The thermostat for a water heater is an important element of the boiler design. The main task of the device is to maintain the specified temperature regime of the heated liquid, and for some models it must be maintained during an emergency shutdown of the electrical appliance in the event of a malfunction. Recommendations regarding the selection and installation of such a device will be discussed in this article.

Purpose

A capillary thermostat is used to control the temperature. Used as a relay in household appliances, industry, to ensure safety in case of fire.

This device can be used as a double-acting thermostat. In the first case, the element can shut down various systems in the event of an increase in temperature. In the second case, he is able to turn off running systems, switching to ensuring the operation of other systems. For example, when the temperature rises, it can turn off appliances, heating elements and turn on the air conditioner or fan to cool the room. Also capable of triggering an alarm in case of fire. This element has many purposes, the main thing is how it is connected to the electrical circuit.

Main types

Heating elements come in different capacities. The more powerful it is, the more intensely the liquid inside is heated. Moreover, the thermostat is exactly the part that is the basis. If you have chosen all the technical characteristics correctly and conscientiously follow all the rules for its operation, the water heater will serve for a long time without unscheduled cleaning. So what are they like?

Rod

It consists of a steel tube of small diameter (up to approximately 10 mm) and length (about 25 to 45 cm), which depends on the volume and power of the heater. This thermostat is placed in the heating element tube and it works according to the elementary laws of physics. As the tube heats up, it expands linearly, allowing the switch to be pressed. However, their main disadvantage is inaccuracy and high cost of use. When hot water leaves the tank, cold water entering cools the thermostat very quickly. For this reason, the boiler heats up more than it actually needs, and this increases electricity costs and shortens the service life of its parts.

Principle of operation

The operating principle of a capillary thermostat is very simple. First you need to understand what it is and what the device consists of. The element consists of the following parts:

- Capillary flask made of copper or brass.

- Tubes made of the same materials.

- Diaphragm regulator with electrical contacts.

- Gas or liquid in a flask.

A capillary tube thermostat operates using the principle of pressure from an expanding fluid. The sealed flask contains a liquid whose density is less than that of ordinary water. The flask is soldered to a tube, which in turn is attached to a membrane on the mechanical part of the capillary thermostat. When the temperature increases above 3 degrees, the liquid begins to expand, creating pressure on the surface of the adjustable membrane. After overcoming the elasticity value, the membrane is activated, opening the electrical contacts of the regulator. Depending on the settings, the regulator can operate at temperatures from + 3 to +40 degrees. It all depends on where the capillary thermostat is used.

What is good about a capillary thermostat?

There are some classifications of thermostats, according to which a water heater can be divided into several types. Electromechanical-electronic, which affects the control method. Programmable or simple, which will affect how the temperature is set. Mortise or overhead, which affects the installation method.

Basically, a thermal switch is:

The peculiarity of the rod model is that it is the oldest device. It looks like a small tube, 35 cm long and 1 cm wide. When it is exposed to high temperature, the tube expands in size and pressure is applied to the switch. This is exactly how this system works.

The operating principle of the capillary thermostat is slightly improved, since it appeared after the rod thermostat. The thermostat is a tube with cylinders located inside it. They contain liquid with a density different from water. When heated, the volume of liquid increases, the cylinder begins to put pressure on the membrane and on the shutdown device. In terms of accuracy, this method has a discrepancy of 3 ᵒС.

An electronic type thermal sensor is the most common model and it is the most accurate compared to the others. The perfection of the model lies in the fact that the temperature sensor has direct interaction with the protection relay, due to which an emergency automatic power shutdown is carried out if there is no liquid in the tank.

Varieties

There are 2 main types of temperature controller. Mechanical devices have manual adjustment of the response temperature. They are among the simplest devices.

There are electronic regulators. They can be adjusted remotely via a computer or Wi-Fi network.

Non-adjustable sensors are increasingly appearing on the market. Such options cannot be configured at the moment of operation; they have a very narrow scope of application.

Thermostats for single-chamber refrigerators

Temperature regulators T-110, T-111, T-112 are mounted on refrigerators with one chamber. The T-112 thermostat may be designated TAM-112, or TAM-112-1M. In terms of temperature indicators, all devices are the same, turning off is done at a temperature of -14 degrees Celsius, turning on at -12 degrees.

