The basis of autonomous heating systems is most often a reliable gas unit from a responsible supplier. But even the products of companies that are highly rated in terms of the quality of the equipment they produce have problems. Sometimes it is necessary to repair Ferroli gas boilers; not only gas workers, but also the owners themselves can cope with it.

Devices of this brand do not differ much from each other in terms of their operating principle. Therefore, the problems they encounter are typical. Ways to solve the problems that have arisen are also well researched.

We will tell you how to correctly identify the malfunction. We will help you understand the problems and correctly decipher the error code that appears on the electronic display of the unit. Compliance with our recommendations will provide home craftsmen with a positive result from their efforts.

All main error codes and their interpretation and solution

Let's look at the main errors of Ferroli gas boilers and options for eliminating them:

| Code | Decoding | Ways to solve the problem |

| A01 | No flame (ignition attempt failed) | Check the presence of gas in the line, open the gas supply valve, |

| A02 | False presence of flame (voltage detected at the ionization electrode when the burner is off) | Check the condition of the ground loop or the presence of condensation drops on the control board |

| A03 | Boiler overheating | Wash the heat exchanger, check the condition of the circulation pump |

| A06 | No flame after ignition cycle | Check the gas supply system, clean the gas burner nozzles |

| A08 | Coolant temperature sensor failure | Replace element |

| A09 | Gas valve failure | Check functionality, replace element |

| F04 | Flue gas thermostat overheating | Clean the chimney, check the operation of the fan |

| F05 | Failure of the smoke removal system, fan shutdown | Replace fan |

| F08 | Primary heat exchanger overheating | Rinse the heat exchanger and, if necessary, replace it |

| F10 | Break or short circuit of the exhaust temperature sensor | Restore contact or replace sensor |

| F11 | Break or short circuit of the DHW temperature sensor | Restore contact or replace sensor |

| F14 | Malfunction of sensor No. 2 direct line of the heating circuit | Restore contact or replace sensor |

| F34 | The supply voltage dropped to 180 V | Check the line, install a stabilizer or uninterruptible power supply |

| F37 | Exhaust pressure drop | Detect heating agent leak and fix it |

| F40 | Excessive exhaust pressure | Check the condition of the expansion tank |

| F47 | Open or short circuit of the exhaust gas pressure switch | Restore or replace the relay |

| F50 | Problems with the control board | Replace control board |

Ferroli boiler errors are divided into critical (A) and non-critical (F). Those with the letter A lead to independent blocking of the boiler, but those with the letter F do not.

Main malfunctions of Ferroli gas boilers

The design of Ferroli boilers is distinguished by well-thought-out and high-quality elaboration of all components and parts.

However, any system has weak points, and gas boilers are no exception.

The operating conditions of some parts of the units are very complex; temperature loads contribute to the occurrence of fatigue of metals and other materials.

According to experts, the most common malfunctions include:

- The boiler does not turn on. There may be different reasons and ways to eliminate them, one of the most common problems.

- Blood pressure drops or rises. This is a serious problem that leads either to a coolant leak, which causes overheating and blocking of the boiler, or to excess pressure and blocking. Particularly dangerous is the increase in pressure, which can cause parts of the unit to burst.

- Fan or circulation pump failure. The loss of both functions means the system is unable to operate - the inability to remove smoke causes sudden overheating and blocking, and the lack of fluid movement has the same consequences, only detected by other sensors.

- Problems with the electronic control board. The cause of these problems is most often an unstable supply voltage or lack of quality grounding. The boiler electronics are very sensitive to any changes in operating mode. When drops or jumps appear, it begins to produce a continuous series of errors that do not repeat when restarted. Often, a static charge accumulates on the housing, which is transmitted through ground to the control board and ionization electrode, which causes error A02 to appear (the system sees a flame when there is none). The solution to the problem is to completely disconnect the boiler from the power system for some time and restore (or create) high-quality grounding.

In addition to the above, there are a lot of problems with the combustion mode:

- Flame too small.

- Spontaneous start of combustion.

- There is no DHW heating.

- A sharp flash of flame with a pop.

All these problems are associated with deterioration in gas supply due to clogged injectors, failure of a thermocouple or fuel valve coil.

