Due to interruptions in heating, the temperature in the living space may drop. To raise it, all kinds of heaters are used, including oil heaters with a fairly high efficiency. The latter has a number of advantages, since the operating principle of an oil heater can leave air humidity almost unchanged. The industry produces a wide variety of heaters; they have different characteristics, capabilities and design features. Once you get to know them better, you can choose the right one for your specific living space.

Oil fired heater

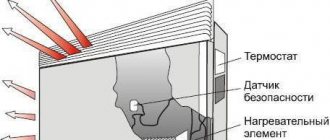

Oil radiator design

Different models of heaters may have different numbers of heating elements, thermostats and switching devices for connection and connection. They also have forced airflow systems installed to enhance convection and increase heat transfer.

The heating elements are placed in a durable, oil-filled, sealed housing with fins, coated with a durable dielectric powder coating. The switches are attached to the heater from the outside. All connections of heating devices and external control elements are connected through a sealed coupling.

The oil heater circuit is designed as follows: the power wire with a plug is connected through switches and a thermal fuse to the heating elements. In this case, the thermal fuse ensures a break in the supply circuit in the event of emergency overheating of the device. The latest models of oil heaters are also equipped with a position sensor, which turns off the device if it falls or critically deviates from the operating condition.

Installation

Installation of the heater does not require special skills and knowledge. If it is a hanging model, it is mounted on brackets that are pre-installed at the required distance from each other. If the model is mobile on wheels, then all that is needed for installation is to determine the safest place near the outlet. It is worth considering that there should be no obstacles in the heater’s path - curtains, sofas or chests of drawers. It is best to install it in the central part of the room in the first 2-3 hours of operation. After the space has warmed up, it is moved to a more comfortable distance - near a wall or fireplace.

Oil heater repair

The older generation remembers that previously, the accompanying documentation for all electrical appliances always included a detailed diagram, thanks to which it was possible to repair the product with your own hands.

Modern instructions, as a rule, do not contain such explanations. But you shouldn’t despair, an oil heater is not a spaceship and it’s quite possible to understand it.

Location of nodes.

Common breakdowns

Schematic diagram.

- If the indicators light up, the fan spins when it is on, but there is no heat, you need to check the operation of the thermostat. Such things often cannot be repaired, the price is low and such relays are available for sale. Unscrewing a couple of fasteners and reconnecting the terminals is not difficult;

- In the case when the unit heats up normally, but does not turn off after heating, the reason must be sought in the thermostat. As in the case of a thermostat, the thermostat cannot be repaired; it is immediately replaced with a new one. Despite the fact that the device seems to be working, you should not delay replacing the thermostat. Heating elements, operating in constant overload mode, will quickly burn out, and this is already serious;

- If the wires and automation are normal, you need to check the serviceability of the heating elements. A “broken” heating element can only be replaced if the possibility of dismantling is provided. In inexpensive models, the heating elements can be tightly sealed into the housing; here it is already cheaper to buy a new heater;

Diagnostics of the heating element using an ohmmeter.

Fault repair

Repairing a socket, plug or cord is extremely simple. The socket or plug is unscrewed and if carbon deposits are detected, all burnt parts are removed and sanded. The cord is simply inspected and “ringed” using an ohmmeter.

Do not forget about the contact group inside the device itself. Having removed the protective casing, the internal contacts should also be inspected and preventive maintenance performed.

It happens that small debris gets into the thermostat armature and the contacts also burn. In this case, you need to disconnect this unit, remove the cause of the blockage, clean the area of the short circuit, and additionally wipe it with alcohol.

When completely replacing the thermostat, it is advisable to immediately adjust the settings. This can be done by setting the armature movement in the range of 1.5 - 2.5 mm. Since the casing has been removed, it would be useful to immediately ring the thermal relay and fuse.

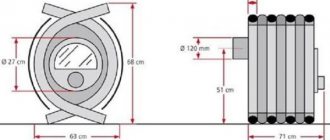

Heater based on MS-140.