The thermostat models of this group differ somewhat in external characteristics. First of all, this concerns the dimensions; the handle rod and the bellows tube can have different diameters. Some models have a crossbar for easy fastening. The length of the bellows tube is indicated on the thermostat body and looks like two numbers separated by a comma. Example: a) 0.6 - tube length - 60 cm; b) 1.3 - tube length - 1 meter 30 cm.

TAM-112-1M

Ranco K50-L3392 (0.8)

Ranco K57-S5588 (0.5)

In some cases, products are interchangeable. To install thermostats of the new TAM-112 model instead of T-110, an installation kit is provided, consisting of a crossbar, a nut and a nylon adapter that increases the diameter of the adjusting rod.

Ranco K50-L3392 with a long capillary tube of 0.8 meters, is an analogue of the domestic thermostat TAM-112-1M, suitable for most domestic single-chamber refrigerators.

The Ranco K57-S5588 thermostat is suitable for Liebherr single-chamber refrigerators.

Scope of application

The capillary thermostat is a very common temperature sensor. It is often used in:

- Household instrument making. The element is installed in air conditioners, furnaces, water heating boilers, washing and dishwashing appliances, and ventilation systems of “Smart” homes.

- In industry, this mechanism is used to control the temperature of gases and liquids. Used for ventilation of rooms. There are devices for monitoring the temperature of electric motors that are operated without human supervision.

- Before the invention of fire and smoke detectors, thermostats with a capillary system were used as temperature controllers in warehouses and unguarded premises.

As mentioned earlier, this mechanism can be included in the electrical circuit of almost any device.

Area of use of capillary thermostats

In theory, the temperature sensor and the calibration unit can be separated to any distance. Moreover, they can use working fluids with different physical parameters (for example, freons), which makes it possible to use a capillary thermostat even at sub-zero temperatures in freezers.

Very often, these devices are used in technology where the calibration unit needs to be protected as much as possible from heating. Due to this, capillary-type thermostats are installed in heating boilers, instantaneous water heaters, electric water heaters and other heating equipment, ovens, baking and frying cabinets, air conditioners, etc.

Examination

Despite their simplicity and reliability, capillary thermostats fail. This is due to the following factors:

- Carbon deposits on electrical contacts. Fixing this malfunction is very simple if the mechanism is suitable for disassembly. Carbon deposits are removed by cleaning the contact group with fine sandpaper. As a result of sticking, dents may form on the surface of the contacts. Cleaning is carried out until the surface is completely leveled.

- Loss of membrane elasticity. For collapsible devices, this problem is solved by leveling the surface. For those that cannot be repaired, the defect cannot be eliminated.

- Breakdown of the tube or flask of the capillary system. The only solution is to completely replace the device. In some workshops, the flask is filled with liquid and sealed. But the cost of repair is often higher than the new original.

To determine the operability of an element, you can only check the contact group. Often, regulators for household use are equipped with 3–4 contacts, 2 of which are in the closed (working position), and the next 2 contacts close when the mechanism is activated. To check you need:

- Set the tester to dialing mode with sound notification.

- Connect one probe to the first contact of the element.

- The second one is to find the contact with which the first one is closed. The tester's audio alert will indicate it.

- Next, the flask must be brought to a heating device or open flame without disconnecting the tester probes.

- When the response temperature is reached, the membrane will open the contacts, thereby interrupting the tester's notification.

- Now you need to ring contact 3 of the mechanism. To do this, attach one probe to a contact that has not been tested, and with the second probe find a circuit from the tested terminals. An audible alert will indicate that the circuit is closed and the correct terminal has been found.

Successful testing of all terminals is a sign of complete serviceability of the regulator.

A full check can be carried out in the same way, only with an increase in the trigger moment.

How to do DIY repairs

If possible, the element can be repaired or a new one installed.

How to remove the thermostat:

- Disconnect the equipment from the network.

- Turn off the water supply.

- Drain the contents of the tank. You can use a special valve for this. Why you need a safety valve, read in a separate article.

- Dismantle the heating element. To do this, unscrew the nuts and bolts of the flange and remove it from the housing.

- The thermostat is usually located at or near the base of the heater.

- Disconnect the wiring and remove the sensor from the base.

In the case of a mechanical model, you can clean the bimetallic plates from oxidation . To do this, soak a piece of cloth in alcohol and wipe the plates. If the oxidation has spread greatly, then clean it with fine sandpaper.

