Operating boilers around the clock leads to increased wear and tear. Do you agree that the operation of heating and water heating equipment should be safe? Why periodic inspections and repairs of gas units are carried out.

Prevention with the identification of existing defects allows you to prevent the occurrence of emergency situations. Who should carry out maintenance of gas boilers and what set of measures does it include? It is these questions that we will consider in detail in the article.

Our material contains a description of the main stages of service activities and step-by-step photos of maintenance. In addition, we have selected videos on maintenance of the boiler and its components.

Professional solution to the issue

At first glance, there is nothing complicated in carrying out preventive maintenance measures for boiler units. But you shouldn’t set up and clean a gas boiler yourself. And it's not just a matter of experience.

Such a critical procedure should only be performed by a qualified specialist who has the precise equipment necessary to diagnose faults.

The quality of boiler equipment maintenance directly depends on the professionalism of the technician. Therefore, such work should be entrusted only to professionals with special permission.

In the event of an unforeseen situation, the master will be able to react correctly and quickly, thereby preventing unjustifiably serious, sometimes catastrophic consequences

According to paragraph 6.2 of the current SNiP, servicing of boiler equipment must be carried out by licensed organizations that have their own emergency dispatch service.

Leading manufacturers of gas boilers, in order not to open branded service centers in every region of the country, issue licenses to organizations specializing in the field of maintenance.

You may be interested in information on how to choose a good and reliable gas boiler, discussed in our other article.

In addition to a certificate for performing a specified range of work, such organizations receive full access to technical documentation for equipment produced by the manufacturer, as well as the opportunity to receive new boiler components for warranty replacement. A list of certified companies is usually listed on the manufacturer's website.

When choosing a service organization and drawing up a contract, you should focus on two parameters:

- Certification of the boiler manufacturer, confirmed by the presence of a license to carry out work.

- The location of the service center in the same city or region, which will reduce the response time of the field technician.

In most cases, a service contract is signed before the boiler is fully put into operation. It clearly states the list of future works and the deadlines for their completion.

As a supplement to the contract, a boiler passport is attached, which specifies all the design features of the system, a complete list of its components and elements, as well as the timing of maintenance.

The work offered by service organizations is divided into three types:

- Routine maintenance is regular preventative work carried out to assess the technical condition of the unit, identify and eliminate impending breakdowns, to prepare the unit for the heating season and after its completion before summer inactivity.

- Maintenance upon request of the subscriber - includes measures to identify violations and damage to the system, diagnose the performance of the gas appliance or its individual parts, and eliminate breakdowns and malfunctions.

- Overhaul is a set of measures in the event of a unit breakdown, carried out in the event of emergency situations caused by external factors or as a result of equipment failure.

The regularity of preventive maintenance of equipment depends on the purpose of the installed unit and its design.

A list of mandatory “procedures” for routine maintenance and overhaul, as well as the frequency of their execution, is provided by the manufacturer for each specific model

On average, routine inspections are recommended to be performed 2 times a year. They are carried out both for devices included in the heating circuit and for units of hot water supply systems.

Failure to meet the deadlines for such an important event can lead to serious consequences. Thus, a clogged pipeline can cause a failure of the heating system, and depressurization of a gas pipeline can cause an explosion and fire.

Image gallery

Photo from

Stage 1: General diagnostics of the technical condition of the equipment

Stage 2: Adjusting the column ignition and gas combustion process

Step 3: Checking the tightness of the heat exchanger

Stage 4: Monitoring the condition and performance of the turbine

Why do breakdowns occur and how to prevent them?

Modern equipment is distinguished by a high level of quality and reliability. Despite this, minor and major breakdowns are possible over time. They don't just happen - there is always a reason for them. As a rule, major breakdowns are preceded by small failures, which, unfortunately, users often do not pay attention to. However, if you respond in a timely manner to seemingly insignificant failures, then serious breakdowns may not occur at all, since a chain reaction from minor to major breakdowns will not be “set into motion.”

It is precisely based on the scheme “small failures lead to major breakdowns” that the manufacturer recommends maintenance of boiler equipment at least once a year, and preferably twice a year: before the start and at the end of each heating season. Prevention allows you to prevent minor failures and shortcomings in the operation of the boiler, to ensure high-quality and uninterrupted operation of the heat-generating installation, especially in winter.