If after all the efforts it turns out that the cause of the malfunction is a “broken” heating element, then it will need to be replaced. This is not difficult to do, but you need to act carefully so as not to overfill the oil. Plus, our Chinese friends prefer to save on the quality of gaskets, which often leads to slight oil leakage; the algorithm of actions will be similar.

The oil radiator design provides for the installation of heating elements in the lower end part of the device. The cover can be secured with several bolts or a pair of locknuts. The device must be turned upside down, unscrewing the fasteners, and carefully remove the heaters.

Thermostat sensor.

In order to eliminate or prevent oil leakage when replacing the heating element, you should use paronite gaskets; as a rule, they come complete with the heating element. Please note that it is not recommended to use rubber gaskets; they may be destroyed upon contact with technical oil or will not withstand elevated temperatures. To be on the safe side, in addition to paronite, you need to additionally lubricate the connection with heat-resistant sealants.

Sealing the heating element.

How to choose a device?

Heating problems in the cold season can arise both for residents of city apartments and private country houses. The problem that arises must be solved in an emergency mode using electrical equipment.

Why not take care of buying an oil heater in advance? These devices are very reliable and safe to use. The heating elements are closed, so there is no risk of fire. These designs were invented a long time ago, the principle of use has not changed.

The latest models have added several new features:

- light indicators;

- timers;

- fans;

- humidifiers;

- thermostats;

- overheat shutdown sensors.

Oil heaters are divided into several types:

- Floor-standing. These are the most common radiators.

- Wall flat. They consume energy very economically.

- Tabletop. These are low-power devices and have low heat transfer.

Some models have a fireplace effect. They operate silently and quickly heat the room. They have drafts installed on both sides, so the heated air circulates very quickly.

Modern models have blocks with programs and timers. If there is such a block, you can set the on and off times. As a rule, new units are controlled remotely and have an emergency shutdown sensor.

Oil heater does not take up very much space

When choosing a device, consider the following factors:

- Power. This is the main indicator. A power of 1 kW is enough to heat a room of 10 square meters. meters with a three-meter ceiling. If there are windows or doors, then we add 0.2 kW for each element. In a room from 30 sq. meters you need to install several such devices.

- Dimensions. This indicator depends on the number of modules: the more modules, the larger the structure, the power of the device increases and the area of the heated room increases. This must be taken into account when choosing such equipment.

- Design features. This refers to additional functions that improve the ease of use of the device and increase the quality of its work. For example, the presence of a network indicator, temperature control mode, etc.

- Manufacturer. The manufacturer should also be taken into account. Brands that have been on the market for a long time are well-known and recognizable. They guarantee the quality of their products and long service life.

When choosing a heater, you need to take into account that the more functions installed on the equipment, the more expensive its cost and the more energy it will consume. Also, brands from well-known manufacturers are more expensive. You need to determine the optimal price for yourself, and also take into account the functionality of the device. This will allow you not to make a mistake in your choice.

Oil heater device

Temperature conditions and oil heater tank

The operating principle of an oil heater is to transfer energy from a small heating element to oil, then through it to the surface of a steel tank. The amount of heat loss depends on the temperature difference on both sides of the plane or area. It is unprofitable to increase the first parameter - the coil will burn out. If we increase the area, we will achieve the desired result. The calculation is such that you cannot get burned on the surface of the tank, but the temperature difference with the room must be significant for heat exchange.

Normal conditions: the room is 20 degrees Celsius. Citizens raise their temperature to 35, even higher - not good for health. Manufacturers have chosen the lesser evil - the surface of the oil heater heats up to 70 ºС.

We disassembled the oil heater to determine the modes:

- Emergency thermostat KSD 301 with a response temperature of 80 degrees Celsius.

- Left brand thermal fuse set to 142 degrees Fahrenheit (61.5 degrees Celsius).