You need to do this carefully so as not to touch the sensor contacts.

Due to power surges, the break contact could become stuck. To adjust, carefully remove it from the body and clean the problem area. Normally, the contact should fit into the socket automatically.

How to repair a contact if it does not work:

- Remove the part completely from the housing.

- Clean its surface, as well as the seat.

- If the contact does not turn on after cleaning, place insulating tape underneath.

- Reinstall the stem.

- Assemble the body.

Connection

It is very easy to connect the capillary thermostat yourself. Before starting work, you need to study the electrical circuit diagram on the device body. If it is not there, then you will have to dial the entire contact group. It is worth considering that the connection of any device is carried out strictly from the source of electrical energy consumption, through the thermostat to the device that must work through it. There are 2 schemes for connecting the mechanism.

Direct connection

Below is an example of direct connection of an incandescent lamp through a capillary thermostat. The thermostat will be used as a switch.

- 2 wires are connected to the lamp socket contacts.

- The “1” end of the wire is directly connected to one core of the power source, for example, to the “-” battery.

- End “2” of the wire is connected to output “2” on the regulator terminal block.

- “+” from the power source is supplied to the “1” terminal of the regulator unit.

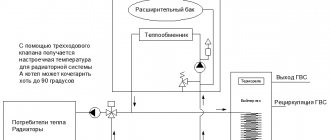

With this connection diagram, the lamp will light. If you heat the thermostat bulb, the contacts open and the lamp goes out. This connection diagram is used in heating boilers. The water does not have time to boil, the thermostat turns off the boiler when the set temperature is reached, which prevents the formation of steam and high pressure.

Reverse connection

An example of reverse connection with the same incandescent lamp. The thermostat is now used as a switch.

- Connect both ends of the wire to the incandescent lamp socket.

- Connect the “1” end of the wire directly to the “-” terminal of the battery.

- Connect the “2” end to terminal “3” on the thermostat block.

- Apply “+” from the battery to terminal “1” of the thermostat input.

When testing the regulator terminals, it was determined that contacts “1” and “3” are closed when input contacts “1” and “2” are opened. In the assembled circuit, the incandescent lamp does not light because it does not receive electrical energy. When the capillary flask is heated, contact “1” will open, closing the circuit with contact “3”. In this position, voltage is transferred from one terminal to another. The incandescent lamp is now lit. This connection diagram is used in ventilation and air conditioning systems. The appliances do not turn on until the room temperature rises. As soon as the sensor is triggered, the devices turn on to cool the room.

Using the contact group of a capillary thermostat, you can distribute the operating torque of several devices or devices. The main thing is to know the exact circuit for switching on and off the contact group.

In heating boilers, a three-contact thermostat is used to operate the device and an active warning relay. Until it opens, the thermostat works in conjunction with the boiler. After exceeding the response threshold, the contacts open the circuit, turning off the boiler. This closes the secondary contact, turning on the light bulb or warning signal that the operation has stopped.

When the regulator needs replacement

There is no point in carrying out repairs if:

- The copper tube has become unusable.

- The electronics have failed.

- The element burned out due to a power surge.

But how can you be sure in practice that the thermostat is faulty? This can be checked with a multimeter.

- Set the multimeter to resistance measurement mode, as shown in the picture:

- Attach the probes to the contacts of the part.

- Look at the scoreboard. If the resistance is infinite, the thermostat cannot be restored and must be replaced.

- Does it show resistance? Do this: set the multimeter to the minimum value. Use a lighter to warm up the thermostat tube. If it is working properly, the resistance will increase and the protective relay will operate.

If you are convinced of a malfunction, it is important to choose a suitable product for replacement. How to do it? It is best to take the old regulator and go with it to the store to purchase an analogue. Or write down the serial number that is on each product.

What to pay attention to:

- Fastening method.

- Size.

- Voltage.

- Additional functions.

The parameters must match those specified in the passport for the boiler.

If you are not good at repairs, then you can call a specialist to replace it.

Remember about safety precautions and watch the video on the topic:

Installation features

At its core, a capillary temperature controller is a very fragile element. When installing it, the following rules must be observed:

- The capillary flask should be located next to the heated device. If the design provides for a radiator, then directly on the fins of the radiator. If the flask is located in the air duct box, then the location should be strictly along the path of the air flow.

