In accordance with the laws of physics, air rises when heated, so insulating the ceiling in a house with a cold roof is not a way to get rid of extra money, but a decision dictated by expediency. If you live in a private house, then you have directly encountered the problem of a cold ceiling in the room above which the attic is located. It is usually not heated, and its own thermal insulation is minimal to ensure normal temperatures during the cold season. As a result, there is a source of constant heat leakage above the living room.

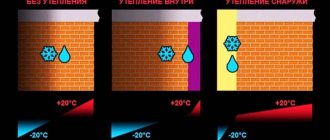

You can insulate the ceiling in a private house from the inside or outside. Both options have their own advantages and disadvantages, the use of which is dictated by rationality, circumstances, technical nuances and other significant characteristics.

Insulation of the ceiling from the outside using rolled material Source buildfun.ru

Features of ceiling insulation in a wooden house

When working with wooden buildings, primary attention should be paid to the final weight of the insulating layer. Excessively high mass increases the likelihood of collapse or cracks in the ceiling covering.

Some are trying to insulate the ceiling in a private house with a cold roof by reducing the insulation layer, but work standards require a certain value for each region in accordance with temperature and humidity indicators. As the thickness decreases, the thermal insulation properties decrease, and the meaning of laying insulation disappears.

Insulation of the ceiling in a wooden house from the inside Source evejoy.top

Relevance of the issue

As you know, warm air always rises. If during the construction of the building you did not take care of insulating the ceiling, then you will lose 30-50% of the heat. For example, if you used four cubic meters of gas during the day, then 1.2-2 cubic meters. meters will be spent on “heating the street” (or attic).

Uninsulated ceilings are the main reason for the formation of condensation on their surface, which contributes to the emergence and development of fungi or mold. If this has already happened, get ready for expensive repairs, and they cost several times more than carrying out ceiling insulation work.

In order to choose the optimal material and method of insulation, the following factors must be taken into account:

- Design (features) of the ceiling and roof.

- Climatic features of the region (pay attention to the air temperature outside and indoors at different times of the year).

- Physical properties of the material used.

In addition, you should know that there are internal and external methods of insulating ceilings. The effectiveness of each of them is determined individually.

List of materials used for insulation

For thermal insulation, installers use materials that are divided into four large groups:

- bulk – expanded clay, dry sawdust, ecowool;

- rolled - mineral wool and its varieties from other materials;

- slab - sheets of compacted mineral wool, expanded polystyrene (foam), cork plates;

- sprayed/self-leveling – penoizol.

When choosing insulation for the ceiling in a wooden house, you need to know which one has the best insulating properties. To do this, it is necessary to take into account a number of factors that influence the final result:

- external or internal installation;

- weather conditions and average annual temperature in a particular area, affecting the thickness of the layer;

- the need and list of additional work;

- time spent and project budget.

The combination of these features will indicate the rationality of using one or another type of thermal insulation.

The photo shows a bulk version of the ceiling insulation from the outside - thermal insulation with expanded clay Source hi.decorexpro.com

How to choose the right insulation thickness

Since the thickness of mineral wool affects the thermal characteristics of the thermal insulation system, it should be selected taking into account the climatic conditions of the region of residence, air humidity, and technical characteristics of the insulated surface. The averages are approximately as follows:

- For an external wall, where it is necessary to achieve the standard indicator of the material’s resistance to heat transfer, the recommended thickness of mineral wool should be from 8 to 10 cm.

- For basements (walls, ceilings), surfaces in contact with the ground - the layer of insulating material should be from 6 to 15 cm.

- The thickness of mineral wool for the floor in a heated room is at least 6 centimeters, with a maximum thickness of 15 cm.

- The thickness of mineral wool for the ceiling of a house in contact with an unheated attic should range from 10 to 16 cm.

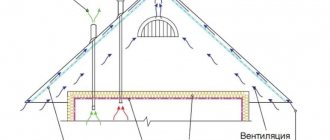

- Pitched roofs should be insulated with thermal insulation material with a thickness of 15 to 30 cm.

Average data may vary depending on the climate in the region of residence.

External insulation

In most cases, insulating the outside ceiling of a home is a more convenient way to prevent heat loss. It allows you to expand the list of insulating materials used, reduce the time spent on work and reduce, in comparison with internal installation, the cost of thermal insulation when insulating a house with finishing finishing.

See also: Catalog of companies that specialize in insulating country houses.

Ceiling insulation with sawdust

The cheapest among all bulk insulator options. Thanks to the cheap cost of the material and minimal additional costs, the total cost of the work is the lowest among those described.

There are certain requirements for sawdust.

- A minimum moisture content is required, otherwise mold will begin to form over time. To do this, the material is kept in a dry room for about a year before use.

- Sawdust is mixed with fire retardants to reduce flammability.

- Combining with antiseptic substances, fungicides and slaked lime will prevent the appearance of fungus and protect against rodents.

Insulating the ceiling in a house with sawdust is done in two ways. In the first, they are mixed with dry cement, followed by the addition of a small amount of water. Cement acts as a connecting material. The second method involves dry filling of sawdust without adding a connector, but due to the natural shrinkage of the material and the need for regular addition, it is not popular.

Ceiling insulated with sawdust Source ohiogas.info

Expanded clay as insulation

The second most frequently used bulk material for insulation. Among its advantages:

- acceptable price;

- availability;

- thermal insulation properties are above average.