Emergency thermostats KSD 301 and thermal fuse

The first one stood as a sensitive platform on the channel of the radiator section closest to the electronic unit. The oil is in an accordion made up of sections. They are welded to each other, the seams are tacked on the outside by spot welding (dashes in reality). The accordion-radiator is non-separable, stands on a platform with wheels: it is pulled in by two steel wire brackets. On one side is an accordion in the form of a heating radiator, on the other is the cover of the electronics unit (a loud name for a couple of resistors).

Each section is flat. The upper and lower channels are cut. They are connected vertically by veins: a small amount of oil oozes through. In the lower channel, with the base facing the electronic unit, there is a heating element. Difference: the water heater does not have a thermostat. But there is a thermal fuse screwed to the base. Low temperature - 61.5 degrees (although the element does not touch the working part of the heating element). The thermal fuse is wrapped in a rubber gasket and additionally protected with heat-resistant fabric: when the oil boils, the temperature will be low.

A thermostat with a fixed operating temperature of 80 degrees Celsius leaned with its metal side (on two screws) against the central vertical vein of the first section. No matter how you set the modes with the upper thermostat, or press the power buttons for the heating elements sections, the limit will not be exceeded.

Models of oil heaters

The myth about the hot surface of oil heaters is not true. Maximum – 80 degrees Celsius. Then an emergency shutdown occurs with hysteresis (return on at 65 degrees Celsius).

Oil heater temperature control

We started with emergency modes for a reason. When repairing leaks or choosing cold welding, you need to know the temperature conditions (operating conditions of the glued joint). Let's move on to the main characteristics of the oil heater. The heating element consists of two unequal branches: they are switched on together or separately. Provides three operating temperature modes, differing in heat transfer. Switching is provided by two buttons located on the top of the oil heater electronic unit.

There is a thermostat under the control panel. Does not control emergency mode - it is represented by an adjustable bimetallic plate that sets the room temperature for heating by the heating element. The response temperature is not high, like the emergency one - 40 - 60 degrees Celsius, even lower. Due to the rotation of the screw, which changes the tension of the plate, the response temperature changes in the desired direction:

- By pressing the buttons, we change the heating rate of the oil, heater, and room.

- By turning up the thermostat, we ensure that the device turns off at the right time.

Temperature control

The heating element consists of two branches that can work both together and separately. Therefore, heating radiators can operate in three modes. They differ from each other in terms of heat transfer. The switching circuit is very simple. To select the appropriate mode, there are buttons at the top of the device. The thermal fuse is located under this panel. It works if the temperature is above 80°C. The process is carried out according to this principle:

- when you press the button, the oil heating rate changes, and as a result the room temperature;

- During the process, a mode is set in which the device turns off.

Which is the best gas heater for a home or cottage, judging by the reviews?

That is, at night the minimum mode is set. To ensure quick heating of the device during the day, it is turned on to maximum.

Many people use electric radiators to dry things. This procedure is best carried out in a minimal mode.

Advantages and disadvantages

Advantages:

- safety;

- noiselessness;

- simplicity;

- compactness;

- durability;

- maintainability;

- aesthetics.

Safety is maintained by strict adherence to instructions and timely repairs in case of malfunction. The devices do not make noise, with the exception of the built-in fans. However, if the fan is of high quality and in good working order, the noise is almost imperceptible. The simplicity of the design allows you to quickly master the control method; it does not require time to start or stop the structure.

Some electric heaters provide for replacement of the heating element. The weak point is the body, which should be protected.

Flaws:

- high energy consumption;

- When the automation fails, the housing becomes very hot and can cause burns.

All about oil cooling radiators

1.3 Junior (105) AR 00530

Since the internal combustion engine is a heat engine, during its operation it generates excess heat that must be removed. A liquid radiator, inside of which antifreeze circulates, helps with this. Due to, for example, high efficiency with relatively small dimensions, automobile engines also have additional forced cooling. Simply put, car engines have a combined cooling system in which the liquid system does most of the work of removing heat. Air cooling elements are activated only at high coolant temperatures.

