant flatbread. The meat is cooked either on skewers like shish kebab, or in ceramic dishes, which are placed on special brick stands installed at the bottom of the oven.

The main advantage of an Asian stove is its ability to maintain a high temperature for a long time with a small amount of fuel. In addition, the food is not fried, but baked inside the oven, retaining all its beneficial properties.

Since ancient times, stoves were buried or built directly in the ground, this allowed them to save building material. But these days, you can choose any type and size of oven, which will cook your favorite dishes many times faster.

Making a nozzle with your own hands

Before you start using a product made at home with your own hands, you need to go through the following procedures:

- The burner must undergo a quality check at the local Rostechnadzor office in accordance with the regulations established in the Federal Law on the Safety of Buildings and Structures dated December 30, 2009.

- After this check, it is necessary to obtain a certificate from Rostekhnadzor regarding the suitability of the burner for operation.

In order to start making the nozzle, you need the following materials:

- A valve that will serve to regulate the fuel supply of the device. To supply gas to the burner, you must use the valve installed on the gas source.

- Steel pipe. It is desirable that it have a thickness of up to 2 mm and a length of up to 100 mm.

- Steel cap for making a fuel dispenser. You can also use a jet from a blowtorch.

- Steel handle. It can be made from a regular fitting.

- Rubber for handle lining.

- Wire. It will be used for welding.

You will also need the following tools:

- Welding machine.

- Grinder for cutting parts.

For homemade production, an atmospheric nozzle is preferable due to the simplicity of its design. The procedure is as follows:

- First, screw the cap onto the valve. For example, if a standard VK-74 valve is used, then the cap has a conical thread.

- Then, by cutting the existing steel pipe with a grinder to the required size, the nozzle of the future nozzle is made - its basis.

- Next, the nozzle is welded to the cap using wire. In this case, the cap and nozzle should not touch.

- A piezoelectric element is installed, which is needed to activate the device.

After this, the product is ready for installation.

Attention! To install a system for supplying fuel to the stove from a central heating system, you need special equipment and experience working with gas systems

Furnace installation

When installing a finished unit in a furnace, take into account what materials it is made of:

The gas nozzle - the heart of the stove - must be of high quality and correctly installed. If this unit malfunctions, fuel-related problems may occur, which can lead to irreversible consequences.

How to properly install a chimney with a gas generator

The easiest option is to install a sandwich pipe in the bathhouse. For a gas stove and boiler, a chimney is needed in the same way as for wood burning. Carbon monoxide will form in the stove and, in the absence of a chimney and good exhaust hood, will accumulate in the steam room. The main danger is that it has neither color nor smell and it is very easy to get poisoned by it.

Modern gas furnaces are equipped with special sensors that, if the exhaust is poor, are triggered and shut off the gas supply. But in order to save money, they buy the cheapest generators for their dacha or garden plot.

A properly organized chimney should have the following components:

- Passage hole in the ceiling.

An umbrella that prevents sparks from hitting the roof of the bathhouse.

For a brick oven, you can assemble a gas pipe. But it will be more difficult to care for it, and installation work will not be cheap. It is easier to install a sandwich pipe.

The structure is easy to install; even a beginner with no prior training can handle it. The joints will be located at the outlet of the furnace, at the joints between the ceiling and the roof.

The sandwich pipe design has a heat-insulating lining, but since the temperature in the bathhouse is always high, the roof and ceiling can still burn out. To avoid this, it is necessary to insulate the ceiling and roof from asbestos fiber or metal sheets.

An umbrella is mounted on top of the pipe. You can do it yourself from an old tin can: cut out the bottom and lid, cut the walls in one place to form a rectangle, and roll it into a cone. It will prevent precipitation from getting inside.

With proper installation of the chimney and equipment, gas in the bathhouse will become a convenient and safe fuel. You can make an iron stove with your own hands. But you need to understand that any little thing can lead to dire consequences. If you are not confident in your knowledge, then it is better to seek the help of specialists.

Heating a private building is one of the main tasks

, which arises in front of people who want to live in a warm and comfortable room.

The use of a stove is still considered a very popular method, the type of which depends on the size of the building, the preferences of the owners and other factors.