How to identify and eliminate possible errors in Ferroli Domiproject boilers

_______________________________________________________________________________

The red indicator is flashing - Error means that there is a malfunction in the ignition mechanism. The flame ionization sensor notifies about a problem. Such an electrode sensor analyzes the presence of a flame and stops the functioning of the Ferroli Domiproject boiler if the main burner is not fully burning or if there is a gas supply interruption. Blocking occurs after 3 unsatisfactory starts. To restore functionality, press and hold the R key. Damage to the gas valve - The operation of the gas valve is controlled by the electronics board. This part is checked by determining the resistance and voltage values. If it is determined that the values differ from the standard parameters, it is recommended to replace the valve with a functional one. There is no gas flow into the boiler - There is a valve in the gas distribution system that limits the gas flow. Consequently, a failure to start the boiler may occur due to a closed tap. Poor contact or signal from the flame control sensor is not detected. The control board has a malfunction - When the ignition cycle occurred without error, but the device suddenly died out, it is possible that the electronics cannot detect the flame. Therefore, it is necessary to test it. The red LED is flashing - Ferroli Domiproject boiler overheating error. The device is blocked. The overheating thermostat has tripped - The temperature sensor and overheating thermostat are mainly installed on the outlet pipe of the primary heat exchanger. The main purpose of a thermostat is to protect the device from high temperatures. An emergency situation most often occurs due to problems in the thermostat, temperature sensor, as well as problems with the main circulation circuit. The temperature sensor is faulty - The control board receives an incorrect signal or there is poor contact between the sensor and the control board. Damage to the overheating thermostat - When the component is operational, but there is a real overheating of the coolant, then there is probably a problem with the circulation of the coolant in the heating circuit. The primary heat exchanger or filter element of the heating circuit is clogged (insufficient circulation process implies an increased heating temperature of the liquid). The circulation pump has failed or there is an air blockage in the heating system. The yellow indicator is flashing - An error means that the pressure inside the system is low. The main factors causing this malfunction are: low water pressure in the heating circuit. The contact between the minimum pressure sensor and the electronic board is broken. The pressure switch is faulty. First of all, you need to look at the pressure gauge readings. Usually the failure can be eliminated by using a feed tap, which is installed to fill the system with coolant. If the failure occurs again, there is probably a fluid leak. The circulation pump, main heat exchanger, relief valve, damaged gaskets, make-up valve and other parts may be leaking. You can detect leaks when inspecting hydraulic units and components. Green indicator flashes - Error means weak traction. For the correct and uninterrupted operation of the device, it is necessary to provide draft to remove exhaust gases so that they do not penetrate into living spaces. The exhaust of gases is controlled electronically, and if any problems occur, the draft sensor will turn on and the boiler will stop working. The main factors for the lack of draft: narrowed size of the chimney duct, defective installation, contamination, icing of the inner wall. A decrease in the diameter of the chimney may cause a weakening of draft. The chimney pipe is too long. You must carefully read the operating instructions for the appliance and follow the relevant requirements. Too long a horizontal section of the smoke exhaust pipe may cause a lack of necessary draft. Traction sensor failure - If a vacuum occurs in the supply tube, you can hear a characteristic click. There is no contact between the air relay sensor and the electronic board, there is condensation, as well as incorrect fastening of the tubes with the air relay sensor. Incorrect fan operation - The fan impeller is clogged. The fan shaft is not lubricated, which is why it does not develop the required speed. The contact between the fan and the electronic board is broken. The green and yellow indicators are flashing - An error means a failure to detect the temperature by the DHW sensor. This circumstance means that the DHW temperature sensor has failed or the required temperature is too high. Possible reasons why this malfunction appears: the DHW temperature sensor is faulty. Poor contact between the electronic board and the DHW temperature sensor. The control board has burned out. When the hot water supply temperature sensor is operational and firmly connected to the electronic control board, but the boiler detects an error, then, apparently, the electronic board has failed. The green indicator is on - Error indicates incorrect ignition. This code occurs if there is no ignition or the burner flame goes out. It is necessary to inspect the contacts between the ignition mechanism and the flame sensor, and also between the electronic board and the gas valve. One of the reasons for the burner flame to come off is a lack of draft. The yellow and red indicators are flashing - An error means that the temperature sensor for the heating system is not working correctly. This circumstance indicates