Please note: when talking about the engine cooling system, they often use the concept of antifreeze temperature. However, there are times when the engine oil also needs to be cooled. The oil comes into direct contact with engine components, which become very hot. If the oil temperature becomes critically high, it will lose many of its properties, which will be critical for the rubbing parts of the engine. The task of cooling the lubricant is taken over by an oil cooler, otherwise called an oil cooler. Avto.pro decided to look into its structure and key features.

Design and principle of operation of the heater

Comprises:

- oil tank;

- electric heater;

- control unit.

When a tubular electric heater (TEH) is heated, heat enters the oil, and it gives off heat through the metal body to the air. The reservoir can be structurally:

- lamellar;

- sectional.

Plate ones are thin and convenient to place on walls. Compared to sectional ones, they have less power. This is explained by the smaller area.

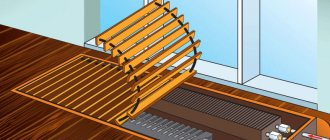

Plate heaters can be combined with furniture

Sectional ones are large in size; you can install a fan to increase heat transfer. Refers to floor. Legs or wheels are used for support. The advantage is fast heating. The sections create convection - air mixing, circulation allows you to heat the surrounding space faster and more evenly.

Elements:

- fuse;

- thermostats;

- warning lamps;

- switches.

Power adjustment, rollover protection, and an emergency valve may be provided.

Operating principle: when voltage is applied to the electric heater, heating occurs. Heat is transferred to the oil. It expands, becomes lighter, rises. In its place comes cold, heavy. It turns out to be a cycle.

Heating element with two spirals

An adjustable thermostat is attached to the plastic cover to adjust the temperature of the case. The bimetallic plate, when the set temperature is reached, opens the power contacts, de-energizing the heater. When the temperature drops, the plate cools down and switches on the contacts. Some heating elements have two spirals and are connected via key switches located on the body.

To protect against rollover, a device is provided - an eccentric moving contact that opens when the radiator is tilted. Overheating protection - thermostat, there is a button to turn it on again, or an emergency valve. The electric heater will not turn on so that the owners are warned of a malfunction.

Electrical circuit diagram

Parameters to consider when choosing

Depending on the purpose for which the heater is purchased, the requirements for the device will differ. Therefore, before going to the store, you should think about how long this unit will be used, how much space it should heat, where it will stand, and so on. Sometimes even the color of the case matters. Other features to consider when purchasing can be seen in this video:

For ease of movement, some structures are equipped with handles, this makes it possible to easily move them, for example, from one floor to another. If you need to first heat one room, then another, then the built-in rollers will come in handy.

They won't scratch the floor and only require one person to move, even if the unit is hot. In cases where there are few outlets in the house, a long cord is required, this is also provided by some manufacturers. If the cable is not completely used, its remains are wound on a special bracket. What else should you pay attention to?

Power

This is the main indicator; the time spent heating the room depends on the power. A lack of power will not allow you to raise the temperature to the required value, and an excess will not be considered a disadvantage, unless heating occurs faster and the price is higher. Another thing is that more powerful heaters consume more current per unit of time. This can be seen in the table below.

Dependence of current on power

If you add an electric kettle, a powerful vacuum cleaner, or a water heater to the heater, the home electrical system will fail. Another reason to choose a less powerful unit is to reduce humidity. The more powerful the device, the drier the air becomes.

Advice. It is usually recommended to choose power at the rate of 1 kW per 10 square meters, provided that the room is insulated. If there are cracks in the doors and windows, then a powerful device will not cope, especially if there is severe frost or wind. For a more accurate calculation, you can use the electronic version of the power calculator.

Radiator section thickness

Manufacturers try to make the thickness of the sections as small as possible, because the oil cools faster. Unlike water radiators, which use process water with many impurities deposited in them, oil radiators use pure coolant. To increase heat transfer, in some models the upper part of the heater is expanded, as can be clearly seen in the figure.