.

Types of burners

According to their design and functional differences, burner devices are divided into:

By purpose:

- for high power industrial equipment

- for household equipment.

By type of fuel used:

- devices for natural gas;

- devices for liquefied gas;

- universal devices.

By adjusting the flame:

- single-stage – capable of operating on/off;

- two-stage (as a variation - models with smooth modulation) - operate at full power, when the desired temperature is reached, the flame is reduced by half;

- modulating - boilers with a modulating burner are characterized by smooth adjustment of the flame power.

According to the principle of operation:

- injection/atmospheric. They operate by supplying air from the room. They are installed respectively in open combustion chambers. Also used for old-style boiler models.

- fan/supercharged. They work in isolated combustion chambers. Combustion air is supplied by a fan. According to their design features, they are divided into: - vortex (round-shaped nozzle holes) - direct-flow (shape of a narrow slot with a round/rectangular cross-section).

- diffuse-kenetic. Air enters two simultaneously: one is mixed with gas fuel, the second is added directly to the chamber during combustion.

Oven nozzle

Gas stove burner is used to burn gaseous fuels such as gas. They are available as atmospheric or pulse burners. When comparing the two systems, especially the blower burners provide very clean and efficient combustion of gas products in all power ranges by precisely controlling the supply of fuel and combustion air.

Modern and compact heaters currently use mainly flat burners, in which the flame is distributed over several nozzles over a larger area. The operator's hand makes the combustion particularly efficient and also cleaner due to the lower temperature. Particularly favorable and clean is the so-called catalytic combustion, in which the gas enters into a chemical oxidation reaction on the surface of the catalyst with oxygen from the air. This process does not require conventional ignition and is characterized by a very low flame temperature.

Operating principle and differences of gas equipment

You cannot objectively judge the quality of the purchased injector. Do not disassemble the finished product in search of possible defects. So there is a chance to damage rather than check an expensive device.

By assembling each element of the burner yourself, you will receive not only pleasant satisfaction from the work done, but also savings. At the same time, the operation and repair of gas bath equipment will become safe and conscious.

The heating gas unit is a sauna stove body with a gas supply device located in it. Here are the main elements of the control mechanism with which the fuel supply is regulated.

The burner heats the air in the firebox. The thermal energy of the nozzle is transferred through the body to the tray with stones

A heating stove with a gas nozzle requires special attention to the chimney, which must be cleaned periodically.

The advantages of heating water and sauna stones with a gas burner include:

- Simplicity of the workflow. To heat up, just turn the valve and ignite the gas in the burner. In an hour, the steam room of the bathhouse will be sufficiently heated.

- Environmentally friendly. During operation of a gas device, harmful emissions during gas combustion have the smallest volume compared to other types of fuel.

- Ease of maintenance of the burner and the stove itself. There is no need to deal with soot from walls and remove waste, as with coal or firewood.

You can equip the oven with special sensors that are triggered at a critically low exhaust speed. In this case, the gas supply is automatically turned off.

Inexpensive fuel from a gasified stove allows you to not limit the number of bath procedures. Even with daily heating of the bathhouse, maintaining cleanliness becomes very easy

Such a disadvantage of a homemade burner, such as additional registration of technical permits, pays off due to high productivity. Using a gas injector will save 30% costs compared to solid fuels. Heating a sauna with gas is two times cheaper than using an electric boiler.

Types of stoves for gas heating

Gas stoves are often used for heating residential premises, but they are mainly widespread in the construction of baths. As a rule, these are ready-made factory models in metal cases, designed for certain operating conditions, taking into account design calculations. Brick analogs are also assembled for gas.

By heat generation method

Based on the method of generating heat, furnaces are divided into two main types:

- with combustion chamber,

- with heat exchanger.

In the first case, gaseous fuel enters the refractory chamber, where, when burned, it heats its walls. The temperature of the air rises as it passes through the holes in the casing and comes into contact with the outer surface of the chamber. The second option is heating gas stoves for the home, which are often also called “heaters”. In such designs, burning gas is supplied to a curved heat-resistant steel pipe, which also serves as a heat exchanger.