a breakdown of the heating circuit temperature sensor or the temperature required for operation has risen. Open circuit in the heating water temperature sensor circuit - This problem occurs when the connection between the temperature sensor and the electronic board is broken, or the temperature reading is lower than recommended. Five seconds after identifying a problem, the Ferroli Domiproject gas boiler should restore its normal operation if the problem occurred spontaneously. Make sure there is no moisture on the sensor connector and the control board connector. If there is no moisture, the sensor must be replaced. The appearance of a short circuit in the heating water temperature sensor - This problem occurs during a short circuit in the temperature sensor circuit or the temperature of the coolant is much higher than required. First of all, it is necessary to measure the resistance of the temperature sensor. If the resistance readings differ from the nominal values, the sensor should be changed. If installing a new sensor does not help, repair the board. We installed a Ferroli Domiproject F24 wall-mounted gas boiler six months ago. Lately, the red light, ignition error code, has been flashing almost every day. After restarting using the reset button, the unit sometimes starts satisfactorily, but this happens quite rarely. I recently removed the air intake cover and it works better. What could be wrong? When a smoke exhaust error occurs, you need to open the protection covers. This will help draw air from the living space. Then check the chimney pipe for ice and, if there is any, clean it. If the accident is related to combustion, you should find out whether there is a gas supply to the room. All the time, an error code is displayed on the boiler, in which the yellow and red indicators flash. I just can’t understand what it means? This code may indicate a breakdown of the heating circuit temperature sensor. Looks like it needs to be changed. What is the breakdown when the Ferroli Domiproject S 24 gas boiler does not start? And it often starts giving an error with the red LED blinking. How to fix this? This failure often occurs due to some problems in the thermostat, temperature sensor, and also when there is a malfunction in the main circulation circuit. There is probably overheating of the liquid in the heat exchanger. If the temperature sensor and thermostat are working properly, then the problem is in the electronic board. It needs to be replaced. Why does the unit not start and the yellow indicator blinks? The pressure is normal and there are no leaks. I tried to turn off the power, but the problem does not go away. What's the matter? A fault code may be displayed when the coolant pressure in the heating circuit decreases. If such a malfunction occurs, you need to check the water level sensor. Apparently it's faulty. The problem with the device is as follows: the DHW is set to 40 degrees. If you open a hot water tap, the burner burns for a few seconds and then goes out. This process is ongoing. Either warm water or cold water flows out of the mixer. The red LED blinks periodically. What is the reason? This code indicates boiling water in the DHW circuit. The heat exchanger may be heavily soiled, or the thermostat may not be adjusted correctly. We have the following problem. When igniting, the device displays an error code (the flame breaks). If you restart it, it turns on normally, but as soon as the burner ignites, you can hear some clicks, and then an error is displayed. I replaced the ionization electrode, washed the flow sensor, turned the plug over, but no result. What's happened? This problem can occur in three cases. The control electrode is faulty. Incorrect gas supply. The electronics board is damaged. The device has stopped working autonomously and the yellow indicator is flashing. What could it be? There is no liquid in the unit or the pressure switch sensor is broken. First fill the system with water. The unit stops working with the green indicator flashing. Cleaning and blowing helps for a short time. What can be done? This code indicates a lack of draft, and you need to check the smoke exhaust channel. The membrane may have stuck. In another case, we advise you to contact a specialist for a detailed diagnosis of the unit and then repair it. At home we use a Ferroli Domiproject C24 wall-mounted boiler. The green and yellow indicators began to blink. The device itself functions, the temperature of the liquid is set manually. When it was installed, it seems that overheating occurred because the automatic temperature mode was turned on. An outdoor air temperature sensor was not installed. For what reason did this happen? The DHW temperature sensor may be damaged. Sometimes the electronic board is faulty. The device operates for approximately 4-5 minutes, after which the gas burner goes out and an error is displayed with the green indicator flashing. It glows for no more than a minute, the burner starts again, and the device performs its functions well for another 5-6 minutes, and so on many times. This failure, based on the operating manual, means that the draft sensor is triggered, although the chimney channel is not contaminated and combustion products are discharged well. Can anyone explain what's wrong? In this case, the main sources of lack of traction can be: damage to the traction sensor. The contact between the control board and the traction sensor is broken. Condensation in the tubes, as well as poor connection of the tubes to the pressure switch. Damage to fan components. It probably runs at low speeds.

