Here you will learn:

- What is convection

- Advantages and disadvantages of convector heating

- Types of convectors

When planning to create heating in our home, we want it to be economical and efficient. Convector heating has precisely these characteristics - it is based on convectors powered by bottled or main gas, water systems or an electrical outlet. Let's see what convectors are, how they work and how they differ from each other. We will also look at the main features of convector heating of residential premises.

Main varieties

Various energy sources can be used to operate convection heating in a private home, but most household devices of this type are equipped with electric heaters. There are also gas convectors that run on gas. The great popularity of electric models for heating rooms is explained by their compact dimensions. In cases where convective heating plays the role of the main one (which often happens in country houses and dachas), it is more profitable to use gas modifications, because gas is much cheaper.

Based on the installation method, convectors are:

- Floor-standing

. Designed for floor placement. Some models are equipped with special wheels for mobility. In other cases, a rigid installation is used, without the possibility of movement. - Wall mounted

. They are hung on the walls of the room, for which the product kit includes the appropriate fasteners. - Built into the floor or baseboard. This installation principle allows you to save living space.

Self-installation

You can install gas equipment in a private home with your own hands, but to do this you need to have all the necessary tools and have certain skills.

The following materials and tools are used during the work:

- metal-plastic pipe with fittings;

- pipe cutter;

- wrench;

- sanitary silicone;

- gas tap;

- perforator with a “spatula” crown;

- drill with drill bit;

- crosshead screwdriver;

- high-temperature polyurethane foam and silicone;

- dowels and screws made of plastic.

Stages of installation work:

- First you need to decide where the gas appliance will be installed. According to GOST, it is mounted under the window.

- The convector is fitted to the selected location. You can use a tape measure and transfer the dimensions, or simply attach the unit to the wall and mark the locations of future holes.

- Let's look at where the gas inlet is located. If at the bottom of the device, then you need to leave enough space for the supply of a pipe with a fitting.

- A hole is punched in the wall along the diameter of the exhaust pipe. This can be done with a hammer drill. This procedure is not only labor-intensive, but also dusty, so it is recommended to cover things with film in advance.

- Holes are drilled and dowels are hammered into them.

- The exhaust pipe is inserted into the convector. The joint should be treated with high-temperature silicone. After the pipe is inserted into the wall, the convector is secured using self-tapping screws.

- A gap is sealed between the pipe and the wall. This can be done conveniently using high-temperature foam.

- A special cap, included in the package, is installed at the end of the pipe. It prevents the burner from going out due to wind. Self-tapping screws are used to secure it.

Procedure for gas supply:

- The pipe leading to the heating device must be laid outside. This is the requirement of GOST. If the gas pipe already has a threaded connection, then just screw the tap onto it and shut off the gas supply to the convector. If there is no withdrawal, then one will have to be made. To perform this work, it is necessary to invite an electric and gas welder.

- After installing the gas tap, a metal-plastic pipe is connected to the convector. You can calculate its length using a tape measure.

- When laying the pipe, every meter should be secured with clips, for which you will need to drill holes in the wall.

- Installed fittings, like pipes, are lubricated with silicone, which provides additional sealing and facilitates installation work.

Now you need to check how the equipment works by doing a test run:

- The gas valve is opened and a soap solution is applied to all fittings and connections. Inflating bubbles will indicate a leak. If any are found, the tap should be turned off and the problem fixed.

- Next, the convector starts up. The gas supply button is pressed for about a minute, during which the gas will pass through all the pipes and end up in the combustion chamber.

- The piezo igniter is pressed, causing a spark to form in the firebox and ignite a flame.

- The device is adjusted so that the room temperature is comfortable.

At first after starting, you may notice an unpleasant smell of burning oil. This is normal - this is how the camera burns on new devices. If the smell persists for a long time, you need to check the quality of the joint between the exhaust pipe and the outlet of the device.

Frame

Most often, steel is used for the manufacture of modern convectors. The design of the housing can be very diverse, so there are usually no problems with choosing a heater for a specific style of room. There are special fastenings (brackets) on the body of wall-mounted modifications: they make it possible to remove the device from time to time for maintenance.

In some cases, the protective steel box of the convector is equipped with adjustable blinds on the sides: by changing their angle, you can adjust the direction of air flow. This design solution allows for volumetric distribution of heat in the room, which makes its heating more uniform. To avoid underheating, when choosing a convector, it is recommended to leave some power reserve (especially if it is installed in a corner room).

Useful additional features

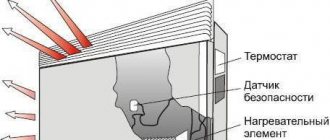

When choosing electric heating convectors, pay attention not only to technical parameters. There are also additional functions that increase comfort and safety:

- Overheat protection. An additional sensor is installed on the case, which turns off the power when a threshold value is reached. Usually it is +60°C.

- Drop shutdown. This function is relevant for models with floor-mounted installation. If the position changes (falls or bends too much), the power turns off. This function prevents possible fires.

- Restart. When turned on again, the electric convector automatically sets the settings that were when it was turned off.