- The flask should be installed with its end down. The liquid will not respond to temperature changes if it flows to the other end of the system.

- Do not bend the capillary tube at a right angle. This will disrupt the effect of fluid pressure on the membrane.

- The length of the tube can only be shortened by bending it into rings.

- For household devices, the length of the tube should not exceed 35 centimeters.

- It is prohibited to impact the membrane with foreign objects.

- If the regulator has an open housing, it is necessary to periodically clean it with a stream of air to remove accumulated dust and insects.

- It is worth taking seriously the connection of the thermostat to the electrical circuit. Poor contact can cause the terminals to melt, heating the membrane. When heated, the metal of the membrane loses its properties, due to which the elasticity coefficient is lost.

- When replacing a faulty element, it is necessary to select its exact analogue. This is especially important for devices that heat water. Deceleration in breaking the electrical circuit can lead to the formation of steam, followed by depressurization of the housing.

Full compliance with the rules of installation and operation of the capillary thermostat will significantly extend its service life.

Adviсe

In order to notice malfunctions in the operation of the device in time and take measures to eliminate them, you should know the main causes of breakdowns and their symptoms. The most common thermostat problems include:

- wear of the copper capillary tube;

- poor interaction between the three-pin thermostat and the heating element;

- failure in adjustment and scale formation on the heating element;

- failure as a result of power surges.

Signs of a malfunctioning thermostat:

- the water in the boiler does not heat up;

- the display shows incorrect temperature values that differ from the actual water heating indicators;

- the thermostat does not turn off the heating element at the set temperature, resulting in uncontrolled heating of water, which can only be stopped by disconnecting the boiler from the network;

- The indicator light does not light up on mechanical models.

Immediately after problems in the operation of the device are noticed, it is recommended to make diagnostics and determine the possibility of further operation of the thermostat. To do this, you need to remove the thermostat from the boiler, set it to maximum temperature mode and measure the resistance of the contacts at the input and output. The absence of a response from the device indicates a malfunction and the need to replace the thermostat.

If there is still a reaction, then the device must be set to the minimum temperature level and the measurement must be repeated. Then you should light a candle and heat the thermostat tube over the flame. If the device is working properly, after a few minutes the relay will operate and the circuit will automatically open.

The resistance value should tend upward. If this does not happen, the thermostat must be replaced with a new one.

The thermostat is the main regulating element of the boiler. Not only the uninterrupted operation of the water heater, but also the comfortable use and safe operation of the device depends on its correct operation.

You can learn more about how to repair the thermostat on a water heater below.

The thermostat for a water heater is one of the components of the boiler protection system (the second is a safety valve). It is needed for convenient operation - thanks to it you can always find out how much stock is currently in the container.

The thermostat also controls the heating process and prevents overheating. If it fails, it needs to be replaced. We can say that this is an element that stops the action of the heating element (heating element) when the temperature has approached the established limits. In the event of a breakdown, the temperature will begin to rise and enormous pressure will form in it. After some time this may lead to an explosion.

Therefore, proper operation in general, as well as individual parts, will save your money and ensure safe use. It is for this purpose that this article will reveal the principle of operation, types, technical problems, diagnostic methods and tips for effective operation.

Advantages and disadvantages

A capillary thermostat is an element of many electrical appliances. The main advantages of the device include:

- Simplicity of design and small dimensions.

- High frequency of response to increased temperature.

- Wide range of applications.

- Possibility of connecting several devices at once.

- High reliability when used correctly.

- Relatively low price.

The only disadvantage of this element is its unsuitability for repair. It is impossible to replace melted contacts or a membrane that has lost its elasticity. Thermostats used in industry are large in size. Depending on the design, some models are repairable.

The most common breakdowns

How to detect and eliminate:

- The water is too hot (this may occur due to the failure of the structure that performs the regulating function)

- Failure in copper capillary tube. This part itself is very sensitive to various types of mechanical damage. Unfortunately, it cannot be repaired, only a new one can be installed.

- The adhesion of the heating element and electrical connectors is insufficient.

- The thermostat turns on and off very often (the reason is excessive scale formation, which exceeds the permissible limit).