Extended top model

Others incorporate a fan, forcing air through the sections.

Power mode switch

This function allows you to adjust the heating speed. Mainly used to quickly heat a room. For example, arriving at a dacha or country house for weekends or holidays. Two types of switching are used:

- using switches;

- using a thermostat.

The first method uses additional heating element coils. Turning on all the switches located on the case puts the device into forced mode. After the temperature has reached the desired level, the additional heater coils are turned off, and the device operates in gentle conditions.

In the second case, a wire with increased resistance is wound onto a bimetallic plate through an insulator and connected to the heater circuit. During operation of the heating element, the wire heats up and heats the plate. The more the spiral works, the more the plate heats up; when the set level is reached, it is triggered, turning off the spiral. Usually there is a second indicator that signals when the device is turned on and off.

Humidifier

Rapid heating of the room is associated with one unpleasant consequence - the air becomes dry. This occurs due to an increase in its volume. When heated, the gas expands and the excess goes outside, causing the water vapor content to decrease and the air to become dry. This phenomenon is poorly tolerated by many people. Some heater models are equipped with an air humidifier. This is a plastic water container that is installed on the radiator. While the heater is operating, the container heats up and the water begins to evaporate, saturating the air with the necessary moisture.

Interesting! To raise the humidity, just hang a damp cloth next to the device. When it dries, the water passes into the surrounding air. Wet cartridges can also be used; they are installed in the path of the fan, which drives air through the radiator.

Built-in fan

The main purpose of the fan is to speed up heating. It is mounted in the cover in such a way that the air flow created by the fan is directed towards the radiator. Passing through the heat exchanger, the air heats up and, leaving the unit, mixes with the surrounding atmosphere. Turns on and off using a switch located on the lid. Thanks to forced circulation, air mixing occurs faster. Typically, fans are installed on more powerful devices.

Heater with fan

The disadvantages are noise and the need to control the condition of the fan, because... it is not designed for long-term operation.

Device weight

When choosing, do not forget about the weight of the device. If it needs to be carried and transported frequently, then it is best to choose one with handles and wheels. Weight will depend on the power of the heater and the presence or absence of a fan. The number of sections and the size of the device itself also affects the weight. Therefore, you should consider all the pros and cons, and, if everything suits you, make the final choice.

Disassembling a failed oil heater

The work of replacing the heating element begins with dismantling the front panel. In order to remove it, you first need to unscrew the two mounting screws from the top, then place the heater on the rear edge and unscrew two more from the bottom. After this, the cover with the front panel located on it can be easily removed.

PHOTO: youtube.com The cover with the front panel is held in place by 4 fixing screws - 2 on top and 2 on bottom

What is located under the removed cover?

When the cover is unscrewed and removed, you can see that all the automation is located on it. On the heater body itself you can see the wires leading to the heating element, and just above it there is an emergency cut-off switch that interrupts the voltage supply to the heating element in case of overheating. It works on the same principle as the disconnect device for an electric kettle. When the temperature limit is exceeded, the plate sharply changes its shape, opening the contact.

PHOTO: youtube.com The cover is removed, you can see what is located under it

Guarantee

The warranty period for storage of oil radiators is 1 year, and for use - 2 years.

During the warranty period, the manufacturer guarantees satisfaction of the buyer's requirements related to problems in the operation of the radiator, subject to the rules of operation, transportation and storage of the device.

Warranty obligations are fulfilled only if the fact of purchase is confirmed by a receipt, where the date of purchase is clearly visible.

Warranty obligations are not fulfilled in case of mechanical damage to the device, such as dents, scratches, or other defects.

Do I need to change the oil?

If you look at the heater body, you will notice that it is hermetically sealed. This is done to keep the volume of liquid constant throughout the entire service life. This period must be indicated in the passport. After this interval is completed, the device cannot be used, because the oil loses its properties.