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers

- Electric boilers

- Boiler error codes

- Troubleshooting boilers

- Gas water heaters

- Malfunctions and repairs of geysers

- Water heaters

- Troubleshooting water heaters

- Repair of indirect heating boilers

- Troubleshooting electric convectors

_______________________________________________________________________________

_______________________________________________________________________________

- BAXI ECO FOUR

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

- BAXI LUNA

Peculiarities. Installation and assembly. Automation components.

- BAXI MAIN FOUR

Technical specifications. Installation. Adjustment and checking. Maintenance.

- BAXI SLIM

Adjustment and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

- BAKSI - REPAIR

After starting, a malfunction appeared. It doesn’t want to turn on, it worked for two years, now the whole display lights up, just like when the boiler is turned on, when the self-diagnosis mode is in progress, then it clicks, turns off for miles and seconds and turns on the whole display again. It turned on once, but it gives error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me, what could it be?

- BAXI - OPERATION

In operation, the Baxi main four 240 boiler shuts down with error E35 (stray flame). Tell me what to do? First season in operation.

- BAXI - SETTINGS

We installed and connected the Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW device?

- BOSCH - REPAIR

Bosch 6000 24 kW boiler, single-circuit with built-in three-way valve. The boiler sensor does not see it and gives an error. Tell me how to do it so that it doesn’t give an error and works normally for both the heating and the boiler?

- BOSCH - ADJUSTMENTS

If you turn off the DHW flow sensor, maybe it will be possible to reprogram it into a single-circuit device through menu L3?

- ARDERIA - REPAIR

We installed an Arderia esr 2.13 ffcd boiler. If my coolant pressure drops slightly by a couple of notches over 2-3 days, could the reason be a faulty three-way valve (there are no leaks from the radiators)?

- ARDERIA - ADJUSTMENTS

The gas boiler Arderia 2.35 is in operation. Tell me about reducing power. I heard something about modulation, fan speed, etc. Is it really possible to reduce power?

_______________________________________________________________________________

- BUDERUS FLOOR

We installed and connected the Buderus Logano G234-WS-44 kW boiler, automatic Logomatic 4211. Heating is based on cylinders without hot water, and the jets for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the outside temperature was +16+18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and the red button light on the front wall came on. We pressed the button, turned the power back on and everything worked. This happened several times, then the boiler was turned off completely for the summer, what could be the problem?

- BUDERUS WALL

In the single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is used for DHW?

- VAILLANT - REPAIR

Tell me, for Vaillant wall-mounted gas boilers, are there real/actual differences for the better in the new generation turboTEC plus VU/5-5 compared to /3-5?

- VAILLANT - ADJUSTMENTS

There is a malfunction in the boiler, the green LED (power) is flashing, the instructions say that the thermal protection has tripped, the green indicator is flashing, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is fine.

- DAEWOO

In operation there is a double-circuit gas boiler Daewoo Gasboiler with an electronic panel. When the DHW is turned on, the heating heats up, the operating mode is summer. I removed the three-way valve, there is no dirt or wear. It seems that the board does not control the three-way valve. How to check?

- ELECTROLUX

The Electrolux Basic Xi wall-mounted boiler has been installed and connected. A problem began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts it gave error E1. How can I fix it?

- KOREA STAR

Koreastar boiler malfunction. The heating works perfectly, the hot water comes intermittently, when you turn on the hot water tap, cold water comes out first, then boiling water. After a few seconds it’s cool, then boiling water again. What could be the problem?

- FERROLI

Malfunction of the Ferroli Domiproject 24 boiler - I set it to 60-70 degrees, it switches to minimum combustion, does not turn on, does not turn off. Restart is unstable. No pattern emerges. What to do?

- JUNKERS

In operation, a Junkers euroline gas boiler, when hot water is turned on, gas ignites, then goes out, and so on several times. If you turn it on while the heating is running, the water heating starts immediately. Tell me, please, what could be the problem?

- NAVIEN

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. It is not possible to adjust the fan run-on. I set it to 30 seconds, but still 2 minutes. spins.

- OASIS

Malfunction of the Oasis ZRT18 boiler. The unit starts, the gas lights up, then goes out. It lights up again and then goes out (this happens three times). Then it lights up and works fine. It doesn't give any error. What is the reason?