Regular service inspection of boiler equipment has advantages, including from a cost-saving point of view. Minor repairs and inspections once or twice a year are much cheaper than major repairs when equipment breaks down.

Basic steps of the current service

To fully control the situation, you should understand what work is performed when servicing various parts and components. Routine maintenance of a boiler generator includes three main types of work: cleaning, checking and adjustment.

Before servicing gas equipment, it is mandatory to turn off the system and gas supplies. The disconnected system should cool down slightly.

Step #1 - inspection of heating circuits

At this stage, a general idea of the current state of the operating system is formed.

First of all, the technician checks the documents and the warranty seal, determining whether the installation of the gas appliance meets the requirements of two main regulatory documents:

- SNiP - sanitary building codes and regulations.

- “Rules of technical operation and safety requirements in the gas industry of the Russian Federation.”

Since a gas boiler is a set of equipment that uses both gas and electricity, electrical elements are also subject to visual testing.

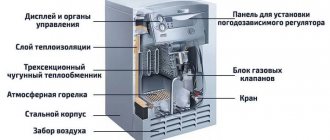

For an external inspection of a gas boiler, the protective casing is removed from the unit and all visible elements are sequentially inspected, identifying the degree of wear of parts

Checking the condition of the boiler unit is intended to clarify the following points:

- integrity of the device structure;

- gas valve pressure;

- ignition electrodes, if available;

- condition of gas supply connections;

- electronics performance;

- serviceability of emergency machines.

At this stage, the expansion tank is monitored and pumped, which is designed to protect the system elements and compensate for the pressure that is created during the expansion of the coolant.

During the technical inspection, the condition of the unit itself, protection devices and gas communications is visually and using instruments.

The pressure level in cold water, depending on the type of boiler, is 1.1-1.3 bar. It is important to ensure that after heating the pressure does not exceed the recommended standard specified in the passport for the unit.

Step #2 - cleaning system elements

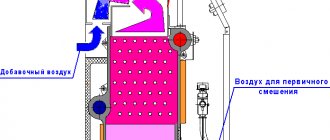

Before starting work, empty the boiler. After this, they begin to inspect the gas burner, determine the quality and direction of the flame.

To do this, remove and clean sequentially:

- retaining washer - a device that regulates the position of the burner torch relative to the installed heat exchanger;

- air sensor - it is designed to regulate the ratio of the mixture of air and gas;

- flame detector sensor - it generates a signal when traction indicators deteriorate;

- ignition device electrode – responsible for igniting gas-air mixtures;

All metal structures can become deformed over time under the influence of high temperatures and carbon deposits.

To prevent scale from clogging the burner, which is a key working element of the boiler, it must be cleaned in a timely manner using special brushes.

During normal operation of the burner, the flame has the shape of a cone, colored blue. A yellowish color indicates contamination.

Measuring and analyzing the boiler exhaust gases will help check the operation of the key operating element of the boiler and assess the compliance of the burner settings with the composition of the supplied gas, as well as the completeness of its combustion.

The fire area on the fuel combustion chamber and all parts of the boiler that are in direct contact with the torch must be cleaned. This task can be easily accomplished using a soft brush and a vacuum cleaner.

When cleaning injectors, do not use a metal brush, the bristles of which can damage the surface.

Separately, unscrew and blow air through the gas channels of the boiler. The gas supply pipe to the burner is removed, disassembled and purged under pressure.

The heating system is equipped with two filter elements. The first is located in the hydraulic unit, and the second is located on the cold water tap. These filters also require periodic cleaning of salt deposits by washing.

As maintenance is carried out, all faults discovered by the technician must be eliminated, replacing failed parts and assemblies with new elements.

Step #3 - checking the control automation

Modern boilers are equipped with automatic control systems, the main purpose of which is to ensure the operation of the unit without constant human supervision. The degree of complexity of automation can be very different.

But regardless of the model, its main elements are:

- Thermostat is a regulating device responsible for maintaining the set temperature parameters of the coolant in the boiler.

- Gas valves are designed to open and shut off the gas supply.

- Gas fittings are an actuator designed to execute commands from the boiler control circuit.

- The controller is an electronic device designed to implement a complex algorithm for controlling the unit depending on changing environmental conditions.

- Minimum and maximum pressure switches are membranes that act on groups of contacts, turning off the unit if the pressure drops/increases below/above the setting value.