Skirting-type convector - very low and long

Overheat protection and drop shutdown are very useful features that increase the safety of the equipment. Something else you can pay attention to is how quiet or loud the unit is. It's not just the heating element (it usually clicks). When activated, the mechanical thermostat also clicks. When choosing convection heaters for your bedroom, quiet operation is very important.

A heating element

Electric convectors are equipped with various heating elements. The most inexpensive solution is steel products, found in the cheapest appliances. The high temperature of the heating coil (up to +160 degrees) allows the room to quickly warm up. However, spirals of this type have a low degree of safety: phenomena such as the accumulation of dust or accidentally ingress of water can cause the device to catch fire. The popularity of spiral convectors is explained, first of all, by their low cost. Some manufacturers additionally equip the device housing with special fans, which, in combination with a high-temperature coil, increases the heating intensity.

More expensive models are equipped with safe low-temperature coils that heat up only to +100 degrees. Elements of this type have the form of dissipative radiators made of aluminum with a built-in steel pipe. A special heating filament is located inside this tube. Thanks to the aluminum housing, heating efficiency is noticeably increased. In some models, instead of one, two tubes are used, which allows you to adjust the operation of the heating block.

The different degrees of expansion exhibited by aluminum and steel provoke a gradual decrease in the reliability of the connection between the heating tube and the housing. As a result, this can lead to a complete breakdown of the connection between them. As a result, there is a danger of local overheating of the tube and damage to the heating element. Manufacturers of convection equipment are constantly searching for a solution to this problem.

RX-Silence heating devices, developed and patented by NOIROT (France), are particularly unique. The innovative design of these convector boilers lies in the complete tightness of the silumin body, where magnesium powder is used to seal the nichrome heating filament. The expansion coefficient of the materials used has very similar values, which makes it possible to significantly reduce energy consumption and increase the service life of the convector to 15-17 years.

Safety rules when using EC

Any type of electrical appliance requires compliance with certain safety rules. There are some restrictions for the use of convectors.

If the electrical wiring is in good condition, heating convectors can be left unattended for some time, especially if the models are equipped with overheating sensors

Safety regulations:

- Under no circumstances should the appliance be covered or used as a clothes dryer.

- It is not recommended to place the convector near an electrical outlet: the minimum distance at which the device should be located is 0.8 m.

- For rooms with a high content of water vapor, device models marked IP 24, indicating a high degree of moisture protection, are suitable.

In general, modern devices have a high level of reliability and fire safety.

Convector heating control unit

The simplest version of the control unit for convection heating is a thermostat installed inside the heater body. Thermostats are divided into electromechanical and electronic. Electromechanical devices are cheaper, which affects their operating accuracy (the error sometimes reaches 2C0). It is also worth highlighting the noise that occurs from the clicks of the bimetallic sensor when the device is turned on. To set the required temperature regime, electromechanical models have a knob marked with the conditional values of the convector power.

Electronic thermostats are more accurate: their error rarely exceeds 0.1 C0. In addition, convectors of this type are completely silent. A number of models make it possible to program the electronic control unit to enable various operating modes and power, depending on the time of day and day of the week. At the same time, electronic thermostats have the function of remote control of the heating element using an external control device.

As a result, it becomes possible to monitor the operation of a significant number of heaters located in different parts of the home. The convector heating system unit allows the use of built-in operating mode programs separately for each room, or for the entire house in the complex. The French manufacturer NOIROT and the German corporation Siemens are leaders in the market of “intelligent” convectors. Their products provide the ability to control the temperature remotely via phone. This allows you to warm up your home well before your arrival.

Electric heaters

This group of heating devices independently produces heat by converting electricity. The heart of the device is the same finned heat exchanger, only inside it, instead of pipes with water, a heating element is installed. The element is placed inside a metal case, where slots are made in the lower and upper parts for air passage. The electric convector is automated from the very beginning, since even the cheapest version is equipped with a thermostat that controls the operation of the heating element.

It should be noted that heating with electric convector heaters is not only convenient, but also effective. The efficiency of the devices reaches 98%, and a high degree of automation allows you to save electricity, this is achieved by programming the heater for different operating modes at certain times of the day. According to their design, electrical appliances are:

- wall-mounted;

- floor (mobile);

- baseboards;

- intra-field.

For reference. Several convectors can be combined into a common system controlled from one center, for example, a remote programmable unit with a thermostat.

If you study all the reviews about such heaters, the negative is expressed only in one respect: it is expensive to pay for electricity. Otherwise, there are very few complaints, which is not surprising, because the price of the equipment and its installation is quite affordable for a wide range of buyers. There are also no problems with the heating speed; any convectors are famous for this.

Main settings

Having figured out what convector heating is, you should arm yourself with general information about its technical characteristics. The power of electric convectors is in the range of 0.8 -3 kW, weight - from 3 to 9 kilograms.

Electric convectors currently available for sale are divided into three groups:

- High (450-670 mm).

- Medium (up to 330 mm).

- Narrow (for skirting boards), 140-200 mm high.