However, the application has a number of limitations:

- The own weight of expanded clay does not allow its use on thin wooden ceilings; concrete floors are desirable.

- the material has low moisture resistance, so a vapor barrier must be laid as the first layer.

- to ensure high-quality heat retention, you will need a layer more than 20 cm thick (in cold regions of the country it is increased to 50 cm).

When using expanded clay, experts use a mixture of large and small fractions to ensure a high percentage of filling the empty space. On top, a layer of material is filled with cement mortar 5–10 cm thick, which provides protection from moisture and serves as a floor covering.

External ceiling insulation with expanded clay Source obustroeno.com

Ecowool

Modern insulation for the ceiling of a house, made from recycled cellulose, with the addition of fire retardants to provide fire resistance and boric acid, which serves as protection against fungus and harmful microorganisms. The main advantages of the material:

- high-quality coverage of the entire floor space; thanks to the low weight of the individual parts, the cotton wool is easily blown into all the cracks;

- the composition does not contain compounds harmful to humans;

- low material consumption to ensure reliable thermal insulation.

The disadvantages include:

- low resistance to moisture, you will have to spend money on laying a vapor barrier;

- manual installation without special equipment is impossible or will be of poor quality;

- ecowool is subject to shrinkage, so you will need to lay it with a margin of about 15%;

- if crushed, it loses its thermal insulation qualities, so it is necessary to cover the ecowool with a layer of boards to ensure the ability to move around the attic.

Advice! Experts do not recommend using the material close to chimneys and other sources of high temperature, despite the addition of fire retardants to the composition. If this is not possible, then you will need to make an additional fence made of a fire-resistant coating that reflects heat.

Ceiling insulation with ecowool Source ko.decorexpro.com

Application of expanded clay

In many respects, the presented material is one of the best for use as a material that retains heat in the house.

It will not be eaten by mice or damaged by insects, it is designed for a long period of use, does not rot and has excellent sound insulation.

To install insulation, in addition to expanded clay, you will need:

- Drywall/Boards.

- Vapor barrier film.

- Scotch.

The entire process of installing insulating materials can be divided into the following stages:

- 1. Preparing the coating. The debris is removed, the joints are sealed, and the film is laid.

- 2. Expanded clay is poured. The height of the covering must be at least 20 cm.

- 3. Vapor barrier film and boards are laid on top.

By the way, here is a very revealing video in which a foreman with many years of experience shares his thoughts on ceiling insulation using expanded clay:

Some owners of wooden houses lay expanded clay so that its height is 30-50 cm. Of course, the thicker the protective layer, the better the heat will be retained, but do not forget about the loads on the floors. This amount of expanded clay has a decent weight; not every structure can support it.

Video description

Which insulation divides heat better, watch the video:

Advice! When working with penoizol, it is recommended to wait until it hardens completely; it has a slight shrinkage that will have to be compensated to prevent the formation of voids.

The process of thermal insulation of the ceiling with foam insulation Source lestorg32.ru

Sawdust

Sawdust is a natural material and has proven itself for thermal protection of wooden houses. This technology is somewhat more complicated than gluing with foam plastic. The main difficulty lies in the preparation, or more precisely, the manufacture of insulation, which is a cement-sawdust mixture.

Preparation of the composition

It is better to use medium-sized shavings. Thyrsa is not suitable for insulation. Its volume contains very little air. The sawdust should not be fresh. The raw materials are treated with antiseptic and antifungal compounds. The simplest solution to this problem is to soak wood chips in a solution of copper sulfate, after which it should be thoroughly dried.

The process of preparing a cement-sawdust mixture consists of the following steps:

- in a spacious container (a trough with sides 25-30 cm), prepare “cement milk” by mixing water with cement in a ratio of ten to one, and mix thoroughly;

- Sawdust is added to the resulting mixture, which during the mixing process should be evenly covered with a layer of solution.

Surface preparation

Before you begin making insulation, you should prepare the area for its application. This preparation includes the following:

- dismantling the attic floor;

- cleaning the space between the joists from debris and other foreign objects;

- treatment of all available wooden floor structures with antifungal and antiseptic agents;

- laying a vapor barrier carpet (as insulation, you can use thick polyethylene film overlapped on the joists).

Video description

Insulating the ceiling from the inside, watch the video:

The process of insulating the ceiling from the inside with polystyrene foam Source nl.decorexpro.com

Thermal insulation of the ceiling from the inside with polystyrene foam boards Source barmanlive.ru

What to choose - external or internal insulation

The choice between these types of work is based on a combination of factors:

- in the absence of finishing, they are equal in the degree of thermal insulation;

- if the renovation of the room is completed, you will have to remove the ceiling covering, which will increase the cost and time of work;

- laying from the inside reduces shrinkage of the material, but increases the thickness of the ceiling, reducing the total volume of the room;

- with internal insulation, the ceiling ceiling is not protected from low temperatures;

- external insulation allows the use of a wider range of heat insulators.

Before insulating the ceiling in a private house, you need to carefully calculate all the pros and cons, only after that can you make a clear decision on what is best to use in your case.

Mineral wool

The nature and first stages of performing these works are the same as in the case of sawdust. After preparing the surface, cotton wool is laid, cracks and holes are blown out (large ones will definitely be caulked), and then the whole thing is covered with film. You can put boards on top or make a screed.

Some experts advise doing combined protection. To do this, lay the first layer of polystyrene foam (its analogues), and the second layer of mineral wool. Further steps are carried out according to the above scenario.