This type of furnace is equipped with a forced air supply and forced removal of combustion products. It can be installed both vertically and horizontally

By heat capacity

Like solid fuel heating devices, gas units can differ in heat capacity. It all depends on the furnace’s ability to accumulate thermal energy. On this basis, gas stoves for the home are classified into stoves:

- constant burning,

- periodic combustion.

Constant burning furnace equipment does not have thick walls and cools quickly. But at the same time, it quickly heats the room, since the air receives energy from the heated thin walls without any obstacles. To ensure a stable temperature regime, the stove must always be “on”. This is a suitable gas stove for a summer house, where people come from time to time, and they need to quickly heat the house to a comfortable temperature.

Periodic combustion systems have a heat-intensive mass, which, when heated, then (after stopping the gas supply) releases heat for some time. To create an accumulating array, clay bricks are usually used, which can be used to line channels, line the combustion chamber, and also make simple heating shields. By the way, due to their high calorific value, gas sauna stoves can heat a large mass of stones and “work” for heating for several hours - this is a classic example. Heat-intensive stoves for home use are more relevant.

A stove for a gas bath, in which, in addition to stones, brick walls will also be heated. In such structures, combustion products are removed in a direct flow

Note! Many heating gas stoves for home and garden can operate both when connected to a common system and from liquefied bottled gas, including biofuel obtained by decomposing organic waste. You just need to make the necessary equipment reconfigurations

Modernization of heating equipment

Any home craftsman can install a homemade atmospheric gas burner for a sauna stove. So, without any special costs, a solid fuel boiler can be converted into a gas one.

Equipping an existing solid fuel stove in a sauna with a factory-made gas burner unit will require some adjustment. You will be faced with the need to modify the dimensions of both the burner and the combustion chamber of the wood-burning stove.

Converting a solid fuel sauna stove into a combined gas and wood stove is within your power, but it will require precision and some effort. Do not allow the flame to come into contact with the walls of the firebox

To heat the combustion chamber evenly, the burner should be positioned closer to the bottom of the stove and strictly in the center. It is unacceptable to place the source high and offset in any direction. In this case, the camera will not warm up completely. And the flame from the burner can touch metal parts or the heater of the sauna stove.

Safety rules when using burners

Failure to comply with precautions when installing and using gas burners for heating premises can lead to emergency situations and accidents: fire in the house, carbon monoxide poisoning. When operating gas equipment, you should adhere to the following rules:. When operating gas equipment, you should adhere to the following rules:

When operating gas equipment, you should adhere to the following rules:

- Observe the service life. The burner's service life, depending on the model, can range from 8 to 15 years. Then it must be replaced.

- Use models with a function that automatically turns off the device in the absence of draft or flame.

- A stove equipped with gas burner units must meet safety requirements.

The design, installation or repair of a gas burner must be carried out by certified gas service workers, with whom an agreement has been concluded for the supply of fuel and maintenance of the units.

If possible, it is still necessary to use gas boilers or special furnaces that are designed to work with natural or liquefied gas

To obtain permission to install and connect to the main gas network, a number of conditions must be met:

- compliance with the rules for connecting a gas burner;

- appropriate design of the smoke channel, its high-quality insulation;

- installing a spark arrester at the top of the chimney.

This is the minimum requirement for installing forced-air gas burners.

For atmospheric there are additional requirements:

- presence of adjustable traction;

- ensuring good ventilation;

- the volume of the room in which the gas burner is installed is from 12 m3.

If equipment is converted to use liquefied gas, it is necessary to ensure safe storage of the gas cylinder. This can be a separate room or a metal cabinet. If you plan to store gas reserves in a gas tank, then the tank is installed underground at a distance of no closer than 5 m from the building.

How to choose?

What you need to pay attention to when choosing a burner device for a boiler:

- productive power - noise level during operation (applies to supercharged models) - type of heating equipment for which the burner is purchased - type of fuel - pros and cons of this device - provide for possible malfunctions in the operation of the local gas supply line.

Taking these factors into account, you can choose the most suitable burner device for your boiler so that it operates as efficiently as possible without the burden of frequent preventative maintenance.