Due to their parameters, high-type heaters are able to provide a significant level of convection. Skirting models are equipped with less powerful heating elements. To maintain the proper level of efficiency, they are given a large length (up to 2.5 m).

Installation in a private house

The ease of installation of electric convectors allows you to implement this procedure yourself.

Before you make convector heating with your own hands, you need to prepare the following tools:

- Hammer.

- Screwdriver.

- Hammer.

- Level.

A wall-mounted electric convector is installed in the following sequence of operations:

- Assembling the device, during which it is necessary to secure all the brackets to the body.

- Fitting the structure to the wall surface: it must be leveled. During this, marks are made at the location of the brackets.

- The brackets must be removed from the panel and attached one by one to the applied markings. This makes it possible to mark points for drilling holes for fasteners.

- Using a hammer drill, holes are made in the marked places.

- Using a hammer, carefully hammer the dowels into the base.

- To screw the brackets, use a screwdriver or screwdriver.

- The instrument panel is hung on well-fixed brackets.

- To start operating the convector, it must be connected to the network.

When using electrical appliances, it is important to understand that such convector heating of the house will significantly increase the load on the network, so you should calculate in advance whether the old wiring will withstand this. To ensure heating safety, it is recommended to equip devices of this type with separate cable lines. https://www.youtube.com/embed/WZnvggq6oWI

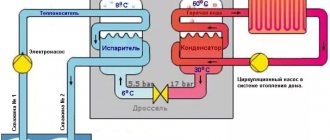

Gas convectors

Along with electric convectors, gas-powered appliances with a very similar operating principle are also produced. In this case, gas burners are used instead of spirals to operate the devices. They look like special chambers, the walls of which, as they heat up, transfer heat to the battery. Heating of the surrounding space is carried out directly by the radiator.

Pros and cons of gas convector heating:

- Gas devices do not use complex electronic controls.

- The cost of gas is an order of magnitude cheaper than electricity, so it takes less money to heat your home.

- The complexity of their installation and increased operational requirements (for example, the presence of a chimney) limits the scope of use of gas convectors exclusively to the private sector.

What is convection

Convective heating uses the simplest laws of physics, according to which heated air becomes lighter and rises. Every heating convector is built on this principle, regardless of what it is powered from. As practice shows, this scheme is highly effective - residential premises become warm, and relatively quickly .

Convector heating allows you to heat rooms for any purpose - these can be living rooms, children's rooms, corridors and foyers, kitchen areas, bathrooms and toilets, covered balconies and loggias. It heats using heated air, quickly saturating the heated rooms with heat. Let's see how the warming up process occurs:

All convectors work on the same principle - they create air circulation in the room, gradually warming it up.

- Possessing a large working surface area, the heating element heats the air around it;

- Warm air masses rise upward, leaving the equipment (or simply going upward if convector-type heating radiators are used);

- Cold air masses replace the air that has gone up.

The process is repeated until convector heating warms up all the air in the rooms.

Heating elements can be powered by electricity or by burning gas fuel. Convector-type heating batteries operate due to the coolant entering them. By the way, the batteries do not have housings, unlike the same electric and gas convectors. But their operating principle is similar - heating is carried out due to the heating air, and the thermal radiation from them is very weak.

How to choose the optimal model

The selection of heating equipment for a country house is primarily associated with determining the required power of the unit. Based on practice, it is quite difficult to clearly determine what power a convector to buy. Most often, sellers use a simple calculation formula, multiplying the area of the room (in square meters) by a factor of 0.1. The calculation looks like this:

20 sq.m. x 0.1 = 2 kW.

Therefore, to heat 20 square meters you need a convector with a power of at least 2 kW. If the room has high ceilings (above the standard 2.7 m), then the indicator is multiplied by an additional factor of 1.5:

2 kW x 1.5 = 3 kW.

In addition to area, other factors can affect heating:

- lack of interior decoration;

- lack of insulation on the floor and walls;

- structural or other openings in walls, windows, door openings, as well as cracks.

Naturally, if the room is absolutely not heated and not insulated, it will be difficult to warm it up the first time. A convector is only suitable if it operates without interruption in winter. For example, a frozen concrete room with an area of 30 square meters will have to be warmed up (to +10°) for about 5 - 6 hours with a three-kilowatt heater, or 3 hours with two of these. To reach a higher temperature you will have to wait a couple more hours.

Note! It is recommended to purchase heating appliances with a small power reserve, about 15% of the required one.

This is done so as not to regularly operate the electrical appliance at maximum power. In addition, if external conditions change (for example, at low temperatures that are not typical for the climate zone), you will not have to buy additional equipment.

Let's sum it up

Assessing the features of convector heating devices, we can conclude that most models will be a suitable solution for a country house. Moreover, it does not matter whether the dacha is a substantial country house or a small building for rare visits.

It is important to eliminate all sources of heat loss and take care of insulation of walls and floors. If you plan to use the device as the only source of heating, its failure in the winter threatens to disrupt your plans or vacation. Considering that country houses are usually located far from city limits, preference should be given to reliable convector models. The priority will be the presence of a monolithic heating element, a mechanical thermostat and a durable housing.