This technique “painfully” endures a regular drop in tension. The technician’s task is to promptly detect problems in the electronic system, possible problems with parts, and correctly adjust the automation.

The boiler connected to the gas boiler, which is designed to supply the DHW system, must also be checked annually and regularly adjusted.

To check the functionality of the boiler safety system and identify vulnerable areas of the equipment, the technician simulates the occurrence of an emergency situation. After starting the system, he monitors the speed of operation of the alarms, the tightness of the shut-off valve and other devices.

If the automation does not work correctly, the unit is disassembled and the failed membranes are replaced with new ones.

The inlet part of the gas pipe is also subject to inspection. It is examined for corrosion and other damage.

The master must ensure the integrity of the gas supply pipeline throughout the entire section laid in the house, paying special attention to the outer surface of the pipes and their connections

All connections of the gas path, including flanged, threaded and prefabricated, are tested for leaks. Measure the pressure in the gas pipeline. If necessary, adjust the gas fittings. Places where paint has peeled off from the surface of the pipe are repainted.

Having adjusted all components of the boiler unit, the technician sets the parameters recommended by the manufacturer.

At the final stage, it carries out a final inspection of the boiler. The master fills out certification documents, confirming with his signature personal responsibility for the quality of the inspection performed. Finally, he makes a note indicating the period for the next service.

What does the law say?

Today, all owners who have entered into a gas supply agreement are required to carry out annual maintenance of gas equipment. The consumer must provide the gas service with documents confirming the conclusion of a maintenance agreement with the relevant company.

It is noteworthy that in Europe there is no practice of boiler maintenance - this is an exclusively Russian norm.

On May 14, 2013, the Decree of the Government of the Russian Federation was adopted

№ 410.

Who can carry out maintenance?

Both legal entities and individual entrepreneurs can provide services. The list of approved organizations is published in the register of the State Housing Inspectorate for your region. Specialists from authorized companies and firms undergo training at special plants, in our case, “UKK Mosoblgaz”.

What happens if you don't carry out maintenance?

Everything that is in the apartment (house) is the responsibility of the consumer. That is, it is the consumer who is obliged to find an organization to carry out maintenance, conclude an agreement with it and send the necessary documents to Mosoblgaz or Mosgaz.

If the regulatory authorities do not receive the necessary papers, then you may face a fine, and in the future, the gas supply will be turned off. They will cut the pipe and put a plug on it.

Carrying out major repairs

After the expiration of the operational period specified in the product passport, the gas boiler is subject to technical diagnostics. The main task of engineering activities is to determine the possibility of further safe operation of the equipment.

Major repairs are carried out to restore the technical characteristics of gas heating equipment. As necessary, worn parts and functional units are replaced.

In addition to diagnostics, as part of a major service the following is performed:

- Flushing the heat exchanger.

- Comprehensive inspection and cleaning of all closed boiler components.

A properly carried out set of measures guarantees the proper operation of gas equipment during the subsequent period of operation.

Scaling that forms in the heat exchanger coil due to improper maintenance leads to a gradual deterioration in the efficiency of the equipment

The heat exchanger is cleaned from scale after the first five years from the date of commissioning of the boiler unit. Although most service organizations recommend carrying out preventive flushing once every two years.

A simple procedure for flushing the boiler heat exchanger can eliminate the problem at the stage of scale formation.

To carry out major cleaning, remove the device casing and disassemble all removable parts of the unit. Separately, dismantle the heat exchanger and, using a pumping station, thoroughly wash it with chemical reagents.

This flushing allows you to remove all the scale that has formed in the pipelines and fins of the heat exchanger over several years. After this, the boiler is assembled and the system is filled with coolant.

In addition to servicing the gas boiler itself and the gas pipeline leading to it, it is important to regularly check the condition of the chimneys

Cleaning of smoke channels, designed to remove combustion products from gas appliances and create draft, is not included in the list of activities required to be performed by the master.

He can do this work for an additional fee. If desired, you can clean the chimney yourself. It is advisable to wash it at least once a year.

Maintenance agreement with an accredited organization

It is recommended to sign a boiler maintenance agreement before putting it into operation and operation. The contract must specify the full range of upcoming maintenance work along with the deadlines for their implementation.