DIY instructions

Next, we will talk about several options for homemade propane burners that you can make with your own hands. In order to build a simple burner, you won’t need a lot of effort and skill, but creating the other two options will require you to work harder.

Option 1 - the simplest burner made from a piece of pipe

Building such a burner will require very little time and effort. But the process of creating a homemade product must be approached with all responsibility, because you will have to work with an explosive substance and any error in the design of the device can lead to dire consequences.

Using such a device, you can heat metal blanks for forging or warm them up before welding, and you can also repair bitumen roofing. The owner of a private house will definitely not find such a homemade product superfluous.

A properly made propane burner will last a long time. With its help you can perform many household tasks without using a number of expensive tools.

To make a homemade gas burner you will need the following tools and materials:

- two pieces of pipe of different diameters;

- union;

- gas hose;

- gearbox;

- propane tank;

- welding machine;

- Bulgarian.

Having prepared all the tools and materials, you can begin assembling the propane burner. But before that, we recommend that you familiarize yourself with the rules for safe work with an angle grinder.

As you can see, there is nothing complicated about assembling a gas burner yourself. Having studied the instructions and having the necessary set of tools and materials at hand, assembling the device will take no more than an hour.

Option 2 - powerful gas burner

We also suggest trying to assemble a more structurally complex, but also more powerful burner.

To build this option, you will need a little more tools and materials, but the result will not disappoint you.

Such a propane burner can be used, for example, for melting metal in a forge, for burning weeds in your own area, as well as for other purposes

So, to build a propane burner you will need to prepare the following materials:

- connecting couplings – 1/2” and 1/4”;

- threaded barrel – 1/2” and 1/8”;

- plug with internal thread – 1/8”;

- foot – 1/4”*1/8”;

- nipple – 1/2”;

- quick connector for low pressure gas equipment;

- propane supply regulator – 0.068-0.34 atmospheres;

- thread sealant;

- a metal sheet;

- self-tapping screws;

- drills – 6.4 mm and 0.8 mm.

It is better to give preference to brass products. In addition, to construct a homemade product you will need the following set of tools: an adjustable wrench, a drill, a punch, solder and flux, a blowtorch.

Having prepared everything you need, you can begin assembling the device.

During work, do not forget that propane is an explosive gas, and any failure to comply with safety regulations can lead to irreversible consequences.

Therefore, before testing the device, it is necessary to check all connections for leaks. And only after making sure that there is no leak, you can start working with your homemade product.

Option 3 - miniature burner model

Let's look at another option for a gas burner that runs on propane. This miniature gas burner is often called a Bunsen burner.

The peculiarity of this device is that you can hold it freely in your hands without fear of getting burned. Let's try to assemble it with our own hands.

To work you will need:

- Old gas burner.

- Thin copper tube 10 meters.

- Copper wire.

- Needle from a medical syringe.

- Bolt No. 8.

Having prepared all the necessary materials, you can begin to create our homemade product.

To do this, we will use the following instructions:

Now you know how to build a gas burner with your own hands and what you will need for this. As you can see, there is nothing complicated about this; it is enough to follow the rules for the safe operation of equipment, which we will discuss a little below.

Conclusions and useful video on the topic

The video will talk about how to make a propane gas burner yourself:

Having at hand a small supply of tools, a gas burner diagram and the necessary materials, every home craftsman can assemble a propane burner. It is important to follow fire safety rules and use only high-quality materials approved for use in the domestic gas supply system. But if you are not confident in your own abilities, it is better to purchase such a device in a store.

If you had to assemble a propane burner yourself, please share your knowledge with our readers and tell us which option you chose. Why was he chosen and were there any difficulties during the work process? Perhaps you have a diagram of the device and a photo of the finished homemade product - include visual information in the discussion of the material.

Kinds

Burners can be of different types. Let's look at the main ones.

Atmospheric

Such devices are quite cheap. The reason is obvious - their production is not too difficult technologically. The operation of atmospheric burners is also simple. Air is sucked directly from the surrounding space. The formation of a gas-air mixture does not require additional effort.