- The water is not heated enough, although the power of the heating element is very high (this occurs when the adjustment is incorrect)

- Malfunction of electrical components (most often this is due to voltage fluctuations in the electrical network; you need to install a means that will provide uninterrupted power supply or a voltage stabilizer)

Model overview

Capillary thermostats for domestic use must be reliable, durable, and have a simple connection diagram. Next, a description of the 3 most suitable thermostats for domestic use will be given.

AZT-6

Mechanical thermostat. Main purpose: temperature control of water heaters. The device is equipped only with a knob for adjusting the operating temperature. Operates in modes - 15 + 85 degrees C.

Among the advantages:

- Easy to connect.

- Fast cut-off.

- Miniature appearance.

- Low price.

AZT-6 is an excellent assistant for monitoring air temperature changes in the house.

Ballu BMT-2

Temperature controller for heaters and ventilation systems. Operating range +5–35 °C. The device is used to switch between heating devices and ventilation systems. Has a built-in notification about changing the operating mode. Can be used to connect 4 devices at once into a common system, with their subsequent division according to temperature conditions.

Pros:

- High reliability.

- Ease of Management.

- Multiple connection pairs.

- Not a high price.

The Ballu BMT-2 regulator can be trusted to control the temperature in the house with an electrical load of more than 10 amperes.

Terneo EG

The device is designed to control the temperature in the incubator. The model is completely electronic. Has an additional socket on the body. Working in incubators is not the only purpose of this model. It can be used for work in warehouses and basements.

Pros:

- Easy setup of parameters.

- Easy to read display.

- Availability of sound notification about operation.

- Additional socket.

Terneo EG is very reliable. Through this device, you can connect several devices and set the response temperature for each device.

How does a mechanical thermostat work?

The operating principle of the device is simple: When the air in the room is heated to the required level, the working medium in the bellows expands under the influence of heat, which causes the cylinder to straighten. The rod connected to the bellows rushes forward and presses on the valve, pressing it tightly against the through hole.

Interesting materials:

How to Stream on Xbox One? How to reset iPad via iTunes? How to reset Apple ID? How to reset FreeBuds 3? How to reset a PS3 gamepad? How to reset your name in Undertale? How to reset Honor headphones? How to reset Redmi AirDots headphones? How to reset Samsung a51? How to reset Xiaomi Redmi 7a?

Thermostats for two-chamber refrigerators

Most often, for refrigerators with two chambers, thermostats are used, designated by the symbols T-130, T-132, T-133, TAM-133, TAM-133-1M. Temperature parameters are the same. They differ in appearance, the diameter of the handle rod and bellows tube, and the presence of a transverse bar for attaching the thermostat.

All devices in this group turn on at +4 degrees Celsius and turn off at -14 degrees. The handle rod and bellows tube may have different diameters, so the selection of the model is carried out according to the equipment documentation.

An analogue of the TAM-133 (1.6) thermostat is Ranco K59-L2172 or Ranco K59-S1887.

An analogue of TAM-133 (1.3) is Ranco K59-P1686, which is suitable for all 2-chamber refrigerators of domestic (except OKA-6) and foreign production with a capillary tube length of 1-1.3 m.

Analogues of TAM-133 (2.5) are DANFOSS 077B6496, ATEA A13 0646, Ranco K59-L1275, which are suitable for all 2- and 3-chamber refrigerators of domestic and foreign production with a capillary tube length of 2-2.5 m.

TAM-133-1.3M

Ranco K59-P1686 (1.3)

Ranco K59-Q1916 (2.0)

Ranco K59-L2172 (1.6)

Ranco K59-S1887 (1.6)

Thermostats for freezers

Temperature regulators T-144 and T-145 are used for installation in freezer cabinets. The T-144 thermostat differs from most models in that the manufacturer did not leave room for independent temperature control. Usually there is a special rod for this. The thermostat turns on at -20 degrees Celsius and turns off at -24 degrees.

There are four terminals on the side of the thermostat body, two of them are double terminals, this is “ground”. Terminals numbered 3 and 4 are contacts through which electricity is supplied to the compressor. A special function is performed by contact number 6; it turns on a lamp indicating that the permissible temperature standards in the chamber have been exceeded. Activation of this contact is performed at -15 degrees Celsius.

Analogs of the TAM-145 freezer thermostat are Ranco K59-L2829 (2.5), Ranco K56-L1916, Ranco K56-P1431, Ranco K56-L1954.

Ranco K59-L2829 (2.5)