However, this is not the only reason limiting service life. This has to do with thermostats. The operation of the bimetallic plates, which are the main element of this device, begins to malfunction

This is especially important for protective elements, on the action of which the safety of people and property depends.

However, sometimes the oil still needs to be changed. This can happen for two reasons:

- radiator breakdown;

- depressurization due to corrosion.

To reduce the weight, they try to make the radiator walls thinner; the minimum value is limited by the pressure created inside. Due to this, the radiator can be easily damaged by a sharp solid object. Damage can be detected by dust; it is firmly attached to the body.

The coolant itself may not penetrate through such a gap, but its vapors, and even under pressure, come out

Therefore, you should immediately pay attention to such places. It is recommended to protect the heating device from falls, do not store it near sharp objects and keep children away from it.

Visible stains

The second reason for loss of sealing is rust. Although the body is carefully coated with paint and varnish, microcracks appear during operation. This is due to the different expansion coefficients of metal and paint. Moisture, penetrating into these cracks, begins to corrode it, and internal pressure completes the action of water, breaking through the body. The result is a leak. It can also be detected using dust collecting in this place.

Appearance of rust

You can, of course, cover the radiator with an additional layer of paint from time to time, painting over microcracks. However, paint and varnish materials have thermal insulation properties that interfere with the normal operation of the device. It will be easier to use the heater in places where there is no high humidity. Also, for the same reason, manufacturers do not allow the radiator to be used as a clothes dryer; in some models, special frames are used for this purpose.

Electric heaters are especially susceptible to corrosion during storage. If the air around it is quite dry when the device is operating, then during storage the humidity is not controlled in any way. It will be better if it is located in a dry place protected from moisture.

Technical parameters of the oil device

During operation, some important requirements must be observed. The device must be stable and the cord must not be strained. Install in a place out of the reach of children or secure it. Avoid exposure to moisture. Do not operate near flammable materials. Do not use after the service life has expired.

Compliance with these rules will allow this useful device to work for a long time and bring joy to its owners.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

We repair the heater

The appearance of the heater creates the feeling that it is a single whole, that is, the electrical unit and the body are connected using rolling. But this is only an appearance

Pay attention to the inscription “do not cover” - under it there are several screws with which the lid is held on the body. They need to be unscrewed, but the lid will not come off, because there is a spring installed in its lower part that holds it

Simply remove it and remove the lid.

Now pay attention to the heating element. It is tightly and hermetically sealed

Manufacturers did this on purpose to prevent curious people from prying into it. These tubular heating elements last for decades, so there is no point in touching them. If one of them fails, then it is better to purchase a new oil heater. No one can repair such a breakdown with their own hands. To do this, you will have to replace the elements, but at home and even in some workshops it is impossible to roll the heating element back into the housing with 100% tightness. The result is constantly leaking oil, which can lead to big troubles.

But anyone can wipe the connection elements with alcohol. All of them are made in the form of terminals, so disconnecting, cleaning and connecting them back will not be a big problem

It is important here not to confuse anything when installing the wire to a specific terminal.

The same goes for replacing power supply and safety parts. It will be difficult to repair any of them with your own hands. And if you are not an expert in this matter, then you are unlikely to succeed. Therefore, there is only one way out - to replace the failed elements with new ones. They are all held on by screws or brackets, so removing them won't be too difficult. Again, we remind you that your main task is not to confuse the connection wires. After all, the electrical circuit of a radiator is the basis for its correct and efficient operation.

For industrial purposes or for home: household or industrial

If for domestic needs there are a large number of offers at different prices, then for industry there is a separate line of products that differ in power, size and, accordingly, price. The maximum number of sections of one oil radiator is 14. For industrial premises, it is important not only their required number, but also their correct location. Thus, suspended models heat the air faster, and the power of the device must be at least 2.5 kW.

What is an oil heater and how does it work?

In terms of its design, an oil heater is a regular heating radiator, into which an electric heating element is mounted, and the free space inside is filled with mineral oil. Why not water, like regular batteries? The oil has a low coefficient of expansion when heated and retains heat longer.