Supercharged

This option uses a fan that actively pumps air. Stabilization of air pressure (pressure) allows you to compensate for almost all negative external factors

What is important is that “fire separation”, which often occurs with atmospheric burners with a significant increase in pressure, is also excluded

The following evidence supports such devices:

- stable operation under any conditions;

- efficiency of 95% or more;

- a fairly high level of safety (determined by the design);

- almost complete combustion of fuel;

- wide range of achieved powers;

- excellent level of automation;

- Possibility of use in furnaces and boilers of a wide variety of structural types.

It is worth noting that forced-air burners are much more expensive than their atmospheric counterparts. Even the most affordable models of this kind cost at least 4.5 times more. However, the main technical advantages fully justify such a fee. When the burner is operating with supercharging, noise of varying volumes may occur. Special protective covers will help to cope with this problem.

Such models are approximately twice as efficient as traditional flare designs. Some people even take tourist-type ceramic burners (for cylinders) and convert them into a boiler or stove. But you can do this only with complete confidence in your actions.

Advantages and disadvantages

The use of gas heat generators in a bathhouse has many advantages:

- efficiency. You just need to open the valve and light the nozzle, and in an hour the steam room will be ready. There is no need to prepare and store firewood/coal, load the firebox, control the work process,

- high efficiency. The productivity of gas equipment is significantly higher compared to TT units,

- environmental friendliness. During operation, gas burners for sauna stoves provide a low level of emissions harmful to the environment,

- ease of maintenance and care. There is no need to remove ash, as is the case with solid fuel. All that is required is timely cleaning of the chimney,

- efficiency. This figure is almost 30% higher than that of TT boilers, and more than 100% higher than that of electric heat generators.

The main disadvantage of gas burners for sauna stoves is the need to obtain permits for installation.

Criterias of choice

Tandoor has been known since the 10th century in all countries of the East and Transcaucasia. At that time, all such stoves were made of special clay and heated with wood. But in the modern world, tandoors are made of ceramics, clay, brick and metal. According to the heating method, tandoors are divided into wood, coal, electric and gas.

What does a tandoor burner look like?

Clay tandoors are made according to the classical model. But not all clay can be used to make a stove, because at high temperatures (up to 500 degrees) the stove can crack.

Today, Uzbek ceramic tandoors, made of clay taken near Akhangaran and fired to the state of ceramics, are very popular.

Brick tandoors are built from bricks of a special shape and size. They are laid in a semicircle to preserve the classic shape of the stove and secured with clay mortar.

In the Middle Ages, ceramic tandoors indicated the high social status of the owner, since they were made large and decorated with small ceramic tiles covered with bright ornaments. Only wealthy people could afford such a stove.

Metal tandoors are made in factories and most often they are installed in public places: cafes and restaurants. Such ovens come in various sizes and shapes: they can be rectangular and polygonal, spherical and square. A clay oven with thermal insulation is installed inside the metal body to retain heat for as long as possible. These stoves are usually wood-fired, but there are also gas stoves.

Metal tandoors usually have gas burners; they run on natural gas. A gas burner and a sheet of reflective plate are cut into the body of such a tandoor to remove the flame. These ovens are easy to use, economical and allow you to quickly prepare many delicious dishes. But their installation requires professional knowledge and skills.

The advantage of gas tandoors is the ability to install them indoors, the only condition being proper ventilation.

Gas ovens typically have temperature controls, no automatic ignition, and a removable lid. Stones are used to obtain even heat.

What types of burners are there?

If a gas burner is considered from the point of view of the method of controlling thermal power, then all models can be divided into the following categories:

- Single stage. In this case, gas supply (switching off) occurs automatically, based on a rheostat signal.

- Two-stage. The burner has the design ability to switch to an economical mode. This process is regulated automatically.

- Burners with floating adjustment. The burner power can be changed smoothly, from 10 to 100 percent.

Burners are divided according to the method of air supply:

- Atmospheric. In this option, no electricity is needed; air flows to the burner under the natural action of draft. The efficiency is not very high, no more than 90 percent. This is a simple design: a pipe with holes into which fuel is supplied. It works in open combustion chambers. They can be quickly converted, if necessary, to use liquid fuel; the service life of such burners is very long. However, such burners impose increased safety requirements.