- SAUNIER DUVAL

Malfunction of the Senor Duval gas boiler - the water pressure sensor shows 0.0, the indicator flashes red, the hot water does not heat up, but the water pressure in the apartment is good. How to fix the problem?

- VIESSMANN

Where should a condensate trap be installed in a coaxial chimney? The boiler wh1d with a closed combustion chamber is located at a distance of 1 m from the wall.

- WESTEN

Problem starting the Westen Pulsar D boiler. Piezo ignition works, but there is no flame, error E01 after a crackling sound. I moved the fork around.

- BERETTA

The Novella floor-standing gas boiler is blocked - the green lights on the panel are on and nothing else happens. How to fix?

- ARISTON

An Ariston gas wall-mounted boiler has been installed and connected, which does not hold pressure at all: while cooling the heated water, the pressure drops to zero, although water is regularly filled. What about the pressure?

- SIME

Metropolis dgt 25 bf boiler malfunction. The hot water supply has stopped working, the heating is working, it does not display an error. What do you advise?

- SOLLY

Please tell me how to solve the problem. The Solly Standard boiler, whenever you try to turn it on or hot water, displays a GS error.

- WOLF

Wolf boiler in operation. Lately it has begun to behave strangely: during the pause between starts, it turns on the burner for one second five times, and 70 degrees appears on the display. Where to look for a problem?

- ACV

ACV Wester Line works very unstable: it often crashes, makes a characteristic knock and stalls when starting, but at times everything is fine. The unit is almost new, what's wrong with it?

- DEMRAD

In the gas boiler Demrad, the gas supply to the burner stopped. The piezo element clicks, but there is no ignition. There is nothing wrong with the gas stove, there is gas. What is the reason?

- KITURAMI

The Kiturami world boiler is malfunctioning and stops periodically. I clean the flame sensor and the unit works fine for a while, but soon the same thing happens again. He also began to smoke heavily. Maybe the problem is that the chimney is short, and it needs to be lengthened?

_____________________________________________________________

- IMMERGAZ - ERRORS

Errors of Nike Star, Eolo Star/Mini, Mythos boilers. Malfunctions of boilers with the possibility of automatic unlocking.

- IMMERGAZ - REPAIR

My boiler systematically raises the temperature to 80 degrees in winter mode. I called the repairman three times. He said that many models have this problem and suggested installing a programmer, but it’s not certain that it will help. Tell me how to solve this problem and will this programmer help?

- AOGV

Models 11.6; 17.4; 23.2; 29.3 kW. Specifications. Control elements of the automation unit. Installation and maintenance. Malfunctions and their elimination.

- AOGV - REPAIR

The AOGV gas boiler was installed and put into operation. Problem with hot water supply. The heat exchanger was washed. Less than a month has passed and the water is not flowing again. We put a filter on the water, but time passed, and again there was no hot water. What kind of breakdown could this be?

- AGV

Installation and installation. Start-up and adjustment. Malfunctions and ways to eliminate them.

- AKGV

Technical specifications. Installation and connections. Startup and operating procedure. Automatic adjustments.

- NEVA LUX

The boiler Neva Lux 7023 is malfunctioning. It gives error E7 twice a month. But after reboot it still works. Now it gives error E6. It will work for 15 minutes and turn off. What could it be?

- ROSS

Design and automation unit. Ignition order. Malfunctions and repairs.

- ATEM ZHYTOMYR

Tell me, is it possible that due to low gas pressure the Atem Zhytomyr boiler goes out, a click occurs and goes out. What is the problem? Is it possible to temporarily disable automation and how?

- LEMAX

We installed a Lemax KSG-12.5 Premium gas boiler. After turning off the main burner, a clicking sound occurs after a couple of minutes, what is the reason? Tell me?

- KEBER

A KS-G gas boiler of 250 sq.m. was installed and connected. m. When ignited, it does not turn off, the temperature rises, if I am not mistaken, automatic Arbat 1. The flame is not regulated - it is too large. What to do?

- LIGHTHOUSE

I installed the Mayak gas boiler and connected it. It works fine. But the reason is this. When it works on unit it squeaks a lot, if you turn the knob 2-7 the squeak disappears. Tell me, what could it be?

- DANKO

We installed and connected a Danko gas boiler with automatic Kare, it works great on the igniter, but as soon as you add power to the burner, it goes out completely, yesterday it went out within 5 minutes, today it works for about 20 minutes and goes out completely. Has anyone encountered this problem?