The principle of operation of an oil heater is similar to the principle of operation of a water heating radiator: the oil comes into contact with the heated surface of the heating element located at the bottom of the tank, heats up and rises. The entire volume of oil gradually warms up and transfers heat to the metal walls of the heater. The heated walls of the radiator radiate thermal energy into the space, heating it.

To prevent overheating of the coolant, the device is equipped with a thermostat, which allows you to control the heat transfer of the device.

Classification and main characteristics

There are many oil-type radiators, which differ in the number or presence of additional options - built-in mechanisms, fans or place of operation.

Wall mounted

Models that can be attached to a vertical surface are called wall-mounted. They tend to be flatter and have non-protruding sections that do not interfere with the bracket's ability to catch on the hanging hooks. Often such modifications are universal - they have a place for screwing on wheels, which allows you to install them on the floor in the right place.

Floor-standing

This type is the most common and is popular due to its portability: if it is necessary to heat several rooms, it can be reinstalled with little physical effort.

The heat transfer of such a floor-mounted device is the highest. There is a separate subtype of floor models - baseboard heaters. They are installed in the corner of the wall and floor in place of the baseboard. They have a long and narrow shape.

Tabletop

Modifications that can be placed on a table are small in size and the same weight. They are designed to provide additional heating to a small room. Also used in the form of heating a children's room or crib.

The number of sections for tabletop types is no more than 5; the height of such sections is half that of floor ones.

For cots

Radiators designed for heating children's rooms differ, in most cases, in their appearance and mobility.

These can be either wall or tabletop modifications with bright colors. A significant advantage of using such a heating element is that the air does not dry out, and the humidity during battery operation is at least 60%, which is important for children who are often ill.

Children who often suffer from acute respiratory viral infections or chronic lung diseases - bronchitis, laryngitis, tracheitis - need constant air humidification. Fans that operate on the principle of a hair dryer cannot be used to heat a room - they heat up and move air around the room.

How does the heater work?

The main parts of the unit include a metal casing consisting of hermetically joined sections. Powder coating is applied on top, enhancing the strength characteristics of the metal.

There is oil in the housing.

The heating source is a tubular electric heater (TEH). Located at the bottom of the body. By heating the oil from below, the heating element stimulates the formation of convection currents inside the device. Uniform heating and heat transfer occur.

The control system consists of a switch and a power regulator. Power mode switches, timers for turning on and off the device, thermostats that respond to room temperature are present in the new models.

Equipped with fans and humidifiers. In case of breakdown, older models are easier to repair.

Safety is ensured by overheating and tip-over sensors.

- The first controls the oil temperature. If overheated, it may boil. High temperatures in the housing can lead to equipment failure. When the oil filler boils, air is released, increasing pressure on the housing from the inside. Due to high pressure, the housing may become deformed and crack. Leakage of boiling oil liquid poses a fire hazard.

- The second is a position sensor. For the heater to function normally, the heating element must be completely immersed in an oil environment. When the unit overturns, oil accumulates on one side, the heating element runs dry, quickly overheats, and burns out. The sensor, when the heater tips over, instantly cuts off the electricity supply to the heater.

Precautions for use

In order for household electric oil heaters to function effectively, and to bring you, as users, joy and comfort, you should follow some easy-to-follow precautions:

- Remember that oil radiators should not be placed in rooms with high humidity (such as a bathroom).

- Do not touch or place the power cord on the hot body of the device, because the “jacket” of the cord may melt.

- Electric oil heaters should always be in a vertical position.

- It is better not to connect the heating unit using an extension cord, since no one has ruled out overheating during operation.

- An electric oil heating radiator should be located as far as possible from products that are easy to melt. It is advisable to place furniture at a distance of at least half a meter.

- Do not pull electric oil radiators by the power cord (a special handle was invented for this purpose!).