- Supercharged. They are also called blower or fan burners. This is a rather complex design. Air is supplied to the burner by a fan; in this case, the combustion chamber is closed. Efficiency exceeds 95 percent. Stoves with such burners do not require bulky chimneys. At the same time, the furnace operates stably even at low gas pressure. However, they produce a lot of noise and are volatile.

- Diffuse-kinetic. The air is partially pumped into the combustion chamber, the rest is supplied directly to the flame.

Date: September 25, 2022

Types and characteristics of elements for gas combustion

The gas burner for the boiler is selected according to the following characteristics:

- Life time. The period cannot be less than the operating life of the heater.

- Low noise level. If the injectors make a lot of noise, this indicates a malfunction - all parts are checked at the factory and must comply with sanitary and hygienic standards.

- Type of fuel. Manufacturers offer universal nozzles that operate on main gas, bottled gas, diesel fuel, etc. When changing the energy carrier, a simple reconfiguration of the equipment is required - such burners are especially convenient for owners of country houses.

- Easy to install and dismantle.

The main purpose of the device is to mix gas and air to form a flammable medium. The efficiency of the burners is high; the type of mixing differs between atmospheric and fan. It is worth considering their features in more detail.

Atmospheric burners

To form a combustible substance, the burners take air from the room where the heater is installed. Atmospheric gas burners for heating boilers operate on the ejector principle - nozzles for supplying gas are located inside the channel structure. Air is delivered to the nozzles, then a combustible mixture is formed, exiting through the perforation of the nozzle.

As the mixture exits, a low air vacuum is created, which allows oxygen to be drawn in and a new portion of the mixture to be formed. The gas combustion chamber is equipped with several parallel channels with nozzles, so the process of forming the gas-air mixture is carried out in a continuous cycle.

After combustion, the heated gas moves to the upper part of the heat exchange structure, giving off heat to the heat exchanger, and then the combustion products are drawn into the chimney. The warm gas reacts with the cold outside air, resulting in the formation of draft, which provides the supply of fresh air to form a gas-air mixture.

Advantages of atmospheric gas devices:

Simplicity and relative cheapness; there will be no problems with replacing equipment. Energy independence. No electricity is required to start the boiler

It is important to maintain an optimal level of fuel supply pressure and build a high-quality chimney. Low noise level, compact device.

The disadvantages include the necessity of constructing a chimney so that combustion products are completely removed.

As for the efficiency of the equipment, it is quite high, since manufacturers are increasing the number of inlet holes with a small diameter. This “perforation” ensures uniform distribution of the gas-air mixture throughout the combustion chamber, increasing the performance and energy efficiency of the system.

Fan burners

These are more complex gas burners for heating stoves, allowing control of the fuel combustion process. The fan is installed to force air into the combustion chamber and ensures the formation of a gas-air mixture in a sealed compartment for fuel combustion.

Fan-type nozzles are used in combined heaters equipped with a sealed combustion chamber.

Device Features:

- high efficiency;

- forced air injection;

- the optimal combination of portions of gas and oxygen to form a combustible mixture.

In addition to pumping air into the chamber, the fan is responsible for removing combustion products to the outside and allows you to change the pressure in the network by changing the speed of rotation of the blades.

The main difference between fan nozzles and atmospheric ones is the formation of a combustible mixture. In atmospheric boilers, a gas-air portion is formed at the entrance to the burner, in fan boilers - at the entrance to the combustion chamber.

A fan gas nozzle for heating a private home has a wide list of advantages:

- Monitoring the operation of the network, the ability to influence the process of forming the gas-air mixture, and change the boiler power.

- Saving fuel consumption.

- High efficiency.

- Can be installed in apartments and small buildings. This is achieved by eliminating the need to connect to a standard chimney. The coaxial pipe is run through the nearest exterior wall.

Domestic gas fan heaters are expensive energy-dependent devices, which is a disadvantage of the units. If the device breaks down, only a specialist can replace it, and the burner turns off if there is a failure in the supply of fuel or electricity.