- GAZLUX

The gaseko 18 boiler is in operation. When hot water is turned on, the pressure in the system drops after replenishment, the pressure reaches 3 bar. Have to reset. What's wrong, how to fix it?

- NOVA FLORIDA

Water often boils in the boiler, causing it to fail due to overheating. The heat exchanger was recently washed, the system is not clogged. What's the matter?

- RINNAI

Rinnai 167 RMF boiler malfunction. Recently I started showing error 14. How can I fix the problem?

- CELTIC

The Celtic DS boiler heats up to 45 degrees and sits all day, does not turn off and does not heat the batteries, sometimes it shows error A3. How can I fix this problem?

- MORA

The hot water pressure in the Mora Top boiler has dropped. What is the reason?

- MASTER GAS SEOUL

The Seoul gas wall-mounted boiler stopped turning on due to a no-ignition error. How can it be eliminated? What exactly went wrong?

Operating instructions on how to start correctly

The operation of Ferroli boilers does not differ in any specific actions or procedures.

The owner is only required to organize periodic maintenance, clean the body and interior of the boiler, and maintain the burner nozzles in proper order.

The procedure for starting the boiler is similar to the procedure for igniting other gas units.

A special feature is the need to maintain a pause between startup attempts, during which code D3 or D4 appears on the display (50 or 30 seconds).

The first code occurs after a critical error occurs and the unit is blocked.

Until the required time interval has been met, a repeated restart is not possible.

The second code appears between attempts to start normally, if the previous one was unsuccessful.

This is usually due to air in the pump, piping or heat exchanger. Attempts are repeated until the air is removed from the boiler.

How to setup

The basic settings of the Ferroli boiler are carried out at the manufacturer . At the first start, additional adjustments are made to the parameters of all communications to ensure full compliance with the operating modes of the system and the supply of resources - gas, water, voltage.

The upper and lower limits of temperature and pressure of liquids, gas, and other important parameters are also determined.

Most actions are performed from the external control panel; the casing has to be opened only when carrying out complex repair work or to connect a room thermostat.

NOTE!

The setup must be carried out by a technician from the service center, otherwise the warranty agreement will become invalid or important components of the unit will fail due to improper operation.

Accessories

For each category of boilers, the manufacturer also provides additional accessories. In particular, double-circuit wall-mounted models can be supplemented with a kit for smoke removal systems and devices that allow the equipment to operate on liquefied gas. In turn, a Ferroli floor-standing gas boiler can be equipped with boilers, DHW priority systems, turbo nozzles and devices for cascade control. Condensing units have the largest range of additional options. They can be provided with outdoor temperature sensors, control boards for multi-circuit systems, hydraulic arrows, a mounting manifold frame, as well as special fitting kits for connecting boilers.

Conclusions and useful video on the topic

An example of solving an elementary problem in the event of a boiler breakdown associated with an error in the readings of the air pressure switch. Quick repairs on your own:

Cleaning the chimney system using a vacuum cleaner:

You can repair a Ferroli gas boiler yourself if you know the type of error and how to eliminate it. However, it should be remembered that gas equipment is an element of increased danger. Therefore, it is better to entrust all maintenance and repair work to representatives of the gas service with which the contract has been concluded.

In the block below you can share your own experience in cleaning and restoring the performance of gas boilers from an Italian manufacturer. It is possible that you have useful information that is worth sharing with site visitors. Share information and photos on the topic of the article, please ask questions.

Why does blood pressure drop?

A drop in pressure in the boiler can be due to three reasons:

- The appearance of a leak in the heating circuit (including in the boiler itself). The peculiarity of this option is the constancy of the process, since the coolant will not stop leaving, no matter how much the system is recharged. In this case, you need to find the location of the leak. First of all, you need to check the condition of the drain tap or valve to see if it is open or damaged. If no problems are found in this unit, the entire heating circuit is checked sequentially. Sometimes they forget to close the drain valve on radiators, fistulas appear in pipelines, and connections fail. It is most difficult to detect a leak if the tap supplies a water-heated floor system embedded in a concrete screed. You can detect the problem by a wet spot on the floor or ceiling of the lower floor, and to do this you often have to remove the floor covering or suspended ceiling.