- It is better not to store the device on the balcony or in the closet. This may contribute to its failure.

The recommendations are not complicated, however, if followed, they will help protect you and your home from unpleasant situations, fill the room with warmth and create a favorable microclimate.

You can read about possible oil radiator malfunctions, methods for diagnosing and eliminating them here.

How to repair an electric convector?

Electric heater device

So, first, let’s look at the design of an electric convection heater so that you understand what will have to be checked and repaired. The heater consists of a cord with a plug plugged into an outlet, an on/off button, a thermostat and a heating element (heating element). In addition, the circuit may contain a thermal fuse that protects against overheating, as well as a tilt sensor that will turn off the power and save from fire if the mobile convector is tipped over. Also, some models may have a special sensor installed to protect against the penetration of foreign objects into the housing.

We've sorted out the design, now let's move on to the basics of repairing an electric heater with our own hands.

Malfunctions

The most common problems with oil radiators are:

- A cracking noise is heard when turned on and during the first 10-15 minutes of operation. If after this time the cracking disappears, it’s okay. It occurs when the oil inside the radiator heats up.

Perhaps drops of water got into it, which causes such a reaction. This is possible if the device was assembled in conditions of high humidity.

- The radiator does not turn on. First, carefully inspect the cord and plug for cracks or creases. If they are not found, try plugging the heater into a different outlet.

If this does not work, then the problem is in the contact, which has come loose. Try to repair the device yourself or send it to a service center, where experienced technicians will solve the problem.

- The device turns on, but does not heat up. At the same time, indicator lights, a fan and other additional devices on the case work.

The cause of such a breakdown is problems with the thermal relay; it cannot be eliminated without special tools. Contact the service center.

- Oil is leaking. Such a breakdown occurs due to a manufacturing defect (poorly sealed seam) or a long period of use of the device.

Over time, the metal at the joints burns out and becomes thinner, which leads to this type of failure. Unfortunately, it is impossible to repair an oil leak either independently or at a service center.

If the breakdown is serious, you should carefully consider the prospect of buying a new radiator, because sometimes repairs cost more than a new device.

Conclusion

An engine oil cooling radiator is not included in the standard equipment of all cars, but it copes so effectively with the task of controlling the oil temperature and protecting the engine that many car enthusiasts decide to install this device on their vehicles. The radiator cannot be called a durable car part - it has little mechanical strength, and the connecting elements of the oil system tend to gradually age and depressurize. An engine oil leak should never be ignored, and in systems with a special cooler it can also be observed in the radiator. If the car requires replacement of the oil cooler, we recommend purchasing spare parts from well-known European manufacturers. Although they will not be cheap, they will guarantee the efficiency and durability of the engine oil cooling system.

Source

Selecting an oil cooler

If your car has a standard “supplemented” oil system, then you can search for its components using the VIN code, the parameters of your vehicle, or the radiator code. It’s easier to search for car parameters in online stores - this gives a fairly accurate result. This way you can find codes for both the original radiator and the closest analogues. If the standard equipment of your car did not include an oil cooler, then you will have to select it yourself. Here's what to remember:

What power is needed

You need to choose an oil cooler not only based on its set of functions or appearance, but also on its power. A small device will not be able to fully provide heat to a large room, but buying a large multi-section heater is also not always advisable. To understand how powerful the device should be, you need to make simple calculations.

Compact heater for a small room

For high-quality heating of 10 m2 of area, 1 kW of energy is required. This rule works for rooms with a standard ceiling height of 2.7 meters. That is, for a room of 15 m2 you need a device with a power of at least 1.5 kW. If the height of the room is greater or less than that indicated above, then the calculation becomes a little more complicated:

- Calculate the area of the room (multiply the length by the width).

- Calculate the volume of a room by multiplying the area by the height.

- The result obtained is divided by 25.

These calculations are not valid for all cases: professionals recommend taking into account such factors as climate, age of construction, condition of seams in walls and ceilings, presence or absence of insulation and other points.