When drawing up an agreement, the document contains the following information:

- details of the owner of the equipment, his full name and address;

- name, name and bank details of the organization providing maintenance;

- a complete list of devices and heat-generating equipment located on the owner’s premises;

- a list of services and maintenance work that are implemented on the basis of the concluded contract;

- expiration date and validity of the document (agreement);

- cost of services under the contract.

Operation of the boiler during force majeure

In the event of an emergency, it is necessary to react to the problem as quickly as possible and try to return the boiler to working condition. Breakdowns, if they occur, occur only during the heating season.

And the reason for this is most often that the unit operates at maximum power without interruption for a long period.

The unit can fail at the most inopportune moment, working at the limit for a long period of time, which leads to rapid wear of parts

Low-quality fuel, which is often supplied to the gas system, often leads to the same disastrous result.

Having a service agreement in hand, the owner can only call the organization. Having received the request, the repair team will arrive on site and fix the problem.

Since service centers always keep records of boilers, the visiting team’s specialists arrive on site with the necessary set of tools and spare parts that correspond to the specific model of the gas boiler installed in the house.

But there are situations when, during the peak of the heating season, repair crews are at a loss. And the masters may not satisfy the request as quickly as we would like. In this case, some owners resort to.

But it’s worth considering that calling the first gas worker you come across is not the best option. And it’s not even a tidy sum that the owner will have to pay. After all, no one guarantees that the master will be able to perform repairs at a high professional level in an emergency situation.

Therefore, in order to avoid such situations and save unnecessary costs, you should not neglect the opportunity to conduct a routine technical inspection before the onset of cold weather.

Warranty and post-warranty maintenance of boilers

A service agreement can be concluded for warranty and post-warranty cases. The first post-warranty inspection of the unit is carried out six months after the official warranty period from the manufacturer expires.

Our company provides a wide range of services for the maintenance and repair of boiler equipment of any level of complexity. We are an accredited service center for many global manufacturers whose boilers are sold in our range. Our company has an engineering and design department and a team of specialists for service diagnostics, maintenance and repair of boiler units, and has all the necessary licenses and permits to carry out work.

How to clean the heat exchanger of a floor-standing gas boiler

To disassemble a heating unit at home, you do not need any special tools; a regular set with screwdrivers, keys and pliers is sufficient. Preventive cleaning of the heat exchanger from soot and scale is carried out in the off-season, when the heating of the house is turned off. Having previously shut off the gas supply, we begin disassembling the boiler by removing the burner device in the following sequence:

- Disconnect all wires from the gas valve.

- Remove the thermocouple connected to the gas valve by a capillary tube from the combustion chamber.

- Disconnect the gas supply pipe.

- Unscrew the 4 nuts (or bolts) holding the stove with the burner. Pull the assembly out as shown in the photo:

The burner is removed along with the safety valve and mounting plate.

The gas boiler burner can be cleaned without further disassembly using an old toothbrush. The igniter, piezoelectric ignition device and flame control sensor (if equipped) should also be cleaned of soot. Now you need to get to the heat exchanger, for which you need to remove the top cover of the boiler, disconnect the draft sensor and the chimney pipe.

In the opened opening you will see insulation covering the chimney casing. Carefully remove the insulation, and then unscrew the screws securing the casing and remove it. Below it is a heat exchanger, from which you need to remove steel turbulators, as is done in the photo:

When removing the turbulators from the heat exchanger, the soot spills downwards, so the first thing to do is remove the burner

Cleaning the turbulators is easy; this can be done with a regular brush with metal bristles. But cleaning the heat exchanger of a floor-standing boiler is best done with the help of simple tools made by yourself according to the size of the smoke pipes. If they have a rectangular cross-section, then you need to bend a convenient flat spatula and a small scoop-shaped scraper from thin metal, then nail it to a wooden handle.

For round flame tubes, these same tools are made slightly curved. First, the walls of the pipes should be cleaned with a scoop, after which the soot remaining in the corners should be removed with a spatula.

At the end of the work, all surfaces of the heat exchanger can be cleaned with a brush screwed to a long handle. The last step is to remove soot from the bottom, where it was poured when cleaning the smoke pipes. This is what a clean heat exchanger of a heating unit looks like:

You can take a closer look at how to clean a gas boiler at home in the video:

Note. In the video presented by the master, the sequence of actions is broken. First he cleans the heat exchanger and then removes the burner, which is covered in soot. It is wrong to do this; first you need to remove the burner, and only then clean off the carbon deposits from the walls of the flame tubes.