- Circulation pump failure. This problem is immediately detected by the self-diagnosis system, and it is easy to check the functionality of the pump. It is enough to carry out a visual inspection of the element and take appropriate measures.

- Expansion tank membrane rupture. In this case, the pressure will drop until the coolant fills the entire volume, after which the process will stop. Then an uncontrolled increase in pressure is possible, especially intense as the temperature of the heating agent increases. If it turns out that the problem element is the expansion tank, urgent measures must be taken to repair or replace the unit. Otherwise, with thermal expansion of the liquid, the heat exchanger or other element of the system will fail, which will require significant costs for repairs and restoration of the boiler’s functionality.

The boiler does not start, the burner does not turn on

Problems with starting a boiler occur most often, since there are many reasons for such a situation.

Among them may be:

- The gas supply valve is closed.

- Gas valve problems.

- The burner nozzles are clogged with soot.

- The control board has failed.

- The boiler is blocked due to a problem with a component.

Most possible causes are detected by the self-diagnosis system and display the corresponding code.

However, some possible reasons - failure of the gas supply system, a closed valve and other mechanical obstacles may not be noticed by the system, so you should independently verify that it is ready for operation. In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes, after connections have been made, the wires on the panel are mixed up.

Fault indications on different models

Ferroli boilers are equipped with a self-diagnosis system and, if an emergency occurs, they give the user an error code. Knowing the type of malfunction, you can quickly find the cause of its occurrence. Many breakdowns do not require special knowledge to fix.

The manufacturer divided all the problems that arise during the operation of Ferroli boilers into 2 categories:

- Critical errors causing complete blocking. Indicated by the letter “A” before the code. If such a malfunction occurs, it is necessary to fix the problem and restart the boiler by pressing the “reset” or “reset” key.

- Problems causing temporary shutdown of the boiler or one of its components. Indicated by the letter “F” before the code. The automation waits for the situation to normalize, after which it will restart the boiler itself.

Error code information can be displayed on the LCD or remote control. For older models, you can find out the type of failure by looking at the indicators.

If the boiler does not have an LCD display, the type of error can be recognized by the flashing lights. For each problem, the user manual describes a unique combination of indicator behavior

Also, sometimes a code starting with the letter “D” appears on the screen. This is technical information warning the user that the boiler is changing from one mode to another.

Wall-mounted gas boilers Ferroli

Wall heater from the Italian company Ferroli.

Ferrol wall-mounted boilers are available in different configurations and power, so you can choose a unit according to your requirements and budget. The first characteristic is the number of circuits. Thus, heaters can work not only to heat water in the heating system, but also simultaneously supply the house with hot water. Accordingly, single-circuit and double-circuit boilers are distinguished.

The second aspect is the type of combustion chamber and its configuration. The combustion chamber can be open or sealed. Open combustion chambers, just like a regular stove burner, burn out the air from the room (there is no fire without oxygen). Sealed chambers draw in air from the street through a special chimney pipe called a coaxial chimney.

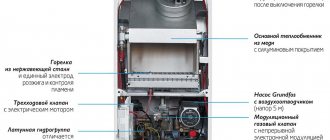

A heat exchanger (one or two) is installed in the combustion chamber. One heat exchanger (bithermal) is a pipe within a pipe into which pipes are embedded for separate smoke removal. The heat exchanger is made of copper. If there are two heat exchangers, then they are separated from each other. The primary one is made of copper, and the secondary one is made of stainless steel.

Complete set of Ferroli gas boilers according to the instructions:

- heat exchanger (one or two);

- gas valve – Siemens or HoneyWell;

- Wilo three-speed circulation pump;

- smoke exhaust pipes – separate smoke removal system;

- bypass;

- Control block.

There are models with and without a liquid crystal display. The display shows information about the operating parameters of the heater and errors that occur during operation. The display lights up blue. The DivaTop 60 model is available with a built-in 6o liter boiler.

The efficiency of a Ferroli wall-mounted heating boiler of any model is approximately 93%. Minimum power 7.2 kW, maximum – 40 kW. The unit heats the coolant for high-temperature heating systems up to 85 degrees, and water for hot water supply up to 55 degrees. Boilers operate on natural and liquefied gas. The nominal energy consumption is indicated in the passport for each model. The gas inlet pressure must be at least 20 mbar for natural gas and 37 mbar for liquefied gas.

Read here how effective vermiculite is for ceiling insulation.