Decoding

According to the instructions for the Vailant boilers of the TurboTec series, the following messages are displayed on the display:

- F – fault codes (failures);

- P – adjustment programs;

- d – diagnostics of the Vaillant boiler;

- S – states.

The 5er (Ser) indication is not an error indicating a problem with the heating unit. The code reminds the user of the need to service the burner of the Vailant boiler. The frequency is determined by the operating hours of the node and is set in the range 0–3000. The symbols do not affect the operation of the equipment; it continues to function in the specified mode.

Error Ser is displayed on the control panel of the Vaillant boiler

How to proceed

The user himself decides whether this hint is needed or not. But failure to adhere to the maintenance schedules recommended by the Vailant manufacturer negatively affects the efficiency and durability of the equipment, and often becomes the cause of errors and emergency blockages.

Clean the burner

The injectors gradually become clogged with dust and soot, the amount of combustible mixture entering the chamber decreases, and the intensity of the flame weakens. The unit is cleaned regularly, as indicated by error 5er (Ser).

Clean the gas burner of your Vaillant boiler

Methodology

The work is done with a vacuum cleaner and a toothbrush. Dirt enters the nozzle holes from the walls of the chamber, the lower part of the body of the heat exchange device. They also become clogged with sludge penetrating through the filter.

- Disconnect the Vailant boiler from the network, remove the unit casing and combustion chamber cover.

- Gently sweeping the brush over the surfaces, suck up the smallest fractions with a vacuum cleaner. The time spent on such work is no more than 10–15 minutes; the services of a service technician are not required.

On the Internet there are “helpful tips” from a number of users on removing dirt from the camera with a jet of air. A dubious recommendation: dust and soot will scatter throughout the room and clog the nozzles - such maintenance will only cause harm.

The parameter can be controlled in menu item d 84 (2nd level code).

Vaillant boiler control panel

How to login

- Press the button at the same time. "i", "+".

- Select parameter d97.

- Use the “+” button to go to 17.

- Press and hold “i” for 5 seconds.

- The 2nd level menu will be displayed.

- Select d 84.

- Log in and set the required Ser value.

- Record the data by pressing and holding the button for 5 seconds. "i".

Setting up the Vaillant boiler burner

Change the number of hours, and the 5er (Ser) error will appear more often or less frequently. When entering, please note that 1 corresponds to 10 hours

When determining the period between burner maintenance, take into account: the duration and intensity of operation of the Vailant boiler, the quality and type of “blue fuel” (main gas, liquefied), features of the installation site (dimensions of the room, ventilation efficiency, cleanliness in the room and a number of other factors)

average cost

Service centers usually provide the following cooperation options:

- One-time visit to inspect and repair the boiler, diagnostics.

- One-time maintenance of equipment during the first start-up or before the start of the heating season.

- Annual service, including preparation for the heating season, optionally scheduled visits for inspection and diagnostics, as well as a prepaid visit in case of breakdown.

The cost of each type of work includes payment to the employee, payment to the service center, as well as overhead costs. If the first two aspects are approximately the same across regions and depend on the boiler model, its power and manufacturers, then overhead costs often vary significantly. This depends on the distance between the service center and the client, working conditions, the number of specialists in the center and many other factors, which introduces a wide range between the price tags of different service companies.

The table shows average prices for various types of work depending on the power of the gas heating boiler.

| Name of works | Boiler power | ||

| up to 20 kW | up to 40 kW | up to 100 kW | |

| One-time visit, diagnostics and repair, if the fault can be fixed on site | 3000-5500 | 3000-5500 | 3000-5500 |

| One-time maintenance, routine maintenance before the heating season | 4000-6000 | 4500-6000 | 5000-7500 |

| Annual service | 4500-7500 | 6500-9000 | 12000-16000 |

Basically, the table takes into account the servicing of imported gas heating boilers by service centers with the appropriate certificate from the manufacturers. Domestic boilers, both to purchase and to maintain, are cheaper; spare parts are easier to find and replace. However, their main feature is simplicity and unpretentiousness, so you can’t expect comfortable heating or extensive functionality from them, or, in fact, trouble-free service.